From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-15 Origin: Site

Content Menu

● What Is 3D Printing in the Energy Sector?

● Why the Energy Sector Needs Additive Manufacturing

● Core Benefits of 3D Printing in Energy

>> Faster Prototyping and Development

>> Customization and Complex Geometries

>> Reduced Waste and Improved Sustainability

>> Cost-Effectiveness and Accessibility

● Key Challenges and Limitations

>> Safety, Environmental, and Regulatory Concerns

>> Intellectual Property and Standardization

● How 3D Printing Supports Renewable Energy

>> Solar Energy: Advanced Panels and Cells

>> Wind Energy: Turbine Blades and Structures

>> Nuclear Energy: Complex Metal Components

>> Energy Storage: Batteries, Fuel Cells, Electrolyzers

>> Fossil Fuels: Efficiency and Emissions Reduction

● Future Trends: 3D Printing and Energy Innovation

>> Materials and Process Advancements

>> Integration with Digital and Smart Technologies

>> Policy, Collaboration, and Standardization

● Practical UX Enhancements and Visual Suggestions

● Action Steps for Energy Companies Exploring 3D Printing

● Frequently Asked Questions (FAQ)

>> 1. How is 3D printing most commonly used in the energy sector today?

>> 2. Is 3D printing safe for critical energy infrastructure?

>> 3. Does 3D printing always reduce costs in energy applications?

>> 4. What are the main barriers to scaling 3D printing in energy?

>> 5. How does 3D printing support the transition to renewable energy?

3D printing in the energy sector is transforming how components are designed, produced, and maintained, helping energy companies cut costs, boost efficiency, and accelerate the shift to renewable power. This additive technology supports solar, wind, nuclear, storage, and even fossil fuel applications, from rapid prototyping to full-scale production of complex parts.

3D printing, or additive manufacturing, builds parts layer by layer directly from CAD models, enabling complex shapes and functional components that are hard or impossible to make with traditional processes. In the energy sector, this means customized turbine blades, advanced solar cells, nuclear components, battery structures, and more, tailored for performance and reliability.

Key characteristics in energy applications include:

- Layer-by-layer fabrication based on digital designs for high precision.

- Compatibility with polymers, metals, ceramics, and composites as materials advance.

- Ability to consolidate multi-part assemblies into a single 3D-printed component.

The energy sector underpins modern society, powering homes, industries, and digital infrastructure, while also contributing significantly to greenhouse gas emissions. As governments and companies commit to decarbonization, they must redesign systems for efficiency, resilience, and sustainability—areas where 3D printing provides significant advantages.

Major drivers for adopting 3D printing include:

- Decarbonization: Lighter, more efficient components reduce energy losses and fuel consumption.

- Supply chain resilience: On-demand local production reduces dependence on global logistics and long lead times.

- Innovation pressure: New designs for turbines, solar cells, and storage systems demand fast, iterative prototyping.

3D printing enables energy companies to move from design to physical prototype in days instead of weeks or months. This rapid iteration is especially valuable for complex components like turbine blades, heat exchangers, or battery housings.

Key benefits:

- Reduced time-to-market for new energy technologies and components.

- Cost-effective prototype production without expensive tooling or molds.

- Easy adjustment of designs based on test results, supporting continuous optimization.

Traditional machining and casting impose design limits that 3D printing largely removes. Engineers can now create complex internal channels, lattice structures, and optimized shapes that improve aerodynamics, heat transfer, or flow behavior.

Applications include:

- Custom turbine components designed for specific wind conditions or site constraints.

- Tailored oil and gas parts that integrate multiple functions into a single printed piece, cutting assembly time.

- Scale models and prototypes to validate renewable plant layouts and equipment integration.

Because material is added only where needed, additive manufacturing minimizes scrap compared to subtractive machining. It also supports recycled and biodegradable materials in suitable applications, reducing environmental impact.

Sustainability gains:

- Lower raw material use due to precise material deposition.

- Extended lifespan of equipment through low-cost, on-demand spare parts instead of full component replacement.

- Localized production that reduces transport emissions and logistics overhead.

Compared with traditional CNC machining, 3D printing avoids many tooling, setup, and inventory costs, especially for short runs and complex designs. It is particularly attractive for smaller batches, remote sites, and highly customized parts.

Cost advantages:

- No need for high-cost molds for low-volume or customized energy components.

- On-demand printing reduces warehouse inventories and storage expenses.

- Local production in remote energy sites (offshore platforms, isolated wind farms) cuts logistics time and cost.

Many industrial 3D printers still primarily work with polymers or limited metal families, while energy applications often need high-temperature, corrosion-resistant, or high-strength materials. Specialized properties such as electrical conductivity, optical performance, or exact surface roughness can be difficult to achieve consistently with current processes.

Implications:

- Not all solar, nuclear, or high-temperature components can yet be fully 3D-printed at production scale.

