From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Loretta Publish Time: 2025-12-25 Origin: Site

Content Menu

● What Is High-Speed Machining

● Why High-Speed Machining Matters Today

● Core Requirements for High-Speed Machining

● Machine Tool Design and Dynamic Stiffness

● Spindle Technology and Monitoring

● Cutting Tools, Coatings, and Geometry

● Toolholding and Interface Selection

● CNC Control, Look-Ahead, and Motion Planning

● Toolpath Strategies and CAM Best Practices

● High-Speed Machining in General Job Shops

● High-Speed Machining in Die and Mold Applications

● High-Speed Machining in Aerospace Components

● Latest Trends in High-Speed Machining

● Step-by-Step Roadmap for Implementing HSM

>> 1. Assess current machine capabilities

>> 2. Upgrade tools and toolholding

● How Buyers Evaluate HSM-Capable Suppliers

● Take the Next Step With a High-Speed Machining Partner

● FAQs About High-Speed Machining

>> 1. Is high-speed machining only about increasing spindle speed

>> 2. Can older machines be used for high-speed machining

>> 3. Which industries benefit the most from high-speed machining

>> 4. Does high-speed machining always reduce tool wear

>> 5. How important is CAM software for successful high-speed machining

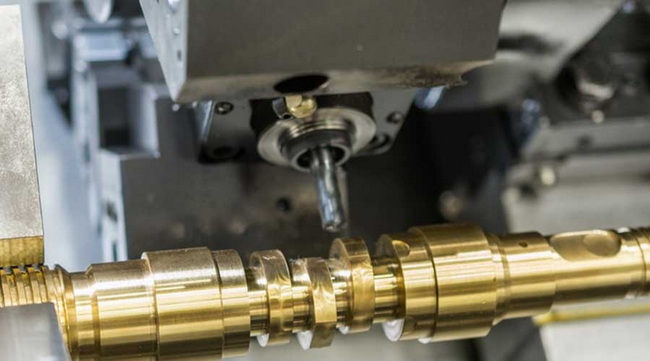

High-speed machining (HSM) is transforming how precision parts are produced, enabling faster cycle times, better surface finishes, and longer tool life across demanding industries such as die/mold, aerospace, automotive, and precision consumer products. This guide presents a structured, practical overview of HSM, with a focus on requirements, benefits, and implementation steps that support modern OEM and outsourcing needs.

High-speed machining generally refers to removing material at much higher cutting speeds and feed rates than conventional machining while using lighter chip loads to maintain stability and surface quality. Instead of defining HSM by a single rpm threshold, it is better understood as a complete system that combines machine dynamics, spindle performance, tool design, toolpath strategies, and process control.

Key characteristics of high-speed machining include:

- Elevated cutting speeds and feed rates compared with conventional machining.

- Light, controlled chip loads to reduce cutting forces and vibration.

- Emphasis on heat evacuation through chips rather than flooding the workpiece.

- Integration of advanced CAM strategies to maintain constant engagement.

High-speed machining has become a strategic capability for shops that serve global OEMs, brand owners, and high-precision industries. It supports competitive pricing, short lead times, and consistent quality for complex parts and tooling.

Core business benefits include:

- Faster cycle times that increase throughput without adding machines.

- Improved surface finish that reduces or eliminates polishing and secondary operations.

- Extended tool life when parameters, tooling, and toolpaths are correctly optimized.

- Lower cost per part through higher metal removal rates and fewer process steps.

To achieve stable and repeatable HSM, the entire cutting system must be balanced and rigid from the base casting to the cutting edge. Simply increasing spindle speed and feed is not sufficient and often leads to chatter, premature tool failure, and inconsistent surface quality.

Essential requirements include:

- Rigid machine structure that resists deflection and damps vibration under dynamic loads.

- High-acceleration linear axes capable of fast contouring and smooth motion.

- Thermally stable spindle that maintains dimensional accuracy over long, high-speed cycles.

- Adaptive CNC control with look-ahead, smoothing, and high data processing capacity.

- Properly selected cutting tools and high-precision, balanced toolholders.

- CAM software and post-processors configured for HSM-style toolpaths.

Modern HSM machines are designed for dynamic stiffness rather than only static rigidity. The machine must maintain positional accuracy while accelerating, decelerating, and changing direction at high speed.

Typical design features include:

- Optimized casting geometry and ribbing to reduce vibration and thermal distortion.

- Direct-drive spindles that eliminate gearbox backlash and reduce rotational inertia.

- Linear guideways and ball screws built for high acceleration and precise contouring.

