From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-14 Origin: Site

Content Menu

● What Is CNC Acrylic (PMMA) Machining

● Why Choose Acrylic (PMMA) Over Other Plastics

● Cast vs Extruded Acrylic for CNC Machining

● Step by Step CNC Acrylic Machining Workflow

>> Material Selection and Stock Preparation

>> CNC Machine Setup and Calibration

>> Feeds, Speeds, and Depth of Cut

>> Final Machining and Quality Checks

● Design Guidelines for CNC Acrylic Parts

>> Minimum Wall Thickness and Features

>> Fillets, Corners, and Stress Concentration

>> Hole, Thread, and Tolerance Practices

● Surface Finishes from As Machined to Optical Grade

● CNC Acrylic Machining vs Laser Cutting

● Practical Use Cases for CNC Machined Acrylic

● Step by Step Checklist for OEM Buyers

● Trends in Acrylic CNC Machining

● Expert Tips to Avoid Cracks, Chips, and Melting

● When to Use a Professional CNC Acrylic Service vs DIY

● Where a Full Capability OEM Partner Adds Value

● Take the Next Step with a Professional OEM Partner

● FAQ About CNC Acrylic (PMMA) Machining

>> Q1. What tolerances are realistic for CNC machined acrylic

>> Q2. How do you prevent acrylic from melting during CNC machining

>> Q3. Is CNC acrylic machining suitable for low volume prototypes

>> Q4. When is laser cutting better than CNC machining for acrylic

>> Q5. What information should OEM buyers send when requesting a quote

CNC acrylic machining (PMMA machining) is one of the most reliable ways to produce crystal clear, tight tolerance plastic parts for modern brands, OEMs, wholesalers, and manufacturers. When done correctly, CNC machined acrylic can rival glass in appearance while offering lower weight, higher impact resistance, and flexible design freedom for enclosures, displays, and precision components.

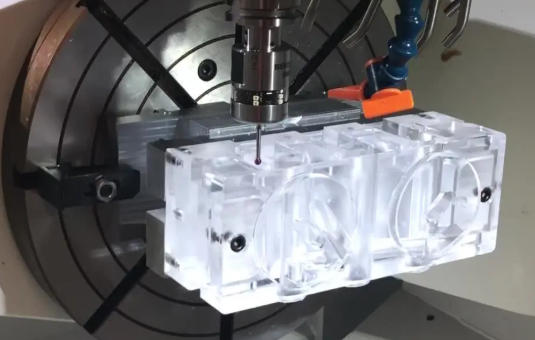

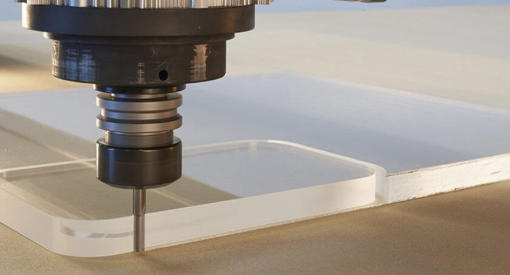

CNC acrylic machining uses computer controlled mills, routers, or lathes to cut and shape acrylic (PMMA) sheets, blocks, or rods into precise 2D and 3D parts. The process removes material with rotating cutting tools rather than melting it like a laser, which helps maintain clarity and dimensional accuracy.

Acrylic (PMMA) offers glass like transparency, good scratch resistance, and a high gloss surface when properly finished. CNC machining supports pockets, countersinks, threaded holes, and complex 3D forms that are difficult or impossible with laser cutting alone.

Common CNC operations with acrylic (PMMA) include:

- Milling and routing of panels, windows, pockets, and contours.

- Turning cylindrical parts such as lenses, knobs, and fluid connectors.

- Drilling, tapping, and countersinking for mechanical fastening.

Acrylic sits in a sweet spot between clarity, rigidity, and cost, making it ideal when visual appearance and durability both matter.

Compared with polycarbonate, acrylic is more scratch resistant and maintains clarity longer but is slightly more brittle. Compared with ABS or nylon, acrylic offers superior transparency and a more premium, glass like aesthetic.

