From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

| Common Grades: | Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36, Die steel, Alloy steel, Chisel tool steel, Spring steel, High speed steel, Cold rolled steel, Bearing steel, SPCC |

| Available Finish: | As machined, Electroplating, Passivation, Powder coating |

| Price: | $$$ |

| Common Grades: | KG5, KG7, and ST7. |

| Available Finish: | As-Machined, Polishing, Lapping, Brushing, Tumbling, Grinding, PVD Coating... |

| Price: | $$$$$$ |

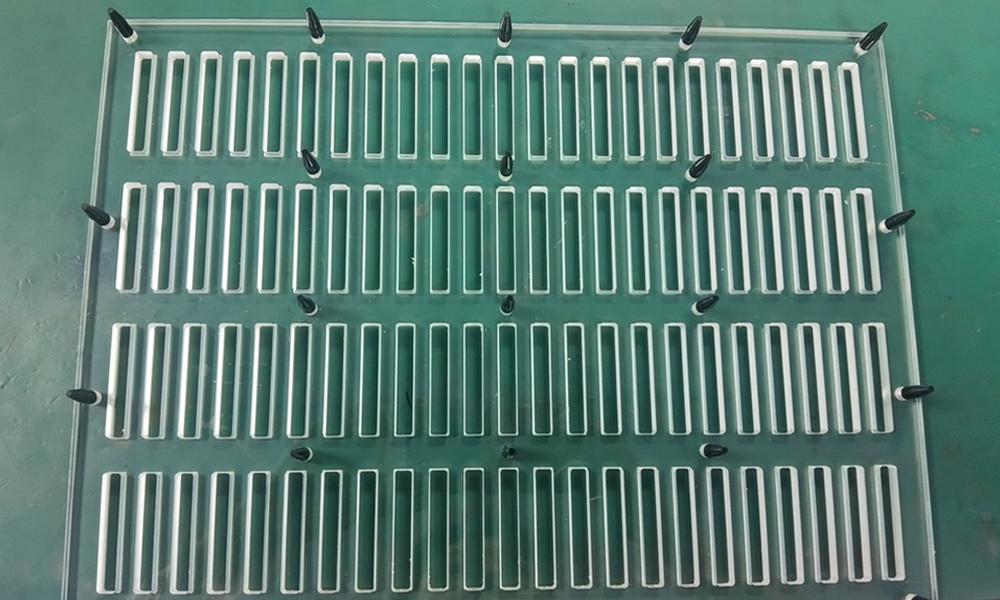

| Common Grades: | Aluminum 6061, 6061-T6, Aluminum 2024, Aluminum 5052, Aluminum 5083, Aluminum 6063, Aluminum 6082, Aluminum 7075, 7075-T6, Aluminum ADC12 (A380) |

| Available Finish: | As machined, Anodizing, Powder coating, Electroplating, Painting, Sand blasting, Polishing |

| Price: | $$ |

| Common Grades: | Stainless Steel SUS201, SUS303, SUS 304, SUS316, SUS316L, SUS42, SUS430, SUS431, SUS440C, SUS630/17-4PH, AISI 304 |

| Available Finish: | As machined, Electroplating, Passivation, Powder coating |

| Price: | $$$ |

| Common Grades | Copper C101(T2), Copper C103(T1), Copper C103(TU2), Copper C110(TU0), Beryllium Copper |

| Available Finish: | As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickel, Chrome plating, Brushed finish |

| Price: | $$$ |

| Common Grades | C36000 and C46400. |

| Available Finish: | As-Machined, Polishing, Lapping, Grinding, Sandblasting, Passivation, Electroplating... |

| Price: | $$$ |

| Common Grades: | Tin Bronze |

| Available Finish: | As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickle, Chrome plating, Powder coating, Brushed finish |

| Price: | $$$ |

| Common Grades: | Titanium Alloy TA1, Alloy TA2, Alloy TC4/Ti-6Al 4V |

| Available Finish: | As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickle, Chrome plating, Powder coating, Brushed finish |