- Some advanced energy parts still require hybrid manufacturing that combines additive and traditional processes.

3D printing excels in prototyping and low-volume runs, but large-scale mass production remains challenging due to speed, size limits, and consistency concerns. Variations in print parameters and environmental conditions can affect part quality, especially when producing large batches across multiple machines or sites.

Issues to manage:

- Build time for large components such as full blades or towers can be significant.

- Dimensional accuracy and mechanical properties must be tightly controlled for safety-critical parts.

Some 3D printing processes release ultrafine particles and require careful ventilation and filtration, especially in indoor facilities. In addition, energy use per printed part can be higher than that of some traditional processes if systems are not optimized.

Regulatory and safety considerations:

- Standards and certifications for 3D-printed energy components are still developing, especially for nuclear and grid-critical equipment.

- Environmental trade-offs must be evaluated: reduced transport and waste vs. energy consumption and material sourcing.

Because value shifts from the physical part to the digital design file, intellectual property protection becomes more complex. Without clear rules and standards, unauthorized replication and quality inconsistency pose operational and legal risks.

Risks include:

- Pirated designs leading to unsafe parts in critical systems.

- Lack of universal 3D printing standards making it difficult to guarantee consistent quality across suppliers and geographies.

3D printing is used to improve both solar panel structures and underlying cell architectures. Techniques such as semiconductor inks or volumetric printing can increase panel efficiency while reducing cost and material use.

Notable directions:

- Applying conductive semiconductor inks to ultra-thin wafers to boost conversion efficiency by around 20% at lower cost.

- Volumetric 3D printing processes that cure entire structures in one step, speeding production of lightweight, high-performance solar modules.

- Perovskite-based 3D printed solar cells that operate at lower manufacturing temperatures and potentially lower cost than traditional silicon.

Research institutions and companies are leveraging additive manufacturing to improve wind turbine performance and economics. Projects range from new blade molds to 3D-printed towers and anchors.

Examples:

- The National Renewable Energy Laboratory (NREL) and the University of Maine developing improved blade and mold methods, including plans for one of the world's largest 3D printers to produce full-scale blade molds using biopolymers.

- Universities exploring ways to turn blade waste into 3D-printable materials, closing the loop on turbine lifecycle.

- GE and partners using 3D printing for lighter turbine blades and 3D-printed concrete tower elements to increase hub heights and efficiency.

Nuclear applications demand precision, safety, and materials capable of withstanding extreme conditions, making 3D printing's ability to produce complex shapes highly valuable. Organizations such as Rosatom are testing metal additive manufacturing to produce reactor components and fuel-related parts.

Benefits:

- Optimized geometries for improved heat transfer, fluid flow, and structural performance.

- Potentially shorter lead times for critical replacement components in nuclear plants.

Energy storage systems gain from the geometric and material flexibility of additive manufacturing. Custom-shaped batteries, structural energy storage, and highly engineered fuel cell components are active research areas.

Key trends:

- 3D-printed lithium-ion and supercapacitor structures tailored to fit devices or assemblies where standard prism or cylinder cells are inefficient.

- 3D structuring inside batteries to improve surface area, ion transport, and cycle life.

- Additively manufactured polymer exchange membrane (PEM) and solid oxide cell (SOC) components, where thin functional layers and complex geometries increase performance.

Even as the world transitions away from fossil fuels, 3D printing helps reduce their environmental impact in the interim. The technology supports more efficient drilling equipment and novel carbon capture systems.

Applications:

- Customized, durable drilling tools that improve performance and safety while reducing fuel consumption for operations.

- Additively manufactured heat exchangers and reactor internals that improve thermal management in solvent-based carbon capture, enabling interstage cooling and lower energy use.

New printable metals, ceramics, and composite materials are expanding what is feasible in energy applications. Multi-material printing allows the integration of different properties in one component, such as conductive paths and structural elements.

Areas of progress:

- High-temperature alloys for turbines, reactors, and concentrated solar power receivers.

- Ceramic ionic conductors printed by stereolithography and DLP for advanced fuel cells.

- Graded materials that adjust composition across a part to manage stresses and thermal behavior.

3D printing is increasingly combined with AI, robotics, virtual reality, and IoT to build smarter, more automated energy systems.

Examples:

- AI-driven design optimization that automatically generates lightweight, high-performance geometries for energy components.

- VR/AR used for collaborative design reviews and virtual prototyping of 3D-printed systems.

- Robotics and IoT for automated printing, inspection, and monitoring of critical parts in the field.

Governments and industry bodies are investing in standards, R&D funding, and public–private partnerships to accelerate safe adoption of additive manufacturing in energy. Universities collaborate with manufacturers to develop new materials, validate designs, and share best practices that shorten learning curves.

