From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2025-12-31 Origin: Site

Content Menu

● What Is Tool Wear in CNC Machining

● Main Types of Tool Wear and Their Symptoms

>> Crater Wear on the Rake Face

>> Chipping and Micro-Breakout

>> Built-Up Edge and Adhesion Wear

>> Thermal Fatigue and Notch Wear

● Early Warning Signs of Tool Wear in CNC Production

● Traditional Tool Wear Detection Methods

>> Visual and Tactile Inspection

>> Dimensional and Surface Quality Checks

● Advanced Tool Wear Monitoring Technologies

>> Vibration, Force, Current, and Sound Monitoring

>> Machine Vision and Image-Based Wear Measurement

>> Digital Twin and AI-Based Predictive Maintenance

● Practical Steps to Implement Tool Wear Monitoring

>> Step 1: Identify Critical Tools and Operations

>> Step 2: Set Wear Limits and Replacement Rules

>> Step 3: Select Monitoring Methods and Sensors

>> Step 4: Use Data for Continuous Improvement

● Strategies to Reduce Tool Wear and Extend Tool Life

>> Optimize Cutting Parameters by Material

>> Choose Proper Tool Grades and Coatings

>> Improve Cooling, Lubrication, and Chip Evacuation

>> Enhance Tool Handling, Cleaning, and Storage

● Intelligent Tool Life Management Systems

>> Tool Life Monitoring Software

>> Predictive Maintenance and AI Analytics

>> Automatic Tool Changers and Lights-Out Machining

● Economic Impact of Tool Wear on Cost per Part

● Traditional and Intelligent Tool Wear Management

● Take the Next Step: Partner With a High-Precision CNC OEM

● FAQ

>> 1. How often should CNC tools be inspected for wear

>> 2. Is manual visual inspection still useful when using automated monitoring

>> 3. Which sensors are most effective for in-process tool wear monitoring

>> 4. How does predictive maintenance help reduce machining costs

>> 5. Are tool wear monitoring concepts applicable to plastic and silicone machining

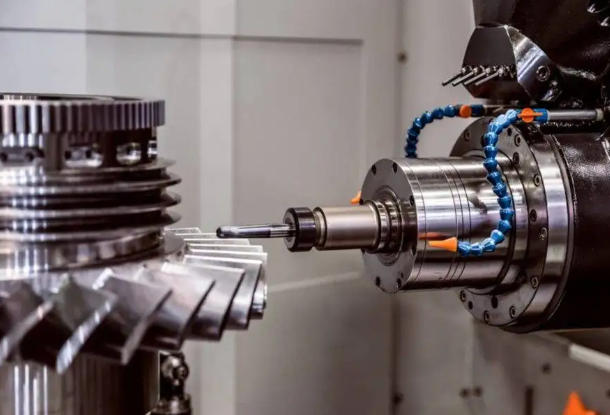

Tool wear directly determines machining accuracy, surface finish, and overall production cost in CNC machining. Tool wear management is therefore essential to keep quality stable and avoid unexpected downtime in high-precision production.[1]

In CNC machining, tool wear refers to the gradual loss or damage of the cutting edge and tool surface due to friction, heat, and mechanical stress during cutting. As wear accumulates, cutting forces rise, surface roughness worsens, and dimensional accuracy becomes harder to control.[2]

For OEM projects in aerospace, automotive, electronics, plastic parts, silicone parts, and metal stamping, even slight tool wear can cause dimensional deviation, poor surface finish, and higher scrap rates. A structured approach to tool wear detection and intelligent maintenance is therefore a critical part of any high-precision CNC production system.[3]

Understanding the mechanisms and symptoms of tool wear helps you choose suitable monitoring strategies and replacement thresholds.[2]

Flank wear is the most common form of wear and appears as gradual abrasion along the relief side of the cutting edge.[2]

- Caused by long-term rubbing between the tool flank and the machined surface.

- Leads to increased cutting forces and progressive loss of accuracy.

