From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

| Common Grades: | Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36, Die steel, Alloy steel, Chisel tool steel, Spring steel, High speed steel, Cold rolled steel, Bearing steel, SPCC |

| Available Finish: | As machined, Electroplating, Passivation, Powder coating |

| Price: | $$$ |

| Common Grades: | KG5, KG7, and ST7. |

| Available Finish: | As-Machined, Polishing, Lapping, Brushing, Tumbling, Grinding, PVD Coating... |

| Price: | $$$$$$ |

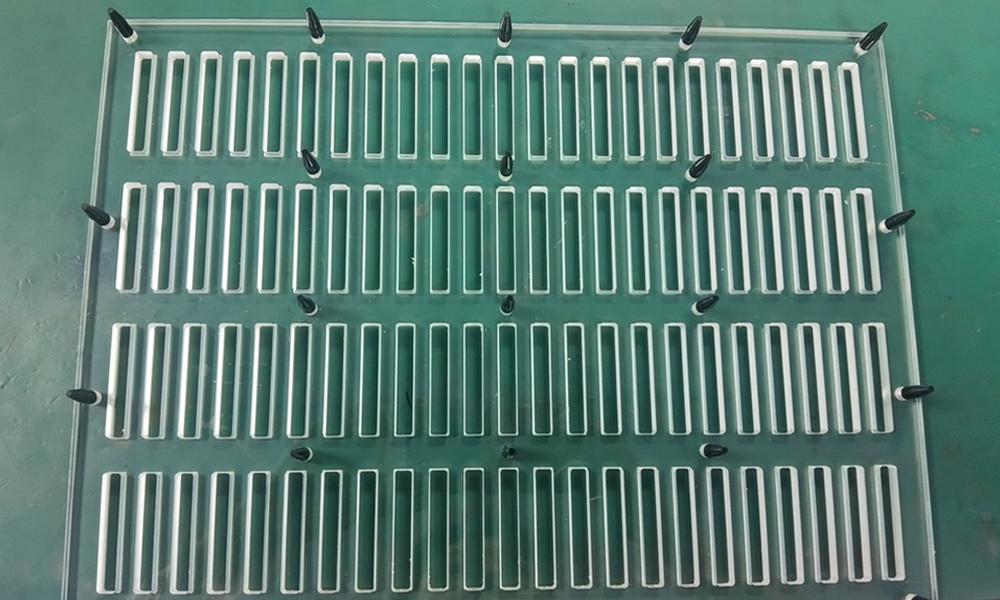

| Common Grades: | Aluminum 6061, 6061-T6, Aluminum 2024, Aluminum 5052, Aluminum 5083, Aluminum 6063, Aluminum 6082, Aluminum 7075, 7075-T6, Aluminum ADC12 (A380) |

| Available Finish: | As machined, Anodizing, Powder coating, Electroplating, Painting, Sand blasting, Polishing |

| Price: | $$ |

| Common Grades: | Stainless Steel SUS201, SUS303, SUS 304, SUS316, SUS316L, SUS42, SUS430, SUS431, SUS440C, SUS630/17-4PH, AISI 304 |

| Available Finish: | As machined, Electroplating, Passivation, Powder coating |

| Price: | $$$ |

| Common Grades | Copper C101(T2), Copper C103(T1), Copper C103(TU2), Copper C110(TU0), Beryllium Copper |

| Available Finish: | As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickel, Chrome plating, Brushed finish |

| Price: | $$$ |

| Common Grades | C36000 and C46400. |

| Available Finish: | As-Machined, Polishing, Lapping, Grinding, Sandblasting, Passivation, Electroplating... |

| Price: | $$$ |

| Common Grades: | Tin Bronze |

| Available Finish: | As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickle, Chrome plating, Powder coating, Brushed finish |

| Price: | $$$ |

| Common Grades: | Titanium Alloy TA1, Alloy TA2, Alloy TC4/Ti-6Al 4V |

| Available Finish: | As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickle, Chrome plating, Powder coating, Brushed finish |