| Price: | $$$$$ |

| Subtypes : | Magnesium Alloy AZ31B, AZ91D |

| Available Finish: | As machined, Polishing, Sand Blasting, Tumbling, Alodine, Heat treatment, Anodizing, Teflon coating, Electroless nickel, Painting, Powder coating, Electrophoresis |

| Price : | $$$$$ |

| Common Grades: | ABS Beige(Natural), ABS Blac, ABS Black Antistati, ABS Milky Whit, ABS+PC Black, ABS+PC White |

| Available Finish: | As machined, Sand blasting, Tumbling, Teflon coating, Painting, Powder coating, Electrophoresis |

| Price: | $$ |

| Common Grades: | Common Grades |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting, Brushed Finish |

| Price: | $$ |

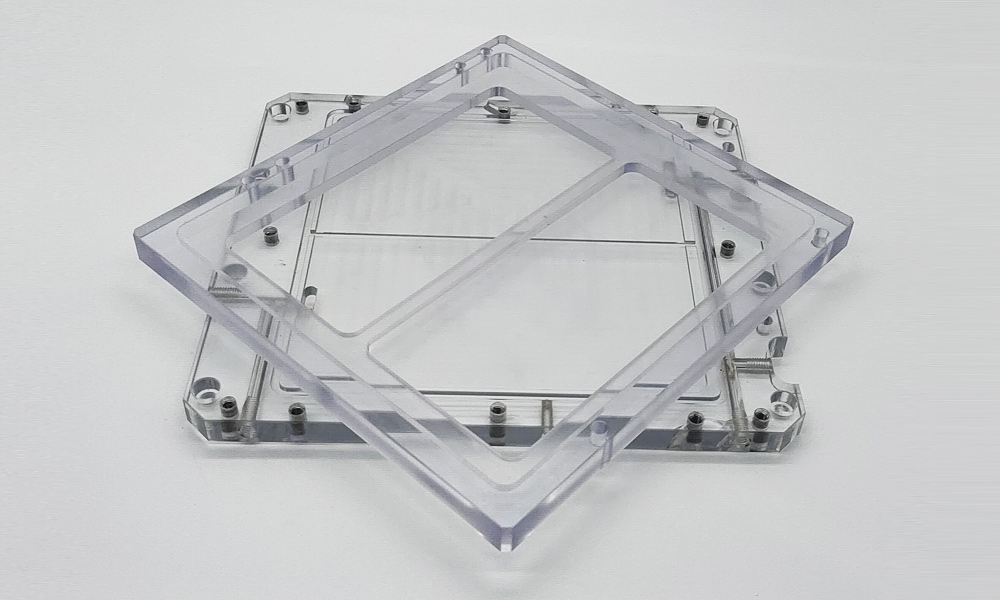

| Subtypes: | PMMA Black, PMMA Transparent, PMMA White |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting |

| Price: | $ |

| Common Grades: | Dark brown (coffee) POM 100AF, POM Black, POM Blue, POM White |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting |

| Price: | $$ |

| Common Grades: | PA(Nylon) Blue, PA6 (Nylon)+GF15 Black, PA6 (Nylon)+GF30 Black, PA66 (Nylon) Beige(Natural), PA66 (Nylon) Black |

| Available Finish: | As machined, Sand blasting, Tumbling, Teflon coating, Painting, Powder coating |