- Typically monitored by measuring wear land width \(V_B\) under a microscope.[4]

When flank wear exceeds a defined limit, it is best practice to change the tool before catastrophic failure and part defects occur.[5]

Crater wear forms on the rake face in the chip-flow region, especially during high-speed cutting of steels and superalloys.[2]

- Prominent at elevated cutting temperatures and high cutting speeds.

- Reduces rake strength, increases chip friction, and accelerates edge degradation.

- Usually evaluated by the maximum crater depth \(K_T\).[4]

Excessive crater wear destabilizes chip formation and can cause inconsistent chip breaking in turning and milling.[1]

Chipping is a sudden localized break of the cutting edge caused by overload or impact.[2]

- Often triggered by interrupted cuts, hard inclusions, or inappropriate tool paths.

- Produces random surface defects, micro-cracks, and burrs on the workpiece.

- Can rapidly evolve into complete edge failure if not detected in time.[3]

For high-precision OEM parts, even micro-chipping is unacceptable and should be included in visual inspection criteria.[4]

Built-up edge occurs when workpiece material welds to the cutting edge and periodically breaks away.[2]

- Common in machining of low-carbon steels, aluminum, and some plastics at low cutting speeds.

- Causes fluctuating cutting forces, poor surface finish, and dimensional inconsistency.

- Can be mitigated by improved coolant application, higher speeds, or coated tools.[6]

Adhesion wear, in which material sticks and tears at the tool surface, is closely related and accelerates edge dulling in many operations.[2]

Thermal fatigue cracking appears when the tool experiences repeated heating and cooling cycles, especially in dry or interrupted cutting.[4]

- Leads to small cracks perpendicular to the cutting edge, particularly near the depth-of-cut line.

- Can develop into notch wear at the workpiece surface intersection.

- Is critical in hard turning, high-speed milling, and other high-temperature processes.[3]

Controlling temperature by coolant optimization and stable cutting parameters helps reduce thermal fatigue and associated wear.[6]

Before a tool fails, the machine and workpiece usually show identifiable warning signals.[3]

Key early indicators include:

- Rising spindle load and cutting force at constant feed and speed.

- Changes in cutting sound, such as squeal, chatter, or irregular noise.

- Increased vibration levels measured by accelerometers or integrated sensors.

- Deterioration of surface finish or rising \(R_a\) values over successive parts.

- More burrs, discoloration, or gradual dimensional drift in finished components.[1]

In modern factories, these indicators are monitored through sensors and software to trigger alarms or automatic tool changes before defects occur.[7]

Traditional methods are still widely used and remain an important foundation in many CNC shops.[2]

Visual inspection relies on the operator examining the tool under normal or magnified view.[8]

- Check for edge dulling, chipping, crater formation, and discoloration on the tool.

- Use a loupe or tool microscope to measure wear land width on the flank.

- Tactile inspection can detect rough or chipped edges by gently touching the cutting area when the tool is removed.[9]

This method is low cost, but depends heavily on operator experience and requires machine downtime for tool removal and inspection.[8]

Part measurement provides indirect evidence of tool wear in everyday production.[3]

- Use CMM, micrometers, or calipers to monitor critical dimensions over time.

- Track surface roughness with portable roughness meters and record trends.

- Sudden deterioration in accuracy or finish often correlates with tool deterioration.[10]

Integrating measurement data into statistical process control helps identify wear-related trends early, before large quantities of scrap are produced.[11]

To meet modern Industry 4.0 requirements, more facilities are adopting automated, sensor-based, and AI-driven tool condition monitoring.[5]

Modern systems collect multi-sensor signals in real time and correlate them with tool wear levels.[7]

- Vibration and acoustic emission sensors capture changes in cutting dynamics.

- Spindle motor current and power draw reflect increasing cutting forces.

- Force sensors installed in the machine structure measure cutting loads directly.[12]

Machine-learning algorithms can transform these signals into accurate wear predictions and real-time alarms for tool changes.[12]

High-resolution cameras or microscopes can automatically capture tool images and evaluate wear.[13]

- Deep learning models classify wear states from tool images with high accuracy.

