From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-07 Origin: Site

Content Menu

● What Is a 3D Printed Living Hinge

● Common Living Hinge Types and Applications

● Advantages and Disadvantages of Living Hinges

>> Advantages

● Why Use 3D Printed Hinges in Prototyping

● Key Design Factors for 3D Printed Hinges

>> Hinge Geometry and Air Gaps

>> Hinge Thickness and Fatigue Life

● Material Properties and Selection

● Matching Design to Printer and Process

● Build Orientation and Process Settings

● Suitable 3D Printing Technologies for Living Hinges

● Post‑Processing to Improve Hinge Performance

● Calculating the Length of 3D Printed Hinges

● Practical Examples of 3D Printed Hinges

● Strength Considerations for 3D Printed Hinges

● When to Collaborate With Professional 3D Printing Providers

● FAQs About 3D Printing Living Hinges

>> Q1. Can 3D printed parts include moving elements?

>> Q2. Why are 3D printed hinges useful in development?

>> Q3. Are special printers required for living hinges?

>> Q4. Which materials are commonly used for 3D printed hinges?

>> Q5. Is PETG suitable for living hinges?

3D printed hinges and living hinges allow engineers and product designers to prototype fully functional assemblies without investing in expensive tooling for early-stage testing. When correctly designed, they can open and close many times and closely mimic final injection-molded parts in motion and ergonomics.

A living hinge is a thin, flexible section that joins two rigid parts and allows them to pivot repeatedly without separate mechanical hardware. In many designs, hinge and body are printed as a single continuous piece, avoiding any secondary assembly.

- Living hinges appear in doors, caps, clips, boxes, and industrial enclosures where frequent opening and closing is needed.

- In additive manufacturing, they reproduce these behaviors directly in prototypes so designers can validate movement and usability.

In 3D printing, a hinge can be a classic mechanical construction with pins or a flexible web between two bodies that works purely by material elasticity. Both approaches help verify clearances, range of motion, and user interaction before mass production.

Different hinge geometries provide different motion profiles, stability, and assembly behavior. Matching geometry to use case is essential for durability and user experience.

- Flat hinge – Flexible strip between two parts, usually allowing up to 180 degrees of rotation, ideal for lids and small boxes.

- Double hinge – Two flat hinges separated by a small gap, providing 360 degrees rotation or extra clearance when folded.

- Bi‑stable hinge – Three-section design that remains locked in open or closed positions until force is applied.

- Butterfly hinge – Common in dispensing caps, automatically flips open or closed past a specific angle.

Prototypes using these living hinge types allow teams to test ergonomics, accessibility, and closing forces under realistic conditions.

Living hinges are widely used because of their simple structure and practicality, but they also have important constraints that must be considered. Understanding both sides leads to better engineering decisions.

- Low cost – No additional components are required because hinge and body can share the same material, reducing part count and production cost.

- Durability in motion – When made from suitable plastics, living hinges can open and close repeatedly without becoming brittle too quickly.

- Clean appearance – The hinge blends into the adjoining rigid parts, which helps when a natural or invisible look is preferred in the final product.

- Reduced inventory – Integrated hinges remove the need to manage separate hinge stock during prototyping and low-volume builds.

- Limited strength – These flexible joints are not designed to carry heavy loads or withstand strong, uneven forces without damage.

- Temperature sensitivity – Heat can soften and deform plastic hinges, while cold conditions may cause them to become brittle and crack over time.

- Material constraints – Available 3D printing materials with ideal flexibility and fatigue life are still limited compared with traditional molding materials.

Designers should use living hinges where frequent motion and low cost matter more than maximum structural strength.

Printing hinges directly into prototype parts is often the most efficient way to evaluate functional assemblies. This approach offers several concrete benefits.

- Cost reduction – Printing hinge and body as a single part cuts out assembly labor and additional components, especially when using external printing services.

- Improved durability during tests – Integrated hinges can better withstand repeated test cycles compared with taped or improvised attachments.

- Professional look – Prototypes with purpose-designed hinges and good surface finish present a more accurate picture of the final product to stakeholders.

These advantages make printed hinges particularly attractive in concept validation, investor presentations, and customer demos.

Design controls how long a living hinge will survive and how well it performs. Geometry, thickness, and stress distribution are the main parameters to optimize.

Any printed moving element requires air gaps or negative space to avoid fusing together during printing. Proper clearances let the hinge move without binding or breaking prematurely.

- Include uniform clearance between hinge components so they do not bond during the build.

- Avoid sharp internal corners and use smooth transitions to reduce stress concentration at the hinge base.

The bottom radius and recess details largely determine how stresses are transmitted, and poor geometry will significantly shorten hinge life.

Thickness determines flexibility and number of cycles before failure. Selecting the right thickness is a balance between manufacturability and performance.

- Hinges typically perform best with no more than two contours to keep the section slender and flexible enough for printing.

- There is a direct relationship between wall thickness and cycle life, but thicker hinges also increase tensile stress and printing difficulty.

A practical working range for many plastic living hinges is around 0.18–0.38 mm thickness for repeated bending.

Living hinges demand materials with strength, endurance, and flexibility. The right material will resist cracking under continuous bending.

- Common materials for printed hinges include PLA, PETG, ABS, nylon, resin blends, and rubber-like materials.

- PLA is easy to print but less durable, PETG combines flexibility with strength, and nylon or rubber-like materials offer higher fatigue resistance.

For traditional living hinges in mass production, polypropylene is preferred, while 3D printing often relies on PETG, ABS, or nylon for functional prototypes.

Printer capabilities have a direct impact on hinge quality and consistency. Different printing technologies favor different geometries and materials.

- Some printers work better with flexible materials, while others excel with rigid engineering filaments or resins.

