From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-29 Origin: Site

Content Menu

● What Is GD&T in CNC Machining?

● Why GD&T Matters for Precision CNC Manufacturing

● GD&T vs Traditional Dimensioning in CNC

● Core Building Blocks: Datums, Feature Control Frames, Tolerance Zones

>> Datums: The Functional Reference Anchors

● Key GD&T Symbols Used in CNC Machining

● GD&T in Real CNC Production: Metals, Plastics, Silicone, Stamping

● How GD&T Affects Cost, Lead Time, and Scrap

● Best Practices for Applying GD&T in CNC Projects

● Step-by-Step: How a Supplier Uses GD&T in a CNC Project

● Common Mistakes in Applying GD&T (and How to Avoid Them)

● Advanced Trend: Model-Based Definition and Digital GD&T

● Partner With a GD&T-Capable Manufacturing Expert

● FAQs on GD&T in CNC Machining

>> 1. Do I need GD&T for every part?

>> 2. What is the difference between true position and concentricity?

>> 3. How does GD&T affect CNC machining cost?

>> 4. How is GD&T inspected in practice?

>> 5. Can GD&T be applied to plastic and silicone parts, not just metals?

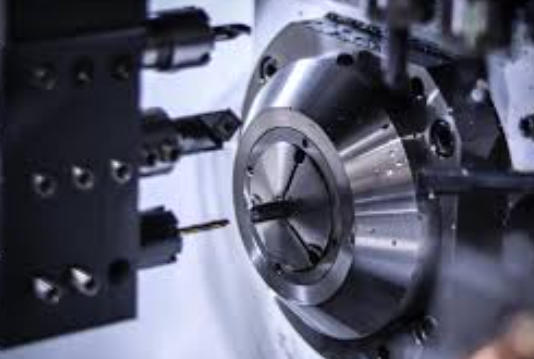

Geometric Dimensioning and Tolerancing (GD&T) is the engineering language that connects design intent with real-world CNC machining, inspection, and assembly performance. When used correctly, it cuts costs, reduces scrap, and ensures that every part from prototype to mass production fits and functions as designed.

GD&T (Geometric Dimensioning and Tolerancing) is a symbolic system that defines the allowable variation in a part's form, orientation, and location so that it functions correctly in its final assembly. Instead of vague notes like “make this hole straight,” GD&T specifies how straight, how flat, and how aligned each feature must be relative to datums.

In modern CNC machining, where tolerances are often in microns, this shared “tolerance language” eliminates guesswork between designers, machinists, and quality engineers. It is standardized globally through ASME Y14.5 and ISO 1101, making drawings readable across countries, suppliers, and industries.

For high-precision metal machining, plastic molding, silicone products, and metal stamping, GD&T directly affects cost, lead time, and reliability.

Key business benefits include:

- Fewer misinterpretations between design, CNC programming, and inspection teams.

- Lower manufacturing cost by applying tight tolerances only where function demands it.

- Higher assembly yield because mating parts are controlled by functional relationships, not just size.

- Better alignment across global suppliers, especially important for OEMs outsourcing to manufacturing partners in different regions.

For example, a bolt-hole pattern defined by GD&T true position relative to datums is easier to machine and inspect consistently than the same pattern defined only with linear plus/minus dimensions.

The table below highlights the differences between traditional dimensioning and GD&T in practical CNC projects.

| Aspect | Traditional ± Dimensioning | GD&T in CNC Machining |

|---|---|---|

| Communication | Text notes and linear dimensions; interpretations vary by person. | Symbol-based, standardized language understood across design, machining, and inspection. |

| Functional intent | Focuses on size and simple location only. | Controls form, orientation, position, and profile based on how parts assemble and move. |

| Accuracy control | May allow hidden variation that causes misfit or binding. | Defines explicit tolerance zones (cylindrical, circular, profile) tied to datums. |

| Cost impact | Often uses overly tight, non-functional tolerances that raise cost and scrap. | Enables controlled variation where it does not affect function, making parts more economical. |

| Inspection | Inspectors may measure features differently, leading to disputes. | Datum reference frames and feature control frames standardize how to measure each feature. |

| Best use cases | Simple parts with generous tolerances and low risk. | High-precision CNC components in aerospace, automotive, medical, and industrial equipment. |

A datum is an ideal reference plane, axis, or point used as the starting “zero” for critical measurements on the part. In practice, designers choose datum features that match how the part will be assembled or located in the final product.

- Primary, secondary, and tertiary datums simulate the three-point contact of real fixtures or mating surfaces.