- Systems can be extended to multiple tool types with minimal reconfiguration.

- Image-based methods are ideal for automated tool rooms and high-volume production environments.[13]

These solutions reduce manual inspection time and standardize decision criteria for tool replacement.[5]

A more advanced approach is to build a Digital Twin of the CNC machine and tooling system.[14]

- The Digital Twin model simulates tool behavior under real machining conditions and programs.

- Real-time sensor data, such as vibration, current, and temperature, feeds into predictive models.

- Hybrid methods combining physics-based models and AI improve estimate accuracy for remaining useful life.[15]

Case studies show that predictive maintenance significantly reduces unplanned downtime and tool-related losses in CNC machining.[16]

A step-by-step implementation plan helps align quality goals and cost control in OEM production.[1]

- Determine which machining steps have the strictest tolerances or surface requirements.

- Prioritize finish operations such as fine milling, grinding, reaming, and precision turning.

- Define quality targets and process capability indices for these key operations.[10]

- Define flank wear land \(V_B\) thresholds and surface roughness limits for each tool type.

- Establish a maximum number of parts or cutting time for every tool under standard conditions.

- Standardize acceptance criteria for micro-chipping and minor surface damage on the cutting edge.[4]

- Combine scheduled visual checks with part measurement for smaller or less complex setups.

- Add vibration, current, or sound sensors for higher-volume or lights-out production lines.

- Integrate tool life monitoring software with the CNC control to track usage and trigger alarms.[11]

- Record tool life, sensor signals, and nonconforming parts in a central database.

- Analyze correlations between parameters, materials, and tool life patterns.

- Use the insights to optimize feeds, speeds, tool grades, and coolant strategies.[6]

Reducing wear improves part quality and lowers cost per part in high-precision machining.[6]

- Avoid cutting speeds and depths that generate excessive heat and rapid wear.

- Adjust feed per tooth to maintain stable chip thickness and prevent rubbing.

- Maintain separate parameter libraries for steel, aluminum, plastics, and other specific materials.[3]

Trial cuts combined with wear monitoring help define a robust parameter window for each project.[4]

- Select carbide grades and geometries according to workpiece hardness and cutting mode.

- Apply coatings such as TiAlN, AlTiN, or DLC to reduce friction and built-up edge formation.

- Consider high-wear-resistant grades or advanced materials when machining abrasive alloys.[5]

Correct tooling selection can dramatically extend tool life in continuous CNC production.[1]

- Direct coolant flow precisely into the cutting zone to control temperature.

- Apply high-pressure coolant or MQL as required for difficult materials and deep cavities.

- Optimize chip evacuation to avoid recutting chips in pockets, holes, and dies.[2]

Effective cooling and chip control reduce thermal shock and mechanical impact on the cutting edge.[3]

- Clean tools after use to remove chips, built-up material, and coolant residue.

- Store tools in dedicated holders or drawers to avoid edge collisions and damage.

- Keep tool presetting equipment calibrated to ensure reliable offset data.[8]

Proper tool management maintains consistent performance and reduces unexpected tool-related issues.[11]

Modern CNC environments benefit from integrated systems that coordinate tooling, machines, and planning.[11]

- Tracks cutting time, part count, or passes for each tool ID in real time.

- Communicates with the CNC to stop or trigger tool changes when limits are reached.

- Provides historical information for analysis of tool cost and performance.[15]

Such systems standardize tool replacement and reduce reliance on individual operator judgment.[5]

- Machine-learning models predict remaining tool life from sensor data rather than fixed counters.

- Systems detect patterns that precede failure and initiate maintenance before breakdowns.

- Combining these insights with planning enables near zero-downtime machining cells.[16]

Research demonstrates that AI-based tool wear prediction can deliver high accuracy under varying machining conditions.[7]

- Automatic tool changers replace worn tools according to predefined life rules or monitoring feedback.

- Redundant sister tools enable unattended shifts and reduce the risk of scrap from tool failure.