- Integrated thermal management that stabilizes machine geometry during long production runs.

These design elements allow more aggressive cutting parameters while maintaining predictable surface finish and dimensional accuracy.

In high-speed machining, the spindle is a critical performance component. The combination of speed, torque, and thermal stability determines which materials and strategies can be used effectively.

Key spindle-related practices:

- Match spindle speed and power curve to the target material group, such as aluminum, titanium, stainless steel, or hardened tool steel.

- Use accurate, balanced toolholders to minimize runout and vibration at high rpm.

- Implement spindle load monitoring to detect overload, collisions, and abnormal cutting conditions.

Spindle load monitoring is particularly valuable when pushing aggressive parameters, because it can trigger alarms or protective actions before damaging the spindle or the cutting tools.

High-performance cutting tools are essential for reliable HSM. Tool materials, coatings, and geometries are engineered to survive higher surface speeds and temperatures while maintaining edge strength and wear resistance.

Important tooling considerations include:

- Use of fine-grain carbide tools for a balance of toughness and wear resistance.

- Application-specific coatings that tolerate elevated temperatures and allow higher cutting speeds.

- Multi-flute designs, such as 6, 7, or 8 flutes, to increase feed capability and distribute load.

- High form accuracy to ensure consistent contact geometry, especially for ball nose, barrel, and lens-shaped tools.

- Flute-to-flute repeatability so each cutting edge carries a predictable share of the load.

Special geometries like barrel and lens tools enable large stepovers in finishing operations while maintaining excellent surface finish, which can dramatically reduce finishing cycle time on complex surfaces.

Toolholder stiffness, runout, and balance have a direct impact on surface finish, tool life, and dimensional accuracy in HSM. At higher spindle speeds, even small imperfections can create noticeable vibration and cutting instability.

Key points for toolholding:

- Use high-precision, dynamically balanced holders suitable for the required spindle speed range.

- Consider dual-contact interfaces such as HSK for improved rigidity and repeatability.

- Maintain strict maintenance and inspection routines for holders to prevent wear-related runout and imbalance.

Rigid and stable toolholding systems help maintain consistent chip load across all flutes, enabling higher speeds and feeds without sacrificing part quality.

High-speed machining places heavy demands on the CNC control, particularly in terms of data processing, motion planning, and trajectory smoothing. Performance in this area can be the difference between theoretical and actual cycle time.

Important control capabilities include:

- Look-ahead functions that read ahead in the program to adjust feed and acceleration before corners and small radii.

- Smoothing and jerk control to avoid abrupt direction changes that would otherwise create vibration and witness marks.

- Adaptive feed control that adjusts feed rate based on load, geometry, or toolpath conditions.

- Sufficient memory and processing power to handle large, high-resolution programs.

When these capabilities are properly configured, toolpaths can run at the intended speeds with stable motion, rather than being slowed down by constant deceleration at short segments.

CAM systems play a central role in high-speed machining. Toolpath strategies determine how forces, heat, and chip load are distributed during cutting.

Common HSM toolpath strategies include:

- Trochoidal milling, which uses looping or circular motion with small radial engagement and larger axial depth to reduce cutting forces and heat.

- Constant-engagement roughing paths that maintain a near-constant cutter load by automatically adjusting in corners and tight areas.

- High-feed roughing that uses specialized tool geometries to achieve high feed per tooth with shallow depth of cut.

- Adaptive finishing paths that control stepovers and cusps for predictable surface quality.

Modern CAM systems may also use multi-core processing and background calculation to generate complex toolpaths more quickly, which is increasingly important for large 3D surfaces and molds.

In job shops with high-mix, low-volume work, HSM provides a way to improve productivity and responsiveness without expanding floor space. It supports quick changeovers and efficient production of multiple part families on the same platform.

Typical advantages in general machining environments:

- Shorter cycle times on both roughing and semi-finishing operations.

- Reduced reliance on manual polishing due to better as-machined surfaces.

- Improved competitiveness on price and lead time for international customers.

- Enhanced flexibility to run a wide range of materials and part geometries.

Even shops with mid-range machines can gain partial benefits by adopting HSM-style toolpaths and optimized parameters within the limits of their equipment.

Die and mold manufacturing demands high accuracy and excellent surface quality, which makes it an ideal area for HSM applications. The goal is to reach near-net shape efficiently and minimize manual finishing work.

Best practices in die and mold HSM:

- Rough and semi-finish closer to final geometry with controlled stock allowance.