Key material benefits for OEMs and brands:

- Optical grade transparency with very high light transmission in clear grades.

- Good UV stability, especially in outdoor rated grades.

- Stable dimensional behavior for precision assemblies when machined with the right parameters.

Choosing the right acrylic grade is critical before any CNC PMMA machining begins.

Acrylic Type | Characteristics | Pros for CNC | Cons for CNC |

Cast Acrylic | Produced by casting PMMA in molds. | Better optical clarity, machines with cleaner chips, less internal stress. | Higher material cost, slightly more variation in thickness. |

Extruded Acrylic | Forced through a die to form sheets. | Lower cost, consistent thickness for large panels. | More internal stress, more likely to melt or gum during cutting. |

For high end display parts, lenses, or branded panels, cast acrylic is usually recommended to achieve clearer edges and fewer stress marks after machining.

A well defined process is the difference between optical grade parts and cracked, cloudy scrap.

A detailed 3D CAD model defines every contour, hole, and pocket in the acrylic part. During design for manufacturability, engineers optimize the model for acrylic brittleness and machining behavior.

Best practice checks:

- Avoid sharp internal corners and add generous fillets where possible.

- Maintain realistic minimum wall thickness and rib dimensions for the chosen thickness.

The team chooses between cast or extruded acrylic, as well as color options like clear, tinted, frosted, or opaque. Sheets or blocks are cut to oversize blanks that fit the CNC machine bed or custom fixtures.

Protective film is often kept on during fixturing to reduce surface scratching. For turned parts, acrylic rods or thick blocks are cut to length for lathe chucks.

Acrylic is unforgiving of vibration, runout, or heat buildup, so tight machine setup is essential.

Key actions:

- Check spindle runout and tool length offsets.

- Configure compressed air or mist cooling to evacuate chips and reduce heat without flooding the part.

For most CNC acrylic machining work, sharp single flute or polished flute carbide end mills are ideal. They evacuate chips efficiently, minimizing friction and the risk of melting.

Recommended tooling approaches:

- Single flute or O flute cutters for slotting and contouring.

- High shear, polished geometries to produce smooth, clear edges.

- For turning, sharp carbide or diamond tipped inserts to reduce surface defects and tool wear.

Because acrylic can crack under point loads or vibration, secure yet gentle fixturing is critical.

Common strategies:

- Vacuum tables for thin panels and large 2D profiles.

- Custom soft jaws or fixtures that spread clamping forces over larger areas.

- Sacrificial backer boards to prevent breakout during through cuts.

Optimizing feeds and speeds is one of the most important steps in CNC PMMA machining.

Typical guidelines:

- Spindle speed in a high range, adjusted to tool diameter and setup.

- Feed rate tuned to maintain chip load and avoid melting, not too slow and not too fast.

- Shallow depth of cut to control heat and edge quality on delicate features.

Before committing to full rate production, experienced machinists run test passes on scrap acrylic to validate surface finish and chip behavior.

Parameters are adjusted until chips form cleanly and edges appear clear rather than frosted or burnt. CAM paths are refined to avoid sharp direction changes that could induce chatter or cracking.

The approved program runs on production blanks with continuous monitoring for temperature and chip evacuation.

Visual inspection verifies clarity, burr free edges, and the absence of stress whitening. Dimensional checks with calipers or CMMs confirm critical tolerances, often around plus or minus 0.05 millimeters or better in precision setups.

Well designed acrylic parts are easier to machine, more robust in use, and less prone to cracking.

Acrylic is more brittle than ABS or nylon, so ultra thin features can fail during cutting or assembly.

Suggestions:

- Aim for 1.5 to 2 millimeters minimum wall thickness for structural areas, increasing thickness where holes, threads, or inserts are added.

- Avoid long, unsupported fins or tabs that could vibrate or chip under load.

Sharp internal corners act as natural crack initiators in PMMA.

