From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-02-08 Origin: Site

Content Menu

● What Is Traditional (Conventional) Machining?

● CNC Machining vs Traditional Machining: Key Differences

>> 1. Control Method and Automation

>> 2. Precision, Tolerances, and Complexity

>> 3. Speed, Throughput, and Lead Times

>> 4. Material Versatility and Part Types

>> 5. Labor, Skill Requirements, and Consistency

>> 6. Cost Structure and When Each Method Is Cost‑Effective

● Side‑by‑Side Comparison: CNC vs Traditional Machining

● When Does Traditional Machining Still Make Sense?

● How to Decide: CNC Machining or Traditional Machining for Your Project?

● Latest Industry Trends: Why OEMs Are Shifting Toward CNC

● Practical Example: Combining CNC and Conventional Machining

● Call to Action: Work With an Integrated OEM Machining Partner

● FAQ

>> 1. Is CNC machining always better than traditional machining?

>> 2. Why is CNC machining more expensive to start with?

>> 3. Can CNC machines work with both metals and plastics?

>> 4. How does CNC machining improve lead times?

>> 5. When should I consider switching from traditional machining to CNC for an existing part?

For global OEMs and product developers, understanding the real differences between CNC machining and traditional machining is critical to choosing the right manufacturing strategy, controlling cost, and achieving consistent quality. This guide explains how each method works, where CNC clearly outperforms conventional methods, and when manual machining still makes sense in your project mix.

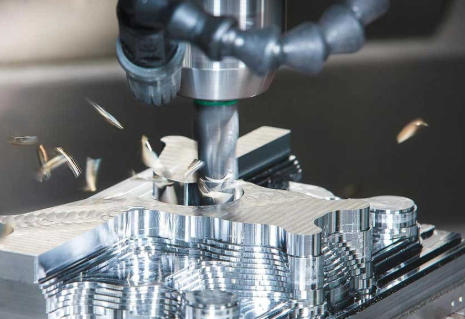

CNC (Computer Numerical Control) machining is a computer‑controlled subtractive manufacturing process that uses pre‑programmed code to move cutting tools and shape material into precise parts. Instead of relying on a human operator's hand movements, CNC machines follow a digital toolpath generated from CAD/CAM software.

Key points:

- Digital instructions (G‑code) drive tool motions, spindle speeds, and feed rates.

- Machines such as CNC mills, lathes, routers, and grinders can all be controlled from a program file.

- Once the program is verified, the machine can run repeatedly with minimal human intervention, even 24/7.

For OEMs, this means repeatability, high throughput, and easy scaling from prototypes to low‑ and medium‑volume production.

Traditional machining refers to manually operated machine tools such as manual mills, lathes, drill presses, and grinders, where a skilled machinist controls all movements with hand wheels, levers, and dials. The operator reads mechanical drawings and adjusts the machine step by step to achieve the required dimensions.

Typical characteristics:

- Manual positioning of the workpiece and tools at each operation.

- Frequent stops for measurements, tool changes, and realignment.

- Output quality and speed depend heavily on the individual operator's skill and experience.

Traditional machining can still be very effective for simple geometries, very small batches, or on‑site repair work where setup time and programming would not pay off.

The most fundamental difference is computerized control versus human control.

- CNC machining:

- Uses programmed G‑code to execute toolpaths precisely as designed in CAD/CAM.

- Reduces human error by automating motions and cutting parameters.

- Can integrate automatic loading and unloading systems for unattended production.

- Traditional machining:

- Relies on real‑time operator decisions to position tools and set feeds and speeds.

- Involves more manual steps, adjustments, and checks, which slow the process.

- Is more vulnerable to variation between different operators and shifts.

For OEM buyers, CNC automation unlocks consistent quality and predictable lead times across batches and locations.

CNC machining is widely recognized for tight tolerances and repeatability, even on complex 3D geometries.

- CNC machining:

- Achieves high‑precision tolerances repeatedly across large batches.

- Handles intricate surfaces, undercuts, and multi‑axis features that would be difficult or impossible manually.

- Offers excellent surface finishes, often reducing post‑processing needs.

- Traditional machining:

- Can produce accurate parts, but quality depends on operator skill and fatigue.

- Is better suited to simpler contours and 2D profiles.

- May require extra polishing or secondary operations to match CNC surface quality.

Industries such as aerospace, medical devices, high‑end electronics, and precision industrial equipment typically rely on CNC to meet strict dimensional and surface requirements.

When you look at total throughput, CNC machining is usually much faster than traditional methods, especially for complex parts or repeated orders.

- CNC machining:

- Performs multiple operations in one setup, shortening cycle times.

- Can run continuously, including overnight, with minimal supervision.

- Easily switches between jobs by loading a new program and workholding setup.

- Traditional machining:

- Requires repeated manual adjustments, tool changes, and repositioning.

- Each additional feature or face adds more setup time.

- For complex parts, machining time increases dramatically compared with CNC.

For OEM projects, this means shorter lead times, higher capacity, and more reliable delivery with CNC, particularly at medium and higher volumes.

Both methods can work with metals and plastics, but CNC machines handle a broader material spectrum and more demanding applications.

- CNC machining:

- Works with aluminum, steels, stainless steels, titanium, copper alloys, engineering plastics, and composites.

- Maintains tight tolerances even in hard or brittle materials.

- Produces complex housings, precision shafts, brackets, molds, and custom enclosures with fine details.

- Traditional machining:

- Often focuses on simpler materials and simpler turned or milled components.

- More common for rework, fixtures, jigs, and simpler maintenance parts.

For OEMs working across metal machining, plastic components, and even tooling, CNC material and geometry flexibility gives a clear advantage.

CNC and traditional machining require different skill sets, which affects labor cost and consistency.

