From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Loretta Publish Time: 2025-12-23 Origin: Site

Content Menu

● What Is CNC Machining for Heat Sinks

● Why Choose CNC Machined Heat Sinks

● Core Design Principles for CNC Heat Sinks

>> Fin Geometry: Thickness, Spacing, Height

>> Airflow Strategy: Passive and Active Cooling

>> Integrated Mechanical and Assembly Features

● Material Selection for CNC Machined Heat Sinks

>> Hybrid Copper Base and Aluminum Fin Designs

● Precision, Flatness, and Surface Finishes

>> Tolerances and Contact Flatness

>> Surface Treatments and Coatings

● Design for Manufacturability for CNC Heat Sinks

>> Geometric Simplification and Tool Access

>> Cost Focused Design Decisions

● Practical Step by Step Heat Sink Design Workflow

● Application Scenarios and Industry Uses

● OEM Support for Complete Thermal and Mechanical Solutions

● Take the Next Step with an OEM Manufacturing Partner

● FAQs About CNC Machined Heat Sinks

>> 1. When is CNC machining a better choice than extrusion or die casting

>> 2. How should aluminum and copper be selected for a specific project

>> 3. Which tolerances matter most for thermal performance

>> 4. How important is surface treatment for a heat sink

>> 5. Can one supplier provide heat sinks and related plastic or silicone components together

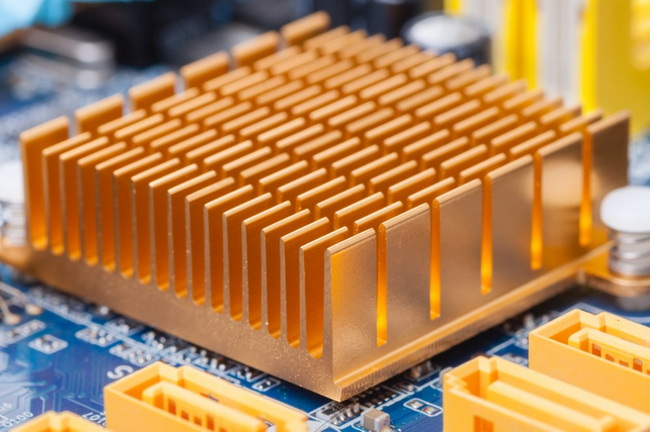

CNC machined heat sinks are essential for high power, high reliability electronics where standard extruded or die cast profiles cannot meet thermal or mechanical requirements. This guide explains how to design, select materials, and cooperate with an OEM manufacturer to obtain high performance heat sinks ready for production.

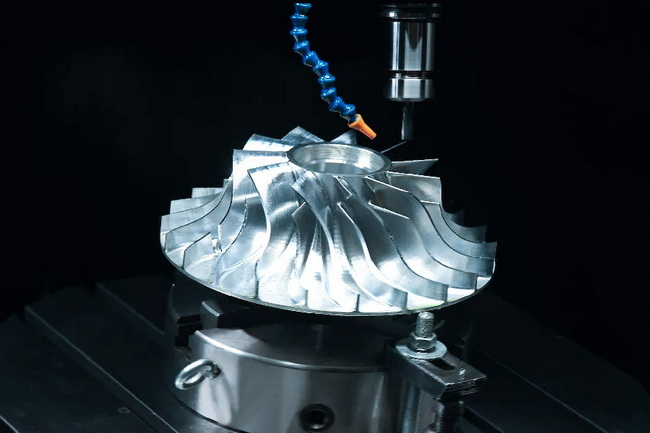

CNC machining uses computer controlled cutting tools to remove material from metal blocks and create custom heat sink geometries with tight tolerances. Compared with extrusion or die casting, it supports complex fin layouts, hybrid structures, and integrated mounting features for demanding applications.

Typical use cases include:

- Power electronics and inverters

- Automotive ECUs and advanced driver assistance electronics

- High performance computing, CPUs, and GPUs

- 5G base stations and RF equipment

Because dedicated molds are not required, CNC machining is suitable for prototypes, small and medium batches, and customized designs where performance is a priority.

CNC machining often provides the best balance of thermal performance, precision, flexibility, and total lifecycle cost for engineering driven projects. Understanding its strengths helps justify process selection to technical and purchasing teams.

