From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-06 Origin: Site

Content Menu

● What Is CNC Machining Surface Roughness?

● Key Surface Roughness Parameters: Ra, Rz and More

● Ra vs Rz in Real Applications

● How Surface Roughness Is Measured in CNC Machining

>> Contact Measurement: Stylus Profilometer

>> Non‑Contact Measurement: Optical and Laser Systems

● Typical Surface Roughness by CNC Process

● When to Add Post‑Processing for Better Surface Finish

● How to Choose the Right Surface Finish for Your Application

● Common Surface Roughness Mistakes (and How to Avoid Them)

● Practical Design Tips for Engineers and Buyers

● Case Study: Solving a Persistent Sealing Failure

● Recommended Visuals and Charts to Support the Article

● Actionable Checklist: Specifying CNC Surface Roughness

● Work With an OEM‑Focused Machining Partner

● Call to Action: Get the Right Surface Finish for Your Next Project

● FAQs About CNC Machining Surface Roughness

>> 1. Is a lower Ra value always better?

>> 2. When should both Ra and Rz be specified?

>> 3. Can I rely only on visual inspection for surface finish?

>> 4. Do different CNC processes produce the same roughness for the same Ra target?

>> 5. How does surface roughness affect coatings and plating?

When outsourcing CNC machining, surface roughness is one of the most critical—but often misunderstood—quality indicators that determine performance, reliability, and cost of your parts. This guide explains CNC machining surface roughness in practical terms and shows how to specify and inspect it so your projects run smoothly from RFQ to mass production.[1]

In CNC machining, surface roughness describes the microscopic peaks and valleys left on a part after cutting, grinding, EDM, or polishing. Even when a surface looks smooth to the naked eye, its roughness level directly affects friction, sealing, fatigue strength, coating adhesion, and appearance.[1]

For OEMs and industrial buyers, roughness is not just a cosmetic value:

- It influences how a shaft slides in a bearing, whether hydraulic seals leak, and how long moving components last under load.[1]

- It strongly impacts post-processing needs such as polishing, coating, or bead blasting, which add cost and lead time.[1]

A well‑defined surface roughness specification helps you avoid disputes, rework, and field failures.

Engineers rarely describe surfaces as just “smooth” or “shiny”; instead, they use standardized roughness parameters. The two most widely used in CNC machining drawings are Ra and Rz.[1]

Ra (Roughness Average) is the arithmetic mean of all vertical deviations from the mean line over a sampling length. In practice, Ra is:[1]

- The most common value on engineering drawings

- A convenient way to compare surfaces produced by different machines or processes.[1]

However, Ra does not describe extreme peaks or valleys, so two surfaces with the same Ra can behave very differently in sealing or fatigue applications.[1]

Rz measures the vertical distance between the highest peak and lowest valley across a defined sampling length. Because it focuses on extremes, Rz is especially useful when:[1]

- Sealing performance is critical (hydraulic fittings, valves, pneumatic components)[1]

- Fatigue life matters (rotating shafts, springs, safety‑critical parts).[1]

A surface may pass Ra requirements but still have deep valleys that cut seals or become crack initiation sites, which Rz will expose.[1]

The most effective CNC surface finish specifications often combine Ra and Rz to balance average quality with extreme defect control.[1]

Consider a hydraulic sealing face:

- A surface with acceptable Ra could still contain a few deep tool marks that allow fluid to bypass a seal.[1]

- Adding a limit on Rz helps ensure no single valley is deep enough to compromise sealing.[1]

Best practice for critical parts:

- Use Ra as the default parameter for general surfaces.

- Add Rz requirements for sealing surfaces, bearing fits, fatigue‑sensitive regions, and any feature where leakage or cracking is unacceptable.[1]

Surface roughness can be measured using contact or non‑contact technologies, each with specific strengths, limits, and cost implications.[1]

A stylus profilometer uses a diamond‑tipped probe that drags along the surface, recording fine height deviations.[1]

- Widely used in automotive, toolmaking, and general machining.[1]

- Delivers high accuracy and aligns closely with traditional drawing specifications.[1]

Key advantages:

- Excellent for most metal parts and hardened components.

- Relatively affordable for production environments.[1]

Limitations:

- May damage soft, delicate, or coated surfaces.

