From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-16 Origin: Site

Content Menu

● What Is Custom Injection Molding

● How the Injection Molding Process Works

>> Mold Design and Engineering

>> Material Preparation and Melting

>> Injection, Packing, and Holding

● Common Materials for Custom Plastic Injection Molding

>> ABS (Acrylonitrile Butadiene Styrene)

>> Polyethylene (LDPE and HDPE)

>> TPE and TPV (Thermoplastic Elastomers and Thermoplastic Vulcanizates)

● Key Injection Molding Capabilities to Consider

>> Standard Plastic Injection Molding

>> Insert Molding and Overmolding

● Why Many OEM Brands Choose China-Based Injection Molding Partners

>> Advanced Technology and Automation

>> Cost-effective Tooling and Production

>> Customization and Flexibility

● U-NEED: Integrated OEM Partner for Injection Molding and More

>> Core Manufacturing Capabilities

>> Benefits of Working With an Integrated OEM Partner

● Practical Steps to Choose the Best Custom Injection Molding Company

>> Step 1: Clarify Requirements

>> Step 2: Shortlist Suppliers

>> Step 3: Request Quotations and DFM Feedback

>> Step 4: Review Quality System and Communication

>> Step 5: Start With a Pilot or Trial Order

● Take the Next Step With U-NEED

>> 1. What information is needed for a custom injection molding quote

>> 2. How long does it usually take to build an injection mold

>> 3. Can one supplier manage both plastic parts and metal components

>> 4. What quality certifications are important for export-oriented injection molding projects

>> 5. How can I reduce the cost of my injection molded parts

A foreign buyer searching for custom injection molding companies wants one thing: a partner that can deliver precise, reliable, and scalable parts with clear communication and predictable lead times. This in-depth guide not only explains how custom injection molding works, but also shows you how to evaluate suppliers worldwide and why partnering with a China-based OEM like U-NEED can significantly lower cost while maintaining tight tolerances and high quality.

Custom injection molding is a manufacturing process where molten plastic is injected into a precisely machined mold to create custom-shaped parts in large or small volumes. It is widely used for consumer products, automotive components, medical devices, electronics housings, and industrial parts that require repeatable accuracy and stable quality.

In modern supply chains, custom injection molding is a core technology because it supports both rapid prototyping and full-scale production, enabling brands to move from design validation to mass production without changing processes.

The injection molding process follows a repeatable cycle designed for high efficiency and consistent part quality. Understanding each step helps buyers communicate better with suppliers and avoid cost-driving design mistakes.

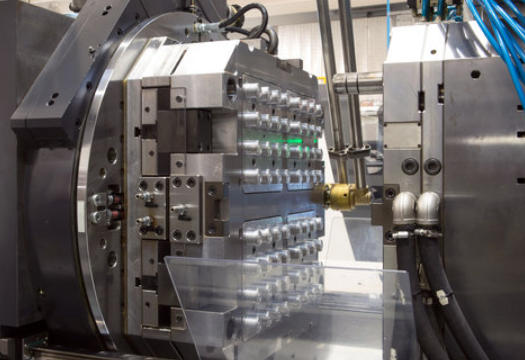

Engineers design the mold with core and cavity, runner system, cooling channels, venting, and ejection systems to match the target resin and tolerances. Proper mold design directly impacts part surface quality, dimensional stability, cycle time, and tool life.

Molds are machined from steel or aluminum using CNC machining, EDM, grinding, and precise fitting to achieve the required accuracy and polish level. Steel molds are preferred for high-volume production, while aluminum molds are often chosen for fast prototyping and lower-volume runs.

Plastic pellets are dried when needed and fed into the machine's hopper, where a rotating screw plasticizes the material in a heated barrel. Temperature, screw speed, and back pressure are tuned to ensure stable melt quality and to avoid defects such as burn marks or surface streaks.

The screw advances and injects the molten plastic into the closed mold at controlled speed and pressure. Packing and holding pressure compensate for material shrinkage, ensuring complete filling and good dimensional accuracy.

Cooling channels in the mold extract heat from the plastic until it solidifies enough to be ejected safely. Ejector pins, plates, or sleeves push the part out; poor ejection design can cause deformation, marks, or cosmetic defects.

