From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

| Common Grades: | Stainless Steel SUS201, SUS303, SUS 304, SUS316, SUS316L, SUS42, SUS430, SUS431, SUS440C, SUS630/17-4PH, AISI 304 |

| Available Finish: | As machined, Electroplating, Passivation, Powder coating |

| Price: | $$$ |

| Common Grades: | Titanium Alloy TA1, Alloy TA2, Alloy TC4/Ti-6Al 4V |

| Available Finish: | As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickle, Chrome plating, Powder coating, Brushed finish |

| Price: | $$$$$ |

| Common Grades: | Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36, Die steel, Alloy steel, Chisel tool steel, Spring steel, High speed steel, Cold rolled steel, Bearing steel, SPCC |

| Available Finish: | As machined, Electroplating, Passivation, Powder coating |

| Price: | $$$ |

| Common Grades: | Aluminum 6061, 6061-T6, Aluminum 2024, Aluminum 5052, Aluminum 5083, Aluminum 6063, Aluminum 6082, Aluminum 7075, 7075-T6, Aluminum ADC12 (A380) |

| Available Finish: | As machined, Anodizing, Powder coating, Electroplating, Painting, Sand blasting, Polishing |

| Price: | $$ |

| Common Grades: | KG5, KG7, and ST7. |

| Available Finish: | As-Machined, Polishing, Lapping, Brushing, Tumbling, Grinding, PVD Coating... |

| Price: | $$$$$$ |

| Common Grades: | Copper C101(T2), Copper C103(T1), Copper C103(TU2), Copper C110(TU0), Beryllium Copper |

| Available Finish: | As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickel, Chrome plating, Brushed finish |

| Price: | $$$ |

| Common Grades: | C36000 and C46400. |

| Available Finish: | As-Machined, Polishing, Lapping, Grinding, Sandblasting, Passivation, Electroplating... |

| Price: | $$$ |

| Common Grades: | Tin Bronze |

| Available Finish: | As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickle, Chrome plating, Powder coating, Brushed finish |

| Price: | $$$ |

| Common Grades: | Magnesium Alloy AZ31B, AZ91D |

| Available Finish: | As machined, Polishing, Sand Blasting, Tumbling, Alodine, Heat treatment, Anodizing, Teflon coating, Electroless nickel, Painting, Powder coating, Electrophoresis |

| Price: | $$$$$ |

| Item | Description |

| Maximum Strok | 300 * 200 * 200 mm / 11.81 * 7.87 * 7.87 inches |

| Machining Accuracy | 0.01 mm / 0.00039 inches |

| Minimum Outer Contour | 1.0*1.0*1.0 mm |

| Minimum Inner Contour | 0.2 mm |

| Minimum Outer Thread | M2 |

| Minimum Inner Thread | M2 |

| Minimum Outer Concave Corner | 0.2 mm |

| Minimum Outer Convex Corner | 0.2 mm |

| Minimum Inner Concave Corner | 0.2 mm |

| Minimum Inner Convex Corner | 0.2 mm |

| GB China | ASTM USA | JIS Japan | DIN Germany |

| 9CrWMn | 01 | SKS3 | 1.2510 |

| 9Mn2V | 02 | SKS93 | 1.284 |

| Cr12 | D3 | SKD1 | 1.2080 |

| Cr12MoV | D2 | SKD11 | 1.2436 |

| Cr12Mo1v1 | D2 | SKD11 | 1.2379 |

| 4Cr5MoSiV1 | H13 | SKD61 | 1.2344 |

| 3Cr2Mo | P20 | SCM | 1.2311 |

| 3Cr13 | 420 | SUS420J2 | 1.4028 |

| W6Cr5Mo4V2 | M2 | SKH51(SKH9) | 1.3343 |

| W6Mo5Cr4V2Co5 | M35 | SKH55 | 1.3243 |

| W2Mo9Cr4VCo8 | M42 | SKH59 | 1.3247 |

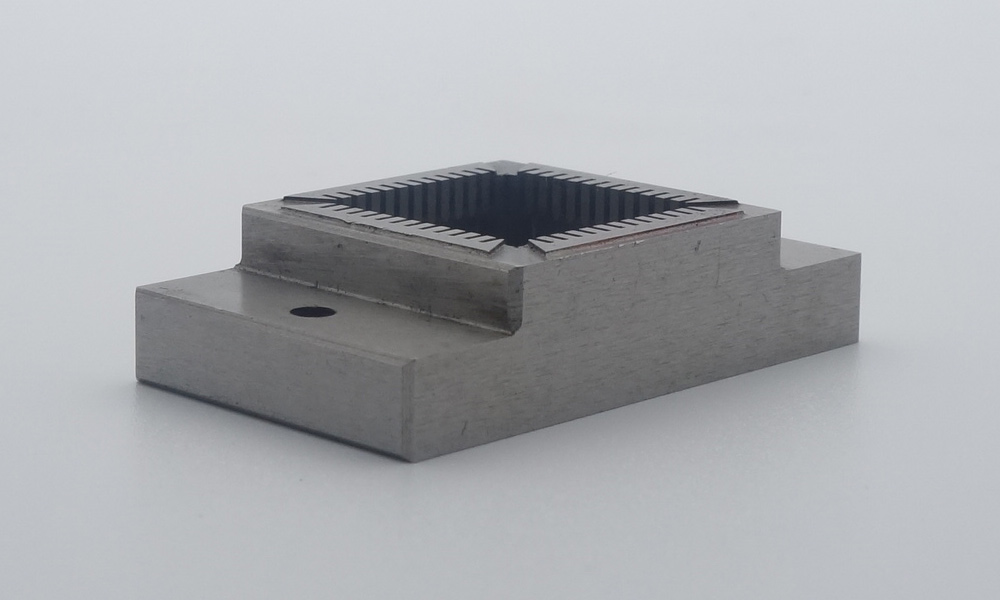

| | Tool and Die Manufacturing * Molds: Used for creating injection molds, die-casting molds, and extrusion molds. * Punches and Dies: Fabrication of punches and dies for stamping and forming operations. |

