From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-21 Origin: Site

Content Menu

● What Is 3D Printing in Aerospace?

● Why Aerospace Is Embracing 3D Printing

● Key Applications of 3D Printing in Aerospace

>> Common 3D Printed Aerospace Components

● Rockets, Spacecraft, and On-Orbit Manufacturing

● Market Growth and Future Outlook

● Technical and Regulatory Challenges

● From Prototype to Flight-Ready Parts

● How 3D Printing Improves Aerospace Supply Chains

● Best Practices for Aerospace OEMs Using 3D Printing

● Emerging Trends: AI, Large-Format Printing, and Space-Based Production

● Where OEM Partners Like U-NEED Fit In

● Call to Action: Partner with an OEM That Understands Aerospace 3D Printing

● FAQs About 3D Printing in Aerospace

>> 1. How is 3D printing used in aerospace today?

>> 2. What are the main benefits of aerospace 3D printing?

>> 3. Are 3D printed parts safe for critical aerospace applications?

>> 4. How does 3D printing impact aerospace supply chains?

>> 5. Will 3D printing replace traditional aerospace manufacturing methods?

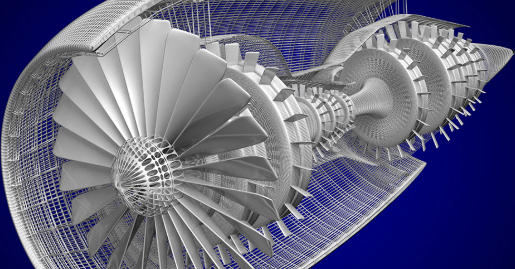

The aerospace industry is rapidly adopting 3D printing to build lighter, stronger, and more efficient components, from cabin brackets to rocket engines, while cutting costs and lead times across the entire lifecycle of aircraft and spacecraft. For global OEM brands, wholesalers, and manufacturers, additive manufacturing has moved from experimental pilots to a strategic production tool that works alongside CNC machining, plastics, silicone molding, and metal stamping.

3D printing in aerospace, also called aerospace additive manufacturing, is the process of building components layer by layer from digital models using metal, polymer, or composite materials instead of subtracting material from a block or using traditional tooling. It enables highly complex internal geometries, consolidated multi-part assemblies, and rapid design iterations that were previously impractical or impossible.

Key aerospace 3D printing technologies include:

- Metal powder bed fusion for structural brackets, engine parts, and heat exchangers.

- Polymer 3D printing for ducts, housings, fixtures, and lightweight interior components.

- Composite and high-temperature materials for applications that require strength, stiffness, and thermal resistance.

For overseas buyers working with OEM suppliers, 3D printing complements processes such as precision machining, injection molding, silicone molding, and metal stamping to create a flexible, hybrid manufacturing toolbox.

Aerospace companies are using 3D printing to solve some of their most pressing engineering and business challenges, particularly weight reduction, cost control, and supply chain resilience. Lightweight, optimized parts reduce fuel burn and emissions, while digital production helps mitigate logistics risk and inventory complexity.

Core benefits for aerospace programs include:

- Weight reduction and fuel savings

- Lattice structures and topology-optimized geometries cut mass while maintaining strength, improving fuel efficiency and range.

- Replacing traditional multi-part assemblies with a single lightweight printed component can significantly lower operational costs over an aircraft's life.

- Cost and lead-time reduction

- On-demand production reduces the need for tooling, long setup times, and large minimum order quantities.

- Localized printing sites shorten logistics routes, helping OEM brands respond faster to maintenance needs and new design requests.

- Design freedom and performance

- Engineers can embed cooling channels, internal ducts, and complex passageways directly into parts, improving thermal management and performance.

- Functional consolidation reduces fasteners and joints, cutting potential failure points and assembly labor.

Aerospace 3D printing is used from early concept validation to flight-ready components in aircraft, drones, and launch vehicles. The technology spans both prototyping and end-use production, with growing emphasis on certified parts.

- Engine and propulsion parts

- Fuel nozzles, injectors, turbine components, and heat exchangers leverage intricate internal geometries for better cooling and combustion.

- 3D printed engine parts reduce part counts and can improve reliability by minimizing welds and joints.

- Structural and interior components

- Brackets, clips, and mounts are redesigned with lattice structures for weight savings and improved stiffness-to-weight ratios.

- Cabin interior parts, such as panels and air ducts, benefit from customization and weight reduction.

