From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-02-22 Origin: Site

Content Menu

● Core Micro CNC Machining Processes

>> Wire EDM for Complex Miniature Features

● Material and Equipment Requirements for Miniature Parts

>> Suitable Materials for Micro CNC Machining

>> Machine Stability and Tooling

● High Precision vs Standard Micro Parts

>> Typical Use Cases and Tolerances

● Key Technical Challenges in Micro Machining

>> Chip Evacuation and Coolant Strategy

>> Workholding and Part Stability

>> Thermal Effects on Miniature Components

● Practical Design Tips for Micro CNC Components

● Real World Industry Applications

● Standard Micro Machining vs Ultra Precision Micro Machining

● How to Choose the Right Micro CNC Machining Partner

● When a Fast Standard Micro Machining Service Makes Sense

● Take the Next Step for Your Miniature Components

>> 1. How small can micro CNC machining really go

>> 2. Do I always need ultra high precision for micro parts

>> 3. Which materials are best for miniature CNC components

>> 4. Why do micro cutting tools break so easily

>> 5. How can I design parts that are easier to micro machine

In modern product design, compact and lightweight devices depend on micro CNC machining to turn extremely small features into stable, repeatable parts that can be mass-produced. For engineers, OEMs, and hardware startups, choosing the right micro machining techniques and suppliers determines whether miniature components are manufacturable, reliable, and cost-effective.

Micro CNC machining is the CNC controlled fabrication of parts or features typically smaller than 1 mm, such as tiny holes, narrow channels, micro grooves, or intricate contours in metals and plastics. It bridges the gap between conventional machining and microfabrication, enabling miniature components without the cost and limitations of semiconductor style processes.

Typical characteristics include:

- Feature sizes down to below 1 mm, sometimes approaching a few hundred microns.

- Tool diameters commonly in the 0.2 mm range, with some applications using tools as small as 0.1 mm.

- Spindle speeds typically between 40,000 and 60,000 RPM to maintain cutting stability at such small tool diameters.

For product teams, the key decision is whether they truly need sub micron accuracy, or if standard miniature parts with practical tolerances are sufficient for performance and cost targets.

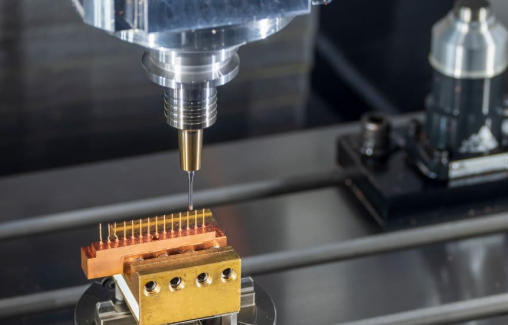

Micro milling uses very small diameter end mills to create detailed 2D and 3D geometries on miniature parts. It is ideal for mini housings, brackets, frames, and structural components that need both shape complexity and dimensional consistency.

Key considerations:

- Use high spindle speeds with conservative step over and depth of cut to prevent tool breakage.

- Prioritize rigid fixturing and short tool overhangs to minimize vibration at the cutting zone.

- Optimize CAM toolpaths specifically for micro tools, including ramped entries and gentle cornering.

Micro drilling focuses on ultra small through holes and blind holes needed for pins, fasteners, fluid channels, or wire passages. At this scale, chip evacuation and alignment become more critical than raw cutting power.

Best practices:

- Combine high spindle speeds with carefully tuned feed rates to avoid snapping drills.

- Use coolant or air blast directly at the drill tip to clear chips from deep micro holes.

- Check runout carefully, because even small radial errors can dramatically reduce tool life and hole quality.

For very hard metals or extremely intricate profiles, wire EDM can cut fine shapes that are difficult or impossible to machine with rotating tools. It is particularly useful when parts demand very sharp internal corners or complex internal profiles on miniature features.

Wire EDM advantages:

- No cutting forces, so delicate or thin walled micro components are less likely to deform.

