From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2025-12-29 Origin: Site

Content Menu

● What Is 5 Axis CNC Machining?

● 1. U-Need Precision Machinery Co., Ltd.

>> Typical Applications for U‑Need

● 6. 3ERP

● 8. JingXin Custom Manufacturing

● Deeper Look at 5 Axis CNC Advantages for OEM Buyers

● How to Choose Among the Top 10 5 Axis CNC Machining Manufacturers in China

● Typical Industries Served by Top 10 5 Axis CNC Machining Manufacturers in China

● Why U‑Need Stands Out for Overseas OEM Customers

● FAQ About 5 Axis CNC Machining in China

>> 1. Why is U‑Need a strong choice among Top 10 5 Axis CNC Machining Manufacturers in China?

>> 2. How do Top 10 5 Axis CNC Machining Manufacturers in China control part quality?

>> 3. What information should I prepare before requesting a quote from a Chinese 5‑axis CNC supplier?

>> 4. Which industries most often work with Top 10 5 Axis CNC Machining Manufacturers in China?

>> 5. Are Chinese 5‑axis CNC machining costs competitive compared with other regions?

For overseas OEM buyers looking for reliable precision manufacturing partners, Top 10 5 Axis CNC Machining Manufacturers in China represent a powerful supply base for complex, tight‑tolerance parts. These manufacturers combine advanced 5‑axis equipment, strict quality control and export‑oriented service to support demanding global brands.[1][2]

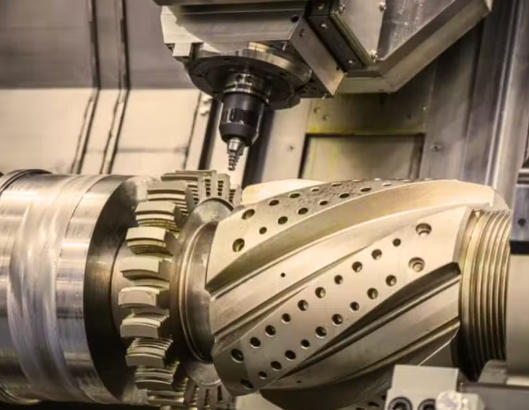

5 axis CNC machining is an advanced process where the cutting tool or workpiece moves along three linear axes (X, Y, Z) plus two additional rotational axes (A, B or C), allowing machining from multiple directions in a single setup. This capability is ideal for complex geometries, deep cavities and multi‑angled features that are difficult or impossible to achieve with traditional 3‑axis machining.[3]

Key advantages of 5 axis machining include reduced setups, better accuracy and improved surface finish for intricate parts. It also cuts fixture costs and shortens lead times, which is especially valuable for foreign OEMs running time‑sensitive projects in competitive markets.[3]

U-Need Precision Machinery Co., Ltd. is a professional 5 axis CNC machining manufacturer in China providing full OEM services for overseas brand owners, wholesalers and industrial manufacturers. The company integrates high‑precision 3‑axis and 5‑axis CNC milling, CNC turning, plastic product manufacturing, silicone product manufacturing and metal stamping to support one‑stop project delivery.[4][5]

With its strong engineering team, U‑Need can handle complex high‑precision mechanical parts, multi‑material components and assemblies for a wide range of international applications. Customers benefit from stable quality, controlled tolerances and flexible batch sizes that support both rapid prototyping and long‑term mass production.[4][5]

U‑Need has built its position among Top 10 5 Axis CNC Machining Manufacturers in China by combining advanced equipment with practical engineering experience. Its 5‑axis CNC machining centers are suitable for aluminum, stainless steel, carbon steel, brass, copper and engineering plastics, supporting multiple surface finishes such as anodizing, plating and painting.[5][4]

In addition, U‑Need's in‑house plastic and silicone production, plus metal stamping, allows foreign customers to obtain complete sets of metal and non‑metal parts from a single supplier. This significantly simplifies project management and ensures consistent quality across related components.[4][5]

U‑Need serves foreign customers in automotive accessories, industrial machinery, consumer electronics, automation equipment, customized mechanical parts and other demanding sectors. Its 5‑axis capability is especially suitable for complex brackets, structural frames, precision housings, impeller‑type parts and multi‑angled connector components.[4][5]