Key advantages include:

1. Design freedom

- Non uniform fin shapes and stepped or interrupted fins

- Multi directional airflow channels and optimized 3D geometries

- Local pockets, cut outs, and integrated mounts

2. Rapid prototyping and iteration

- No tooling lead time or mold investment

- Easy design revisions after thermal testing

- Lower risk when exploring new thermal concepts

3. Material flexibility

- High conductivity aluminum alloys

- Pure copper for maximum heat transfer

- Hybrid copper base plus aluminum fin designs

4. Precise dimensional control

- Flat, stable contact surfaces for reliable thermal interfaces

- Accurate hole positions for easy assembly

- Consistent thread depths for repeatable torque and clamping force

Effective thermal design must also be machinable. Proper fin geometry and structure help avoid vibration, deformation, and unnecessary machining cost.

Fins increase surface area and enhance convection, but if they are too thin, too tall, or too closely spaced, machinability and airflow both suffer.

General design guidance:

- Keep aluminum fin thickness at or above typical CNC friendly minimums.

- Use slightly thicker fins for copper due to higher cutting forces.

- Maintain enough spacing for chip evacuation and airflow.

- Avoid extreme aspect ratio fins unless absolutely necessary.

Practical tips:

- Use stepped or segmented fins if very tall geometry is required.

- Verify tool reach and rigidity in dense fin arrays.

- Consider the fan type or natural convection pattern when selecting spacing.

Airflow strategy should be defined at the same time as fin design, not added later. Different rules apply to natural and forced convection.

For passive or natural convection:

- Align fins vertically relative to gravity to support buoyant flow.

- Prefer wider spacing and adequate fin height.

- Provide clearance around the heat sink to avoid blocking air paths.

For active or forced convection:

- Use angled or staggered fins to guide the air and reduce backpressure.

- Apply slightly narrower spacing with higher air velocity.

- Shape leading edges to reduce pressure drop and fan noise.

CNC machining allows the heat sink to act as a mechanical component as well as a thermal one. Proper integration reduces part count and assembly steps.

Typical features include:

- Counterbores and tapped holes for mounting PCBs or housings

- Recessed pockets for thermal interface materials or heat pipes

- Alignment pins or guides for fast and repeatable assembly

- Local bosses and ribs to increase stiffness at screw locations

When adding such features, maintain adequate wall thickness and use fillets at internal corners to limit stress and improve tool life.

Material selection influences thermal performance, weight, corrosion resistance, machining time, and overall cost. Choosing the correct material early helps avoid redesign.

Aluminum alloys such as 6061 and 6063 are widely used for CNC heat sinks because they combine good thermal conductivity with low density and excellent machinability.

Main characteristics:

- Medium to high thermal conductivity for most electronic applications

- Low weight, suitable for automotive and aerospace assemblies

- Stable chip formation and low tool wear

- Lower cost and easy availability

Use aluminum when:

- Weight is critical.

- There is enough volume to increase heat sink size if needed.

- Cost targets are strict for small and medium volume production.

Copper offers very high thermal conductivity but is heavier, more expensive, and more difficult to machine.

Main characteristics:

- Very high thermal conductivity for extreme heat flux

- High density and greater mass per unit volume

- Tendency to burr and generate built up edge on tools

- Higher raw material cost and longer machining times

Choose copper when:

- Devices generate high heat flux in a very small footprint.

- There is limited space to enlarge the heat sink.

- The application demands maximum conduction at the interface.

Using suitable cutting tools, optimized speeds and feeds, and appropriate coolants is essential for stable machining and clean surfaces with copper.

Hybrid designs combine a copper base with aluminum fins to balance performance, weight, and cost.

Benefits include:

- High conductivity at the device interface

- Reduced weight compared with full copper construction

- Easier machining of fin structures

- Flexible assembly using press fitting, brazing, or thermal adhesives

Hybrid heat sinks are commonly used in high power electronics, telecom equipment, and compact industrial systems.

A well designed geometry cannot perform effectively if the contact surfaces are not flat, smooth, and stable over time. Surface quality directly affects thermal interface resistance.

Uneven contact surfaces create air gaps and thicker thermal interface layers, increasing thermal resistance. Reasonable tolerance targets help maintain performance while controlling cost.