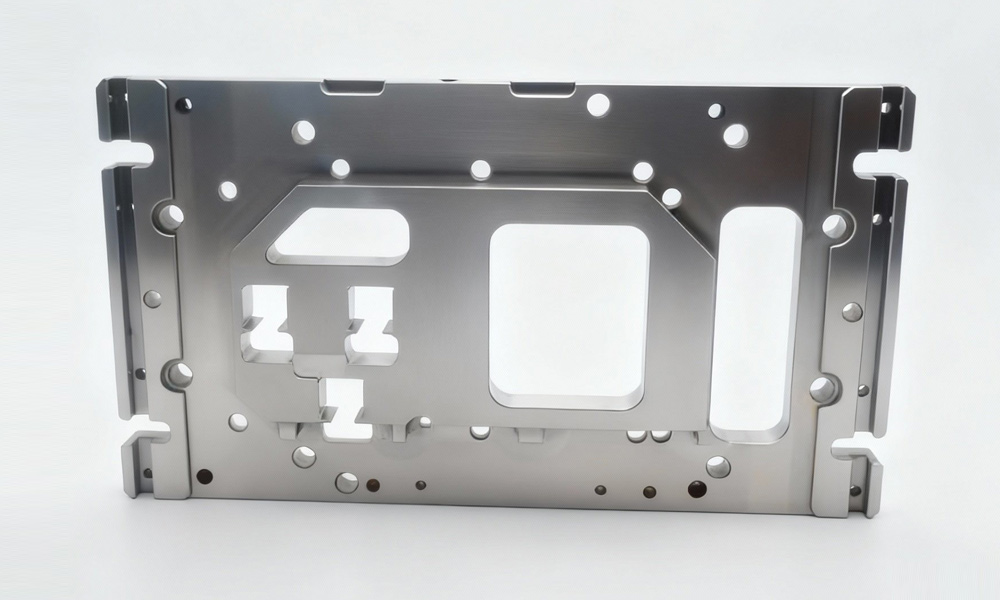

| | Aerospace Industry * Complex Components: Manufacturing of components with intricate geometries like turbine blades, brackets, and other critical flight components. * Hard Materials: Precision parts made from difficult-to-machine materials such as carbide and titanium. |

| | Automotive Industry * Cutting Tools: Creation of high-precision cutting tools and fixtures. * Customization: Machining of custom parts for engines, transmissions, and other assemblies. |

| | Medical Industry * Surgical Instruments: Production of highly precise surgical tools and implants that require strict tolerances. * Prototyping: Rapid prototyping of custom medical devices and components. |

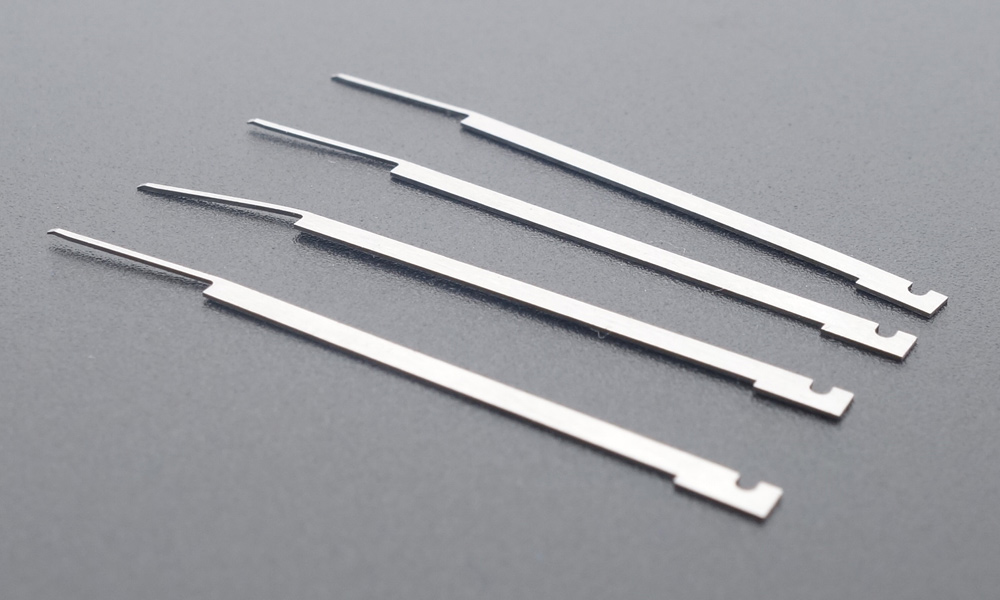

| | Electronics Industry * Micro Components: Fabrication of intricate parts for electronics, such as connectors and circuit boards. * Heat Sinks: Precision machining of heat sinks and other critical electronic components. |

| | Energy Sector * Utility Components: Manufacturing of parts used in renewable energy applications, such as wind turbine components. * Oil and Gas: Precise machining of components in drilling and extraction equipment. |

| | Research and Development * Custom Prototypes: Development of prototypes for testing and research, allowing for rapid iterations of design concepts. |