From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-07 Origin: Site

Content Menu

● Target keywords and search intent

● What are 3D printed motorcycle parts?

● Benefits of 3D printed motorcycle parts

● Common 3D printed motorcycle parts and applications

>> Frequent 3D printed motorcycle components

>> Prototyping vs end‑use motorcycle parts

● Materials for 3D printed motorcycle parts

>> Overview of key 3D printing materials

● Design guidelines for strong 3D printed motorcycle parts

● From 3D printed prototypes to production with OEM processes

● Real‑world case insights: 3D printing in motorcycle projects

● Limitations and safety considerations

● Practical workflow: how to get 3D printed motorcycle parts made

● When to choose 3D printing vs CNC or molding

● Call to action: turn your 3D printed motorcycle ideas into OEM‑grade parts

● FAQs about 3D printed motorcycle parts

>> 1. Are 3D printed motorcycle parts safe for everyday riding?

>> 2. Which 3D printing material is best for motorcycle parts?

>> 3. Can 3D printing reduce the cost of custom motorcycle builds?

>> 4. How long does it take to 3D print motorcycle parts?

>> 5. Can old or discontinued motorcycle parts be reproduced with 3D printing?

3D printed motorcycle parts have moved from simple cosmetic accessories to functional components used for prototyping, customization, spare parts, and even low-volume end-use production. With the right materials, design rules, and an experienced OEM manufacturing partner, riders and brands can turn 3D printed concepts into durable components that integrate seamlessly with CNC-machined, molded, or stamped parts.[1][2][3][4]

The core search intent around “3D printed motorcycle parts” is commercial/transactional: riders, builders, and OEM buyers want to learn what can be printed, how strong the parts are, and where to get them made.[2][5]

- Primary keyword: 3D printed motorcycle parts

- Secondary keywords: 3D printing motorcycle parts, custom motorcycle parts 3D printing, 3D printed motorcycle accessories, 3D printed spare parts, 3D printed motorcycle frame components

- User intents typically include:

- Evaluating whether 3D printed parts are safe and reliable

- Comparing materials like PLA, ABS, nylon, and metal 3D printing

- Understanding cost, lead time, and when to switch to CNC or molding

In the first 2–3 paragraphs and H2/H3 headings, the article should naturally repeat “3D printed motorcycle parts,” “3D printing motorcycle parts,” and one or two intent-specific phrases like “custom motorcycle accessories” and “rapid prototyping for motorcycle components.”[4][2]

3D printed motorcycle parts are components produced layer by layer using polymer or metal additive manufacturing technologies instead of traditional machining, molding, or casting. These parts can range from visual accessories to mechanically stressed brackets and subframes, depending on the material and process.[6][7][8][2]

Typical categories include:

- Cosmetic and ergonomic parts: fairing inserts, dashboards, covers, grips, instrument housings, and small bodywork pieces

- Functional prototypes: levers, brackets, linkages, engine covers, intake ducts, and airbox components

- Tooling and jigs: assembly fixtures, drilling guides, welding jigs, and checking gauges for motorcycle production

- Spare and legacy parts: discontinued vintage motorcycle parts reverse-engineered with scanning and additive manufacturing.[8][9]

When combined with scanning and CAD, 3D printing allows engineers to recreate rare or discontinued motorcycle components at a fraction of the cost of traditional pattern making.[9][8]

3D printing brings several high‑value advantages for motorcycle designers, builders, and OEMs.[2][4]

- Fast prototyping and iteration

- Complex parts that would take 2–3 weeks with traditional machining or fabrication can often be printed within 5–8 hours.[4][2]

- Designers can test multiple geometries in days, refine fit and ergonomics, and then lock in a final design for production.

- Design freedom and weight reduction

- Additive manufacturing supports internal channels, lattice structures, organic shapes, and topology‑optimized brackets that are difficult or impossible with conventional methods.[7][6]

- This enables lighter frames, subframes, and mounting parts, especially for electric motorcycles where weight is critical.[10][2]

- Cost savings for low volume and custom builds

- For custom motorcycles and short runs, investing in injection molds or complex fixtures is often not economical.[5][1]

- Shops using 3D printed motorcycle parts report savings of around €2,000 per modified motorcycle by avoiding tooling and reducing manual fabrication.[1]

- On‑demand spare parts and legacy support

- Vintage or limited‑edition bikes often lack available OEM spares; 3D scanning and printing offer a path to recreate these parts quickly.[8][9]

- This approach is especially attractive for low‑volume castings, brackets, and decorative parts.