| Price: | $$$$$ |

| Subtypes : | Magnesium Alloy AZ31B, AZ91D |

| Available Finish: | As machined, Polishing, Sand Blasting, Tumbling, Alodine, Heat treatment, Anodizing, Teflon coating, Electroless nickel, Painting, Powder coating, Electrophoresis |

| Price : | $$$$$ |

| Common Grades: | ABS Beige(Natural), ABS Blac, ABS Black Antistati, ABS Milky Whit, ABS+PC Black, ABS+PC White |

| Available Finish: | As machined, Sand blasting, Tumbling, Teflon coating, Painting, Powder coating, Electrophoresis |

| Price: | $$ |

| Common Grades: | Common Grades |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting, Brushed Finish |

| Price: | $$ |

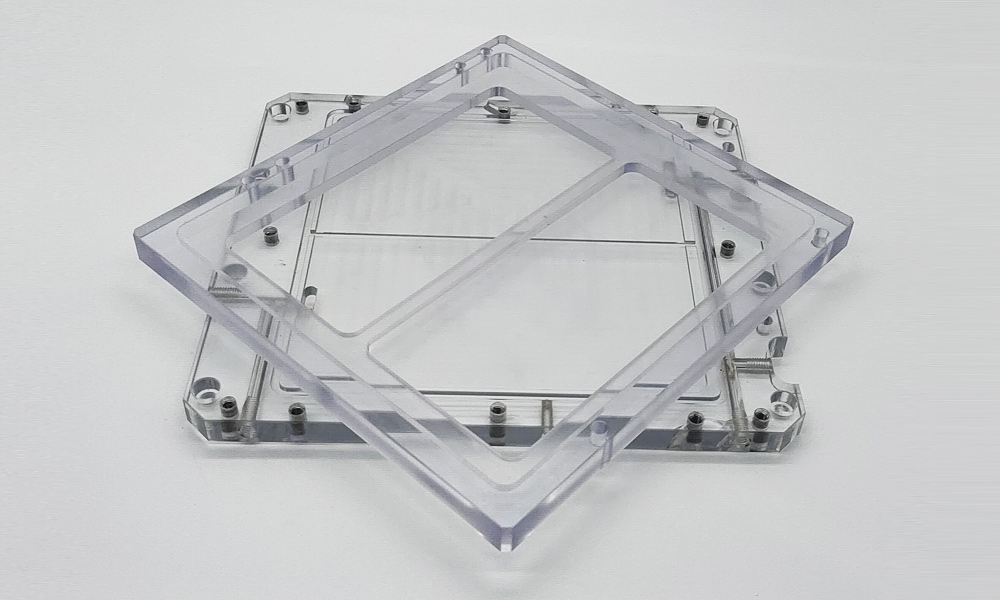

| Subtypes: | PMMA Black, PMMA Transparent, PMMA White |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting |

| Price: | $ |

| Common Grades: | Dark brown (coffee) POM 100AF, POM Black, POM Blue, POM White |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting |

| Price: | $$ |

| Common Grades: | PA(Nylon) Blue, PA6 (Nylon)+GF15 Black, PA6 (Nylon)+GF30 Black, PA66 (Nylon) Beige(Natural), PA66 (Nylon) Black |

| Available Finish: | As machined, Sand blasting, Tumbling, Teflon coating, Painting, Powder coating |

| Price: | $$ |

| Common Grades: | HDPE, UHMW-PE, LDPE |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting, Powder coating |

| Price: | $$ |

| Common Grades: | PEEK Beige(Natural), PEEK Black |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting, Powder coating |

| Price: | $$$$$ |

| Subtypes: | PP Black, PP White, PP+GF30 Black |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting, Powder coating |

| Price: | $ |

| Common Grades: | PET Black, PET White, PET+GF30 Black, PET+GF30 White |

| Available Finish: | As machined, Sand blasting, Tumbling, Teflon Coating, Painting |

