From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-27 Origin: Site

Content Menu

● What Is Plastic CNC Machining?

● Why Choose Plastic CNC Machining?

● Best Plastics for CNC Machining

>> How to Select the Right Plastic

● Core Plastic CNC Machining Processes

>> CNC Milling

>> CNC Turning

● Benefits of Plastic CNC Machining for OEMs

>> Fast Prototyping and Low‑Volume Production

>> Design Flexibility and Complex Geometry

>> Cost Efficiency at the Right Volumes

● Design for Manufacturability (DFM) in Plastic CNC Machining

● Machining Parameters and Tooling Considerations

>> Feeds, Speeds, and Heat Control

● Surface Finishes and Post‑Processing Options

● Typical Applications of Plastic CNC Machining

● Plastic CNC Machining vs Other Manufacturing Processes

● How to Plan a Plastic CNC Machining Project

>> Step 1: Define Requirements

>> Step 2: Prepare Optimized CAD Files

>> Step 3: Choose a Qualified CNC Partner

● Working With an OEM Partner for Plastic CNC Parts

● Clear Call to Action: Start Your Plastic CNC Machining Project Now

● FAQs About Plastic CNC Machining

>> 1. What is plastic CNC machining used for?

>> 2. Which plastics are best for CNC machining?

>> 3. How accurate can plastic CNC machining be?

>> 4. When is plastic CNC machining better than injection molding?

>> 5. How can I reduce the cost of plastic CNC machined parts?

Plastic CNC machining is one of the most reliable ways to turn engineering plastics into accurate, repeatable components for demanding applications in automotive, medical, aerospace, electronics, and consumer products. Compared with molding or basic routing, it offers tighter tolerances, better design freedom, and faster turnaround for low‑ and medium‑volume production.

Plastic CNC machining is a subtractive process where computer numerically controlled (CNC) equipment cuts, mills, drills, or turns plastic stock into finished parts using a programmed toolpath. The machine reads a digital CAD/CAM file and executes precise movements along multiple axes to produce complex geometries from sheets, plates, rods, or blocks.

Compared with manual machining, CNC control enables consistent quality, repeatable dimensions, and efficient production for both prototypes and production runs. Because there is no need to build molds, plastic CNC machining is often more economical and faster for low‑volume and high‑mix part requirements.

Plastic CNC machining is chosen when you need a combination of dimensional accuracy, material performance, and flexible volumes. It is particularly useful for functional prototypes, custom components, and assemblies that must match real‑world performance closely.

Key advantages include:

- Tight tolerances and precision for critical components

- Fast lead times without tooling for low‑volume production

- Broad material compatibility across engineering plastics

- Strong surface finish and cosmetic quality

- Repeatable performance from prototype to production

These strengths make plastic CNC machining an attractive option for OEMs, startups, and established brands looking to de‑risk new designs or support ongoing production with agile supply.

Not all plastics machine equally well, so material selection is a critical early decision. The “best” plastic depends on your required strength, temperature resistance, chemical exposure, regulatory needs, and budget.

- ABS – General‑purpose plastic with good toughness, impact resistance, and machinability, widely used for housings, fixtures, and prototypes.

- Polycarbonate (PC) – High impact resistance and clarity, suitable for guards, lenses, and structural covers, but requires careful heat management when machining.

- Acrylic (PMMA) – Excellent optical clarity and good rigidity, often used for displays, light guides, and transparent covers where polished edges are important.

- Nylon (PA) – Strong, wear‑resistant, and low friction, ideal for bushings, gears, and bearings in mechanical assemblies.

- POM / Delrin (Acetal) – Low friction, dimensional stability, and good machinability for precision mechanical parts, manifolds, and components needing tight fits.

- PEEK and other high‑performance polymers – Excellent temperature and chemical resistance, used in aerospace, oil and gas, and advanced medical components.

When choosing a plastic for CNC machining, consider:

- Operating environment (temperature, chemicals, UV, humidity)

- Required mechanical properties (strength, stiffness, impact, fatigue)

- Regulatory or compliance needs (such as food contact, medical, or flame ratings)

- Desired surface finish and color options

- Budget, volume, and long‑term availability

A good manufacturing partner can help match your functional requirements with a cost‑effective plastic grade and propose alternatives if supply or machining behavior becomes an issue.

Plastic CNC machining uses the same major processes as metal machining but with parameters and tool choices optimized for polymers.

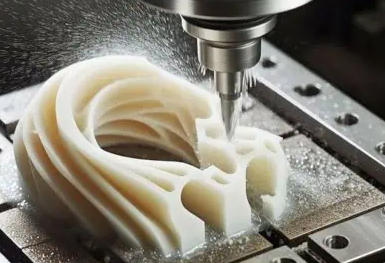

CNC milling uses rotating cutting tools to remove material from a fixed or moving workpiece, producing pockets, slots, contours, and 3D surfaces. For plastics, high‑helix cutters and sharp edges help maintain surface quality while avoiding melting or burrs.