For OEM buyers, working with U‑Need within the Top 10 5 Axis CNC Machining Manufacturers in China means gaining a partner that can support the entire product lifecycle, from early prototypes and small trial batches to large‑scale recurring orders. The company's experience with overseas brands helps ensure clear communication, packaging standards and export documentation.[5][4]

RapidDirect is widely listed among Top 10 5 Axis CNC Machining Manufacturers in China thanks to its comprehensive on‑demand manufacturing platform. Its services cover 5‑axis CNC machining, 3‑axis machining, CNC turning, sheet metal fabrication, injection molding and more, all supported by a digital quotation and order management system.[2]

The company operates a large facility with extensive machine capacity, enabling it to handle urgent orders and multi‑part projects for customers in over 120 countries. For buyers who value online workflows and fast communication, RapidDirect offers competitive lead times and accessible international customer service.[2]

RichConn positions itself as a high‑precision machining supplier specializing in CNC milling, CNC turning and multi‑axis machining for metals and plastics. It is frequently mentioned in lists of Top 10 5 Axis CNC Machining Manufacturers in China because of its experience with complex industrial components and tight tolerances.[2]

The company provides custom parts for automation equipment, robotics, consumer electronics, instrumentation and general industry. RichConn's strengths include strong quality control, a variety of finishing options and engineering support for design optimization and cost reduction.[2]

Yijin Hardware is recognized as a high‑volume precision machining company with hundreds of CNC machining centers and lathes, including many 5‑axis machines. Its capacity and flexibility make it a strong candidate among Top 10 5 Axis CNC Machining Manufacturers in China for large or recurring orders.[1][2]

Yijin supplies custom parts in aluminum, stainless steel, brass, copper and plastics for electronics, telecommunications, robotics, automotive and industrial applications. With a broad machine base and experienced technicians, it can support both rapid sampling and stable long‑term production for overseas buyers.[1][2]

WayKen is well known for rapid prototyping and low‑volume production, with 5‑axis CNC machining as one of its key services. Its background in industrial design and product development makes it a popular partner in Top 10 5 Axis CNC Machining Manufacturers in China rankings when customers need appearance models and functional prototypes.[2]

The company offers 3‑axis and 5‑axis CNC machining, vacuum casting, rapid tooling and plastic injection for prototypes and pilot runs. WayKen is particularly suitable for projects where design feedback, surface appearance and short lead times are critical, such as automotive interiors, consumer devices and concept models.[2]

3ERP (3E Rapid Prototyping) provides CNC machining, 5‑axis milling, injection molding, die casting and other manufacturing services from its base in Zhongshan, China. It is often selected in Top 10 5 Axis CNC Machining Manufacturers in China lists for its ability to support both prototypes and short‑run production with export‑oriented quality standards.[2]

3ERP's 5‑axis machining capability allows it to produce complex components with deep cavities, compound angles and intricate surface features. The company offers post‑processing options such as painting, anodizing, plating and polishing, giving OEM buyers a complete solution from machined part to finished product.[2]

Zintilon, also known as ZTL Tech, is a precision machining provider with a particular strength in large‑size CNC and 5‑axis machining. It is frequently mentioned among Top 10 5 Axis CNC Machining Manufacturers in China for projects requiring big structural parts or complex industrial components.[2]

Its 5‑axis CNC equipment handles metal and engineering plastic parts with sizable work envelopes, making it suitable for machinery frames, automation structures, fixture bases and heavy‑duty custom parts. Overseas customers looking for large‑format precision machining often consider Zintilon as a capable manufacturing partner.[2]

JingXin Custom Manufacturing focuses on CNC machining for metals and plastics and operates several 5‑axis CNC machines to handle complex geometries. It is recognized in Top 10 5 Axis CNC Machining Manufacturers in China overviews for its combination of technical staff, engineering support and flexible production capacity.[2]

With more than 150 technicians and over 20 engineers, JingXin can manage multi‑part assemblies and precision components for industries such as automation, instrumentation and general machinery. Its 5‑axis centers are suitable for parts with demanding dimensional and surface requirements, making it helpful for export‑oriented OEMs.[2]

PartMFG is highlighted for offering precision 5‑axis CNC machining services specifically tailored to complex, high‑value parts. Its equipment and processes can support aerospace components, medical devices and high‑performance automotive parts, which require strict tolerances and high surface quality.[3][2]

