From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2025-12-31 Origin: Site

Content Menu

● Why Most In‑House CNC Setups Hit A Wall

● Ultra‑Tight Tolerances Beyond Typical Shop Capability

● True Multi‑Axis Simultaneous CNC Machining

● High‑Spec Cosmetic And Functional Surface Finishes

● Difficult And Exotic Materials

● Thin‑Wall Structures That Chatter And Warp

● High‑Volume Production With Strict Consistency

● Deep Cavities And Intricate Internal Features

● Micro‑Machining And Complex Threads

● High‑Speed, Synchronized Multi‑Tool Operations

● Multi‑Step Fixturing And Complex Workholding

● When To Keep CNC Work In‑House

● When To Use A Professional CNC Machining Partner

● Practical Outsourcing Checklist

● Example Capability Comparison

● How A Strong CNC Partner Supports Your In‑House Team

● FAQs About Complex CNC Machining And Outsourcing

>> 1. What are typical limits of an in‑house CNC machine?

>> 2. How do I know a part is too complex for my current setup?

>> 3. Is outsourcing complex CNC work more expensive?

>> 4. What information should I send to a machining partner?

>> 5. Can I combine in‑house machining with outsourcing on the same project?

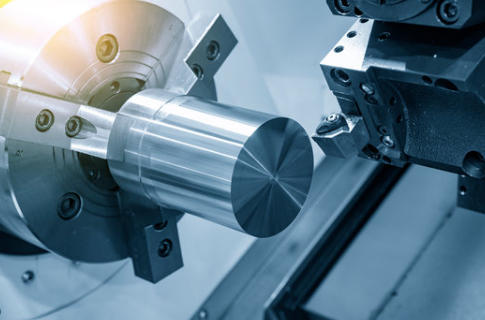

When you invest in an in‑house CNC machine, it is easy to assume it can handle every project your engineering team designs. In reality, certain complex CNC machining tasks sit far beyond what most small or mid‑sized workshops can achieve reliably, safely, and profitably with standard equipment. Recognizing these limits and knowing when to work with a professional machining partner protects your budget, delivery dates, and brand reputation.

Even well‑run internal machine shops are optimized for repeatable, everyday parts, not the most extreme, one‑off, or high‑risk jobs. Typical constraints include limited axes, basic workholding, and standard spindles that struggle with exotic materials, thin walls, and micro‑features. Over longer runs, lack of automation and advanced metrology makes it hard to hold very tight tolerances across batches.

Once projects cross these thresholds, specialized complex CNC machining environments with multi‑axis equipment, advanced fixturing, and full QC labs usually deliver lower total cost and lower risk than pushing internal equipment past its limits.

When your drawing calls for ultra‑tight tolerances, small thermal shifts, spindle runout, and fixture deflection can push parts out of spec. Standard shop‑floor machines often struggle to keep these dimensions stable over a full production run, especially if ambient temperature and machine calibration are not tightly controlled.

Precision‑focused machining environments use climate‑controlled workshops, scheduled machine calibration, and advanced inspection tools to consistently meet these demanding tolerances. If you regularly see borderline dimensions, rework, or scrap on critical features, that is a strong signal those operations should be handled by a specialist.

Most internal shops rely on 3‑axis CNC mills and maybe a simple indexer, which is enough for prismatic, straightforward parts. However, many advanced components in sectors like aerospace, medical, and robotics need true multi‑axis simultaneous machining to reach undercuts, compound angles, and free‑form surfaces in a single setup.

Without genuine multi‑axis capability, you face multiple manual setups, longer lead times, and visible blend lines where surfaces meet. Advanced machining facilities invest in full multi‑axis and mill‑turn platforms plus powerful CAM systems to achieve shorter cycle times and superior surface quality on complex CNC machined parts.

Achieving very high‑end surface finishes on sealing faces, sliding interfaces, or visually critical surfaces is far more complex than simply reducing feed rate. It requires carefully chosen toolpaths, appropriate tool nose radii, and, in many cases, coordinated secondary finishing steps.

Standard in‑house CNC setups usually deliver acceptable functional surfaces but may struggle with demanding cosmetic or ultra‑smooth surfaces across large batches. Specialized finishing processes in dedicated machining environments can provide consistent appearance and performance where surface quality is a critical requirement.