- Slower on large areas and may miss tiny defects between peaks.[1]

Non‑contact methods (optical profilometry, laser scanning, white light interferometry) use light instead of a stylus to map surface topography.[1]

- Popular in aerospace, medical devices, and semiconductor manufacturing.[1]

- Capable of 3D surface mapping and highly detailed texture analysis.[1]

Key advantages:

- Completely non‑destructive, ideal for soft materials and complex geometries.

- Very fast data capture and excellent for full surface evaluation.[1]

Limitations:

- Higher equipment cost.

- Can struggle with highly reflective or transparent surfaces.[1]

Cost vs accuracy trade‑off: stylus profilometers provide cost‑effective control for most CNC parts, while advanced optical systems are justified when parts are high value, safety‑critical, or extremely complex.[1]

Different machining processes naturally produce different Ra and Rz ranges. Understanding these helps you specify realistic tolerances and avoid over‑engineering.[1]

| Machining Process | Typical Ra (µm) | Typical Rz (µm) | Notes on Finish |

|---|---|---|---|

| Turning | 1.6 – 6.3 | 6 – 32 | Heavily influenced by feed rate, tool geometry, and insert wear. |

| Milling | 0.8 – 6.3 | 4 – 25 | Higher spindle speed and proper end mills yield finer surfaces. |

| Grinding | 0.1 – 0.8 | 1 – 5 | Provides very smooth finishes suitable for functional surfaces. |

| EDM | 0.3 – 2.0 (down to 0.1 with fine finishing) | 3 – 15 | Produces a matte, textured surface ideal for molds and tooling. |

For many OEM parts, turned or milled finishes offer the best cost‑performance ratio. In contrast, grinding and fine EDM are more suitable when tight tolerance, low friction, or optical‑grade surfaces are required.[1]

Even if a machining process achieves the target Ra, some industries still require an additional finishing step for performance or appearance.[1]

Common post‑processing options:

- Polishing: Used for mirror‑like surfaces in optics, injection molds, and medical implants.[1]

- Coating (nickel, chrome, anodizing, etc.): Adds corrosion or wear resistance and can improve cleanability.[1]

- Bead blasting: Creates a uniform matte appearance for consumer housings and visible metal parts.[1]

Example: a mold core produced by EDM at approximately 0.3 µm Ra may be functionally acceptable but still require polishing to reach optical‑grade smoothness, eliminating the need for costly manual rework at the customer's site.[1]

The best CNC surface roughness is the one that meets functional requirements without adding unnecessary cost. Matching roughness to application is essential.[1]

| Application | Recommended Finish | Why It Matters |

|---|---|---|

| Hydraulic & sealing parts | Ra < 0.4 µm | Minimizes leakage risk and improves sealing reliability. |

| Aesthetic consumer parts | Brushed, blasted, or polished cosmetic finish | Prioritizes look and feel over extremely tight tolerance. |

| Medical implants | Polished < 0.2 µm, biocompatible surface | Reduces tissue irritation and improves long‑term compatibility. |

| Structural components | Higher Ra acceptable (e.g. > 1.6 µm) | Function is strength, not appearance; finish can be more economical. |

Cost insight: the smoother the finish, the more machine time, tool passes, and manual work are required—so cost rises quickly. OEM designers should always balance performance, aesthetics, and budget when specifying surface roughness.[1]

Many RFQs and drawings contain surface finish mistakes that lead to inflated quotes, supplier confusion, or rejected parts.[1]

Frequent pitfalls:

- Over‑specifying very low Ra on non‑critical surfaces, driving unnecessary polishing and cycle time.[1]

- Leaving drawings vague (“smooth finish”) and forcing suppliers to guess surface expectations.[1]

- Mixing Ra and Rz between suppliers without clarifying which parameter governs acceptance.[1]

To avoid these issues:

1. Define where fine finishes are mandatory and where a standard as‑machined finish is acceptable.

2. Use consistent roughness parameters (Ra and, if needed, Rz) for all critical features.

3. Clarify inspection methods expected at the supplier (contact profilometer, optical system, sampling rate).[1]

Good surface roughness decisions start in CAD and carry through to RFQ and production.[1]

Tips for engineering teams:

- Apply roughness symbols directly to functional surfaces: sealing faces, bearing bores, sliding rails, and mating features.[1]

- Avoid assigning ultra‑low roughness to hidden or non‑critical surfaces, which only adds cost.[1]

Tips for purchasing and sourcing:

- Ask potential suppliers what measurement equipment they use and how they report Ra/Rz.[1]