- The chosen printer should allow repeated iterations with minimal setup changes so design variations can be tested efficiently.

Aligning design rules, material compatibility, and machine performance is crucial for stable hinge production.

Print orientation and process parameters strongly influence hinge performance, especially in FDM processes. Small changes can dramatically affect durability.

- For FDM parts, placing hinges in the horizontal plane tends to increase strength because layer bonding supports bending more effectively.

- Careful calibration, layer height selection, and temperature control help avoid weak interlayer bonds that might cause early hinge failure.

Choosing the correct plane and settings during preparation improves both mechanical strength and motion smoothness.

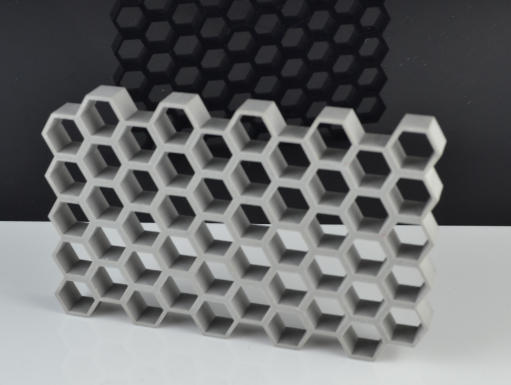

Several 3D printing processes can produce functional living hinges, each with distinct benefits and design rules. Selecting the right one depends on the project's priorities.

- Fused Deposition Modeling (FDM) supports a wide range of thermoplastic materials and is accessible for quick iterations.

- Selective Laser Sintering (SLS) creates strong hinges without support structures, which helps with complex or nested geometries.

- Material Jetting allows very fine detail and can use rubber-like materials, making it suitable for flexible hinge concepts.

These technologies differ in cost, accuracy, and material availability, so they should be chosen with hinge performance requirements in mind.

Most printed hinges can be used directly after printing, but certain post-processes enhance fatigue resistance. One commonly used technique is annealing.

- Annealing involves heating the material until it becomes flexible, then allowing it to cool, which can be repeated for better stability.

- Proper annealing can increase load-bearing capacity and extend the service life of printed hinges.

This simple adjustment can help critical prototypes withstand more cycles during testing.

Appropriate hinge length helps distribute stress along the flexible section. Designers can use a few straightforward formulas to estimate this dimension.

- For right-angle hinges, length \(L\) should be at least four times the material thickness \(t\): \(L = 4t\).

- For other hinge angles, length should be at least six times thickness: \(L = 6t\).

When considering bend radius, additional geometric relationships apply.

- For a semicircular 180‑degree hinge, the arc length is \(L = \pi R\), where \(R\) is the bend radius.

- For other bend angles, length can be calculated as \(L = (\text{Bend}^\circ / 180) \pi R\).

Besides these rules, it is important to keep thickness within the recommended range and ensure stress is spread evenly for maximum fatigue life.

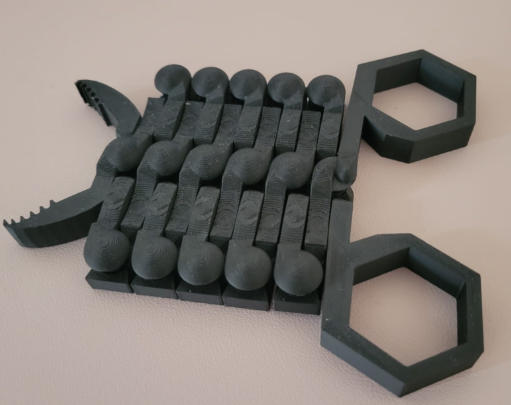

Several common hinge designs show how these principles apply in real components. They cover both everyday products and industrial uses.

- Parametric hinge – A simple, versatile design used in doors and panels that can be scaled in CAD to match different assemblies.

- Bag clip – A folding element with a single hinge that seals bags and helps keep contents fresh, demonstrating straightforward domestic use.

- Hinged box – A proof-of-concept design with integrated hinges for packaging and storage prototypes.

- Jointed robot – Hinges combined with ball joints to build articulated robots or figurines for motion studies.

- Cable chain – Series of linked hinges that guide and protect cables in machinery, elevators, and other equipment.

These examples highlight how printed hinges can be used to validate concepts before large-scale manufacturing.

The actual strength of a printed hinge depends on multiple factors rather than a single specification. Design, material, and printing strategy all contribute.

- Hinges made from materials like carbon fiber nylon can carry significantly higher loads than standard plastics.

- Hinges printed vertically usually show lower strength than those printed horizontally, due to the direction of layer bonding.

Results vary, so mechanical testing of key prototypes is essential to confirm performance.

While small hinges can be printed on desktop equipment, some projects require industrial precision and repeatability. Working with an experienced provider helps in these situations.

- Certified service bureaus with advanced machines maintain tighter tolerances and provide more material choices than typical hobby printers.

- This is especially important for functional prototypes and low-volume production where parts must closely match final engineering requirements.

Such partnerships enable teams to move from early concepts to production-ready designs more confidently.

Yes, moving parts can be produced either as separate pieces for later assembly or as a single integrated print, depending on design complexity, material, and machine capability.

They allow engineers to prototype realistic mechanisms, test multiple design variations, and confirm function before investing in injection molds or other high-volume tools.

There are no printers dedicated solely to hinges, but achieving reliable results demands an appropriate combination of printer, material, and design practices.

PLA and PETG are widely used, while nylon, various resins, and rubber-like materials are also popular choices for more demanding or flexible applications.

Yes, PETG is strong and flexible, withstands repeated bending, and works well with many 3D printers, making it a practical choice for functional hinge prototypes.