From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-02-16 Origin: Site

Content Menu

● What Is CNC Machining Service and Why It Matters for OEMs?

● Key Factors for Selecting a CNC Machining Service Provider

>> Technical Capability and Machine Equipment

>> Range of Materials and Process Integration

>> Quotation Transparency and Cost-Effectiveness

>> Lead Time, Capacity, and Flexibility

>> Quality Control System and Certifications

>> Communication, Engineering Support, and After-Sales Service

● Step-by-Step Guide: From RFQ to Delivery

>> Step 1 – Define Requirements and Prepare Data

>> Step 2 – Request and Compare Quotes

>> Step 3 – Technical Clarification and Sample Order

>> Step 4 – Production, Process Monitoring, and Change Management

>> Step 5 – Final Inspection, Logistics, and After-Sales

● Common Traps When Choosing CNC Machining Services (and How to Avoid Them)

>> Trap 1 – Being Attracted by Very Low Prices

>> Trap 2 – Ignoring Delivery Reliability

>> Trap 3 – Vague Communication and Unclear Requirements

● Why OEM Buyers Choose U-Need as a CNC Machining Partner

>> Cost-Effective CNC Machining Starting from $1

>> Wide Machining Capabilities for Metal and Plastic Parts

>> Fast Delivery and 24/7 Professional Customer Support

● Practical Checklist Before You Place Your Next CNC Order

● Strong Call to Action – Start Your CNC Machining Project with U-Need

● Frequently Asked Questions (FAQ)

>> 1. How do I choose the right CNC machining service for my OEM project?

>> 2. What information do I need to provide to get an accurate CNC machining quote?

>> 3. How can I balance cost and quality when choosing a CNC machining company?

>> 4. Why is lead time so important for CNC machining services?

>> 5. What makes U-Need a good CNC machining partner for overseas OEM buyers?

Choosing the right CNC machining service directly affects your part quality, total cost, and time-to-market, especially for OEM buyers, importers, and brand owners working with overseas suppliers. This guide walks you step by step from initial RFQ to after-sales so you can confidently shortlist, compare, and select a long-term CNC manufacturing partner.

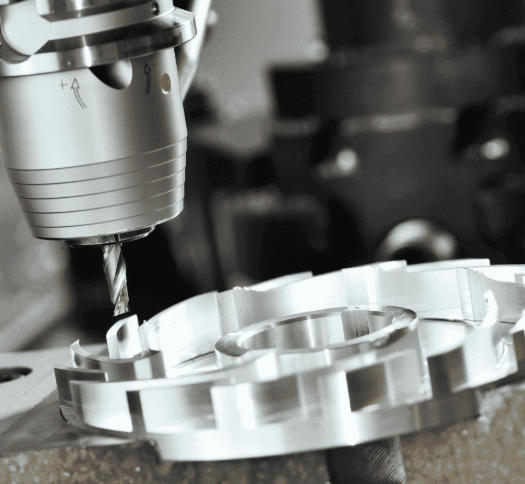

For OEMs and global buyers, CNC machining is a flexible, high-precision way to transform CAD designs into finished metal and plastic parts at scale. Compared with manual machining, CNC offers tighter tolerances, better repeatability, and easier design changes, which is critical for brands that need consistent quality across batches.

Typical CNC machining services for OEM projects include:

- Turning and milling of aluminum, steel, stainless steel, brass

- CNC machining of engineering plastics such as POM, PA, PC, PEEK

- Secondary operations: tapping, drilling, boring, reaming

- Surface finishes: anodizing, powder coating, plating, polishing

If your project includes not only metal parts but also plastic injection, silicone components, or metal stamping, choosing a one-stop partner can reduce management cost, lead time, and quality risk.

Your CNC machining partner must have technical capabilities aligned with your part complexity, tolerances, and volume. This is the foundation for stable quality and repeatable production.

Key points to verify:

- Multi-axis CNC machines (3-axis, 4-axis, 5-axis) for complex geometries

- Stable machining of tight tolerances, especially for critical parts

- CAD/CAM capability (such as SolidWorks, UG, Mastercam) for DFM and toolpath optimization

- In-house fixture design for stable, repeatable production

Ask the supplier to provide sample parts photos, machine lists, and typical tolerance ranges they can routinely hold on similar projects.