- When combined with in-process monitoring, this approach supports stable lights-out production.[1]

This strategy is especially valuable for OEM suppliers that must meet strict delivery schedules and quality standards.[11]

Tool wear is closely tied to the economic performance of a machining operation.[6]

Key cost elements influenced by tool wear include:

- Tool purchase, regrinding, and inventory costs per part.

- Scrap rate, rework time, and potential quality claims from customers.

- Machine downtime for troubleshooting and unscheduled tool changes.[1]

Studies on predictive maintenance in CNC machining show reductions in unplanned downtime and maintenance costs when intelligent monitoring is implemented.[14]

A well-planned tool wear strategy allows OEM suppliers to provide stable pricing, high first-pass yield, and strong quality assurance for international customers.[16]

| Aspect | Traditional approach | Intelligent or AI-driven approach |

|---|---|---|

| Detection method | Manual inspection, part measurement | Sensors, AI models, Digital Twin |

| Trigger for tool change | Fixed part count or operator judgment | Real-time RUL prediction and alarms |

| Downtime | Higher and often unplanned | Lower and mostly scheduled |

| Data usage | Limited historical records | Integrated multi-sensor big data |

| Best suited for | Low-volume and simple jobs | High-volume, high-precision OEM work |

If you are a brand owner, wholesaler, or manufacturer looking for stable quality, reliable lead time, and optimized machining costs, it is important to work with a CNC partner that takes tool wear detection and maintenance seriously. A supplier that combines advanced monitoring, intelligent tool life management, and strict process control can provide consistent high-precision metal parts, plastic components, silicone products, and stamping parts for your projects.[16]

To discuss drawings, tolerances, materials, and annual demand, and to explore a long-term OEM cooperation for CNC machining, plastic manufacturing, silicone product manufacturing, or metal stamping, please contact the U-NEED team and request a customized quotation and technical review for your next project.[11]

Inspection frequency depends on material, cutting parameters, and tool type, but high-precision operations usually combine regular checks with monitoring of key indicators such as surface quality and spindle load.[3]

Manual visual inspection remains a valuable backup and verification method, especially during new product introduction, process changes, and validation of sensor-based tool monitoring models.[8]

Commonly used options include vibration sensors, spindle current monitoring, acoustic emission sensors, and force sensors, often combined to improve reliability and detection accuracy.[7]

Predictive maintenance uses data-driven models to change tools and perform maintenance before failures occur, reducing scrap, unplanned downtime, and emergency repairs, which lowers the average cost per part.[14]

Tool wear monitoring concepts apply to plastic and silicone machining as well, because edge sharpness, built-up materials, and surface finish still influence part quality and process stability in these applications.[3]

[1](https://www.machinemetrics.com/blog/tool-wear)

[2](https://rosnokmachine.com/tool-wear/)

[3](https://mytmachining.com/understanding-tool-wear-in-cnc-machining/)

[4](https://techforumjournal.com/articles/volume-2025-3/432025.pdf)

[5](https://journals.sagepub.com/doi/10.1177/16878132241229314)

[6](https://shoplogix.com/tool-wear/)

[7](https://www.frontiersin.org/journals/mechanical-engineering/articles/10.3389/fmech.2025.1608067/full)

[8](https://super-ingenuity.cn/wear-detection-techniques-for-tool-chucks-on-5-axis-cnc-equipment/)

[9](https://jlccnc.com/blog/tool-wear-detection-maintenance)

[10](https://www.nature.com/articles/s41598-025-92178-3)

[11](https://jbth.com.br/index.php/JBTH/article/download/479/412/)

[12](https://researchfeatures.com/accurately-monitoring-tool-wear-precision-machining/)

[13](https://www.sciencedirect.com/science/article/pii/S0952197624007280)

[14](https://www.sciencedirect.com/science/article/abs/pii/S0736584519306660)

[15](https://www.mechanicaljournals.com/ijmtme/article/50/6-1-3-556.pdf)

[16](https://amfasinternational.com/newsroom/predictive-maintenance-with-ai-in-cnc-machining-the-future-of-zero-downtime-manufacturing/)