- Good datum selection makes setups stable on CNC machines and repeatable in quality inspection.

Feature control frames are rectangular boxes on a drawing that contain:

- The GD&T symbol, such as position, flatness, or perpendicularity

- The tolerance value and any modifiers

- The datum references that define the tolerance zone

A feature control frame tells machinists and inspectors exactly how much deviation is allowed and relative to which datums, turning design intent into clear and measurable criteria.

GD&T defines tolerance zones as three-dimensional regions, such as cylindrical, circular, planar, or profile zones, within which the feature's surface or axis must remain.

Typical examples include:

- A cylindrical zone around the theoretical axis for hole position

- Two parallel planes between which the entire surface must lie for flatness

- A three-dimensional band around a nominal surface for profile

This zone-based approach mirrors how assemblies work in reality: pins must enter holes, shafts must rotate without vibration, and covers must seal evenly.

Although GD&T includes many symbols, several are especially important for CNC metal parts, plastic components, silicone seals, and stamped parts.

| Symbol | Name | What It Controls | Typical CNC Application |

|---|---|---|---|

| ⟂ | Perpendicularity | Angular relationship between features and a datum. | Keeping holes square to a base plate or housing for accurate assembly. |

| ⌖ | Position (True Position) | Location of axes or features relative to datums within a tolerance zone. | Bolt circles on flanges, connector holes in enclosures, bearing bores. |

| ◎ | Concentricity | Alignment of feature axes to a datum axis. | Shafts in bearings, rollers, rotary tools where runout must be minimized. |

| ∥ | Parallelism | Parallel alignment between surfaces or axes. | Sliding guides, linear rails, parallel sealing faces on plastic or metal parts. |

| ⌒ | Surface Profile | Overall shape of complex surfaces within a defined band. | Aerodynamic surfaces, ergonomic plastic housings, silicone sealing profiles. |

| ○ | Circularity (Roundness) | Roundness of a cross-section. | Turned shafts, pins, and bushings used in high-speed rotation. |

In daily CNC production, true position is the workhorse symbol for hole patterns, and profile is essential for complex three-dimensional surfaces produced by five-axis machining or precision molding.

For an OEM-focused manufacturer serving global brand owners, wholesalers, and manufacturers, GD&T is critical across different processes.

- High-precision metal machining uses GD&T to control shaft-to-bearing fits, gear alignment, and housing geometry to meet performance and noise targets.

- Plastic injection molding applies profile, position, and flatness to manage shrinkage, warpage, and snap-fit performance in housings and functional covers.

- Silicone product manufacturing relies on profile and position to manage sealing lips, gasket ribs, and medical-grade geometries where leakage or misalignment is unacceptable.

- Metal stamping depends on flatness, position, and burr control so that stamped parts assemble smoothly in automotive, appliance, and industrial subassemblies.

Across these processes, a stable datum structure and robust tolerance scheme keep quality consistent even when volumes scale to tens or hundreds of thousands of pieces.

Tolerances are closely linked to setup time, machining time, inspection effort, and scrap risk.

- Tighter tolerances increase fixturing complexity, slow cutting parameters, and require more frequent inspection with coordinate measuring machines and gauges.

- Overly tight, non-functional tolerances can significantly raise cost without adding real value to the end customer.

- Function-based tolerancing uses GD&T to keep critical features tight, such as bearing seats and sealing faces, while relaxing non-critical ones.

A hole pattern dimensioned with very tight linear plus/minus tolerances may require extremely careful setups and long inspection programs, while a realistic GD&T position tolerance tied to functional datums can deliver equal assembly performance at lower cost.

Modern standards and industry experience suggest several best practices when tolerancing parts for CNC machining.

1. Start from function and assembly sequence

Identify how the part is located, clamped, and loaded in the final product, then build datum features around those surfaces.

2. Select robust datum reference frames

Use primary, secondary, and tertiary datums that are stable, accessible, and resistant to process variation.

3. Allocate tolerances where they matter most

Apply tight limits on critical fits such as bearings, seals, and sliding interfaces, and allow more generous tolerances on cosmetic or non-critical areas.

4. Keep callouts concise and standardized

Avoid ambiguous notes and follow recognized standards such as ASME Y14.5 to keep communication clear across suppliers.

5. Define an inspection plan together with the drawing

For each critical tolerance, think through how it will be measured, whether with a coordinate measuring machine, gauge, optical system, or functional test.

These practices reduce late design changes, warranty risk, and supplier disputes in complex, international OEM programs.

Below is a practical workflow that can be applied when working with a precision manufacturing partner.