Policy priorities include:

- Funding demonstration projects that prove long-term reliability of 3D-printed energy parts.

- Developing certification pathways for critical components in grid, nuclear, and large-scale renewable systems.

To strengthen user experience and engagement in an online article about 3D printing in the energy sector:

- Use short paragraphs (2–3 sentences) and frequent subheadings to guide scanning.

- Highlight key benefits, challenges, and sector examples with bullet lists and numbered steps to support quick comprehension.

- Insert a sector overview table comparing solar, wind, nuclear, storage, and fossil fuel applications (use cases, key benefits, maturity level).

Suggested visual assets:

- A process diagram showing the workflow from design, simulation, and 3D printing to deployment in an energy plant.

- Infographics summarizing advantages (e.g., reduced lead time, material savings, efficiency improvements) by sector.

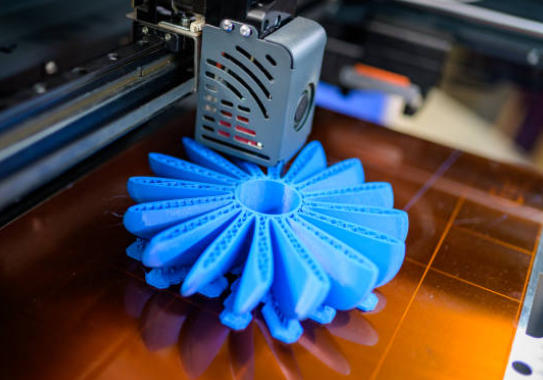

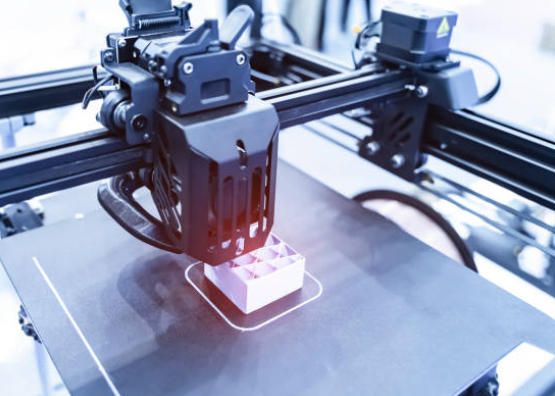

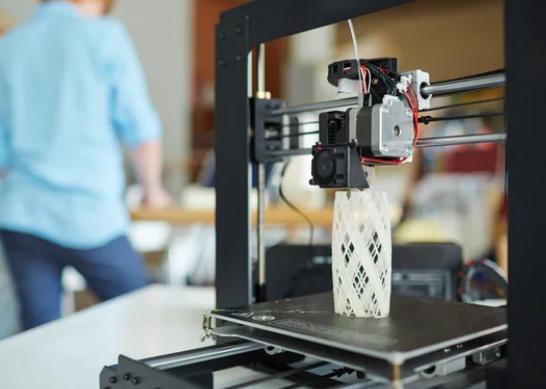

- Photos or renders of 3D-printed turbine components, solar cell structures, or fuel cell stacks for visual credibility.

Energy OEMs, operators, and engineering firms can follow a structured approach to adopt additive manufacturing.

1. Identify priority components

- Focus on high-value parts with long lead times, complex geometries, or frequent failures.

2. Evaluate technical feasibility

- Assess material requirements, mechanical and thermal loads, and regulatory constraints to see if current 3D printing technologies are suitable.

3. Run pilot projects

- Start with rapid prototyping and non-critical parts, gathering performance data and cost benchmarks.

4. Build partnerships

- Collaborate with specialized additive manufacturing providers, research institutions, and standards bodies to accelerate learning.

5. Develop internal design and QA capabilities

- Train engineers in design for additive manufacturing (DfAM) and set up robust inspection, testing, and certification processes.

Energy innovators looking to reduce cost, accelerate development, and support a cleaner energy transition should treat 3D printing as a strategic capability rather than a one-off experiment. By partnering with experienced manufacturing service providers that understand both additive technology and energy-sector demands, companies can move from concept studies to reliable, production-ready components faster and with lower risk.

3D printing is widely used for rapid prototyping, spare parts, customized components, and advanced designs in solar, wind, nuclear, storage, and oil and gas equipment.

Yes, when combined with proper material selection, process control, and certification, 3D printing can meet strict safety requirements, especially as standards evolve for nuclear and grid-critical components.

It typically reduces costs for complex, low-volume, customized, or remote-site parts, but may not be the cheapest option for very high-volume, simple components where traditional methods remain more economical.

Major barriers include material limitations, print speed, part size constraints, inconsistent quality across machines, and incomplete standards and certification frameworks for critical parts.

It enables more efficient turbines, advanced solar technologies, improved storage systems, and localized production, helping renewable projects deploy faster, operate more efficiently, and reduce lifecycle emissions.