From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

| Common Grades: | Stainless Steel SUS201, SUS303, SUS 304, SUS316, SUS316L, SUS42, SUS430, SUS431, SUS440C, SUS630/17-4PH, AISI 304 |

| Available Finish: | As machined, Electroplating, Passivation, Powder coating |

| Price: | $$$ |

| Common Grades: | Titanium Alloy TA1, Alloy TA2, Alloy TC4/Ti-6Al 4V |

| Available Finish: | As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickle, Chrome plating, Powder coating, Brushed finish |

| Price: | $$$$$ |

| Common Grades: | Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36, Die steel, Alloy steel, Chisel tool steel, Spring steel, High speed steel, Cold rolled steel, Bearing steel, SPCC |

| Available Finish: | As machined, Electroplating, Passivation, Powder coating |

| Price: | $$$ |

| Common Grades: | Aluminum 6061, 6061-T6, Aluminum 2024, Aluminum 5052, Aluminum 5083, Aluminum 6063, Aluminum 6082, Aluminum 7075, 7075-T6, Aluminum ADC12 (A380) |

| Available Finish: | As machined, Anodizing, Powder coating, Electroplating, Painting, Sand blasting, Polishing |

| Price: | $$ |

| Common Grades: | KG5, KG7, and ST7. |

| Available Finish: | As-Machined, Polishing, Lapping, Brushing, Tumbling, Grinding, PVD Coating... |