| Price: | $$ |

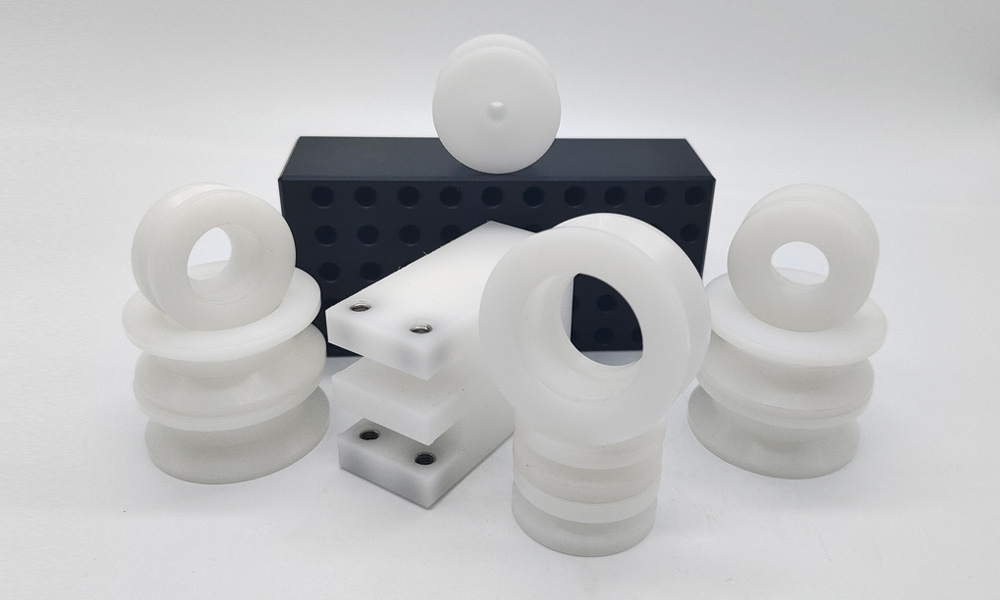

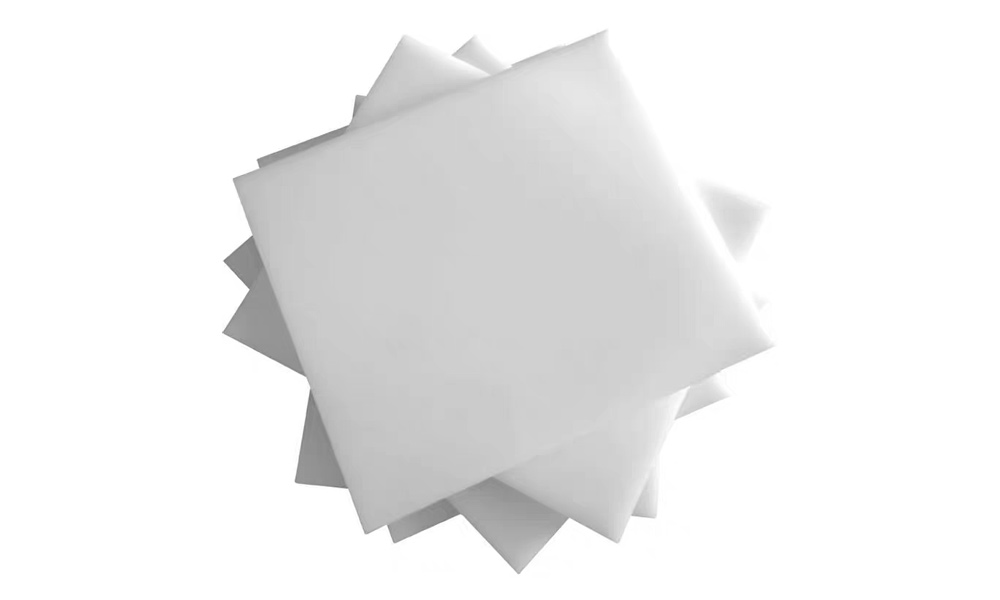

| Common Grades: | HDPE, UHMW-PE, LDPE |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting, Powder coating |

| Price: | $$ |

| Common Grades: | PEEK Beige(Natural), PEEK Black |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting, Powder coating |

| Price: | $$$$$ |

| Subtypes: | PP Black, PP White, PP+GF30 Black |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting, Powder coating |

| Price: | $ |

| Common Grades: | PET Black, PET White, PET+GF30 Black, PET+GF30 White |

| Available Finish: | As machined, Sand blasting, Tumbling, Teflon Coating, Painting |