A strong CNC machining company should be comfortable with a wide range of metals and plastics and be able to recommend suitable materials for your application.

Look for:

- Metals: aluminum (for example 6061, 7075), stainless steel (304, 316), carbon steel, brass, copper

- Plastics: ABS, PC, POM, PA, PBT, PEEK, PTFE, acrylic

- Knowledge of material-specific issues like deformation, burrs, tool wear, and surface finish

If your project also involves plastic parts, silicone parts, and metal stamping, it is more efficient to work with a supplier who can integrate these processes under one roof to simplify supply chain management.

A professional CNC machining service should provide a clear, itemized quotation that breaks down material, machining, finishing, tooling, packaging, and logistics.

When comparing quotes, check:

- Whether machining steps and surface finishes are clearly described

- If unit price changes by quantity (prototype, small batch, mass production)

- Whether inspection reports (for example full inspection vs random inspection) are included

- Any additional costs: programming fees, fixture costs, express samples, shipping

Avoid choosing solely by lowest price; hidden cost from rework, delays, and quality issues is often much higher than a slightly higher unit price.

For OEM projects, on-time delivery can be as critical as price. A delay at the machining stage can affect your entire production schedule.

Evaluate:

- Standard lead time for prototypes and mass production (for example 3–7 days for samples, 15–30 days for batches)

- Capacity to handle peak seasons and urgent orders without sacrificing quality

- Production planning and whether they use digital tracking to monitor work orders

Ask the supplier to describe how they handle rush orders, design changes, and spikes in volume, and what communication channels are used to keep you updated.

A reliable CNC machining provider should have a documented quality management system and the right inspection equipment.

You should verify:

- ISO 9001 or industry-specific certifications where relevant

- In-house inspection tools: calipers, micrometers, height gauges, CMM, projectors, hardness testers, roughness testers

- Clear inspection standards (incoming QC, in-process QC, final QC) and traceable records

Ask for sample inspection reports from similar projects and check whether they match your quality needs.

Smooth communication greatly reduces project risk, especially for overseas buyers.

Focus on:

- Response speed to RFQs and technical questions

- English communication ability and understanding of international standards

- Willingness to offer DFM suggestions and help optimize designs for cost and manufacturability

- After-sales policies: rework, replacement, technical troubleshooting support

A partner who actively points out potential issues before production and proposes improvements usually saves you more time and money in the long term.

Before sending an RFQ, prepare a complete and clear information package. This step directly influences quotation accuracy and later production quality.

You should include:

- 2D drawings (PDF) with all critical dimensions and tolerances

- 3D models (STEP, IGES, STP) for complex surfaces

- Material specifications, surface finish, and special requirements

- Required quantity (prototype, pilot run, mass production)

- Expected lead time and shipping destination

The clearer your requirements are, the more accurate and comparable the quotations will be.

Contact several CNC machining service providers and request quotations with the same data package. Then compare them in a structured way instead of only reading numbers in emails.

Before placing a full production order, arrange a technical review. This prevents misunderstandings and avoids costly modifications later.

Do the following:

1. Confirm all technical details: tolerances, threads, chamfers, surface roughness, assembly interfaces.

2. Ask for DFM suggestions to reduce cost or improve stability.

3. Place a sample order or pilot batch to verify real quality and communication.

Inspect the samples carefully and provide structured feedback so the supplier can adjust before mass production.

Once samples are approved, confirm the PO and production schedule. At this stage, continuous communication is essential.

Recommended practices:

- Use regular email or online portals to check production status

- Keep all changes in design, volume, or delivery time in written form

- If engineering change notices are required, clarify cost and schedule impact in advance

A mature CNC machining service will have change management procedures to control revisions and avoid mixing of old and new versions.

Before shipping, ensure that final inspection has been completed according to agreed standards. Do not skip this step, especially for critical parts.