1. Clarify design intent and functional requirements

Share three-dimensional models, critical interfaces, and target performance, such as leak rate, torque, noise, or dimensional stability.

2. Build a functional datum strategy

Choose datum features that mirror how the part is assembled or located in the final system, such as mounting faces or alignment pins.

3. Apply GD&T symbols to critical features

Use position for holes, profile for complex surfaces, and perpendicularity or parallelism for key faces and alignment features.

4. Align the process plan with tolerances

Match machining processes, such as three-axis machining, five-axis machining, turning, stamping, or molding, to the tolerance stack-up and risk level.

5. Create an inspection plan and sampling strategy

Define first-article inspection, in-process checks, and final inspection methods for high-risk features and assemblies.

6. Close the loop with production feedback

Use measurement data and field performance to confirm capability and adjust tolerances or processes when needed.

Even experienced engineers can misuse GD&T in ways that raise cost or create quality risks.

- Over-tolerancing everywhere

Applying very tight tolerances on non-critical geometry “just to be safe” increases scrap, lengthens cycle times, and discourages suppliers from quoting. The solution is to connect each tolerance to an actual functional requirement.

- Under-tolerancing critical interfaces

Leaving sealing faces, bearing bores, or alignment features with loose or incomplete controls can create leaks, noise, early wear, and assembly failures. Position, profile, and orientation controls should be used to lock down these interfaces.

- Confusing profile with surface roughness

Profile controls shape within a tolerance zone, while surface roughness defines texture and finish. Mixing the two leads to rework and misunderstandings. Designers should specify both when geometry and finish are important.

- Inconsistent datum schemes across revisions or parts

Changing datums late in the project without updating CNC programs and inspection plans can cause confusion and mismatched results. Once a robust datum strategy is validated, it should be kept stable and any changes should be tightly controlled.

More organizations are adopting model-based definition, in which three-dimensional CAD models carry GD&T as product manufacturing information.

- GD&T is embedded digitally, making it machine-readable for computer-aided manufacturing, coordinate measuring machines, and automated inspection systems.

- This reduces manual transcription errors and speeds up CNC programming and quality plan creation.

- For global OEM supply chains, consistent digital GD&T helps synchronize design updates across multiple factories and partners.

Starting with model-based definition on complex or high-cost parts is often an effective way to introduce digital GD&T into an engineering organization.

For overseas brand owners, wholesalers, and manufacturers, working with a supplier that understands and applies GD&T every day is critical to project success. A capable partner can:

- Review drawings and three-dimensional models to align GD&T with real functional requirements.

- Suggest optimizations that maintain performance while improving manufacturability and cost.

- Implement stable, repeatable processes for CNC machining, plastic molding, silicone production, and metal stamping based on a clear tolerancing strategy.

If you are facing repeated assembly issues, inconsistent quality across batches, or suppliers who refuse complex tolerance requirements, now is the time to upgrade your manufacturing partnership. Send your drawings and requirements to U-NEED to receive a detailed manufacturability and tolerance review along with a tailored OEM quotation, and turn your GD&T into reliable, high-precision parts that reach the market faster.

Contact us to get more information!

Not every part requires GD&T. Simple components with generous fits and low functional risk may work well with basic plus/minus tolerances. However, any assembly involving tight fits, rotation, sealing, or multi-part alignment can benefit significantly from GD&T, because it clarifies how features must relate to each other to ensure proper function.

True position controls the allowed location of a feature, often a hole or pin, relative to its datums within a defined tolerance zone. Concentricity focuses on making two axes share the same center and is typically used for rotating components such as shafts, rollers, and rotating connectors. In many practical designs, true position combined with runout controls can be more straightforward to apply and inspect than concentricity.

Well-designed GD&T can reduce cost by allowing functional tolerances instead of arbitrary, overly tight ones. When tolerances are tighter than necessary, they increase setup complexity, tool wear, and inspection time. When tolerances are matched to functional needs using GD&T, many features can be produced more efficiently while still protecting performance and reliability.

Inspection teams verify GD&T controls using tools such as coordinate measuring machines, custom gauges, optical systems, and functional tests. The chosen method depends on the feature type and the specified tolerance. Datum reference frames and feature control frames define how each measurement should be taken, which reduces interpretation differences between different inspectors and facilities.

GD&T is not limited to metals. It is widely applied to precision plastic components and silicone parts, especially when controlling profiles, positions, and sealing interfaces. In these materials, GD&T helps account for shrinkage, elastic deformation, and assembly forces, making it easier to achieve repeatable performance in demanding applications such as medical devices, consumer electronics, and automotive sealing systems.