From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-21 Origin: Site

Content Menu

● Why 3D Printing Is No Longer “Just for Prototypes”

● From Prototype to Production: The Typical Workflow

>> Stage 1 – Concept Models and Design Validation

>> Stage 2 – Functional Prototypes and Engineering Tests

>> Stage 3 – Pilot Runs and Bridge Production

>> Stage 4 – Scaling to Full Production

● Core Benefits of 3D Printing from Prototype to Production

>> Speed, Cost, and Flexibility

>> Design Freedom and Part Performance

>> Sustainability and Material Efficiency

● 3D Printing vs Traditional Manufacturing in Production

>> When 3D Printing Is the Better Production Choice

>> When CNC Machining, Molding, or Stamping Wins

>> At‑a‑Glance Comparison for OEM Projects

● Key 3D Printing Technologies Along the Journey

>> FDM/FFF – Cost‑Effective Prototypes and Fixtures

>> SLA/DLP – High Detail and Smooth Surfaces

>> SLS/MJF – Robust Nylon Parts for Functional Use

>> Metal 3D Printing – High‑Value Components

● Real‑World Use Cases: From Prototype to Production

>> Automotive and Industrial Equipment

>> Consumer Products and Wearables

● How to Decide If 3D Printing Can Handle Your Production

● Practical Design Tips for Production‑Ready 3D Printing

● Market Trends: Why 3D Printing Adoption Keeps Growing

● How an OEM Partner Combines 3D Printing with Other Processes

● Call to Action: Plan Your Prototype‑to‑Production Roadmap with U‑NEED

● FAQs

>> FAQ 1: Can 3D printing handle real production runs

>> FAQ 2: When should I switch from 3D printing to molding or stamping

>> FAQ 3: What materials are available for production‑grade 3D printing

>> FAQ 4: How does 3D printing affect time‑to‑market

>> FAQ 5: Do I need different designs for 3D printing and injection molding

From prototype to production, 3D printing has evolved into a powerful, production‑ready technology that helps OEM brands shorten lead times, reduce risk, and launch better products with greater design freedom. When combined with traditional processes such as CNC machining, injection molding, silicone molding, and metal stamping, it becomes a flexible manufacturing toolbox rather than a standalone solution.

This article explains how 3D printing from prototype to production works in real projects, how it compares to conventional manufacturing, and how overseas OEM buyers can use it strategically with a partner like U‑NEED. It includes practical steps, recent market data, application examples, and tips on integrating 3D printing with other processes for scalable production.

3D printing has moved from simple concept models to end‑use parts in automotive, aerospace, healthcare, industrial equipment, and consumer products. This shift is driven by better materials, more reliable printers, and falling per‑part costs for low and medium volumes.

Key reasons it now supports production:

- Faster time‑to‑market by avoiding tooling and enabling rapid design iterations.

- Complex geometries such as internal channels and lattice structures that are difficult or impossible with subtractive methods.

- Mass customization, allowing brands to tailor products to different users, markets, or SKUs without new molds.

- Lower material waste, because additive processes deposit only what is needed.

These strengths make 3D printing a logical bridge between early prototypes and stable, repeatable production for many OEM projects.

A successful “prototype‑to‑production” journey with 3D printing usually follows clear stages. Each stage can be handled by one integrated supplier to keep quality and communication consistent.

Early in development, brands use 3D‑printed concept models to visualize designs, validate ergonomics, and align stakeholders.

Typical goals:

- Check size, proportions, and basic usability.

- Review aesthetics with marketing and industrial design teams.

- Identify obvious design issues before investing in engineering.

At this phase, fast, low‑cost plastics such as PLA or basic resins are often enough, because the focus is on form, not long‑term function.

The next step is functional prototyping, where engineers test performance, assembly, and environmental behavior under realistic loads.

Common activities:

- Printing parts in engineering plastics or composite materials that simulate final mechanical properties.

- Testing snap‑fits, threads, and assemblies with mating components.

- Evaluating thermal, chemical, or fatigue performance when needed.

At this stage, brands may also combine 3D‑printed parts with CNC‑machined metal or plastic components to get closer to final product behavior.

Once the design is nearly frozen, many OEMs run pilot batches using 3D printing as a bridge before full tooling.

This bridge production helps to:

- Supply early units for field trials, certifications, and beta testers.

- Validate packaging, logistics, and assembly processes.

- Collect feedback before committing to expensive molds or high‑volume machining programs.

For low to medium volumes, some projects remain on 3D printing indefinitely, especially when demand is uncertain, SKUs change often, or geometry is too complex for traditional tooling.

When demand stabilizes, brands decide whether to:

- Keep using 3D printing for end‑use production,

- Shift to CNC machining, injection molding, silicone molding, or metal stamping, or

- Use a hybrid approach where 3D printing covers certain components while conventional processes handle others.

An experienced OEM partner can recommend the most cost‑effective path based on annual volume, tolerances, materials, and lifecycle expectations.