Key points:

- Dimensional inspection of key features using appropriate gauges

- Surface appearance check, including scratches, burrs, and coating quality

- Functional tests for moving or assembled parts, if required

Clarify packaging methods (individual bags, foam protection, carton, pallet) and shipping options (air, sea, express) to balance cost and lead time. If you find any issues after receiving the goods, contact the supplier promptly with photos, videos, and batch records for analysis and resolution.

Ultra-low quotes often mean compromises in material quality, process control, or inspection, which can lead to hidden costs later.

How to avoid:

- Always ask for material certificates and surface treatment reports

- Compare sample quality, not just price lists

- Consider total cost of ownership, including rework, delays, and reputation impact

Some suppliers accept orders even when capacity is insufficient, leading to endless delivery delays and project risks.

How to avoid:

- Check past on-time delivery records or references when possible

- Start with smaller orders to verify real scheduling ability

- Set milestone dates and clear compensation or improvement plans for serious delays

If requirements are not fully aligned, even good factories may produce the wrong parts.

How to avoid:

- Use clearly marked drawings and written specs instead of only photos or samples

- Summarize all verbal discussions in follow-up emails for confirmation

- Request detailed order confirmations before production starts

U-Need offers CNC machining services starting from $1, allowing OEM clients to validate designs with low-cost prototypes before committing to mass production. This pricing structure helps both startups and established brands test new products while keeping early-stage investment under control.

U-Need provides a one-stop solution from prototype to mass production for both metal and plastic CNC parts.

Capabilities include:

- Precision CNC milling and turning for aluminum, stainless steel, and other alloys

- CNC machining for engineering plastics used in consumer products and industrial components

- Support for both simple parts and complex multi-process parts requiring multiple setups

This integrated capability is especially suitable for OEMs that also need plastic parts, silicone components, or metal stamping to be matched and assembled with CNC machined parts.

With fastest delivery in as little as 3 days, U-Need helps overseas buyers shorten development cycles and react quickly to market changes. The team offers 24/7 customer support, providing technical answers, progress updates, and after-sales assistance across time zones.

By combining competitive pricing, broad machining capability, and responsive communication, U-Need supports long-term cooperation with customers in different industries.

Use this simple pre-order checklist to reduce risk on your next CNC machining project:

- All 2D and 3D drawings updated to latest version and clearly marked

- Material, tolerances, and surface finish confirmed in writing

- Sample approval records documented and shared with the supplier

- Quotation scope (price, tooling, inspection, packaging, logistics) confirmed

- Delivery date and shipping method aligned with your project schedule

- After-sales and rework policies clearly defined

Keeping this checklist in your internal SOP helps your team standardize CNC supplier selection and reduce avoidable mistakes.

If you are an OEM buyer, importer, or brand owner looking for a reliable CNC machining service provider in China, partnering with U-Need can significantly simplify your sourcing and engineering workload.

You can:

- Send your 2D and 3D drawings and project requirements to U-Need for a fast, detailed quotation

- Start with a low-cost prototype order to validate quality and communication

- Scale smoothly from samples to mass production with consistent quality and on-time delivery

Contact U-Need today to discuss your CNC machining, plastic parts, silicone components, or metal stamping needs, and get an engineering-driven quotation tailored to your next project. Take the next step now and turn your designs into high-quality parts with a partner you can trust.

Contact us to get more information!

Focus on technical capability, material expertise, quality system, lead time, and communication rather than just price. Request samples and check whether the supplier can give practical DFM suggestions before placing large orders.

You should provide 2D drawings, 3D models, material and finish requirements, quantity, and expected delivery time. Complete data allows the supplier to quote more accurately and avoid later price changes.

Compare several suppliers on unit price, process capability, inspection level, and delivery reliability instead of only picking the lowest quote. Consider total cost, including possible rework, delays, and freight.

Lead time affects your time-to-market, inventory planning, and cash flow. A supplier with stable capacity and transparent scheduling helps you maintain reliable delivery to your own customers.

U-Need combines cost-effective pricing from $1, fast delivery from 3 days, wide machining capabilities, and 24/7 support, which is ideal for overseas OEMs who need both speed and reliability. Its one-stop service from prototype to mass production helps reduce supplier management complexity.