From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

| Capabilities | Description |

| Maximum Stroke (mm) | 400*350*150 |

| Machining Accuracy (mm) | ±0.00039 inches / ±0.01mm |

| General Tolerances | ISO 2768-f for metals ISO 2768-m for plastics |

| Lead Time | As short as 1~2 days for simple work pieces Up to 2 weeks for complex projects |

| Common Grades: | Aluminum 6061, 6061-T6, Aluminum 2024, Aluminum 5052, Aluminum 5083, Aluminum 6063, Aluminum 6082, Aluminum 7075, 7075-T6, Aluminum ADC12 (A380) |

| Available Finish: | As machined, Anodizing, Powder coating, Electroplating, Painting, Sand blasting, Polishing |

| Price: | $$ |

| Common Grades: | Stainless Steel SUS201, SUS303, SUS 304, SUS316, SUS316L, SUS42, SUS430, SUS431, SUS440C, SUS630/17-4PH, AISI 304 |

| Available Finish: | As machined, Electroplating, Passivation, Powder coating |

| Price: | $$$ |

| Common Grades: | Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36, Die steel, Alloy steel, Chisel tool steel, Spring steel, High speed steel, Cold rolled steel, Bearing steel, SPCC |

| Available Finish: | As machined, Electroplating, Passivation, Powder coating |

| Price: | $$$ |

| Common Grades | Copper C101(T2), Copper C103(T1), Copper C103(TU2), Copper C110(TU0), Beryllium Copper |

| Available Finish: | As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickel, Chrome plating, Brushed finish |

| Price: | $$$ |

| Common Grades | C36000 and C46400. |

| Available Finish: | As-Machined, Polishing, Lapping, Grinding, Sandblasting, Passivation, Electroplating... |

| Price: | $$$ |

| Common Grades: | Tin Bronze |

| Available Finish: | As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickle, Chrome plating, Powder coating, Brushed finish |

| Price: | $$$ |

| Common Grades: | Titanium Alloy TA1, Alloy TA2, Alloy TC4/Ti-6Al 4V |

| Available Finish: | As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickle, Chrome plating, Powder coating, Brushed finish |

| Price: | $$$$$ |

| Subtypes : | Magnesium Alloy AZ31B, AZ91D |

| Available Finish: | As machined, Polishing, Sand Blasting, Tumbling, Alodine, Heat treatment, Anodizing, Teflon coating, Electroless nickel, Painting, Powder coating, Electrophoresis |

| Price : | $$$$$ |

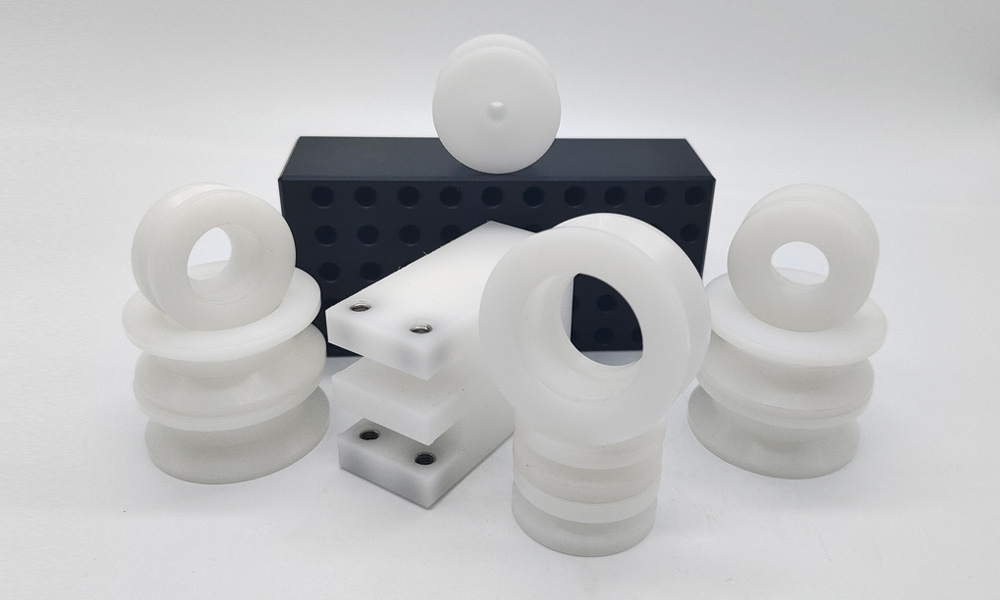

| Common Grades: | ABS Beige(Natural), ABS Blac, ABS Black Antistati, ABS Milky Whit, ABS+PC Black, ABS+PC White |

| Available Finish: | As machined, Sand blasting, Tumbling, Teflon coating, Painting, Powder coating, Electrophoresis |

| Price: | $$ |

| Common Grades: | Common Grades |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting, Brushed Finish |