3D printing delivers value throughout the product lifecycle, from early ideas to mass production support.

- Rapid iteration: Design changes can be implemented within hours or days instead of weeks, accelerating validation and reducing engineering change costs.

- No tooling costs: There is no need for molds or dies, which is a major advantage for low‑volume or frequently updated products.

- On‑demand manufacturing: Parts can be produced when needed, supporting lean inventory and shorter cash cycles.

3D printing enables topology optimization, internal channels, and lattice structures that reduce weight while maintaining strength. These features are especially valuable for:

- Lightweight brackets and fixtures in automotive and aerospace.

- Heat‑exchanger components with complex internal passages.

- Medical and wearable products that need organic shapes and variable thickness.

Because additive manufacturing builds parts layer by layer, it typically uses less raw material than machining from solid stock, which reduces waste. On‑demand, localized production can also lower transport emissions by producing parts closer to final use in some supply chains.

3D printing does not replace traditional methods; it complements them. The best choice depends on volume, tolerances, materials, and part geometry.

3D printing is particularly strong when:

- Annual volumes are low to moderate and do not justify expensive tooling.

- Parts require complex internal features or lightweight lattice structures.

- Product lines change frequently and require agile updates.

- Customization or personalization is part of the value proposition.

Conventional processes often win when:

- Volumes are high, so tooling costs are spread over many parts.

- Very tight tolerances or specific surface finishes are critical.

- Materials are not yet well supported by 3D printing.

- Per‑unit cost in mass production becomes the primary driver.

The most competitive OEM strategies combine 3D printing for agile development and bridge production with CNC, molding, or stamping for mature, high‑volume runs.

| Aspect | 3D Printing (Additive) | CNC / Molding / Stamping |

|---|---|---|

| Upfront tooling cost | Very low or none; ideal for iteration and low volume. | High for molds/dies; efficient at scale. |

| Lead time | Fast for prototypes and small batches. | Longer at start due to tooling; very fast per part later. |

| Design complexity | Excellent for internal channels, lattices, organic shapes. | Limited by tool access and draft angles. |

| Unit cost (high volume) | Higher for large runs in many cases. | Lower for mass production once tooling exists. |

| Customization | Very strong; one‑off or variable parts cost similar. | Limited; each variation may need new tooling. |

| Material utilization | High; minimal waste. | More waste from subtractive cuts or sprues/runners. |

Selecting the right technology is essential for moving smoothly from prototype to production.

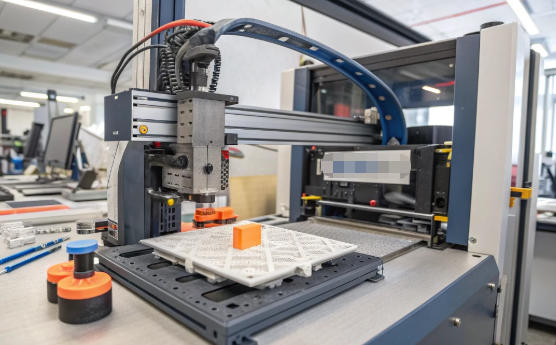

Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), extrudes thermoplastic filament layer by layer.

- Best for: Early prototypes, jigs and fixtures, basic enclosures, low‑stress parts.

- Materials: PLA, ABS, PETG, nylon, and some fiber‑reinforced filaments.

- Strengths: Low cost, fast turnaround, wide material availability.

Stereolithography (SLA) and Digital Light Processing (DLP) cure liquid resin with light to create very fine features and smooth surfaces.

- Best for: Aesthetic prototypes, detailed housings, medical and dental models.

- Materials: Standard resins, engineering resins, biocompatible resins.

- Strengths: Excellent surface finish and fine detail; good for visual and fit testing.

Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF) fuse nylon powder into tough, functional parts.

- Best for: Functional prototypes, clips, brackets, housings, and small‑batch production.

- Materials: Nylon 12, Nylon 11, and filled variants with improved stiffness or heat resistance.

- Strengths: Strong, isotropic parts, no support structures, good for nested builds and series production.

Metal processes such as Powder Bed Fusion are used for high‑value, complex metal parts.

- Best for: Lightweight aerospace parts, optimized heat exchangers, and complex tooling inserts.

- Strengths: Combines performance metals with complex geometries for significant weight and performance gains.

Automotive and industrial firms use 3D printing for prototypes, jigs, fixtures, and end‑use components.

- Grippers and brackets on assembly lines produced via SLS/MJF.

- Custom fixtures that improve safety and reduce changeover times.

- Low‑volume spare parts for legacy equipment without available tooling.

In consumer goods, 3D printing enables personalized and short‑run products.

- Customized wearables and eyewear based on user measurements.

- Limited‑edition accessories and smart‑device housings with unique geometries.

- Short‑run product launches tested via 3D printing before committing to mass tooling.

Medical applications include patient‑specific models, surgical guides, and custom devices.