Common targets:

- Tight flatness on device mounting surfaces to support thin interface layers

- Accurate hole location for reliable assembly and fit with enclosures

- Consistent thread depth for stable clamping and repeatability

Achieving these values requires:

- Dedicated finishing operations such as fly cutting or precision face milling

- Proper fixturing to avoid warpage during final passes

- Optimized machining sequences that minimize residual stress.

Post machining treatments support corrosion resistance, emissivity, and wear resistance, which are important for long term operation.

Typical treatments:

- Anodizing for aluminum

- Provides corrosion protection and electrical insulation.

- Black anodizing improves surface emissivity in natural convection and radiation dominant environments.

- Electroplated coatings for copper

- Nickel plating reduces oxidation on contact surfaces.

- Plating improves aesthetics and wear resistance for repeated assembly.

- Brushed or sandblasted finishes

- Enhance appearance.

- Create mild surface roughness that can increase turbulence in the airflow.

Design for manufacturability ensures that the heat sink is not only thermally effective but also stable, repeatable, and economical to produce.

Complex shapes that require extremely long tools or many setups increase cost and production risk.

Guidelines:

- Avoid very deep and narrow pockets or fin arrays.

- Merge separate brackets or minor attachments into the heat sink when possible.

- Use corner radii that match standard tool diameters.

- Avoid unnecessary undercuts or features that require special tools.

Simple changes in geometry and feature selection can significantly reduce machining time and waste.

Recommendations:

- Group features on common faces to reduce the number of setups.

- Standardize thread sizes and hole diameters across product families.

- Align heat sink size with commonly available stock dimensions.

- Limit purely decorative features on non visible faces.

A clear workflow helps engineers move from requirements to validated prototypes efficiently.

1. Define power dissipation and temperature limits.

2. Specify space constraints, mounting requirements, and environment.

3. Select a baseline material and cooling mode.

4. Draft initial fin geometry using CNC friendly limits.

5. Run thermal simulations and adjust geometry as needed.

6. Review tool access, tolerances, and surface finish requirements.

7. Produce prototypes with the chosen material and process.

8. Test under realistic load conditions and log temperature results.

9. Refine dimensions, mounting features, or materials based on test and manufacturing feedback.

Real projects show where custom CNC machined heat sinks deliver clear advantages over catalog parts.

Common applications:

- Power conversion and drive systems in industrial automation.

- Telecom and networking devices with high packing density.

- Automotive control units and battery management systems.

- High performance computing and graphics subsystems.

In these cases, combining optimized fin geometry, appropriate materials, and precise surface finishes delivers reliable operation under demanding thermal and mechanical conditions.

Many projects require more than just a bare heat sink. Electronic assemblies also need precision metal components, plastic housings, and silicone parts such as seals and gaskets.

An OEM partner with capabilities in high precision machining, plastic manufacturing, silicone molding, and metal stamping can:

- Produce custom aluminum and copper heat sinks with tight tolerances.

- Manufacture metal brackets, shields, and other structural parts.

- Provide plastic and silicone components that interface with the heat sink.

- Offer assembly and testing services to deliver ready to use modules.

This integrated approach shortens the supply chain, simplifies communication, and improves alignment between thermal, mechanical, and enclosure design.

For brands, wholesalers, and manufacturers planning new electronic products or upgrading existing designs, a professional OEM partner can turn thermal concepts into reliable, mass producible solutions. Prepare your drawings, material and surface requirements, expected volumes, and performance targets, then contact the engineering and sales team to discuss optimization, sample schedules, and production terms tailored to your projects.

CNC machining is recommended when the heat sink requires complex geometries, precise tolerances, or low to medium volumes where tooling for extrusion or die casting would be too costly.

Use aluminum for most applications where weight and cost are important and there is enough room for a larger heat sink, and choose copper or hybrid structures when space is limited and very high heat flux must be handled.

Flatness and surface finish on the device mounting area have the greatest impact, followed by hole position and thread consistency, which influence clamping pressure and repeatability.

Surface treatment protects against corrosion, can improve emissivity, and supports long term reliability, especially in outdoor or automotive environments. However, fin geometry and airflow design remain the primary drivers of performance.

Yes, some OEM manufacturers can supply CNC machined heat sinks, stamped metal parts, plastic components, and silicone parts as a complete set, which simplifies logistics and improves fit and integration during assembly.