- Require clear inspection reports for critical parts rather than relying on visual checks.[1]

This design‑to‑inspection alignment helps ensure that parts not only meet dimensional tolerances, but also deliver the intended performance in real‑world conditions.[1]

A customer received parts that appeared visually smooth, yet their seals failed repeatedly in service. The existing supplier's inspection focused only on Ra.[1]

During detailed testing with both Ra and Rz on a contact profilometer, the surface met the Ra requirement, but Rz exposed deep valley defects that compromised sealing.[1]

By:

- Adjusting cutting parameters and tool selection

- Refining the finishing process to reduce Rz into the acceptable range

the sealing failures stopped, saving the customer significant warranty cost and downtime. This example illustrates why accurate measurement and correct parameters matter more than surface appearance alone.[1]

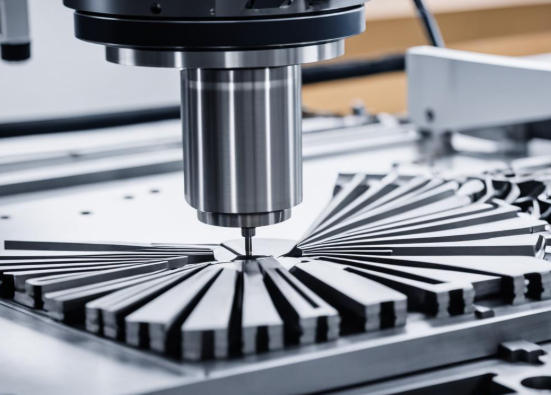

To improve engagement and understanding, consider adding:

- A diagram of surface profile showing Ra and Rz on a simplified cross‑section.

- A comparison chart of typical Ra values for turning, milling, grinding, and EDM alongside example applications.[1]

- Photos of parts with as‑machined, bead‑blasted, and polished finishes to illustrate visual differences.[1]

- A short video clip demonstrating contact vs non‑contact measurement on a sample part.[1]

These visuals help readers quickly connect abstract roughness values to the real surfaces they specify and buy.

Use this quick checklist before sending your next machining RFQ:

1. Identify critical surfaces (sealing, sliding, fatigue‑sensitive, cosmetic).

2. Assign Ra values appropriate to each functional area, avoiding blanket ultra‑tight specs.[1]

3. Add Rz limits where sealing or fatigue performance is crucial.[1]

4. Specify the measurement method and sampling plan for acceptance.

5. Decide whether parts can be shipped as‑machined, or need polishing, coating, or bead blasting.

6. Request sample parts or first‑article reports to validate your assumptions before mass production.[1]

For OEM brands, wholesalers, and manufacturers, surface roughness is not just a lab number—it is directly linked to return rates, field reliability, and customer satisfaction. A capable manufacturing partner can help interpret your requirements and suggest cost‑effective finishes instead of simply quoting whatever is drawn.[1]

Whether you need high‑precision CNC machined metal parts, plastic components, silicone products, or metal stampings, a full‑service supplier can:

- Recommend suitable processes and finishes for each material and application.

- Optimize Ra/Rz targets for performance and cost.

- Provide consistent inspection data so quality teams can track and compare batches.

If you are planning a new product launch or redesign, now is the ideal time to upgrade your surface finish strategy. Instead of treating roughness as a last‑minute detail, build it into your CAD, RFQ, and supplier selection from day one.[1]

Share your 2D drawings or 3D CAD files, and request a machining quote that includes recommended surface roughness, inspection methods, and post‑processing options tailored to your parts. This approach helps you achieve the right balance between performance, appearance, and cost on every project.[1]

Not necessarily; very low Ra requires more machining time and finishing, which increases cost without always improving performance. The best Ra is the one that meets functional needs while staying economical.[1]

Use both parameters on surfaces where sealing, fatigue life, or friction are critical, such as hydraulic faces, bearing fits, and high‑cycle components. Ra alone may miss deep scratches that Rz will reveal.[1]

Visual inspection is useful for cosmetic checks but cannot accurately quantify microscopic roughness. For technical surfaces, always use proper profilometer or optical measurement.[1]

No. Turning, milling, grinding, and EDM all create distinct textures even at similar Ra values. Process selection influences friction, coating behavior, and fatigue performance.[1]

If a surface is too rough, coatings may trap contaminants or exhibit uneven thickness; if too smooth, adhesion can suffer. Matching roughness to the coating type yields better durability and appearance.[1]