- Anatomical models from scan data for pre‑operative planning.

- Dental and orthodontic components built from accurate 3D scans.

- Patient‑specific implants and orthotics with complex internal structures.

OEM brands should evaluate a short checklist before committing to production with 3D printing.

Important questions:

1. What is the realistic annual volume? Low and medium volumes are often a strong fit for 3D printing, especially when designs change.

2. What tolerances and surfaces are required? Many 3D printing processes can hit practical tolerances, but ultra‑tight fits may still require secondary machining.

3. Which materials and certifications are needed? Ensure the chosen process supports mechanical, thermal, and regulatory requirements.

4. How often will the design change? More frequent changes favor additive manufacturing because there is no tooling to modify.

A hybrid approach is often best: validate with 3D printing, then migrate selected parts to CNC, molding, silicone molding, or stamping as volumes grow.

Designing correctly for additive manufacturing helps avoid rework when moving from prototypes to real production.

Useful guidelines:

- Respect minimum feature sizes and wall thicknesses published for the chosen technology.

- Optimize for build orientation to balance strength, surface quality, and support removal.

- Consolidate parts where possible to reduce assembly steps and potential leak paths.

- Plan post‑processing (machining, polishing, coating) early to hit final tolerances and appearance goals.

Working with a manufacturing partner that offers both design‑for‑additive guidance and traditional manufacturing guidance ensures a smoother transition later.

The global 3D printing market is expanding rapidly, with steady double‑digit growth rates in the coming years. Growth comes from:

- Deeper integration of additive manufacturing into long‑term production strategies.

- Increased use in automotive, aerospace, healthcare, and consumer goods.

- Advances in printers, materials, and software that push 3D printing from prototype to production at scale.

For OEM buyers, this means more suppliers, better technology, and a wider choice of materials and finishes for production‑grade parts.

For overseas brands, working with a one‑stop OEM supplier that offers 3D printing alongside CNC machining, plastic injection molding, silicone molding, and metal stamping can dramatically simplify projects.

Benefits of this integrated approach:

- Single engineering team managing prototypes, bridge runs, and mass production.

- Consistent quality systems and inspection methods across different processes.

- Scalable capacity, moving from small batches to large orders without changing suppliers.

A manufacturer like U‑NEED can help evaluate whether a part should stay on 3D printing or transition to traditional methods as volumes and requirements evolve.

If you are evaluating 3D printing from prototype to production for your next OEM project, you need both technical advice and practical manufacturing options. A partner that offers 3D printing together with CNC machining, plastic and silicone molding, and metal stamping can guide you from early concept models through bridge production and full‑scale manufacturing.

Share your 3D files, drawings, or samples with U‑NEED's engineering team to receive a detailed manufacturability review and quotation, including clear suggestions on where 3D printing makes sense and where traditional methods may reduce cost or improve durability. This integrated approach helps you reduce risk, accelerate product launches, and build a robust production strategy that can grow with your business.

Contact us to get more information!

Yes, many companies now use 3D printing for end‑use parts, particularly in low to medium volumes, customized products, or high‑complexity components where tooling is expensive or unnecessary.

You should consider switching when annual volumes are high, designs are stable, and per‑unit cost in mass production outweighs the initial tooling investment. An experienced OEM partner can model total cost of ownership for both paths.

Production applications commonly use engineering plastics like nylon and high‑performance resins, as well as various metal alloys for demanding components in aerospace, automotive, and medical devices.

3D printing shortens time‑to‑market by eliminating tooling lead times and enabling rapid iteration, pilot batches, and on‑demand manufacturing. This helps teams test more concepts and lock designs earlier.

Often yes; designs optimized for additive manufacturing may not be ideal for injection molding due to draft angles, wall thickness constraints, and gate locations. Planning for both additive and conventional manufacturing early makes later transitions much smoother.

1. https://uptivemfg.com/from-prototype-to-production-how-3d-printing-revolutionizes-manufacturing/

2. https://artiluxnmf.se/blog/from-prototype-to-production-integrating-3d-printing-into-modern-manufacturing/

3. https://www.repurvis.com/articles/7-benefits-3d-printing-prototype

4. https://www.protolabs.com/en-gb/resources/blog/the-benefits-of-3d-printing-for-rapid-prototyping/

5. https://www.4mmfg.com/the-benefits-of-3d-technology-in-pre-production/

6. https://ultimaker.com/learn/3d-printing-in-manufacturing-complete-guide-to-industry-3d-printers-and-applications/

7. https://ieee-icit2021.org/blog/revolutionizing-manufacturing-the-impact-of-3d-printing-and-additive-manufacturing

8. https://www.marketsandmarkets.com/Market-Reports/3d-printing-market-1276.html

9. https://www.researchandmarkets.com/reports/5313739/3d-printing-market-global-forecast-2026-2032

10. https://finance.yahoo.com/news/3d-printing-market-reach-usd-140500881.html