- Ideal for: 3D surfaces, housings, brackets, enclosures, and complex geometries

- Typical materials: ABS, PC, acrylic, POM, PEEK

In CNC turning, the plastic workpiece rotates while cutting tools move along its length to generate cylindrical shapes and features. This is especially efficient for shafts, bushings, threaded parts, and round connectors.

- Ideal for: Round parts, bushings, fittings, spacers, and pulleys

- Typical materials: Nylon, POM, UHMWPE, PEEK

Plastic CNC parts often require complementary operations to achieve final functionality or appearance. Common options include:

- Drilling and tapping of precise holes and threads

- Reaming for high‑accuracy bores

- Countersinking and counterboring for fasteners

- Routing for panels and signage

- Deburring and edge finishing to remove sharp or melted edges

These steps are planned into the CNC program or run as secondary workstations depending on the complexity and part volume.

For OEMs and product companies, plastic CNC machining creates a bridge between early prototypes and scaled production. It minimizes upfront tooling risk while supporting robust, functional parts that behave like final components.

CNC machines can hold tight tolerances on plastic parts, enabling accurate fits, reliable sealing surfaces, and repeatable performance over multiple batches. For critical components with tight tolerance bands, this consistency lowers assembly issues and reduces quality failures in the field.

Because there is no mold to design and build, CNC‑machined parts can be delivered in weeks rather than months, depending on material lead time. This supports agile product development, quick engineering changes, and pilot builds without heavy capital investment.

CNC machining handles complex geometries, undercuts, and intricate details that may be difficult or costly to mold. Designers can iterate freely and refine features such as pockets, internal channels, and custom interfaces while staying within reasonable machining time and cost.

For low‑ and medium‑volume parts, machined plastics avoid expensive tooling and potential mold rework when designs change. Once part volumes become very high and stable, injection molding may be more cost‑effective, but CNC remains valuable for spare parts, engineering samples, and variants.

Well‑designed plastic parts are easier to machine, more stable in use, and cheaper to produce. Applying DFM early reduces iteration time and keeps projects on budget.

- Optimize wall thickness to avoid warping, vibration, or deflection during cutting.

- Use generous corner radii to match tool diameters and shorten cycle times.

- Minimize very deep, narrow pockets that trap chips and increase heat.

- Simplify undercuts or use standard tooling where possible.

- Specify only the tight tolerances that are functionally necessary.

Collaborating with an experienced machining team to review drawings often identifies changes that preserve function while reducing cost and lead time.

Specifying tolerances for plastic CNC parts should account for material properties and environmental conditions. Plastics expand and contract more than metals, so over‑tight tolerance bands can increase scrap and machining time without improving real‑world performance.

A practical approach is to:

1. Set looser general tolerances for non‑critical dimensions.

2. Tighten only the dimensions that affect interfaces, sealing, or critical alignment.

3. Discuss achievable tolerances and stability with your machining partner.

Tool selection and cutting parameters play a major role in achieving clean edges, good surface finish, and stable dimensions in plastic CNC machining.

- Sharp cutting edges reduce heat, chipping, and surface defects.

- Single‑ or two‑flute cutters allow larger chip space and help avoid overheating or melting.

- High‑helix cutters can improve surface finish on softer plastics but may increase static cling to chips.

- O‑flute end mills are widely used for acrylic to achieve polished edges with minimal secondary finishing.

Plastics are more sensitive to heat than metals, so machining parameters must be tuned to manage temperature. Common practices include:

- Adjusting spindle speed and feed rate to evacuate chips quickly and avoid melting.

- Using shallower depths of cut to distribute forces and reduce heat buildup.

- Employing techniques such as peck drilling for deep holes to clear chips and manage temperature.

Some applications use air blasts, mist, or compatible coolants to further control heat, especially for high‑speed machining or temperature‑sensitive plastics.

Surface finish affects both the appearance and performance of plastic CNC parts. Depending on the application, you may require purely functional surfaces or highly cosmetic, customer‑facing finishes.

Typical options include:

- As‑machined finish with visible toolpaths for purely functional parts.

- Deburring, sanding, or polishing to improve smoothness and remove edges.

- Vapor or flame polishing for acrylic components requiring optical clarity and high gloss.

- Light bead blasting to create a uniform, matte surface for housings and covers.

More advanced finishing may also include painting, coating, printing, or assembly with metal inserts, depending on your product requirements.

Plastic CNC machining appears across many sectors where engineers balance mechanical performance with weight, cost, and regulatory needs.

- Medical and life sciences – Manifolds, fixtures, housings, and instrument components made from biocompatible or sterilizable plastics.

