From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Loretta Publish Time: 2025-12-24 Origin: Site

Content Menu

● What Is a CNC Turning Center

● Key Differences Between CNC Lathes and CNC Turning Centers

>> Main Technical and Economic Differences

● How CNC Lathes Work in Practice

● How CNC Turning Centers Work in Practice

● Live Tooling and Multi Axis Capability

● Productivity, Automation, and Cost per Part

● When CNC Lathes Are the Better Choice

● When CNC Turning Centers Are the Better Choice

● Application Scenarios in Modern Manufacturing

● Practical Selection Checklist for OEMs and Buyers

>> Step 1. Evaluate Part Complexity

>> Step 2. Confirm Tolerances and Concentricity

>> Step 3. Analyze Annual Volume and Product Mix

>> Step 4. Clarify Lead Time and Time to Market Targets

>> Step 5. Calculate Total Cost per Part

● Integrating CNC Lathes and Turning Centers in a Single Supplier

● Clear Call to Action for OEMs and Global Buyers

● FAQs About CNC Lathes and CNC Turning Centers

>> 1. Are CNC lathes becoming obsolete

>> 2. What is the main advantage of a CNC turning center for OEM projects

>> 3. Is live tooling always necessary on a turning center

>> 4. How does machine choice influence tolerance and quality

>> 5. What information should be provided to a machining supplier when requesting a quote

Selecting between a CNC lathe and a CNC turning center directly affects production cost, flexibility, and delivery speed in CNC machining projects. For OEMs and global buyers cooperating with Chinese suppliers like U-NEED, understanding the real differences helps match the right machine to tolerance, volume, and budget targets.

A CNC lathe is a computer controlled version of the traditional lathe, primarily designed for turning cylindrical parts along two main axes. The workpiece rotates in the spindle while a stationary cutting tool removes material to achieve the desired diameter and length.

Key characteristics of CNC lathes include:

- 2 axis configuration for straightforward turning, facing, and threading.

- Relatively simple structure with chuck, spindle, tool turret, and tailstock.

- Strong suitability for round parts such as shafts, pins, bushings, and simple contours.

Because of their simpler design, CNC lathes are usually more affordable to purchase and easier to set up and operate, which appeals to shops that focus on low to medium complexity turning jobs.

A CNC turning center is a more advanced, multi axis evolution of the lathe, designed for high productivity and complex parts in a single setup. These machines often combine turning, milling, drilling, and tapping with live tooling and sometimes additional spindles and axes.

Typical features of CNC turning centers include:

- Multi axis capability, often combining linear axes with rotary indexing for complex tool paths.

- Enclosed slant bed design for better chip evacuation and coolant management.

- Integrated CNC controls, automatic tool changers, bar feeders, and part catchers for higher automation.

Because they execute multiple operations without removing the part from the machine, turning centers deliver higher precision, reduced handling, and shorter overall cycle times on complex parts.

The following comparison highlights the most important differences for engineers, buyers, and sourcing managers evaluating CNC lathe and CNC turning center solutions.

Aspect | CNC Lathe | CNC Turning Center |

Axes and motion | Typically 2 axes for basic turning operations. | Multi axis for turning plus milling, drilling, and tapping. |

Operation range | Turning, facing, grooving, threading, simple boring. | Turning plus live tooling for flats, slots, and cross holes. |

Setup complexity | Simpler to program and set up. | More complex programming and setup. |

Automation level | Limited automation, more manual intervention. | High automation, suitable for long unattended runs. |

Production volume | Well suited for low to medium volume and simple repeat jobs. | Ideal for medium to high volume and multi step machining. |

Precision on complex parts | High precision on straightforward cylindrical features only. | High precision on complex parts thanks to single setup machining. |

Investment and cost | Lower machine cost, more secondary operations. | Higher machine cost, lower cost per part for complex parts. |

Typical users | Job shops with standard shafts, pins, and bushings. | OEM focused shops producing complex, multi feature components. |

In a CNC lathe, the spindle holds and rotates the workpiece while the tool turret indexes different cutting tools into position. The machine executes programmed tool paths along its axes to create diameters, shoulders, grooves, and thread profiles.

Common CNC lathe operations include:

- Turning and facing to set outer diameter and overall length.

- Grooving and parting for snap ring grooves or cutoffs.

- Threading for internal and external threads using dedicated tools.

Without live tooling, any side holes, flats, or complex pockets are typically machined later on milling equipment, which adds transfer time, additional fixturing, and more complexity to the overall process.

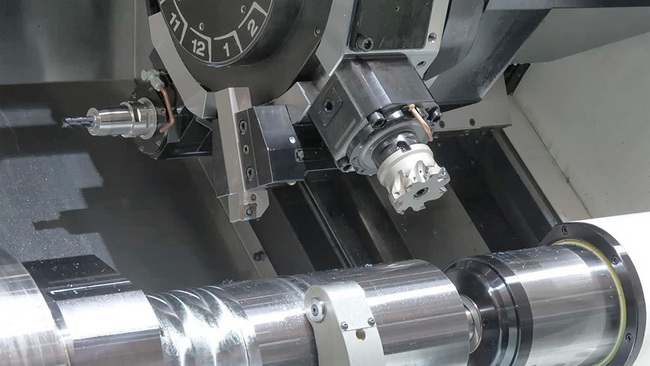

CNC turning centers retain the basic turning functions but add live tooling and extra axes, so the tool can rotate and approach the workpiece from more directions. Rotary indexing allows the spindle to act like a rotary positioning device, while additional linear axes enable off center milling and drilling.

With these capabilities, turning centers can perform:

- Complete turning, facing, and threading operations.

- Milling, drilling, tapping, and contouring on the same machine in one clamping.

- Multi tasking cycles, where the machine switches automatically between different tools and operations.