| Price: | $$ |

| Subtypes: | PMMA Black, PMMA Transparent, PMMA White |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting |

| Price: | $ |

| Common Grades: | Dark brown (coffee) POM 100AF, POM Black, POM Blue, POM White |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting |

| Price: | $$ |

| Common Grades: | PA(Nylon) Blue, PA6 (Nylon)+GF15 Black, PA6 (Nylon)+GF30 Black, PA66 (Nylon) Beige(Natural), PA66 (Nylon) Black |

| Available Finish: | As machined, Sand blasting, Tumbling, Teflon coating, Painting, Powder coating |

| Price: | $$ |

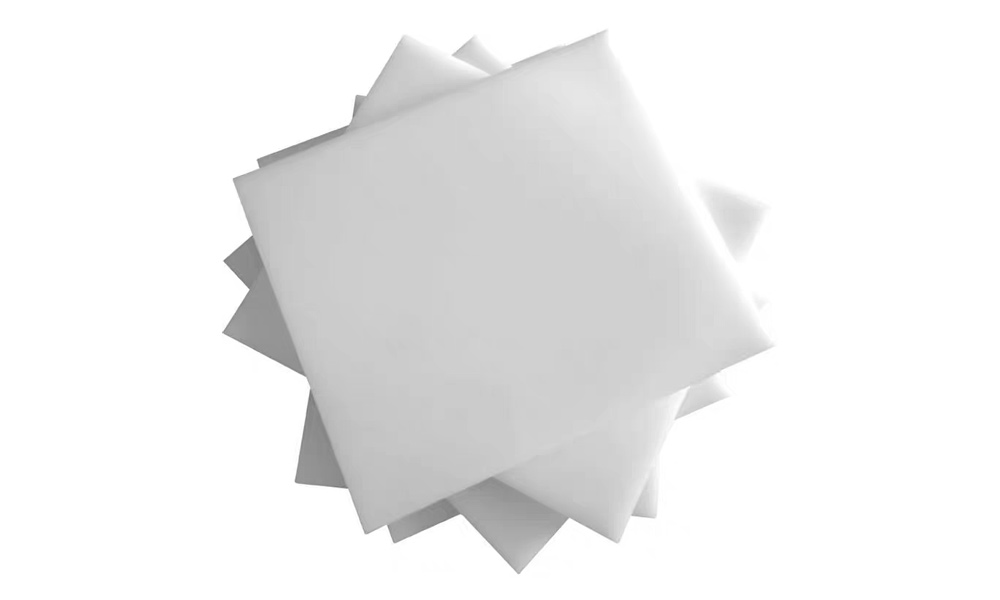

| Common Grades: | HDPE, UHMW-PE, LDPE |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting, Powder coating |

| Price: | $$ |

| Common Grades: | PEEK Beige(Natural), PEEK Black |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting, Powder coating |

| Price: | $$$$$ |

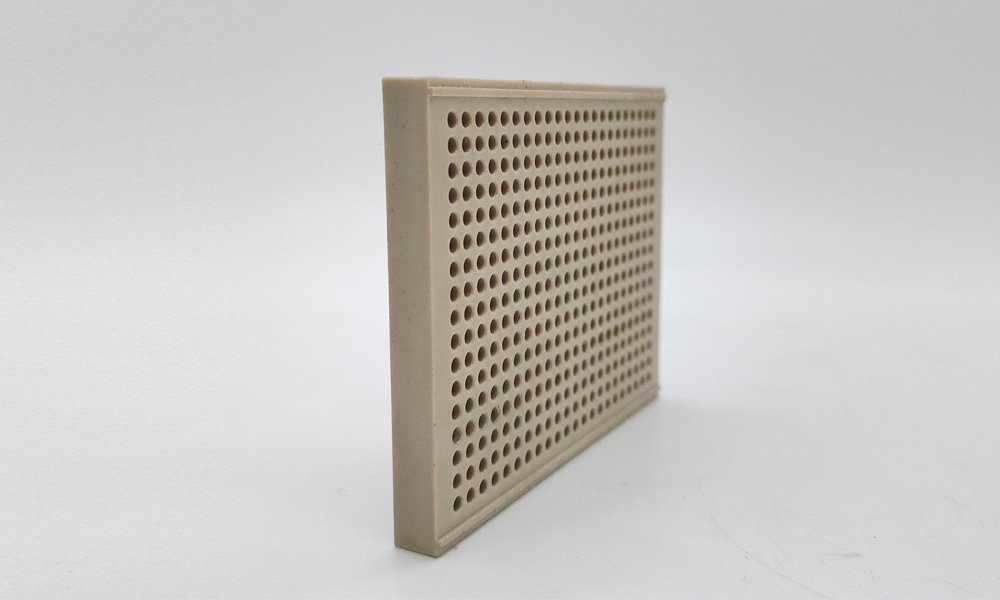

| Subtypes: | PP Black, PP White, PP+GF30 Black |

| Available Finish: | As machined, Sand blasting, Tumbling, Painting, Powder coating |