- Automotive and transportation – Interior components, brackets, bushings, and prototype parts for testing.

- Aerospace and defense – Lightweight structural parts, insulators, and specialty components in advanced polymers.

- Electronics and telecom – Enclosures, insulating parts, connectors, and precision mounts.

- Industrial equipment – Gears, wear plates, guides, and custom fixtures.

In each case, the ability to combine high‑performance polymers with tight machining control makes plastic CNC machining a strong fit for low‑volume and high‑reliability parts.

Choosing the right process depends on volume, geometry, and performance needs. Plastic CNC machining often complements, rather than replaces, other manufacturing methods.

| Aspect | Plastic CNC Machining | Injection Molding | 3D Printing (Additive) |

|---|---|---|---|

| Tooling cost | Low, no mold required for most projects | High upfront mold cost, economical at high volumes | No tooling, only printer setup |

| Best for volumes | Prototypes, low‑ to mid‑volume parts | High‑volume, stable designs | Prototypes and complex low‑volume parts |

| Tolerances and accuracy | Tight tolerances, high accuracy | Good, but some variation due to molding and shrinkage | Depends on process, often lower than CNC for precision features |

| Material options | Broad range of engineering plastics | Limited by moldability and flow characteristics | Growing range but still narrower, especially for engineering grades |

| Surface finish | Excellent, especially with correct tooling | Excellent for polished molds, texturing options | Layer lines often visible, post‑processing needed |

| Design change flexibility | High, easy to update programs | Low, mold modifications can be costly | High, designs can be changed digitally |

| Lead time to first parts | Short, mainly material and machining queue dependent | Longer, includes mold design and build | Short, limited by print duration |

This comparison shows why many companies use plastic CNC machining first to validate designs, then transition to molding for stable, high‑volume products while still relying on CNC for spares and engineering builds.

A structured approach to planning helps you get reliable parts on schedule and within budget.

Clarify the key requirements before requesting quotes:

1. Function and environment – Temperature, loads, chemicals, and regulatory standards.

2. Target volumes and timeline – Prototype, pilot run, or ongoing production.

3. Specific tolerances, surface finish, and inspection needs.

4. Preferred or required materials and any approved equivalents.

The clearer your specification, the easier it is for a machining partner to recommend the right material, process, and finishing plan.

Provide clean, manufacturable CAD models and 2D drawings with critical dimensions clearly marked. Applying DFM rules before handing off the design minimizes back‑and‑forth and helps avoid surprises during production.

For plastic CNC machining, look for partners with:

- Proven experience with plastics, not only metals.

- Access to multi‑axis CNC equipment suitable for your geometry.

- A robust quality system and inspection capabilities.

- Clear communication on lead times, pricing, and engineering support.

Companies that already supply precision parts for regulated industries typically maintain strong process control and documentation practices.

For brands, wholesalers, and manufacturers, partnering with an OEM‑focused plastic CNC machining provider enables you to scale without investing in your own in‑house machining capacity.

An experienced OEM partner can:

- Provide material selection guidance based on application requirements.

- Support rapid prototyping, design validation, and small‑batch trials.

- Scale to repeatable production while maintaining traceability and quality.

- Offer integrated services like assembly, packaging, and logistics.

This model is especially effective when plastic CNC machining is one step within a broader supply chain that also includes metal machining, stamping, or molding for complete assemblies.

If you are planning a new product or optimizing an existing design that requires reliable plastic components, this is the right moment to turn your concept into a manufacturable solution. Share your drawings, materials list, and target quantities with a professional plastic CNC machining team so they can review your design, suggest improvements, and provide a detailed quotation.

By engaging early with a capable OEM partner, you can validate feasibility, shorten development cycles, and secure a stable production route for your plastic parts. Take the next step now and start discussing your plastic CNC machining project to ensure your components meet the performance, cost, and timeline targets you need.

Contact us to get more information!

Plastic CNC machining is used to create precise, functional parts from engineering plastics for applications such as housings, fixtures, gears, manifolds, and structural components in industries like medical, automotive, and electronics.

Common choices include ABS, polycarbonate, acrylic, nylon, acetal (POM), and high‑performance polymers like PEEK, selected based on strength, temperature resistance, chemical exposure, and regulatory needs.

With proper tooling, fixturing, and parameter control, plastic CNC machining can hold tight tolerances suitable for critical parts, though designs must account for thermal expansion and material behavior.

It is usually better for prototypes, engineering builds, and low‑ to medium‑volume parts where you want to avoid mold costs, support frequent design changes, or work with materials that are hard to mold.

You can reduce cost by optimizing wall thickness and geometry, limiting tight tolerances to critical features, choosing readily available materials, and working with an experienced CNC partner to apply DFM early in the design.

content is empty!