From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Loretta Publish Time: 2025-12-25 Origin: Site

Content Menu

● What Is EDM Micro Hole Machining

● Why Micro Holes Matter in Modern OEM Manufacturing

● Extreme Precision for Demanding Components

● EDM Micro Hole Machining vs Laser Drilling

>> EDM vs Laser for Micro Holes

● U-NEED's OEM Manufacturing Capabilities

● Process Fundamentals of EDM Micro Hole Machining

>> Ultra-Fine Electrode Technology

>> Precision Positioning and Motion Control

>> Advanced Discharge Circuit Control

● Productivity, Electrode Wear, and Cost Considerations

● Micro Holes in Medical, Electronics, and Aerospace Applications

● Integrating EDM Micro Holes with Plastic, Silicone, and Metal Stamping

● Project Support for Overseas OEM Clients

● Where EDM Micro Hole Machining Is Most Effective

● Clear Call to Action for OEM Partners

● FAQs

>> Q1. What is the typical size range for EDM micro holes

>> Q2. Which materials are compatible with EDM micro hole machining

>> Q3. How does EDM micro hole machining influence surface finish

>> Q4. Can both prototypes and mass production be supported

>> Q5. How should designers decide whether to use EDM micro hole machining

Electric discharge machining (EDM) micro hole drilling is transforming how high-precision parts are produced for medical, electronics, fiber optics, and aerospace applications. As a China-based OEM partner, U-NEED combines advanced EDM micro hole machining with plastic, silicone, and metal stamping capabilities to help overseas brands achieve higher accuracy, reliability, and speed in mass production.

EDM micro hole machining is a non-traditional machining process that uses electrical discharges between an electrode and a conductive workpiece to create extremely small and precise holes. Unlike conventional drilling, it does not rely on cutting forces, which allows manufacturers to produce holes below 0.01 inch in diameter with excellent positional accuracy and surface finish.

Key characteristics include:

- Ability to create holes in very hard or brittle materials such as carbide or high-alloy steels.

- Minimal mechanical stress on workpieces, which reduces deformation at micro scales.

- High repeatability for multiple-hole arrays in complex components.

For overseas OEM buyers, this means performance-critical components can meet strict dimensional and functional requirements even at extremely small sizes.

As products become smaller, lighter, and more integrated, demand for precision micro holes has grown rapidly across several industries. These tiny features often control fluid flow, optical alignment, or electrical performance, so small deviations can lead to major functional failures.

Typical applications of EDM micro hole machining include:

- Fiber optic connectors and communication components requiring ultra-small alignment holes.

- Medical devices with micro fluid channels and precise orifices to control flow and dosage.

- Aerospace and engine components using cooling holes and micro nozzles in high-temperature environments.

- High-density electronics, sensors, and micro-mechanical parts where space is extremely limited.

By integrating EDM micro hole capabilities with plastic, silicone, and metal stamping services, U-NEED supports clients who need both micron-level features and cost-effective mass production in a single supply chain.

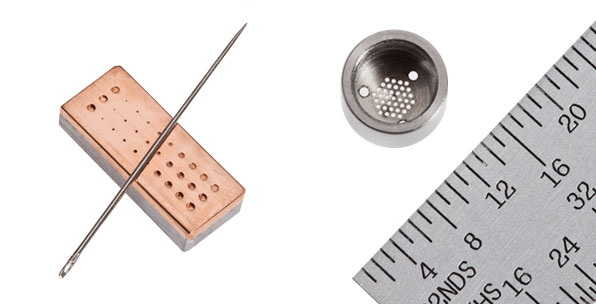

In the EDM industry, pushing the limits of the smallest achievable hole has long been a benchmark of technological capability. Demonstrations have shown finished hole diameters on the order of a few ten-thousandths of an inch using ultra-fine electrodes and specialized EDM technology.

From an OEM perspective, what really matters is how such capabilities translate into consistent, scalable production:

- Tight diameter control within micro-level tolerances demonstrates the upper limit of precision that can be offered.

- High pitch location accuracy enables dense hole arrays for filters, nozzles, or optical parts.

- Stable performance on thin sections supports ultra-light components used in advanced devices.

U-NEED leverages this level of micro machining know-how to design OEM solutions that balance what is technically possible with what is economically viable at production scale.

When designing high-precision parts, many engineers compare EDM micro hole machining with laser drilling. Each technology has strengths, but EDM often delivers superior results when tolerances and surface quality are critical.

Aspect | EDM Micro Hole Machining | Laser Drilling |

Material impact | No mechanical cutting forces and localized thermal effect. | Larger heat-affected zones may occur depending on settings. |

Hole roundness | Very good roundness and straightness at extreme micro scales. | Roundness may vary on very small diameters. |

Edge quality | Smooth edges with high-quality surface finish. | Possible micro cracks or recast layers that may need finishing. |

Tolerance capability | Extremely tight dimensional and positional tolerances. | Good but often less consistent at the smallest sizes. |

Best use cases | Medical, optics, microfluidics, and high-value aerospace parts. | Applications where speed outweighs ultra-high precision. |

For OEM buyers whose components must pass rigorous quality audits, EDM micro hole machining often becomes the preferred choice when reliability and consistency outweigh pure cycle time.

U-NEED acts as a full-service OEM partner for overseas brands, wholesalers, and manufacturers seeking integrated precision solutions. This approach supports both high-mix, low-volume projects and stable long-term mass production.