This integrated approach reduces total cycle time, improves positional accuracy between turned and milled features, and minimizes operator intervention across the production shift.

Live tooling refers to power driven tools mounted in the turret that rotate independently of the main spindle. These tools make it possible to perform operations normally done on a milling machine, such as flats, keyways, and cross holes, while the part stays fixed in the turning center.

Benefits of live tooling and additional axes include:

- Single setup machining, which reduces cumulative errors from multiple fixtures.

- Shorter overall lead times, because parts do not need to move between different machines.

- Greater design freedom for engineers to combine turned and milled features on one part.

For OEM buyers, this translates into stronger geometric accuracy, especially for parts where concentricity between bores, faces, and diameters is critical for function and assembly.

CNC turning centers are designed for high productivity and automation, often running unattended. Once programmed and set up, they can continuously feed bar stock, change tools automatically, evacuate chips, and collect finished parts.

Compared with CNC lathes:

- Turning centers offer higher throughput and reduced labor hours per part.

- Automated cycles reduce scrap and rework by making the process more consistent.

- Higher machine cost is often offset by a lower cost per part on complex or medium to high volume production.

In sourcing decisions, the key question is whether the part mix and production volume justify the higher machine capability and automation level, rather than focusing only on hourly rates.

CNC lathes can be the most cost effective solution when requirements are simple and stable over time. When parts only require turning operations and basic features, the additional complexity of a turning center may not deliver a clear return.

Situations where CNC lathes fit best include:

- Standard cylindrical parts with straightforward tolerances and basic geometries.

- Small batches or job shop work with frequent changeovers and diverse part numbers.

- Projects where milling operations are minimal or can be consolidated on separate machining centers.

Because of lower machine and setup costs, CNC lathes remain attractive for many low risk, low complexity applications where flexibility and quick changeover are vital.

CNC turning centers perform best where complexity, tight tolerances, and lead time are critical. For OEMs that demand high volume, repeatable production with multiple features in one part, these machines often deliver the best total cost of ownership.

A turning center should be prioritized when:

- Parts combine turning with milled flats, slots, cross holes, or complex contours.

- Critical features require tight positional tolerances and must be produced in one setup.

- Production volumes justify automation and lights out manufacturing on stable product lines.

In such scenarios, the ability to machine everything in a single clamping significantly reduces scrap risk, simplifies inspection, and stabilizes quality performance over long production runs.

Both CNC lathes and turning centers serve essential roles in modern manufacturing, but they are typically used in different project types. OEMs in automotive, medical devices, aerospace, and electronics rely on CNC turning technology to maintain consistent and repeatable production quality.

Typical application scenarios include:

- CNC lathes for simpler shafts, pins, bushings, spacers, and straightforward fastener like components.

- Turning centers for valve bodies, precision connectors, implant components, and complex housings with multiple bores and flats.

As product designs become more compact and integrated, demand for turning centers with live tooling continues to grow, especially in global supply chains that focus on rapid iteration and shorter product life cycles.

For engineers, purchasing teams, and foreign brands working with machining suppliers, a structured decision process helps specify the right equipment and avoid unnecessary cost. The following checklist provides a practical reference.

- Confirm whether the part includes flats, cross holes, slots, or angled features.

- If milling features are essential and need tight alignment with turned surfaces, a multi axis turning center is normally preferable.

- Identify the most critical dimensions and geometric tolerances.

- If positional relationships or concentricity between multiple features are strict, single setup machining offers obvious advantages.

- High and stable annual volumes tend to favor automated turning centers.

- Low volumes or very diverse part numbers with simple geometry can be more economical on CNC lathes.

- Projects with aggressive launch schedules benefit from multi tasking capabilities.

- When lead time pressure is moderate and geometry is simple, a conventional CNC lathe can still meet schedule targets.

- Consider programming, setup time, handling, scrap, and inspection in addition to machine rates.

- For complex designs, turning centers typically deliver a lower total cost per part even with higher hourly costs.

A full service manufacturer with precision machining, plastic molding, silicone production, and metal stamping often operates both CNC lathes and CNC turning centers. This combination allows flexible allocation of each component to the most suitable machine type.

In practice, this approach means:

- Simple round inserts or bushings are routed to CNC lathes for fast and economical runs.

- High precision, multi feature parts with combined turning and milling are assigned to turning centers.

For overseas OEMs and traders, working with a supplier that can manage both technologies helps balance cost, precision, and delivery across entire assemblies and long term programs.

If your team is planning a new machining project and is unsure whether a CNC lathe or a CNC turning center is the better option, now is the time to involve a professional production partner. To move forward efficiently, prepare your 2D drawings, 3D models, and estimated volumes, then request a detailed process proposal that explains machine selection, tolerances, and expected lead time. Ask specifically how different machine choices affect cost per part, and invite design for manufacturability suggestions to simplify features that drive up machining time. Taking this step early will help you secure a stable, cost effective manufacturing route and reduce risks in quality and delivery for your next OEM project.

No. CNC lathes remain efficient and competitive for simple cylindrical parts, especially at low to medium volumes, and often offer the lowest cost for straightforward turning jobs.

The main advantage is the ability to complete turning and milling operations in a single setup, which shortens lead time, improves accuracy, and reduces cost per part on complex designs.

Not always. If a part has only basic turning features, live tooling may not bring a clear benefit, but it becomes valuable when cross holes, flats, slots, or other milled details are required.

Single setup machining on a turning center helps maintain tighter positional tolerances between different features, while CNC lathes still achieve excellent accuracy for simpler geometries and standard cylindrical parts.

Provide clear 2D and 3D drawings, annual volume estimates, material specifications, surface finish requirements, and key tolerances, then ask the supplier which machine type they plan to use and how this choice affects pricing and delivery.

content is empty!