- CNC machining:

- Needs skilled programmers and setup technicians, but less manual intervention during runs.

- Reduces dependence on a single highly experienced machinist, because programs can be reused across shifts and facilities.

- Lowers the risk of errors due to fatigue or variation in manual technique.

- Traditional machining:

- Depends heavily on the machinist's manual skills for each cut and measurement.

- Is harder to standardize across multiple operators or locations.

- May be cost‑effective where highly experienced artisans are available, but scaling is difficult.

For international brands and wholesalers, CNC's standardized process window is key to getting the same part quality from batch to batch and from one factory to another.

From a cost perspective, the trade‑off is usually higher upfront investment for CNC versus higher per‑piece labor cost for traditional machining.

- CNC machining cost drivers:

- Higher machine and software investment, plus programming and setup time.

- Much lower incremental labor per piece once the program is validated.

- Strong economies of scale for repeated batches and complex parts.

- Traditional machining cost drivers:

- Lower machine investment and simpler tooling.

- Higher operator time per part, especially on complex geometries.

- More variation in scrap and rework risk.

General rules:

- For one‑off repair parts or ultra‑simple geometries, traditional machining can still be economical.

- For production orders, tight tolerances, or complex designs, CNC usually offers a better cost‑to‑quality ratio.

| Aspect | CNC Machining | Traditional Machining |

|---|---|---|

| Control | Computerized G‑code, automated motions | Manual control via hand wheels and dials |

| Precision and tolerance | High precision, excellent repeatability, tight tolerances | Operator‑dependent precision, more variation between parts |

| Complexity | Ideal for complex 3D geometries and multi‑axis parts | Best for simple shapes and basic features |

| Speed and throughput | Fast cycles, 24/7 operation, high throughput | Slower, more manual steps and repositioning |

| Labor | Fewer operators per machine, focus on programming and setup | High manual involvement for each part |

| Materials | Metals, plastics, composites, including hard materials | Often focused on simpler or softer materials |

| Best use cases | Precision OEM parts, repeat orders, complex features | Simple parts, repairs, very small runs |

While CNC is dominant in modern precision manufacturing, traditional machining still has a role in a balanced OEM sourcing strategy.

Situations where manual machining can be a good fit:

- Emergency repairs and one‑off parts where speed matters more than long‑term repeatability.

- Very simple geometries such as basic shafts, bushings, and brackets in extremely low volumes.

- On‑site modifications and adjustments during installation or commissioning.

However, as soon as tolerances tighten, geometry becomes more complex, or volumes start to scale, CNC machining quickly becomes the more reliable and cost‑effective option.

For OEM buyers, the key is to match process selection to your product and business priorities.

Consider these decision dimensions:

1. Part complexity

- Complex 3D shapes, multiple faces, tight feature relationships → choose CNC.

- Simple turned or milled features for a handful of parts → traditional machining may work.

2. Tolerance and quality requirements

- Aerospace, medical, precision electronics, and high‑end consumer products → CNC is usually required.

- Utility parts with looser tolerances and low visual requirements → either method, depending on volume.

3. Volume and repeatability

- Repeated batches, long‑term supply agreements, or program‑based business → CNC for consistent quality.

- Single‑run components or repair work → traditional machining can be sufficient.

4. Lead time and scalability

- Tight launch schedules and frequent design revisions → CNC enables fast iterations.

- Slow‑moving spare parts or internal maintenance items → traditional machining is often acceptable.

Across many industries, manufacturers are moving further toward CNC‑centric production for their supply chains.

Key trends:

- Higher automation levels with multi‑axis CNC machines, automatic tool changers, pallets, and robotics.

- Increasing design complexity that only CNC can reliably produce at scale.

- Global standardization of machining programs and process windows to align quality across multiple suppliers.

For OEMs working with partners in China and worldwide, CNC machining has become the default choice for high‑precision metal and plastic components.

A typical OEM sourcing strategy might combine both methods.

Use CNC machining for:

- Customer‑facing housings and enclosures with strict cosmetic and dimensional requirements.

- Precision internal parts such as shafts, brackets, manifolds, and connectors.

- Prototypes and small‑batch verification builds before moving to higher‑volume processes such as molding.

Use traditional machining for:

- Low‑risk fixtures, simple brackets, and internal maintenance tooling.

- One‑off or legacy spare parts for older equipment.

By aligning each part family with the right machining method, OEMs can optimize total cost and performance instead of focusing on a single process only.

If you are a brand owner, wholesaler, or manufacturer, choosing a partner that combines CNC machining with plastic molding, silicone products, and metal stamping helps you manage complex projects more easily. By consolidating processes under one roof, you reduce coordination time, shorten lead times, and keep quality and documentation under tight control.

If you already have drawings or samples, send your part files, materials, quantities, and expected timelines to our engineering team. We can review manufacturability, compare different machining options for your parts, and propose a production plan that balances precision, cost, and lead time. Reach out today to discuss your project and get a tailored quotation for your CNC and related OEM manufacturing needs.

Contact us to get more information!

No. CNC machining is generally better for complex, tight‑tolerance, or repeat production, while traditional machining can still be economical for very simple geometries, one‑off repairs, or on‑site modifications.

CNC uses more advanced machines and software and requires programming and setup time, which raises initial cost, but it reduces per‑piece labor and improves repeatability, often lowering total cost at production volumes.

Yes. Modern CNC machines can process a wide range of metals, engineering plastics, and some composites, making them suitable for many types of OEM components and industries.

CNC machining reduces manual steps, allows multiple operations in one setup, and supports continuous operation, so parts can be produced faster and with more predictable delivery dates than with traditional methods.

You should consider switching when volumes increase, dimensional or cosmetic issues appear, or design changes introduce more complex features or tighter tolerances that are difficult to maintain manually.