Design notes:

- Add fillet radii that match or exceed the cutter radius to reduce stress and improve toolpath flow.

- Use smooth transitions between sections instead of abrupt thickness changes.

CNC acrylic machining can achieve impressive precision when designs respect the material.

Guidelines:

- Avoid extremely tight press fits and use controlled clearances or inserts where needed.

- Typical production tolerances of plus or minus 0.05 millimeters are realistic on critical dimensions with stable fixturing and verified tool paths.

The right finishing approach depends on whether the acrylic part is functional, cosmetic, or optical.

Finish Type | Process | Result | Typical Applications |

As machined | Directly off CNC with optimized parameters. | Smooth but slightly matte surface, fine tool marks may be visible. | Machine guards, covers, internal components. |

Flame polished | Controlled pass of a flame along machined edges. | High gloss, glass like edge clarity. | Retail displays, signage, premium panels. |

Vapor polished | Exposure to solvent vapors that soften the outer layer. | Near optical clarity with reduced tool marks. | Lenses, light guides, medical housings. |

For parts that interact with light, such as LED light guides, windows, viewing ports, or lenses, flame or vapor polishing is almost always recommended.

Both CNC machining and laser cutting are widely used for acrylic, but they excel in different scenarios.

Aspect | CNC Acrylic Machining | Laser Cutting Acrylic |

Edge quality | Clear, controllable edges that can be further polished. | Flame polished look but higher thermal stress and potential micro cracks. |

Tolerances and 3D features | Supports tight tolerances, pockets, countersinks, step depths, threads. | Best for 2D profiles and engraving with limited 3D geometry. |

Heat impact | Lower heat input when feeds and speeds are optimized. | High local heat can cause distortion or discoloration on thicker parts. |

Ideal use cases | Thicker plates, 3D forms, precision assemblies, mechanical parts. | Thin sheets, intricate 2D patterns, fast cutting of signage and decor. |

For high precision OEM parts or thick PMMA components, CNC machining is generally the more controlled and repeatable option.

CNC acrylic machining is used wherever clarity, branding, and mechanical performance meet.

Typical applications:

- Signage and display panels such as illuminated logos, retail fixtures, and exhibition stands.

- Protective covers and machine guards that need impact resistance and visibility into equipment.

- Medical and lab equipment including transparent chambers, trays, and housings.

- Consumer product prototypes such as clear housings, concept models, and functional mockups.

When combined with precision metal, plastic, silicone, and stamped components, acrylic parts help build complete assemblies that are ready for final integration.

This practical CNC acrylic machining checklist helps engineering and sourcing teams avoid delays before placing an order.

1. Define the application clearly

- Indoor or outdoor use, cosmetic or fully optical, load bearing or decorative.

2. Specify material and color

- Cast or extruded acrylic, thickness range, and color such as clear, smoked, tinted, or diffused.

3. Provide detailed CAD and 2D drawings

- Include tolerances, critical dimensions, and any surface finish requirements.

4. Highlight functional zones

- Mark sealing surfaces, viewing windows, bearing areas, or fastener locations.

5. Confirm finishing and branding needs

- Flame or vapor polishing, engraving for logos, or printing for graphics.

6. Align on quality and inspection standards

- Sampling plan, dimensional reports, and any compliance or testing requirements.

Recent developments in acrylic machining technology and demand patterns are reshaping how PMMA parts are produced.

Notable trends include:

- Growing use of 5 axis CNC for complex optical geometries and ergonomic product housings.

- Integration with automation and robotic handling for consistent edge quality in medium to high volumes.

- Increased demand from medical, diagnostics, transportation, and energy sectors for transparent, durable enclosures and indicators.

Optimizing spindle speed, feed rate, and depth of cut, together with controlled polishing, can significantly improve surface roughness and visual quality.

Cracking or melting is usually avoidable if a few expert rules are followed in CNC acrylic machining.

Key tips:

- Control heat with sharp cutters, correct chip load, and air blast instead of aggressive flood coolant.

- Minimize vibration through rigid fixturing, shorter tool stick out, and stable machine parameters.