- Tooling, jigs, and fixtures

- Custom assembly tools, drill guides, and inspection fixtures are printed quickly to support production lines and MRO operations.

- Rapid tooling reduces downtime and allows fast adjustment when designs change.

3D printing is particularly transformative in space and launch systems, where weight, complexity, and reliability are critical. Pioneering companies are demonstrating that additive manufacturing can be used not only for individual parts but also for large sections of rocket structures.

Rockets and propulsion systems:

- Companies use 3D printing to produce rocket engines, combustion chambers, and structural elements, significantly reducing part counts and production time.

- Additive manufacturing allows integration of complex cooling channels and optimized load paths, improving performance while cutting material waste.

Spacecraft and on-orbit production:

- Space agencies and aerospace OEMs are exploring printing components in orbit to reduce launch mass and enable on-demand fabrication of tools and replacement parts.

- In-space 3D printing could eventually support construction of satellite components or habitats directly in microgravity environments.

The aerospace additive manufacturing market is scaling rapidly as technology matures, certifications expand, and more programs move into serial production. Both metals and polymers are seeing wider adoption in commercial aviation, defense, and space.

Selected market insights:

| Aspect | Insight |

|---|---|

| Market size | The aerospace additive manufacturing market is projected to grow from around single-digit billions of USD in the mid-2020s to several times that by the mid-2030s, driven by strong demand for lightweight, fuel-efficient aircraft and launch vehicles. |

| Growth drivers | Weight reduction, fuel savings, supply chain resilience, and increasing use of certified printed parts in engines and structures. |

| Technology trends | Advancement in high-temperature metals, composite materials, large-format printers, and integrated digital workflows with AI and simulation. |

Regions with strong aerospace ecosystems, such as the United States and Europe, are leading in additive manufacturing innovation thanks to defense investment, commercial aviation demand, and active space programs. Emerging markets are also building capabilities as air travel grows and local space initiatives expand.

Despite its growth, aerospace 3D printing faces strict certification requirements and process control challenges that must be managed carefully. Safety-critical applications such as engines and load-bearing structures demand consistent, traceable production and robust testing.

Key challenges include:

- Material qualification and consistency

- Aerospace-grade metals and high-performance polymers must meet tight mechanical and thermal specifications across batches.

- Powder handling, recycling, and storage affect material properties and must be tightly controlled.

- Process control and part quality

- Build parameters, support strategies, and post-processing steps, such as heat treatment and machining, influence microstructure and fatigue behavior.

- Non-destructive testing and in-situ monitoring are increasingly used to validate internal features and detect defects.

- Certification and documentation

- Aviation authorities and defense organizations require detailed process documentation, validation testing, and often part-by-part traceability.

- Implementing digital twin and full digital thread approaches helps link design, simulation, printing, and inspection data for faster approvals.

For aerospace OEMs and their manufacturing partners, a structured workflow helps move from early concept to certified production parts. This process is typically iterative, combining virtual tools with physical testing.

Typical aerospace 3D printing workflow:

1. Requirements and application definition

Define target performance metrics, operating conditions, and regulatory requirements for the component.

2. Design for Additive Manufacturing (DfAM)

Redesign parts for lattice structures, internal channels, and part consolidation rather than simply copying a machined geometry.

3. Simulation and optimization

Use structural and thermal simulations to optimize topology, stiffness, and cooling performance before building hardware.

4. Prototyping and iteration

Print and test prototypes to verify fit, function, and performance under representative loads and environments.

5. Process validation and qualification

Define print parameters, post-processing steps, and inspection plans; perform repeated builds to validate consistency.

6. Production and continuous improvement

Transition to serial production with defined quality controls and feedback loops for ongoing optimization.

For overseas brands that work with external OEM partners, choosing a supplier experienced in aerospace workflows, documentation, and cross-process integration is critical to avoid delays and requalification.

Beyond part performance, 3D printing offers strategic advantages for aerospace supply chains that are often global, complex, and heavily regulated. By moving toward digital inventories and localized production, aerospace manufacturers can respond faster to market and operational changes.

Supply chain benefits include:

- Digital inventories and on-demand parts

- Instead of stocking large quantities of slow-moving spares, companies can store qualified 3D models and print parts when and where they are needed.

- Localized and distributed production

- Parts can be produced closer to final assembly lines or MRO hubs, reducing shipping times and customs risks.

- Reduced dependence on tooling and single-source suppliers

- Eliminating hard tooling for certain components lowers switching costs and reduces exposure to tool damage or obsolescence.