Metals such as titanium, nickel‑based alloys, and hardened tool steels introduce significant heat, tool wear, and cutting forces, particularly on lighter or older machines. Certain plastic and composite materials also deform or fuzz if tooling and cutting parameters are not precisely matched to the material.

Professional machining companies mitigate these risks with rigid machine structures, high‑torque spindles, optimized coolant systems, and carefully curated tooling libraries. If your team is burning through tools, struggling with chatter, or failing to maintain size on demanding materials, outsourcing those parts is often more economical than continuous trial‑and‑error in‑house.

As wall thickness decreases, chatter, warping, and collapse become difficult to avoid without very deliberate process planning. Thin ribs, housings, and shells require a careful balance of tool geometry, step‑over, support, and clamping forces to prevent distortion during machining.

Experienced external machining partners design custom fixtures and workholding to support the part as close as possible to the cut. Combined with optimized roughing and finishing strategies, this reduces vibration and deformation. In‑house shops without deep fixture design experience usually face higher scrap rates on thin‑wall parts.

Running high‑volume CNC production is a different challenge from producing a handful of prototypes. Large quantities demand automated tool monitoring, in‑process gauging, and structured process control to keep parts within specification across thousands of cycles.

Many internal shops are better suited to prototypes and small batches than round‑the‑clock production. Outsourcing high‑volume, complex parts to a professional machining partner allows your in‑house team to focus on R&D, maintenance, and core operations while still meeting aggressive delivery schedules and consistency targets.

Deep pockets, internal channels, and blind features pose risks such as poor chip evacuation, trapped heat, and excessive tool deflection. Long, slender tools needed to reach these features are more prone to vibration, which affects both surface finish and dimensional accuracy.

Specialized machining environments address these challenges with optimized tool lengths, advanced toolpaths, and targeted coolant delivery. When geometry pushes past the safe reach of cutting tools, they may also integrate additional processes to create internal details more reliably than a general‑purpose in‑house setup.

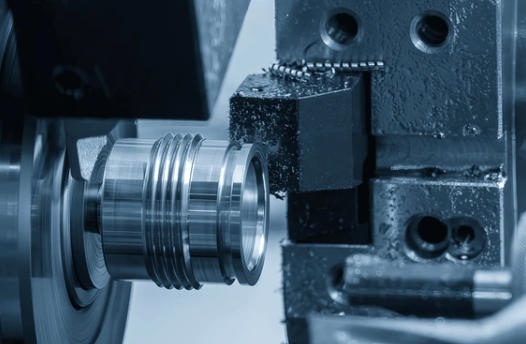

Once your design includes micro‑features or fine threads, even small spindle runout or minor setup errors can render parts unusable. Micro‑machining often relies on high‑speed spindles, extremely precise toolholders, and accurate tool measurement to maintain consistent results.

If your internal equipment is not configured for micro‑scale work, trying to run these parts in‑house can lead to high scrap and unpredictable quality. Dedicated precision machining partners are better positioned to handle micro‑features, miniature threads, and fine engravings at scale.

Advanced parts may need high‑speed contouring and synchronized multi‑tool operations to achieve the required geometry and efficiency. These processes depend on modern control systems, well‑tuned servo parameters, and extensive programming experience to avoid collisions and maintain smooth motion.

Older control platforms and basic programming practices often cannot support these demanding toolpaths without visible quality issues or safety risks. Modern multi‑axis equipment with experienced programmers is better suited to execute these operations while maintaining consistent quality.

As part geometry becomes more complex, so does fixturing and workholding. Each additional setup, re‑clamp, or orientation change can introduce alignment errors if probing strategies, modular fixtures, and robust alignment procedures are not in place.

Professional machining providers treat fixture design as a core engineering discipline, often developing fixtures alongside CAM programming. This integrated approach stabilizes complex parts through every operation and reduces the risk of cumulative misalignment that can happen in a less equipped in‑house environment.

Not every job needs external help. Your in‑house CNC machining is often the best choice when parts are moderate in complexity, use standard materials, and carry tolerances that match your current capability. Internal machining also works well for quick prototypes where iteration speed matters more than ultimate efficiency.