| Price: | $$ |

| Common Grades: | Teflon (PTFE) Black, Teflon (PTFE) White |

| Available Finish: | As machined, Sand blasting, Powder coating, Brushed finish |

| Price: | $$ |

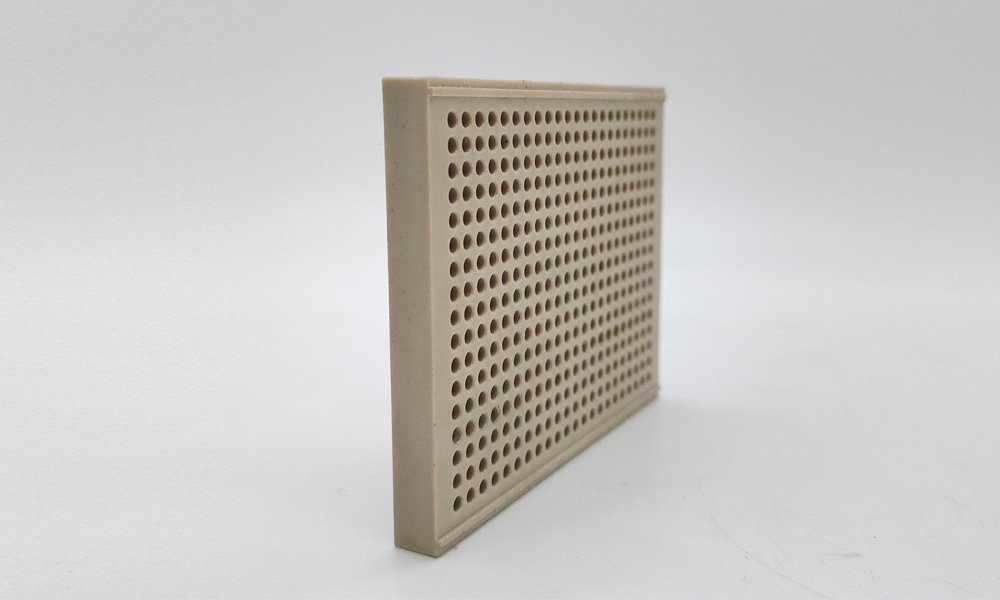

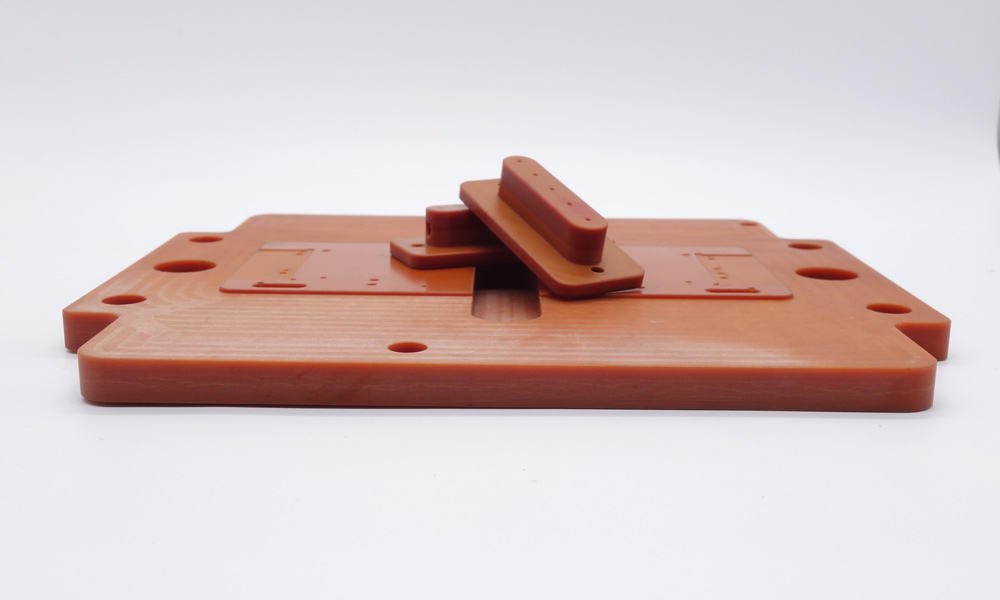

| Subtypes: | Bakelite Black, Bakelite Orange |

| Available Finish: | As machined, Painting, Powder coating, Brushed finish |

| Price: | $$ |

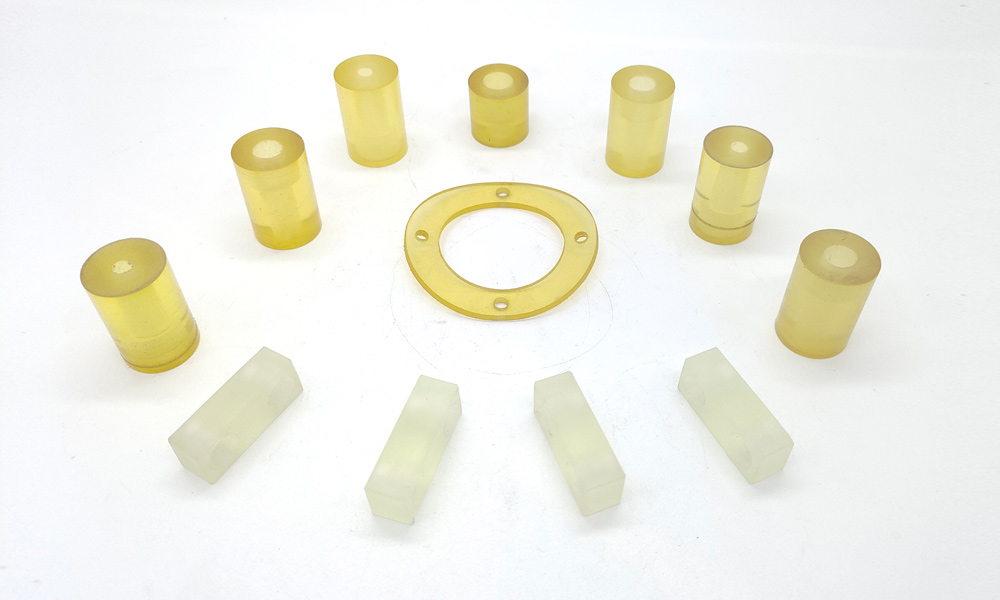

| Common Hardness Grades: | 80 Shore, 85 Shore, 90 Shore, and 95 Shore. |

| Price: | $$ |

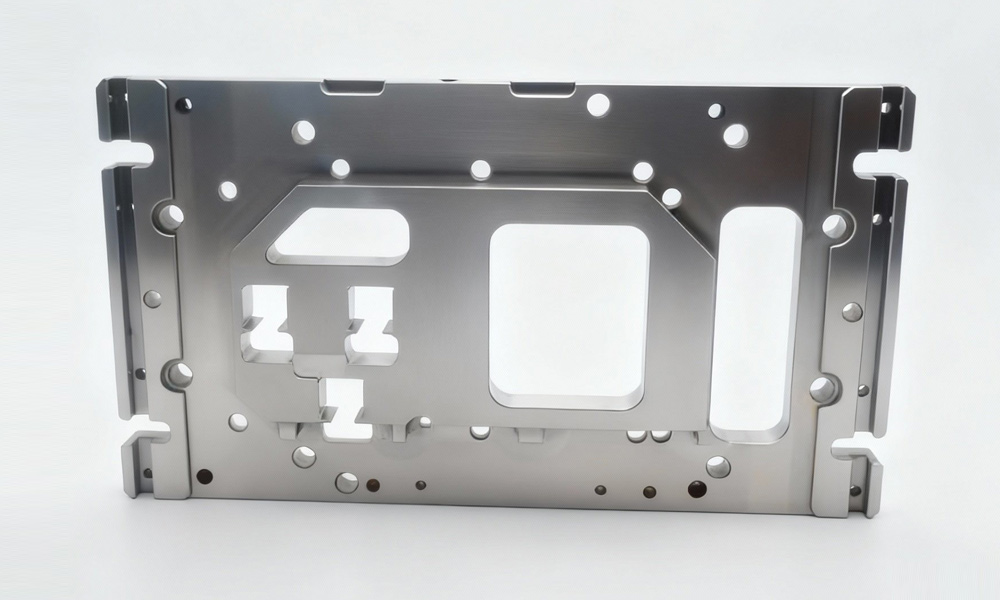

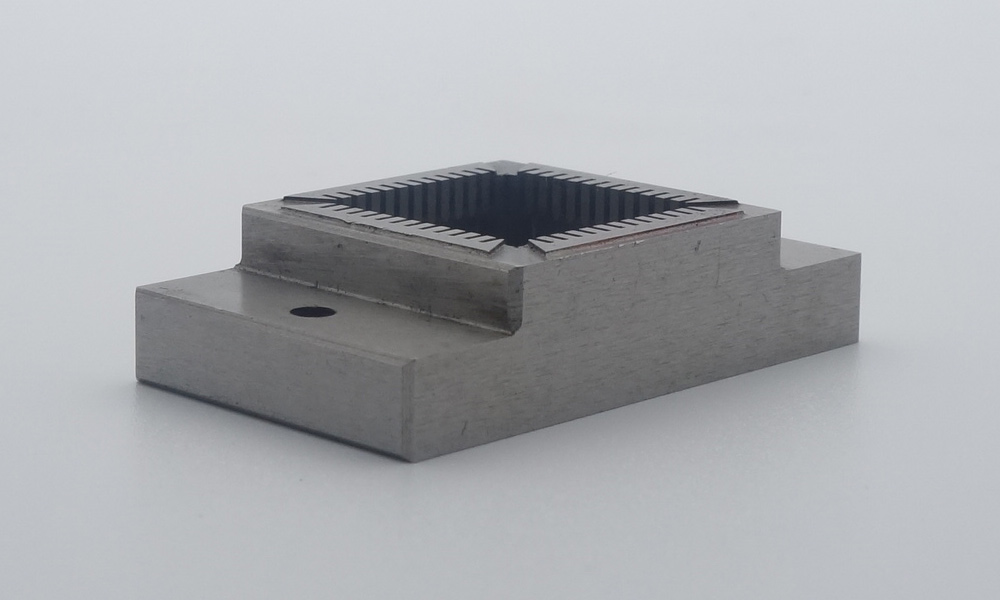

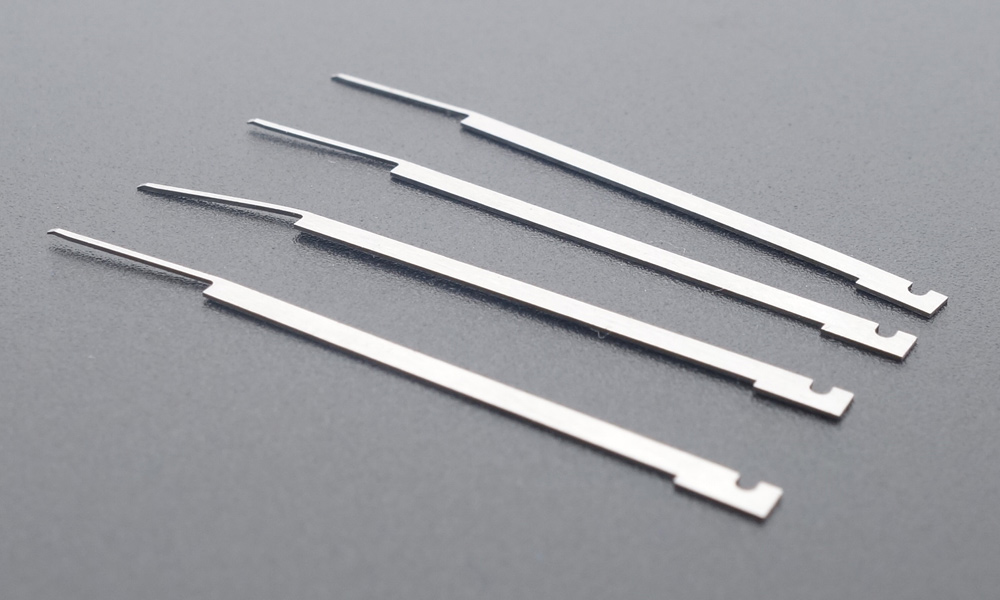

| Machine | 5 Axis Milling | CNC Milling | High Speed Milling |

| Maximum Stroke | 15.75*13.78*5.91 inches (400*350*150 mm) | 43.31*23.62*13.78 inches (1100*600*350 mm) | 50.00*10.00*13.78 inches (1270*254*350 mm) |

| Machining Accuracy | 0.00039 inches (0.01 mm) | 0.00039 inches (0.01 mm) | 0.002 inches (0.05 mm) |

| Lead Time | ≥5 Days | ≥5 Days | ≥1 Day |