Typical post-processing operations include gate trimming, deburring, surface finishing, printing, assembly, and functional testing. For export projects, suppliers often combine molding and downstream operations to reduce logistics steps and shorten lead times.

Choosing the right resin is as critical as the mold design itself because it defines performance, cost, and regulatory compliance. Many projects use multiple materials across different SKUs or generations of the same product.

ABS offers good impact strength and is easy to mold, making it ideal for consumer products and interior automotive components that do not require very high UV or chemical resistance. It is frequently chosen for enclosures, toys, housings, and functional prototypes due to its balance of toughness and cost.

Polycarbonate delivers high impact resistance and clarity, with a relatively high heat deflection temperature. It is often used in safety components, lighting covers, and electronic housings where transparency and toughness are required.

Polypropylene has excellent chemical resistance, fatigue resistance, and a relatively high melting point. It is commonly used in packaging, food-contact products, living hinges, and many consumer goods. Its low density and recyclability make it popular for weight-sensitive and high-volume applications.

Nylon is strong, wear-resistant, and capable of withstanding higher temperatures than many commodity plastics. It is widely used for gears, bearings, mechanical housings, and structural components. Glass-fiber-reinforced grades are often selected to increase stiffness and dimensional stability.

LDPE is flexible with a low melting point and is ideal for films, soft packaging, and flexible components. HDPE is more rigid and is used for containers, pipes, industrial components, and heavy-duty packaging. Both grades are common in cost-sensitive, high-volume consumer and industrial products.

TPEs combine the processability of thermoplastics with the elasticity of rubber and are suitable for grips, seals, gaskets, and soft-touch surfaces. TPVs, often based on polypropylene and EPDM rubber, provide improved compression set and durability for seals and automotive applications.

Not all custom injection molding companies offer the same technical processes, and choosing a partner with the right capability mix is crucial. The following capabilities are especially important when you plan long-term OEM cooperation.

Standard injection molding supports low-to-high volume production with a wide range of thermoplastics and thermoplastic elastomers. It is suited for most housings, covers, connectors, consumer parts, and precision mechanical components.

Two-shot or multi-shot molding processes two different materials or colors in a single cycle. This is ideal for soft-touch surfaces, integrated seals, or multi-color branding in one part. It reduces assembly operations and improves the bond strength between materials.

Insert molding encapsulates metal, ceramic, or other inserts within the plastic to create integrated assemblies with better durability and reduced assembly time. Overmolding adds a secondary material layer over an existing substrate, enhancing ergonomics, sealing, or aesthetics.

Cleanroom molding is required for medical, optical, and certain electronics parts where particulate control and cleanliness are critical. These projects are usually supported by appropriate certifications and traceability systems.

Advanced processes such as gas-assist injection molding, micro-molding, and other specialized methods can be used to hollow out thick sections, reduce warpage and sink marks, or produce very small and precise components. These technologies are especially important for high-end consumer electronics, automotive, and medical applications.

Over the past decade, China has become a global hub for OEM injection molding services due to a combination of cost, capacity, and technical depth. For foreign brands and wholesalers, the right China partner can deliver both price advantages and strong engineering support.

Many Chinese mold makers and molding factories use digital design tools, high-speed CNC machining, EDM, and automated handling to build and run complex molds efficiently. This allows them to handle tight-tolerance parts, multi-cavity tools, and complex geometries at scale.

Lower labor and overhead costs often translate into more competitive mold and part pricing compared with suppliers in high-cost regions. For long-running projects, even modest per-part savings become substantial over large volumes.

Chinese OEMs are known for flexible production models, supporting prototypes, bridge tooling, and full-scale production in the same or closely linked facilities. This flexibility is especially valuable for brands that frequently iterate designs or manage multiple SKUs across different markets.

For foreign brands, wholesalers, and manufacturers seeking a one-stop OEM partner, U-NEED offers more than just plastic injection molding. U-NEED combines several key manufacturing technologies under one service system to support complex, multi-material products.

U-NEED specializes in:

- High-precision machined parts

- Plastic product manufacturing

- Silicone product manufacturing

- Metal stamping production

By combining these processes, U-NEED can support projects that require both mechanical performance and refined appearance, from structural metal parts to precise plastic housings and soft-touch silicone components.