| Price: | $ |

| Common Grades: | PET Black, PET White, PET+GF30 Black, PET+GF30 White |

| Available Finish: | As machined, Sand blasting, Tumbling, Teflon Coating, Painting |

| Price: | $$ |

| Common Grades: | Teflon (PTFE) Black, Teflon (PTFE) White |

| Available Finish: | As machined, Sand blasting, Powder coating, Brushed finish |

| Price: | $$ |

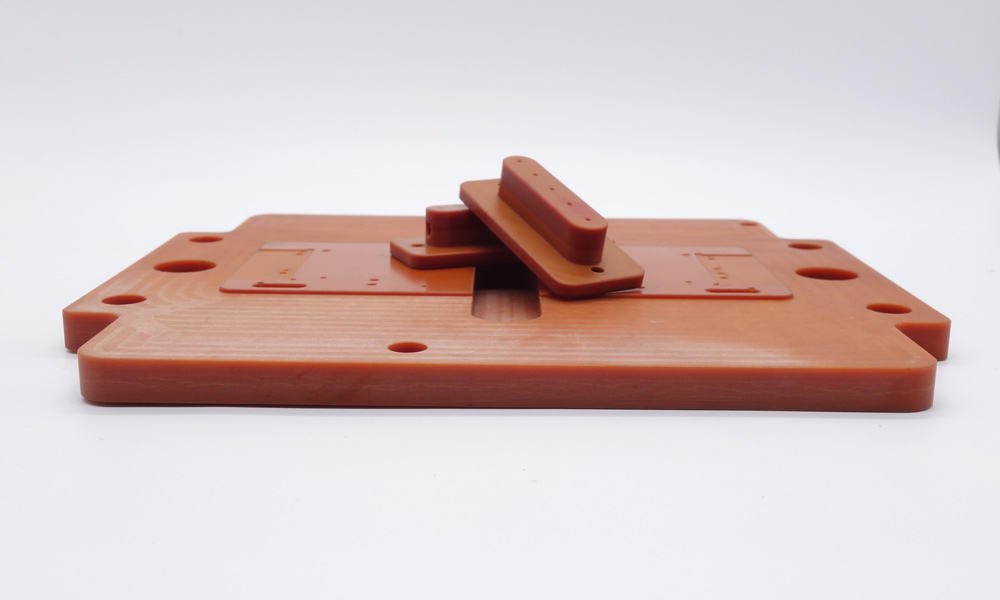

| Subtypes: | Bakelite Black, Bakelite Orange |

| Available Finish: | As machined, Painting, Powder coating, Brushed finish |

| Price: | $$ |

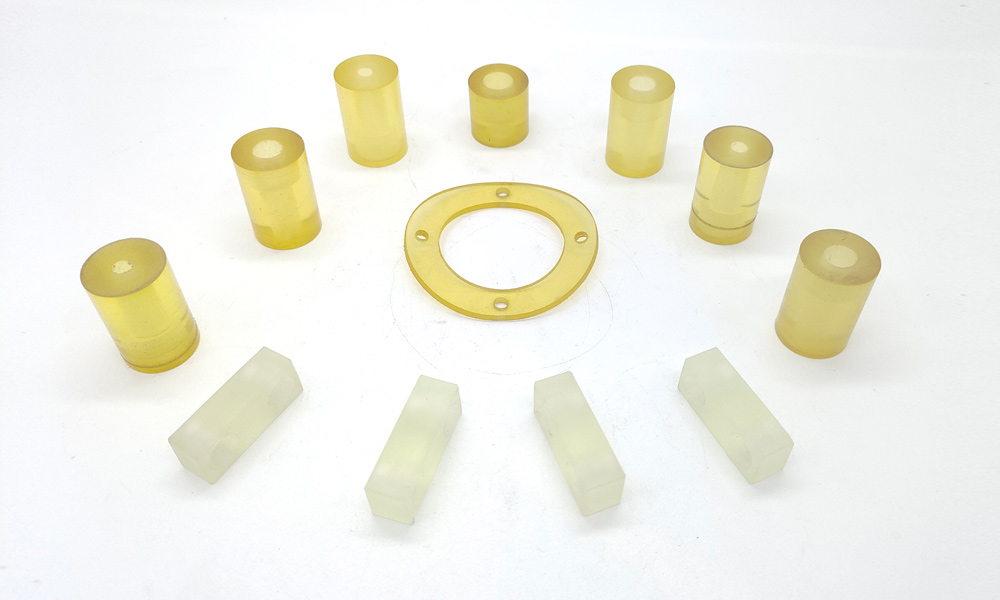

| Common Hardness Grades: | 80 Shore, 85 Shore, 90 Shore, and 95 Shore. |

| Price: | $$ |

2026-02-03

2026-02-02

2026-02-01