- Use coated carbide tools capable of machining hardened steels typically in the 50–65 HRC range when required.

- Apply barrel or lens tools in finishing to achieve fine surfaces with larger stepovers.

- Verify tool form accuracy carefully to ensure that freeform surfaces match design data.

These methods can significantly reduce mold build time, improve repeatability across cavities, and shorten time-to-market for new products.

Aerospace applications apply HSM techniques to both lightweight alloys and hard, heat-resistant materials. Requirements for accuracy, stability, and traceability are particularly strict in this sector.

Typical aerospace use cases:

- High-speed machining of large aluminum structural components with high-rpm, high-power spindles.

- High-torque roughing and semi-finishing of titanium, stainless steels, and nickel-based alloys.

- Multi-axis machining of turbine features, blisks, and complex structural details.

- Integration with process control and quality documentation to meet industry standards.

By combining appropriate machines, tooling, and toolpaths, aerospace manufacturers can reduce machining time while maintaining the structural integrity and dimensional accuracy of critical parts.

Recent developments in technology and software continue to expand what is possible with HSM. These trends affect both large OEM operations and smaller contract manufacturers.

Notable trends include:

- Increased use of automation, pallet systems, and robots for lights-out production.

- Integration of real-time data collection and analytics to monitor spindle load, vibration, and tool wear.

- Growth of 5-axis high-speed machining to reduce setups and improve access to complex features.

- Introduction of AI-assisted CAM suggestions for feeds, speeds, and toolpath strategies based on previous performance.

These developments help shops maintain consistent quality, optimize machine utilization, and respond quickly to changing demand.

A structured implementation plan helps reduce risk and accelerate the return on investment when adopting high-speed machining. The following roadmap can be adapted to different shop sizes and industries.

- Review spindle speed, torque, and available power.

- Evaluate machine rigidity, thermal behavior, and control performance.

- Standardize on high-performance carbide and coatings for key materials.

- Introduce balanced, high-precision toolholders and suitable interfaces.

- Enable and tune trochoidal or constant-engagement roughing strategies.

- Adjust post-processors and tolerances to support smooth machine motion.

- Select representative parts and compare cycle time, surface finish, and tool life against conventional methods.

- Document successful parameter sets and cutting conditions.

- Create internal process guidelines and machining libraries organized by material and feature type.

- Train programmers, operators, and quality personnel on HSM best practices.

This approach supports controlled adoption and helps establish a stable, repeatable high-speed machining environment.

For OEMs, brand owners, and wholesalers searching for long-term manufacturing partners, HSM capability is often viewed as a marker of technical maturity and process control. It can influence supplier selection decisions, particularly for complex or high-precision products.

Typical evaluation points include:

- Demonstrated ability to run high-speed processes across metals, plastics, and other engineering materials.

- Documented process controls, including inspection, monitoring, and traceability.

- Experience in high-precision components for sectors such as automotive, aerospace, medical, or consumer electronics.

- Capacity to handle prototypes, small batches, and volume production within a single supply chain.

Suppliers that combine high-speed machining with capabilities such as plastic manufacturing, silicone molding, and metal stamping can offer more integrated solutions and simplified project management.

For companies that need reliable production of high-precision machined parts, plastic products, silicone components, or stamped metal parts, partnering with a supplier that understands and applies high-speed machining is a practical way to improve product quality and shorten time-to-market. If you are planning a new project or looking to upgrade your existing supply chain, share your drawings, 3D models, and technical requirements to receive a tailored manufacturing proposal, detailed process suggestions, and a clear lead-time estimate from an experienced OEM-focused team.

No. High-speed machining involves balancing spindle speed, feed rate, toolpath strategy, machine rigidity, and tool design to maintain stable cutting, controlled heat, and consistent chip load throughout the process.

In some cases, yes. With carefully chosen toolpaths, high-performance tooling, and conservative parameter tuning, older or mid-range machines can benefit from HSM techniques, although ultimate performance remains limited by their design.

Industries that depend on complex geometries and high-quality surfaces benefit the most. Typical sectors include die and mold, aerospace, automotive, medical devices, precision mechanical parts, and high-end consumer products.

Not automatically. When HSM is correctly implemented, tool wear can often be reduced or stabilized because heat is more effectively directed into the chip and cutting forces are more uniform. Incorrect setups, however, can increase wear.

CAM software is essential. Without HSM-oriented toolpaths, optimized engagement strategies, and accurate post-processing, the machine cannot fully exploit its dynamic capabilities, and potential gains in cycle time and surface quality will be limited.

content is empty!