For international OEM cooperation, this means more flexibility to adapt to design changes, manage demand spikes, and support long-term aftermarket obligations.

To realize the full value of additive manufacturing, aerospace companies and their manufacturing partners should follow best practices that align engineering, quality, and supply chain goals.

Actionable recommendations:

- Integrate DfAM early

Involve additive experts during concept design to avoid late-stage redesigns and qualification setbacks.

- Combine additive with traditional processes

Use 3D printing for complex, high-value components and pair it with CNC machining, molding, or stamping for simpler, high-volume parts.

- Standardize materials and parameters

Build internal or supplier-level databases of qualified materials and validated parameter sets for repeatability.

- Invest in testing and data

Track mechanical properties, surface finish, and dimensional accuracy across builds to build confidence with regulators and customers.

For overseas brands working with OEM partners, asking about these practices is an effective way to evaluate whether a supplier is ready for aerospace-grade 3D printing work.

The next wave of innovation will push 3D printing even deeper into aerospace programs, supported by AI, new materials, and novel manufacturing environments. These developments will shape the future of both commercial aviation and space exploration.

Key emerging trends:

- AI-driven design and process control

AI and machine learning tools are being used to optimize geometries, predict defects, and adjust print parameters in real time.

- Large-format and multi-material printing

New printers can produce bigger, integrated structures or combine metals and polymers in one build for multifunctional parts.

- Space-based 3D printing

Experiments with on-orbit printing aim to fabricate tools and structural elements directly in space, reducing reliance on Earth-based supply chains.

These trends suggest that additive manufacturing will increasingly be viewed not just as a production method, but as a core digital infrastructure for aerospace innovation.

For foreign brands, wholesalers, and producers, working with an experienced OEM partner that combines 3D printing with high-precision machining, plastic and silicone product manufacturing, and metal stamping can significantly reduce risk and time to market. A partner with cross-process expertise can:

- Help select the right process for each aerospace component based on volume, material, and certification needs.

- Provide rapid prototypes via 3D printing, then transfer validated designs to CNC, molding, or stamping for scalable production where appropriate.

- Support engineering changes and design optimization to meet specific performance and regulatory requirements in different markets.

For aerospace and related high-reliability applications, this hybrid approach ensures that innovation in additive manufacturing is always grounded in robust, production-ready capabilities.

If your organization is exploring 3D printing in aerospace for prototyping, tooling, or certified flight components, collaborating with the right OEM partner is essential to manage risk, cost, and lead times. By choosing a manufacturing partner that combines aerospace-grade additive technologies with high-precision machining, plastics and silicone molding, and metal stamping, you gain support from early design through long-term production.

Share your drawings, technical requirements, and target applications with an experienced OEM team, and start evaluating which components are suitable for additive manufacturing, which should remain in traditional processes, and how to structure a cost-effective, reliable production plan. Taking this step now can help you accelerate development, strengthen your supply chain, and bring next-generation aerospace components to market with confidence.

Contact us to get more information!

3D printing is used to make engine components, brackets, ducts, interior parts, and custom tooling, supporting both prototyping and certified flight hardware in aircraft and spacecraft programs.

Key benefits include lighter parts, lower fuel consumption, reduced material waste, shorter lead times, and greater design freedom for complex geometries and part consolidation.

Yes, when produced under controlled processes, tested thoroughly, and certified by relevant authorities, 3D printed parts can meet stringent aerospace safety and reliability standards.

Aerospace 3D printing enables digital inventories and localized, on-demand production, which reduces logistics complexity, inventory levels, and dependence on specialized tooling.

3D printing is more likely to complement rather than fully replace methods like CNC machining, molding, and stamping, with each process selected based on part geometry, volumes, and certification needs.

1. https://uptivemfg.com/how-3d-printing-is-taking-off-in-aerospace/

2. https://www.3erp.com/blog/3d-printing-aerospace-industry/

3. https://www.hubs.com/knowledge-base/aerospace-3d-printing-applications/

4. https://formlabs.com/blog/additive-manufacturing-3d-printing-in-aerospace/

5. https://geomiq.com/blog/3d-printing-in-aerospace/

6. https://www.raise3d.com/blog/aerospace-3d-printing/

7. https://www.researchnester.com/reports/aerospace-additive-manufacturing-market/7221/

8. https://commons.erau.edu/ijaaa/vol9/iss2/4/