- Very high dimensional precision on hard materials such as tool steels or specialized alloys.

- Excellent for micro gears, miniature frames, and precision connector components.

Producing miniature parts is not just about scaling down a normal CNC workflow; mechanical stability and thermal control become decisive factors.

Commonly used materials include:

- Aluminum: Good machinability and strength to weight ratio, widely used in electronics and structural mini parts.

- Brass: Excellent machinability, ideal for miniature connectors, fittings, and decorative components.

- Engineering plastics such as POM, PEEK, and PC: Useful for lightweight, electrically insulating, or low friction miniature parts.

- Stainless steel: Machinable but more demanding, used for small mechanical parts requiring higher strength and corrosion resistance.

Material selection directly affects achievable tolerances, surface finish, and overall machining cost.

At the micro scale, any vibration or runout multiplies into visible defects or scrap.

Key equipment factors:

- Tooling: Micro end mills and drills must have very low runout and high quality geometry.

- Machine structure: High rigidity, precise motion control, and robust thermal stability are essential.

- Fixturing: Workholding must clamp small parts securely without distortion, while still allowing access for tiny tools.

Not all miniature components require laboratory grade tolerances. Many applications only need consistent, repeatable small parts within practical tolerance bands. Understanding this distinction helps you select the right manufacturing partner and avoid overpaying for unnecessary precision.

| Use case | Typical tolerances | Primary focus | Recommended supplier type |

|---|---|---|---|

| Medical implants, optical systems | ±0.005 mm | Biocompatibility, surface finish, accuracy | Specialized high precision CNC shop |

| Consumer electronics cases, mounts, brackets | ±0.05 mm | Consistency, volume, speed | Flexible micro part supplier |

| Mini mechanical parts for enclosures, connectors | ±0.1 mm | Strength, small form factor, durability | CNC platforms experienced in small parts |

If your device does not require sub micron tolerances, a standard micro machining service with fast turnaround often provides a better balance of cost, lead time, and quality.

Even when you are not chasing ultra high precision, micro machining introduces challenges that do not appear in conventional machining at larger scales.

Micro tools have very low cross sectional strength, so they wear faster and break more easily. Incorrect feed rates, sudden load spikes, or poor chip evacuation can cause catastrophic tool failure.

Mitigation steps:

- Use conservative feeds and depths of cut, especially on hard materials.

- Implement gradual tool engagement strategies in CAM to avoid sudden load changes.

- Schedule regular tool inspections and replacements based on actual wear, not just part count.

At small diameters, chips can pack into flutes and block cutting edges, causing heat buildup and tool failure. High pressure coolant or directed air assist is often necessary even for relatively soft materials.

Good practice:

- Direct coolant or air precisely at the cutting zone and into holes or slots.

- Consider peck cycles for micro drilling to break chips and clear them from deep holes.

Clamping very small parts without distortion is more complex than clamping larger blocks. Excessive clamping force can deform thin walls, while insufficient force allows vibration during cutting.

Examples of effective workholding:

- Custom soft jaws sculpted to support thin walls and small features.

- Vacuum fixtures for flat micro plates or thin covers when appropriate.

- Modular micro clamps and fixtures designed specifically for miniature workpieces.

Because miniature parts have less mass, even modest heat input can cause dimensional drift or warping. This affects both short term accuracy and long term stability after the part cools.

Control measures:

- Use optimized cutting parameters to reduce heat generation.

- Apply appropriate coolant to stabilize temperature during long toolpaths.

- Perform in process inspections to validate that critical dimensions stay within tolerance.

To get manufacturable and cost effective miniature parts, design choices must align with micro machining constraints. Small optimizations in CAD often translate into large savings in machining time and scrap.

Design guidelines:

1. Prefer slightly larger minimum feature sizes where function allows, instead of pushing to absolute minimum tool diameters.