Different categories of motorcycle components lend themselves particularly well to 3D printing.[2][4]

- Small body and cockpit parts

- Gauge and display housings

- Fairing brackets and inner panels

- Headlight, taillight, and turn‑signal housings

- Ergonomic and control components

- Custom grips, levers, shifter tips, and pedal extensions

- Switch housings and handlebar controls

- Engine bay and airflow parts

- Air ducts, intake manifolds, airbox inserts, and cooling guides

- Non‑structural engine covers and guards

- Chassis accessories and mounting hardware

- GPS mounts, camera mounts, luggage brackets, and sensor holders.[7][1]

- Prototype parts:

- Focus on fit, ergonomics, and visual confirmation.

- Usually printed in lower‑cost materials like PLA or standard ABS and may not be suitable for long‑term riding.[4][2]

- End‑use parts:

- Require higher‑performance materials such as nylon, carbon‑fiber reinforced polymers, or metal.[1][7]

- Often used for brackets, subframes, or components that must withstand real-world loads and weather.

Material selection is one of the most critical decisions for safe and durable 3D printed motorcycle parts. Different polymers and metals offer trade‑offs in strength, heat resistance, UV stability, and cost.[1][2]

| Material type | Typical use on motorcycles | Key strengths | Main limitations |

|---|---|---|---|

| PLA | Visual prototypes, small covers | Easy to print, low cost, good detail | Low heat resistance, brittle outdoors |

| ABS | Functional prototypes, housing parts | Better temperature and impact resistance than PLA | Warping, fumes, requires controlled environment |

| PETG | Bodywork and cockpit parts | Good toughness, chemical resistance, easier than ABS | Softer surface, can creep under load |

| Nylon / PA | Brackets, mounts, subframes, end‑use parts | High impact strength, fatigue resistance, good for load‑bearing | Moisture absorption, dimensional control required |

| Fiber‑reinforced polymers | High‑performance brackets, structural parts | Superior stiffness and strength‑to‑weight | Higher material and process cost |

| Metal 3D printing (e.g., aluminum alloys) | High‑end structural parts, frames, complex mounts | Excellent mechanical properties, true structural use | Very high cost, specialized equipment and post-processing |

For most custom and low‑volume motorcycle projects, high‑performance polymers like nylon, PETG, and ABS cover a large share of functional needs; metal 3D printing is reserved for critical parts where structural performance justifies the expense.[7][1]

To take full advantage of 3D printing for motorcycles, engineers must design specifically for additive manufacturing instead of simply copying machined geometries. Good design maximizes part strength, reduces print failures, and simplifies post‑processing.[6][2]

Key best practices include:

1. Optimize load paths and wall thickness

- Increase wall thickness in high‑stress areas, and avoid sharp internal corners where stress can concentrate.[6][7]

- Use ribs and gussets rather than massive solid sections to keep weight low while maintaining stiffness.[6]

2. Consider print orientation and layer adhesion

- Critical load directions should ideally run along the layer lines, not across them, to reduce the risk of delamination.[2][6]

- For brackets and mounts, orient the part so that mounting holes and bosses do not rely on layer adhesion alone for strength.

3. Use fillets, chamfers, and gradual transitions

- Fillets at junctions between ribs and walls reduce stress concentrations and improve durability.[7][6]

- Gradual changes in thickness help prevent warping and uneven cooling.

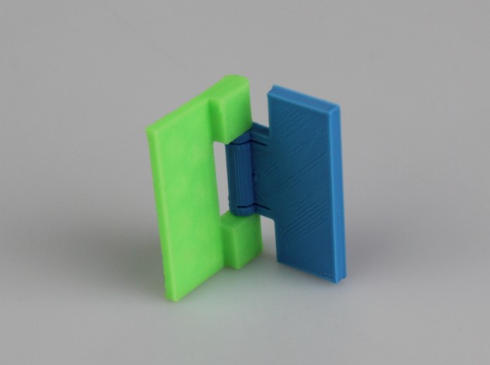

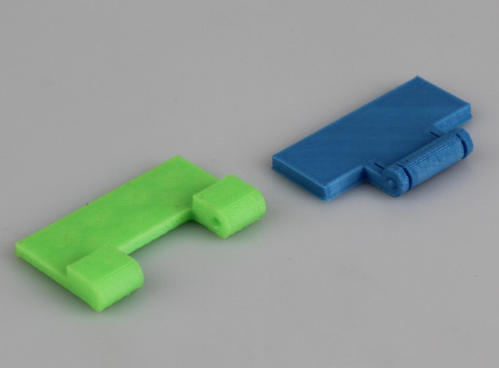

4. Allow for assembly and integration

- Incorporate clearance for mating with CNC‑machined, stamped, or molded OEM parts such as frames, triple clamps, or fairings.[3][8]

- Use standard fastener sizes and torque values where possible to simplify servicing.

Many successful projects start with 3D printed motorcycle parts and then transition to more conventional processes once design is frozen and demand justifies tooling. This hybrid approach balances speed and cost.[3][1]

Typical scaling path:

1. 3D printed prototype

- Validate fit, ergonomics, cable routing, and aesthetics.