| Advantages | Enables the machining of complex parts with a single setup, reducing fixture changeovers. | Offers precise automation for high repeatability, ensuring consistent quality across all production runs. | Significantly accelerates material removal rates, enhancing productivity while maintaining superior surface finishes. |

| ✅ | High Precision and Accuracy CNC milling machines can produce highly accurate components with tight tolerances, ensuring consistent quality in every part. |

| ✅ | Automation and Efficiency CNC milling allows for automated operations, reducing the need for manual intervention and increasing production speed. This leads to lower labor costs and faster turnaround times. |

| ✅ | Complex Geometries CNC milling can create intricate shapes and designs that would be difficult or impossible to achieve with manual machining. This flexibility is vital for industries requiring complex components. |

| ✅ | Repeatability Once a CNC milling program is written, it can be used repeatedly to produce identical parts, ensuring uniformity across large production runs. |

| ✅ | Material Versatility CNC milling can be used on a wide range of materials, including metals, plastics, and composites, making it suitable for various applications. |

| ✅ | Cost Efficiency Despite higher initial setup costs, CNC milling often results in cost savings over time due to reduced waste and increased production efficiency. |

| ✅ | Improved Worker Safety With automation and less manual handling, CNC milling reduces the risk of accidents in the workplace, creating a safer environment for operators. |

| ✅ | Real-Time Monitoring and Adjustment CNC systems can monitor the machining process in real-time, allowing for immediate adjustments and maintenance to maintain quality standards. |

| ✅ | Customization CNC milling allows for easy programming changes to accommodate customized designs or specifications, enhancing design flexibility. |

| ✅ | Aerospace Used to produce complex components such as brackets, housings, and structural elements for aircraft to ensure lightweight and high-strength parts. |

| ✅ | Automotive Employed for manufacturing engine components, transmission housings, and various custom parts, ensuring high precision and efficiency. |

| ✅ | Medical Devices Critical in producing high-precision medical components, including surgical instruments, implantable devices, and anatomical models. |

| ✅ | Electronics Used to fabricate parts for electronic devices, such as housings, connectors, and circuit board supports, ensuring accuracy and fine details. |

| ✅ | Tooling and Molds Widely used to create tooling and molds for injection molding, die-casting, and other manufacturing processes, enabling the production of intricate designs. |

| ✅ | Consumer Products Employed in the manufacture of various consumer products, including household appliances, furniture components, and custom designs. |

| ✅ | Industrial Equipment Used to create parts for machinery, equipment, and tools in various industrial applications, enhancing operational efficiency and reliability. |

| ✅ | Prototyping Ideal for rapid prototyping, allowing for quick development and testing of designs before full-scale production. |

| ✅ | Marine Components for marine applications, such as fittings, hulls, and functional parts for boats and ships, are often produced using CNC milling. |

2026-02-03

2026-02-02

2026-02-01

2026-01-31

2026-01-30