| Price: | $$ |

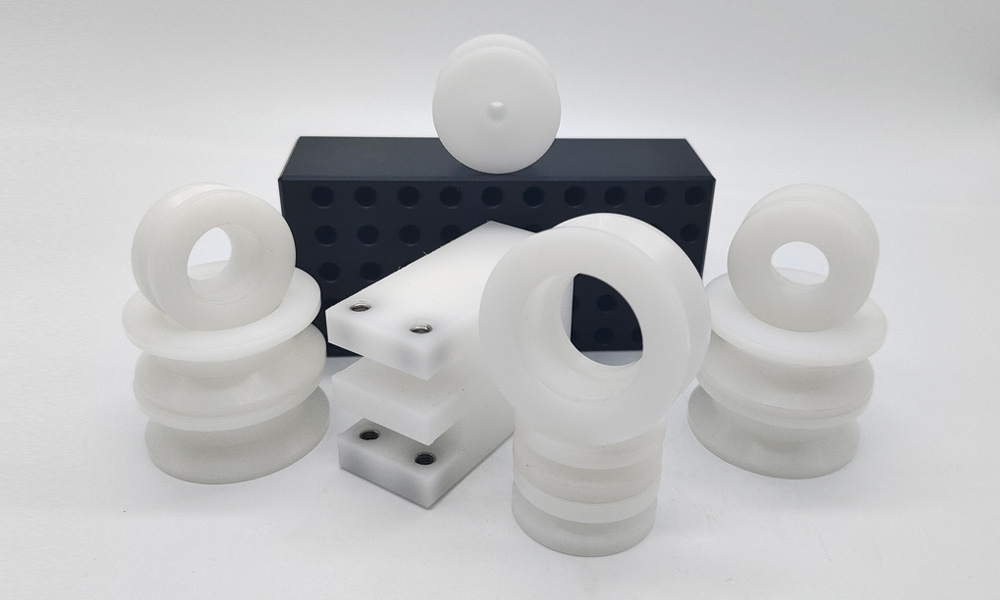

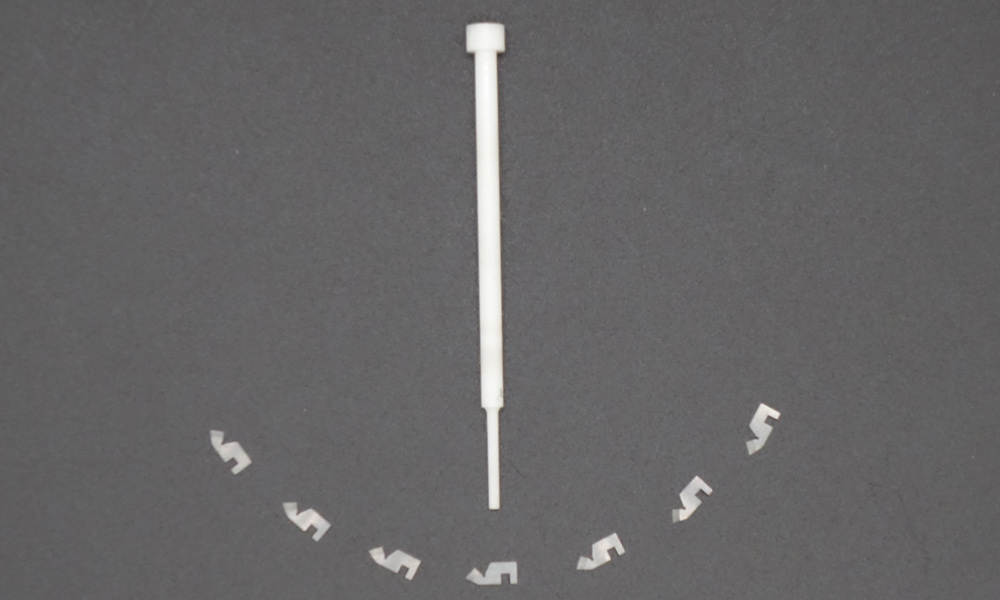

| Common Grades: | Teflon (PTFE) Black, Teflon (PTFE) White |

| Available Finish: | As machined, Sand blasting, Powder coating, Brushed finish |