- Make rapid design changes based on real bike mockups.[4][2]

2. Functional 3D printed pilot run

- Produce a short run in stronger polymers or metal for field testing.

- Collect rider feedback on durability, vibration, and weather resistance.[1][7]

3. CNC machining or metal stamping for structural components

- High‑load parts such as triple‑clamp inserts, foot‑peg brackets, and engine mounts are often moved to CNC machining or metal stamping once geometry is fixed.[3][8]

- This step provides tighter tolerances and improved fatigue performance for long-term use.

4. Plastic injection molding or silicone molding for plastic parts

- For high volumes of controls, housings, and covers, injection molding and related processes reduce per‑part cost significantly.[5][3]

- Soft interfaces like grips or seals may transition to silicone molding for better feel and sealing performance.

An OEM manufacturing partner with CNC machining, plastic molding, silicone, and metal stamping capabilities can take CAD files used for 3D printing and convert them into full production tooling and processes.[5][3]

Several motorcycle brands and engineering teams have publicly demonstrated how 3D printed motorcycle parts shorten development cycles and enable new designs.[7][1]

- Custom builders adopting 3D printing

- Workshops customizing street and racing motorcycles use polymer 3D printing to produce end‑use headlight supports, tail sections, and instrument housings.[5][1]

- By eliminating manual fabrication and molds, they cut build time and gain freedom to experiment with more complex shapes.

- High‑performance and racing projects

- Motorsport teams and suppliers have used SLS nylon and fiber‑reinforced polymers for lightweight subframes, ducts, and electronics enclosures that withstand track use.[4][7]

- These programs validate that properly designed polymer parts can survive high vibration and temperature gradients within defined limits.

- Vintage and legacy spare parts

- Engineers have restored rare classic motorcycles by 3D scanning worn parts, printing casting molds or patterns, and then casting aluminum or steel spares.[9][8]

- This workflow makes single or short‑run spares viable where traditional pattern making would be too expensive and slow.

These examples reinforce that 3D printed motorcycle parts are not just styling exercises; they serve real engineering and business needs when the right materials and processes are chosen.[1][7]

Despite its advantages, 3D printing has clear limits for motorcycle applications, especially in safety‑critical areas. Understanding these boundaries is essential for responsible design and purchasing decisions.[2][4]

- Heat and UV exposure

- Many polymers lose significant strength at relatively modest temperatures and can deform near engines or exhaust systems.[2][4]

- Long‑term UV exposure can embrittle standard plastics, so outdoor components require stabilized materials or protective coatings.

- Fatigue and vibration

- Layer‑by‑layer construction creates anisotropic properties, meaning parts are stronger in some directions than others.[6][7]

- Critical components subjected to cyclical loads and vibration must be tested thoroughly or produced via CNC machining or metal stamping instead.

- Regulatory and liability issues

- Parts that affect braking, steering, structural integrity, or rider protection may be subject to regulatory requirements.[11]

- For such components, metal 3D printing, CNC machining, or certified OEM parts are usually preferred.

A practical rule: cosmetic and non‑critical components are usually safe to 3D print when designed correctly; structural, safety‑critical parts require conservative engineering, testing, and often alternative production methods.[6][7]

For brand owners, workshops, and riders who want to move from idea to finished 3D printed motorcycle parts, a clear step‑by‑step workflow helps avoid mistakes.[5][2]

1. Define requirements

- Part function, location on the bike, expected loads, temperature range, and target lifetime.

- Decide if the part is a prototype, cosmetic component, or functional end‑use part.

2. Create or capture geometry

- Model the part in CAD with proper mounting interfaces and clearances to surrounding components.

- For legacy parts, use 3D scanning to capture existing geometry, then clean and adjust it in CAD.[8][9]

3. Choose suitable 3D printing technology and material

- FDM/FFF is common for prototypes and some end‑use parts in ABS, PETG, or nylon.[1][2]

- SLS or MJF nylon supports more complex geometries and better mechanical properties for production‑grade components.[7][5]

- Metal 3D printing is reserved for high‑value structural parts where performance justifies cost.[6]

4. Prepare the print and post‑processing plan

- Define layer height, infill, support strategy, and orientation to balance strength, detail, and print time.[4][2]

- Plan post‑processing steps such as support removal, sanding, priming, painting, dyeing, or machining of critical surfaces.[5][2]

5. Validate, test, and decide on scaling

- Install the part on the motorcycle, check fit, and monitor performance during controlled use.