By working with U-NEED, customers can:

- Consolidate suppliers and integrate metal, plastic, and silicone parts into coherent assemblies.

- Shorten development cycles through unified engineering communication and design-for-manufacturing support across multiple processes.

- Optimize cost through coordinated process selection, material planning, and packaging solutions tailored for export.

This integrated model is particularly suitable for brands and manufacturers that need stable quality across multiple part categories while controlling total cost and lead time.

Buyers are more confident when they have a clear, actionable checklist for selecting their long-term manufacturing partner. The following steps can be used directly when screening and comparing suppliers.

- Define part function, operating environment, expected lifetime, and any regulatory requirements.

- Prepare 2D drawings, 3D models, and basic tolerance expectations for key features.

- Decide whether you need only molded parts or also assembly, packaging, labeling, and logistics support.

- Look for companies with process capabilities that match your project, such as insert molding, overmolding, cleanroom molding, or multi-cavity tools.

- Check industries served, example projects, and references that are similar to your product category.

- Evaluate whether the supplier can provide engineering support and design input or only pure manufacturing.

- Send the same data set to each supplier: drawings, 3D files, estimated volumes, target material, and expected delivery dates.

- Ask for design-for-manufacturing suggestions, gating and parting line proposals, and estimated mold life.

- Compare not only price but also the level of technical detail and risk analysis included in each quotation.

- Request sample inspection reports and information about incoming and in-process inspection methods.

- Evaluate responsiveness, clarity of communication, and willingness to share technical explanations.

- Clarify responsibilities for mold maintenance, design changes, and long-term support.

- Begin with a pilot order to validate part quality, logistics, and communication flow.

- Use this phase to refine tolerances, packaging, labeling, and documentation for future mass production.

- Once performance is proven, expand cooperation to additional SKUs or related components.

If you are a brand owner, wholesaler, or manufacturer looking for a reliable custom injection molding company that can also provide high-precision machined parts, silicone products, and metal stamping, U-NEED is ready to support your project from concept to mass production. By integrating multiple manufacturing processes, U-NEED helps you simplify your supply chain, enhance product quality, and control cost for global markets.

Send your 3D drawings, basic specifications, and estimated volumes to U-NEED today to receive a professional design-for-manufacturing review and a targeted OEM quotation tailored to your custom injection molding and related component needs.

You should prepare 3D CAD files, 2D drawings with key tolerances, estimated annual volume, target material, and any special surface or regulatory requirements. The more complete the information, the more accurate and reliable the quotation will be.

Lead times typically range from a few weeks to around two months, depending on mold complexity, cavity count, steel selection, and design changes during development. Simple prototype tools are faster, while high-cavitation production molds require more time.

Yes, many integrated OEM suppliers can handle plastic injection molding, CNC machining, and metal stamping under one project team. This approach helps reduce communication steps, speeds up development, and ensures better fit between different components.

For most industrial and consumer parts, recognized quality certifications and documented procedures are important. Automotive and medical projects may require higher-level systems and more detailed traceability, so it is essential to confirm that the supplier's quality system matches your industry.

Cost can be reduced through optimized part design, suitable material selection, higher cavity molds for large volumes, and consolidating multiple small parts into a single molded component where possible. Early design-for-manufacturing reviews are one of the most effective ways to control long-term cost.

[1] https://www.moldingdynamics.net/blog/complete-guide-to-custom-molding-solutions

[2] https://plasticpartsinc.com/custom-injection-molding-precision-plastic-components

[3] https://toolbox.igus.com/10143/what-is-injection-molding

[4] https://www.ptsmake.com/what-is-plastic-injection-molding-and-how-does-it-work/

[5] https://www.imtecmould.com/news/industry-news/top-10-plastic-injection-molding-companies-in-china-2025-guide.html

[6] https://www.china-plasticparts.com/a-best-china-injection-mold-makers-for-oem-orders.html

[7] https://plasticpartsinc.com/custom-injection-molding-precision-plastic-components

[8] https://www.tedesolutions.pl/en/blog/injection-molding-machines-guide

[9] https://www.jaycon.com/injection-moulding-price-a-2025-guide-for-engineers-procurement/

[10] https://sungplastic.com/project/china-plastic-injection-mold-manufacturer/