| Price: | $$$$$$ |

| Item | Description |

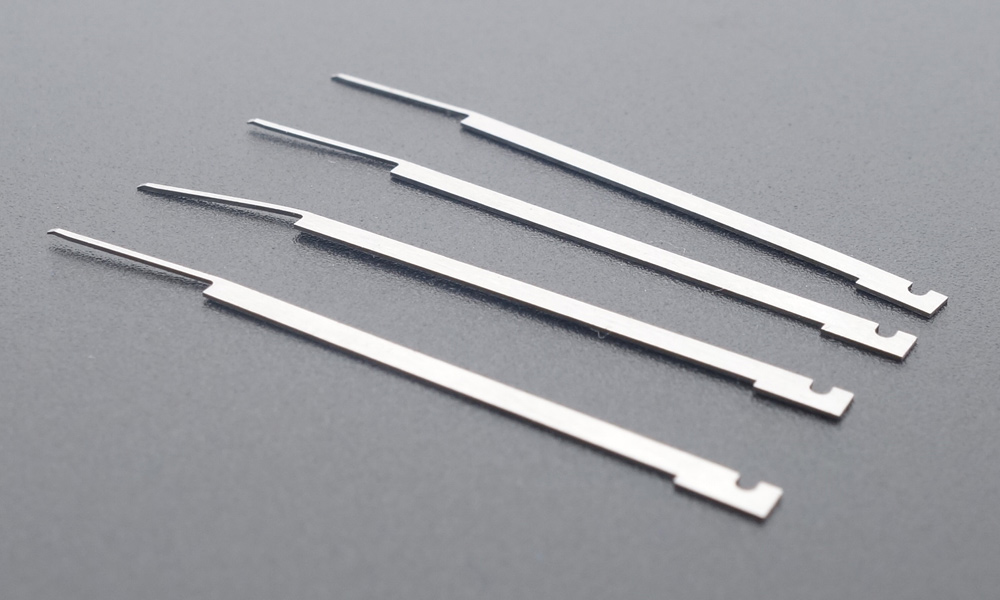

| Thinnest Electrode Wire | 0.1 mm |

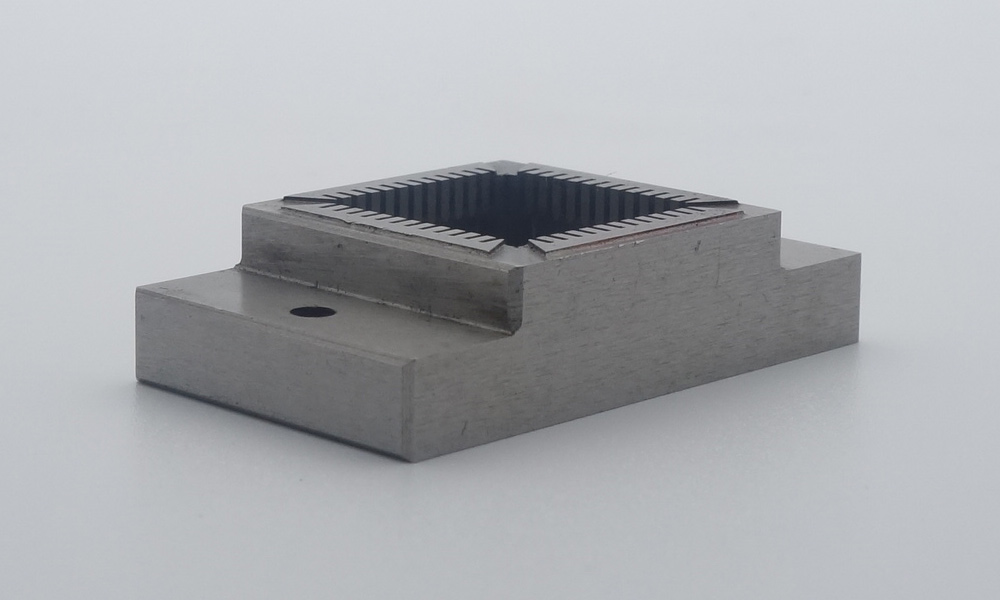

| Maximum Stroke | 350 * 550 * 280 mm / 13.78 * 21.65 * 11.02 inches |

| Machining Accuracy | 0.001 mm / 0.000039 inch |

| Minimum Machining Dimensions | 1.0 * 1.0 mm |

| Minimum Groove Width | 0.15 mm |

| Minimum Inner Corner | R0.07 mm |

| Minimum Outer Corner | R0.02 mm |

| Minimum Inner Hole Diameter | 0.15 mm |

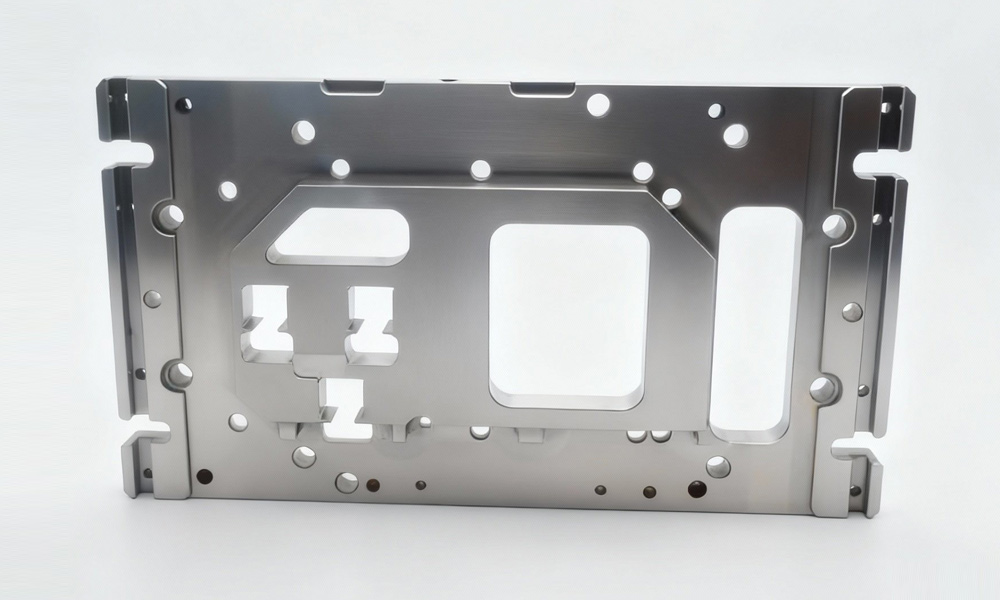

| | Tooling and Molds: Manufacturing complex shapes for injection molds, stamping dies, and other tooling components. |

| | Aerospace Components: Fabricating intricate parts for aircraft, such as brackets, mounts, and components that require high precision and adherence to strict safety standards. |

| | Automotive Parts: Producing precise components such as gears, shafts, and valve seats that need tight tolerances. |

| | Medical Devices: Creating specialized components for medical instruments and implants, where accuracy and quality are critical. |

| | Electronics: Manufacturing precise connectors, circuit boards, and other intricate parts used in electronic devices. |

| | Research and Development: Prototyping complex designs in various industries to test functionality and fit. |

| | Precision Engineering: Crafting custom parts for machines, robotics, and automated systems requiring perfect fit and alignment. |