- If demand grows or higher durability is needed, migrate to CNC machining, plastic molding, silicone, or metal stamping using the validated 3D printed design as the baseline.[3][8]

Working with an OEM‑oriented manufacturing partner from the beginning ensures that geometry, tolerances, and material choices remain compatible with future scaling beyond 3D printing alone.[3][5]

For buyers and engineers, the key strategic question is when to keep parts in 3D printing and when to transition to CNC machining, molding, or stamping.[3][2]

- 3D printing is ideal when:

- Volumes are low, designs are still evolving, or frequent updates are expected.

- Parts have complex internal channels or shapes that would be expensive or impossible to machine.

- You need on‑demand custom or legacy parts without tooling.

- CNC machining or metal stamping is better when:

- Parts are structural, safety‑critical, or subject to high loads and fatigue.

- Medium‑to‑high production volumes justify the setup effort.

- Tight tolerances and specific surface finishes are required on mating features.

- Plastic and silicone molding are best when:

- Design has stabilized and volumes are high enough to amortize tooling costs.

- Components are consumer‑facing controls, housings, or seals where aesthetics, texture, and long‑term durability matter.

Choosing the right mix of 3D printing and traditional processes allows motorcycle brands to innovate quickly while still delivering reliable, long‑life parts to riders worldwide.[3][1]

Whether you are developing a new motorcycle platform, updating a custom build, or trying to replace hard‑to‑find legacy parts, 3D printed motorcycle parts offer a fast and flexible path from idea to physical component. To move beyond single prototypes, work with an OEM manufacturing partner that can:[2][1]

- Review your CAD or 3D scan data for manufacturability and safety

- Recommend the right 3D printing material and process for your application

- Transition validated parts into CNC machining, plastic molding, silicone, or metal stamping when volumes grow

Send your drawings, 3D models, or reference parts along with target quantities and application details to obtain a detailed quotation and manufacturing proposal tailored to your motorcycle project. This integrated approach helps ensure your next set of 3D printed motorcycle parts achieves the right balance of performance, cost, and speed to market.[5][3]

3D printed motorcycle parts can be safe for everyday use when they are correctly designed, printed in suitable materials, and applied to non‑critical or moderately loaded functions. For structural and safety‑critical components, additional testing and often alternative processes such as CNC machining or metal forming are recommended.[7][6][3]

There is no single best material; for many functional polymer parts, nylon and reinforced composites offer a strong balance of toughness, fatigue resistance, and weight. PLA is usually reserved for visual prototypes, while ABS, PETG, and high‑performance nylon grades are more appropriate for parts that must handle impact, vibration, and moderate heat.[1][2][7]

Yes, custom builders have reported saving around €2,000 per modified motorcycle by using 3D printed parts instead of traditional fabricated components and molds. The main savings come from reduced tooling, shorter lead times, and fewer manual fabrication steps for complex shapes.[4][1]

In many cases, complex motorcycle components that would take weeks to fabricate traditionally can be printed in about 5–8 hours. Including post‑processing and finishing, it is often possible to go from design to installed part within a few days for low‑volume projects.[2][4][5]

Yes, legacy parts can be 3D scanned, digitally reconstructed, and then reproduced either as direct 3D printed components or as casting molds and patterns. This method is particularly effective for small batches of parts for rare or vintage motorcycles where conventional pattern making would be too expensive.[9][8]

[1](https://bcn3d.com/using-3d-printing-for-manufacturing-motorcycle-end-use-parts/)

[2](https://www.rapiddirect.com/blog/3d-printed-motorcycle-parts/)

[3](https://www.rapiddirect.com/blog/machining-motorcycle-parts/)

[4](https://3d2go.com.ph/blog/how-does-3d-printed-motorcycle-parts-can-help-the-manufacturing-industry/)

[5](https://www.rapid-protos.com/portfolio/3d-printed-motorcycle-parts/)

[6](https://global.honda/en/tech/serial/Hondas_RandD_Facilities_part08/)

[7](https://www.stratasys.com/en/stratasysdirect/resources/case-studies/selective-laser-sintered-motorcycle-parts-mission-motors/)

[8](https://www.voxeljet.com/additive-manufacturing/case-studies/automotive/reverse-engineering-a-muench-mammut-with-3d-printing/)

[9](https://all3dp.com/4/inside-the-garage-resurrecting-vintage-motorcycles-with-metal-3d-printing/)

[10](https://www.te.com/en/about-te/capabilities/3d-printing/3d-printed-motorcyle.html)

[11](https://scholarcommons.scu.edu/cgi/viewcontent.cgi?article=1073&context=mech_senior)

[12](https://www.csiro.au/en/work-with-us/international/twoplustwo/shifting-gears)

[13](https://www.loctiteam.com/wp-content/uploads/2025/08/Case-Study_M-Tech_Stratasys-IND402-08122025.pdf)

[14](https://www.instagram.com/reel/DSd-VqzjLel/)

[15](https://www.youtube.com/watch?v=z_FWXkpLikg)