Core capabilities include:

- High-precision machined components with complex geometries and tight tolerances.

- Plastic product manufacturing using injection molding for consumer, industrial, and medical applications.

- Silicone product manufacturing for seals, gaskets, keypads, and custom elastomer components.

- Metal stamping production for sheet metal parts, brackets, terminals, and structural components.

By combining these services, U-NEED can supply components that incorporate micro EDM features alongside plastic or metal structures, reducing supplier fragmentation and simplifying project management.

EDM micro hole drilling relies heavily on electrode technology, discharge control, and precision motion systems. Modern micro EDM systems incorporate key innovations that can be integrated into OEM process engineering.

Electrode design is crucial for micro-scale EDM.

- Electrodes can be manufactured in extremely small diameters using suitable materials such as silver tungsten or fine copper.

- Automatic electrode dressing technology helps keep the electrode diameter stable during machining, improving repeatability and reducing manual adjustments.

Accurate motion systems support high-density micro hole patterns.

- High-speed, high-accuracy spindles provide micron-level control over electrode positioning.

- Precision axis systems maintain pitch accuracy and compensate for minor movements, even over long machining cycles.

The electrical discharge itself must be carefully managed.

- Ultra-precision discharge circuits regulate the spark energy and stabilize the gap between electrode and workpiece during micro machining.

- Optimized parameter sets allow balancing electrode wear, machining speed, and target surface finish for different materials.

These process elements enable the development of machining strategies that are repeatable, scalable, and tailored to the specific needs of each OEM project.

EDM micro hole machining involves a trade-off between machining time per hole, electrode wear, and overall cost per part. Understanding these factors helps OEM buyers make realistic decisions about design and production.

Typical reference points from industry demonstrations include:

- Machining times on the order of tens of seconds per micro hole under optimized conditions.

- Complex test parts with more than a thousand micro holes requiring several hours of continuous machining.

- Electrode wear that may reach significant levels on extreme micro features, underlining the need for smart electrode management.

A collaborative engineering approach makes it possible to:

- Define practical tolerances and surface roughness targets for each application.

- Optimize machining parameters to reduce cycle time while maintaining quality.

- Evaluate where micro EDM is essential and where standard machining, molding, or stamping may be more economical.

Many industries depend on micro-scale features that must perform reliably over long lifetimes. EDM micro hole machining has become an important enabler for several key sectors.

Applications include:

- Medical devices that require precision orifices, micro channels, and burr-free edges for safe and predictable performance.

- Electronics, sensors, and optical components where micro holes influence alignment, signal integrity, or environmental protection.

- Aerospace and related fields using small cooling holes, fuel system channels, and high-temperature nozzles.

Combining these capabilities with plastic and silicone manufacturing enables the development of assemblies where metal micro components work together with molded and elastomer parts.

Integrated production can significantly reduce cost and lead time compared with using separate suppliers for each process. Coordinated design from the start allows engineers to create parts that are optimized both for function and manufacturability.

Typical integration strategies include:

- Designing metal inserts with micro holes that are later overmolded with plastic or silicone housings.

- Using stamped metal frames that incorporate critical micro machined features only where necessary.

- Creating multi-component assemblies where micro EDM parts, silicone seals, and plastic covers are produced under one quality system.

This unified approach improves communication, shortens development cycles, and enhances traceability across the entire component lifecycle.

Long-term OEM partnerships benefit from structured support at every stage, from concept to mass production. A clear workflow helps ensure that functional and quality targets are met.

1. Engineering consultation

2. Prototype and sampling

3. Process validation

4. Mass production and logistics

At each stage, technical feedback, dimensional data, and process optimization are used to align expectations with actual manufacturing performance.

Not every small feature requires EDM, so careful selection of the manufacturing method is important. EDM micro hole machining is particularly effective when:

- Hole diameters are very small and beyond the limit of conventional drills.

- The workpiece material is very hard or difficult to machine by conventional means.

- Hole location accuracy, roundness, and surface finish have a direct impact on function.

In other cases, standard drilling, punching, or molding may provide sufficient quality at lower cost, especially for less demanding components.

Overseas brands, wholesalers, and manufacturers that require high-precision components with micro-scale features can benefit from a manufacturing partner capable of integrating micro machining, molding, silicone processing, and metal stamping. For new projects, drawing reviews, or process feasibility evaluations, you can share technical requirements, target volumes, and application scenarios to receive a tailored proposal focused on precision, stability, and long-term cooperation.

In practical OEM projects, EDM micro holes are often used for diameters below approximately 0.01 inch, particularly when conventional drilling becomes unreliable or unstable. The exact achievable size depends on material, geometry, and tolerance requirements.

EDM is suitable for conductive materials, including various tool steels, stainless steels, carbides, and many high-temperature alloys. Non-conductive materials such as plastics and silicone are usually combined with micro machined metal inserts in complete assemblies.

With properly optimized parameters, EDM micro hole machining can produce fine surface finishes and very clean edges that are essentially free of burrs. This is especially valuable for fluid channels, nozzles, and optical components.

The same process principles can be applied from prototype to volume production using consistent process controls and quality systems. Parameter tuning and tooling optimization are typically performed during early stages to ensure stable production at scale.

Designers usually consider EDM when feature sizes are very small, tolerances are strict, materials are difficult to machine, or when product performance depends directly on hole quality. When such conditions are not present, other processes may be evaluated as alternatives.

content is empty!