- Plan toolpaths strategically, favor climb milling, avoid sudden plunges, and use lead in and lead out moves.

- Leave a small amount of finishing stock on critical faces, rough first, then apply a light finishing pass for best clarity.

These techniques are particularly important for thin wall parts, narrow slots, and complex optical features.

For hobby projects, basic cutting of acrylic can be done in house, but professional CNC services provide major advantages for OEM and brand work.

Professional CNC acrylic machining is ideal when:

- Tight dimensional tolerances or flatness are important.

- Edges must be polished and cosmetically perfect out of the box.

- There are complex 3D features, pockets, or threaded holes.

Basic DIY cutting may suffice for:

- Simple 2D panels and covers where slight edge haze is acceptable.

- Non critical mockups or one off internal prototypes.

For overseas buyers, partnering with a full service OEM that can also machine metals, mold plastics, produce silicone parts, and handle metal stamping can consolidate vendors and reduce total project cost.

Acrylic parts are often just one part of a larger mechanical or electronic assembly. Working with an OEM that offers multiple manufacturing capabilities creates a smoother supply chain.

Valuable complementary capabilities include:

- High precision CNC metal machining for frames, heat sinks, and structural interfaces.

- Plastic molding and machining for non transparent housings, clips, and structural components.

- Silicone product manufacturing for gaskets, keypads, and seals around acrylic windows.

- Metal stamping for brackets, shields, and mounting hardware.

With one integrated supplier responsible for the fit and function of all components, brands can shorten development cycles and improve product consistency.

For brands, wholesalers, and manufacturers that need CNC acrylic parts integrated with high precision metal machining, plastic product manufacturing, silicone components, and metal stamping, working with an experienced Chinese OEM partner can transform project outcomes. Share your drawings, specifications, and target quantities to receive a tailored CNC acrylic machining solution, including material selection, finishing options, and combined production for all related components. Contact the team today to get a detailed quotation and turn your clear design concepts into clear, production ready parts.

Most professional shops can hold around plus or minus 0.05 millimeters on critical dimensions when fixturing and parameters are optimized, with even tighter control on small features in stable setups. The achievable tolerance also depends on part size, geometry, and inspection method.

Using sharp tools, correct chip load, appropriate spindle speeds, and continuous chip evacuation with compressed air greatly reduces the risk of melting. Avoiding dwelling in one spot and limiting depth of cut are equally important for keeping temperatures under control.

CNC is highly efficient for low to medium volumes and prototypes because no hard tooling is required. Design changes can be implemented quickly at the CAM stage, making CNC machining an excellent option for iterative product development.

Laser cutting is ideal for thin sheets, intricate 2D shapes, and rapid batch cutting where extreme dimensional precision or 3D features are not required. It is often used for signage, decorative panels, and basic covers that do not need machined pockets or threads.

At minimum, buyers should provide material and thickness, CAD files, 2D drawings with tolerances, required surface finish, target quantity, and any specific inspection or certification needs. Sharing intended application and assembly context also helps the supplier make better material and process recommendations.

1. https://jlccnc.com/blog/cnc-acrylic-machining-and-custom-pmma

2. https://www.hubs.com/knowledge-base/guide-to-acrylic-cnc-machining/

3. https://amfg.ai/2024/05/07/acrylic-cnc-machining-a-comprehensive-guide/

4. https://www.mekanika.io/en/blog/cnc-material-guides/pmma-cnc-milling-guide

5. https://www.rapiddirect.com/blog/cnc-acrylic/

6. https://hplmachining.com/blog/machining-pmma/

7. https://www.elephant-cnc.com/blog/638-cnc-acrylic-laser-cutter-machine-vs-cnc-router-acrylic-cutting-machine/

8. https://www.fastpreci.com/blog/acrylic-cnc-machining/

9. https://www.manufacturingtomorrow.com/news/2024/12/09/pmma-machining-a-comprehensive-guide/23936

10. https://www.omtech.au/blogs/news/cnc-vs-laser-cutter