2. Avoid extremely deep, narrow slots or holes that make chip removal and tool access difficult.

3. Standardize hole diameters and wall thicknesses so a single micro tool can machine multiple features.

4. Use fillets in internal corners to match realistic tool radii and reduce stress concentration.

5. Clearly define which dimensions are critical to function, so your supplier can prioritize those in process planning.

Micro CNC machining supports a wide range of miniature components across different sectors, each with its own balance between precision, cost, and volume.

Typical applications include:

- Wearable electronics: micro brackets, frames, sensor housings, and connector interfaces in aluminum or plastics.

- Compact robotics: miniature gear housings, actuator plates, and sensor mounts requiring high rigidity in a small footprint.

- Consumer devices: camera modules, small structural parts, mounts, and cooling components inside compact enclosures.

In each case, teams must decide whether they need super precision with micron level control, or standard miniature parts that focus on repeatability, strength, and manufacturability.

Before selecting a supplier, it is essential to clarify where your project falls between standard micro machining and ultra precision micro fabrication.

- Ultra precision micro machining targets extremely tight tolerances and superior surface finishes, often needed for implants, optics, or critical fluidic components.

- Standard micro machining focuses on reliable, repeatable small parts with practical tolerances suitable for enclosures, brackets, connectors, and structural mini components.

Choosing the right category avoids overengineering and helps align cost and lead time with real product requirements.

Selecting a machining partner is not only about equipment, but also about process maturity, communication, and understanding of miniature part constraints.

Key criteria to evaluate:

1. Experience with micro features: Request sample parts or case references that match your size and tolerance range.

2. Material coverage: Confirm that the supplier has proven workflows for your specific metals or plastics at miniature scales.

3. Quality controls: Check whether they use in process inspection, tool life management, and final CMM or optical checks for small parts.

4. Lead time and flexibility: For R and D and low volume production, flexible quoting, short lead times, and design feedback are highly valuable.

5. Communication: Engineers who can understand your critical features and provide DFM input will reduce the number of prototyping loops.

For many projects, a fast and flexible manufacturer for standard micro parts is preferable to a highly specialized ultra precision shop, provided your tolerance targets are realistic.

If you are developing functional prototypes, custom low volume parts, or miniature components that simply need to fit and function reliably, a responsive micro CNC partner can accelerate your development cycle.

Such services typically offer:

- Low volume CNC machining for metals and engineering plastics.

- Quick turnaround on small batches of miniature parts.

- Convenient online quoting and file uploads to streamline RFQ and ordering.

This approach is ideal when:

- Your parts are small but do not require ultra tight medical or optical tolerances.

- You are iterating designs rapidly and need frequent prototype revisions.

- Cost and speed are as important as absolute dimensional precision.

If you are working on miniature components for your next product and need stable quality, predictable tolerances, and reliable lead times, now is the right moment to involve a professional micro CNC machining partner. Share your drawings, 3D models, material preferences, and target tolerances, and collaborate early on manufacturability so that your prototypes and production parts can move smoothly from design into mass production. Reach out today to discuss your project and get a tailored machining solution that supports your brand, your schedule, and your cost targets.

Contact us to get more information!

Micro CNC machining can routinely create features smaller than 1 mm, with specialized setups using tools as small as 0.1 mm in diameter, depending on machine capability and part design.

No. Many consumer electronics and mechanical mini parts work well with tolerances around ±0.05 mm to ±0.1 mm, which are achievable with standard micro machining services.

Aluminum, brass, and engineering plastics are widely used because they are easier to machine. Stainless steel and harder alloys are also possible, but they require more careful process control and tooling selection.

At very small diameters, tools have limited strength and are sensitive to feed errors, chip packing, and runout. Incorrect parameters or poor chip evacuation can cause rapid wear or sudden breakage.

Use realistic minimum feature sizes, avoid very deep narrow slots, standardize hole sizes, add internal corner fillets, and clearly mark critical dimensions on your drawings so the machinist can focus on what matters most.