If parts are low risk, volumes are modest, and your existing team can meet both dimensional and cosmetic expectations reliably, keeping these projects in‑house makes sense. This approach lets your internal resources focus on tasks that align with their strengths.

As soon as your project moves into the territory of tight tolerances, complex geometry, demanding materials, or high volumes, a professional machining partner becomes a strategic asset. Outsourcing these projects reduces the risk of costly scrap, machine damage, and missed launch dates.

A capable partner brings multi‑axis equipment, specialized fixturing, robust quality systems, and experienced engineers who deal with complex CNC machined parts every day. This combination helps convert challenging designs into stable, repeatable production processes.

Before sending a complex part to an external supplier, a simple checklist can streamline communication and accelerate quoting.

1. Clarify key requirements

Identify the features that truly drive function, performance, and safety, along with any dimensions that are less critical.

2. Prepare clean CAD and drawings

Provide both 3D models and fully dimensioned 2D drawings, including thread specifications, tolerances, and surface finish requirements.

3. Define volumes and timelines

Share expected prototype quantities, pilot runs, and mass production volumes, together with target delivery dates.

4. State material and compliance needs

Specify material grades, certifications, and any required inspection or documentation that must accompany the parts.

5. Agree on communication and approvals

Decide who will review manufacturability feedback, approve design adjustments, and handle change management during the project.

This preparation helps your machining partner understand priorities quickly and propose a robust production approach.

| Capability | Typical in‑house CNC setup | Professional CNC machining partner |

|---|---|---|

| Axes available | 3‑axis, basic indexing | 3‑ to 5‑axis, mill‑turn, multi‑spindle systems |

| Practical production tolerances | Moderate, general engineering level | Ultra‑tight on critical features with full QC support |

| Material range | Common steels, aluminum, basic plastics | Exotic alloys, hardened steels, engineering polymers |

| Volume capability | Prototypes, small batches | Prototypes to large‑scale production runs |

| Fixture complexity | Standard vises and clamps | Custom fixtures, vacuum, hydraulic, modular systems |

| Quality systems | Basic hand‑gauging and inspection | Advanced metrology, structured process control |

This gap explains why parts that seem nearly impossible internally often become routine when moved to a shop designed for complex CNC work.

A strong machining partner extends your capacity, capability, and flexibility rather than replacing your existing shop. Common cooperation models include overflow support, where external capacity absorbs peak loads, and complexity‑based routing, where challenging parts always go outside and standard parts stay in‑house.

In some cases, a partner develops the initial process from prototype to stable production, then helps transfer certain operations back to your facility once they are well understood. This hybrid approach keeps your internal team focused on high‑value activities while still benefiting from external expertise.

If your team is facing prints with tight tolerances, deep cavities, thin walls, or difficult materials that stretch the limits of your current machines, now is the right time to act. Instead of risking expensive scrap, machine downtime, and delayed launches, move those high‑risk parts to a professional machining partner that works with complex components every day.

Gather your latest CAD files, drawings, and volume expectations, then send them to a trusted CNC machining supplier with proven precision, multi‑axis capability, and robust quality control. Ask for a detailed manufacturability review and quotation so you can compare real outsourcing options against the cost and risk of trying to force these jobs through your in‑house CNC setup.

Most internal machines handle standard materials, moderate tolerances, and straightforward geometries well. They usually reach their limits with ultra‑tight tolerances, multi‑axis surfaces, thin walls, or very hard and heat‑resistant alloys.

Warning signs include repeated scrap, unstable dimensions, chatter, tool breakage, and difficulty reaching internal features. If you see these issues even after tuning parameters and fixturing, the part is likely beyond your present in‑house capability.

Unit prices may be higher at first, but total cost often drops because scrap, rework, tool consumption, and machine downtime are reduced. You also free internal resources to focus on tasks that add more value to your core business.

You should send 3D CAD models, dimensioned 2D drawings, material specifications, tolerance and surface finish requirements, and expected quantities. Sharing target timelines and any critical functional details also helps the supplier propose the best process.

Yes, many companies machine simple parts or operations internally and outsource complex features or entire high‑risk components. This mixed approach balances cost, lead time, and risk while taking advantage of both internal equipment and external expertise.