| Price: | $$ |

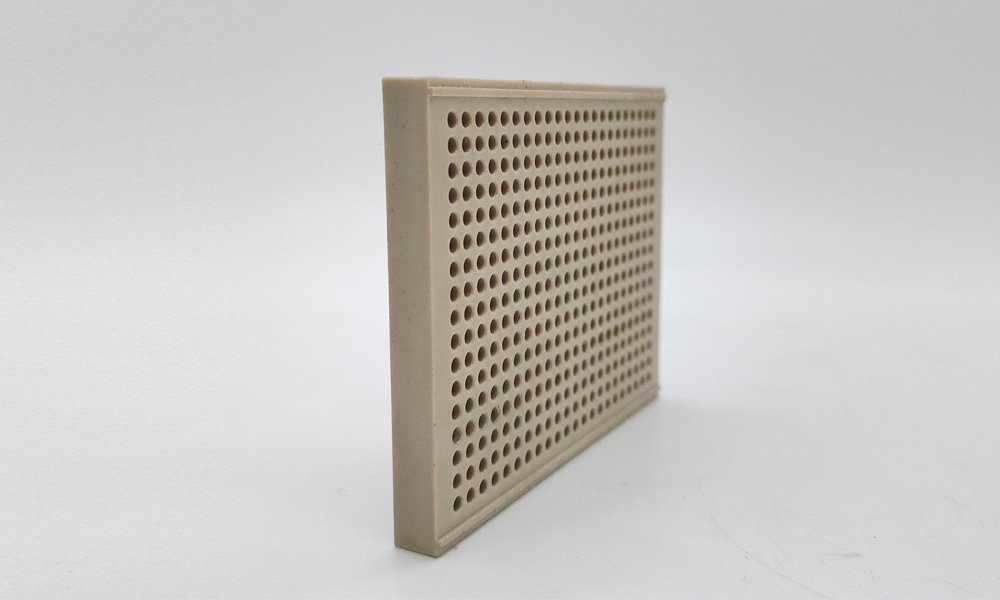

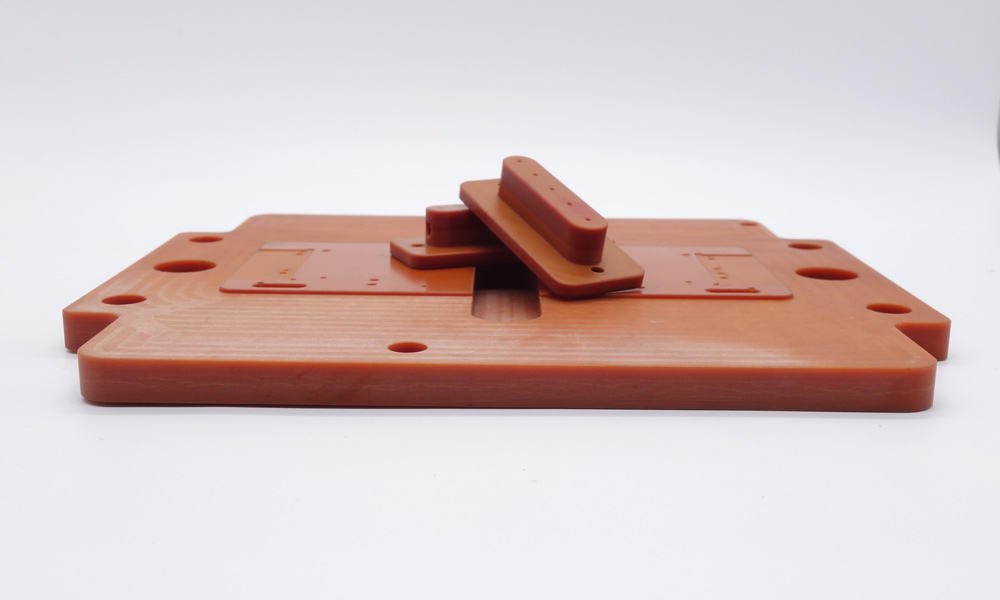

| Subtypes: | Bakelite Black, Bakelite Orange |

| Available Finish: | As machined, Painting, Powder coating, Brushed finish |

| Price: | $$ |

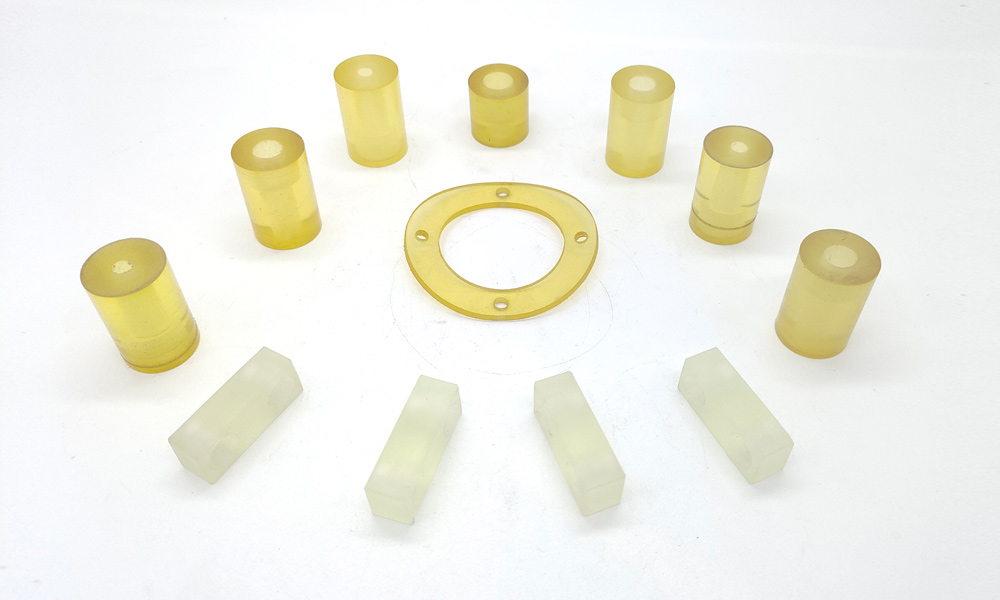

| Common Hardness Grades: | 80 Shore, 85 Shore, 90 Shore, and 95 Shore. |

| Price: | $$ |

| Common Grades: | Alumina Ceramic, Zirconia Ceramics, and Aluminum Nitride Ceramics. |

| Available Finish: | As-Machined, Polishing, Lapping, Grinding, Electroplating, PVD Coating... |

| Price: | $$$$$$ |

| Description | |

| General Tolerances | Metals : lSO 2768-f Plastics : ISO 2768-m |

| Precision Tolerances | U-Need has the capability to produce and examine components with precise tolerances based on your design requirements and geometric dimensioning and tolerancing (GD&T) notes, including tolerances smaller than +/- 0.005mm. |

| Min Wall Thickness | 0.5mm |

| Min End Mill Size | 0.5mm |

| Min Drill Size | 1mm |

| Production Volume | Prototoyping: 1-100 pcs Low volume: 101-10,000 pcs High volume: Above 10,001 pcs |

| Lead Time | Most projects are completed within 5 business days. Simple parts can be delivered in as little as 1 day. |

The time it takes to receive a CNC machined part from U-Need can vary based on a few factors. These include the complexity of the part's design, the type of material chosen, and our current production schedule. CNC machining is known for its speed, especially for simpler parts, which allows for fast turnaround times. In fact, parts can be delivered in as little as one day after the machining setup is finished! For the most accurate estimate of time tailored to your project, we suggest reaching out to us directly for a detailed quote. This way, we can give you a precise timeframe based on your specific needs.

2026-02-03

2026-02-02

2026-02-01

2026-01-31

2026-01-30