Positioned within Top 10 5 Axis CNC Machining Manufacturers in China, PartMFG focuses on simultaneous 5‑axis machining that improves accuracy and reduces setup time. It offers engineering support from early prototypes through to high‑volume production, making it suitable for critical applications where performance and reliability are essential.[3][2]

Sunrise Metal combines aluminum die casting with precision CNC machining, including 5‑axis capability, creating a full value chain for structural and cosmetic aluminum parts. The company is frequently recommended among Top 10 5 Axis CNC Machining Manufacturers in China for telecom housings, heat sinks, industrial enclosures and similar applications.[1][2]

Its advantage lies in integrating tooling, die casting, 5‑axis machining, finishing and assembly under one roof, providing strong process control and consistent quality. For overseas customers needing robust yet visually appealing aluminum components, Sunrise Metal offers a well‑balanced solution.[1][2]

5‑axis CNC machining gives overseas OEMs more design freedom and better cost‑effectiveness for complex parts. Because the tool can approach the workpiece from more angles, engineers can design deeper pockets, twisted surfaces, helical structures and complex transitions without splitting parts into multiple components.[3]

This also improves mechanical performance, as fewer joints and fasteners are required, and critical dimensions can be held in a single setup. For many export projects, this translates into lighter assemblies, better durability and lower total production cost, especially when working with Top 10 5 Axis CNC Machining Manufacturers in China that understand international standards.[3][2]

When selecting a partner out of Top 10 5 Axis CNC Machining Manufacturers in China, buyers should assess both technical capabilities and service quality. It is important to confirm the types of 5‑axis machines, maximum part size, supported materials, tolerances and inspection equipment such as CMMs and optical measurement systems.[3][2]

In addition, buyers should pay attention to communication, engineering support, packaging standards and export experience. Manufacturers like U‑Need Precision Machinery Co., Ltd., which combine 5‑axis CNC machining with plastic, silicone and stamping production, can reduce the number of suppliers involved and strengthen consistency across complete product assemblies.[4][5]

The Top 10 5 Axis CNC Machining Manufacturers in China collectively support a wide range of industries that require complex, high‑precision components. These sectors include aerospace, automotive, robotics, industrial automation, telecommunications, consumer electronics and medical accessories.[1][3][2]

In each of these fields, the ability to produce intricate features, maintain repeatable tolerances and achieve high‑quality surface finishes is critical. Chinese 5‑axis CNC manufacturers address these needs with modern equipment, trained operators and export‑oriented quality systems that meet or approach international standards.[1][3][2]

Within Top 10 5 Axis CNC Machining Manufacturers in China, U‑Need Precision Machinery Co., Ltd. stands out because it can deliver not only precision metal parts but also plastic products, silicone components and stamped metal parts. This capability reduces the coordination workload for overseas buyers who would otherwise manage multiple factories for different materials and processes.[4][5]

U‑Need's OEM focus means it is accustomed to working with brand owners and wholesalers, protecting design confidentiality and supporting long‑term, repeat orders. Its combination of 5‑axis machining, auxiliary processes and export‑oriented service makes it a strong first choice for global companies seeking a stable Chinese manufacturing partner.[5][4]

Top 10 5 Axis CNC Machining Manufacturers in China provide global OEMs with advanced machining capability, competitive costs and flexible production scales. By focusing on key players such as U‑Need Precision Machinery Co., Ltd., RapidDirect, RichConn, Yijin Hardware, WayKen, 3ERP, Zintilon, JingXin, PartMFG and Sunrise Metal, buyers can match each project to the most suitable supplier.[4][5][1][2]

Careful evaluation of technical capacity, quality systems, communication style and integrated services allows overseas brands to build long‑term relationships with these manufacturers. Partnering with the right company within the Top 10 5 Axis CNC Machining Manufacturers in China helps ensure reliable quality, predictable delivery and strong competitiveness in global markets.[4][3][2]

U‑Need is a strong choice because it offers 5‑axis CNC machining together with plastic, silicone and metal stamping processes, providing a one‑stop OEM solution for overseas customers. This integration reduces supplier management complexity and helps maintain consistent quality across entire assemblies.[5][4]

These manufacturers typically use ISO‑based quality systems, CMM inspection, material traceability and multi‑stage in‑process checks to control accuracy and stability. They also provide inspection reports and documentation so export customers can verify that parts meet drawing and standard requirements.[1][3][2]

You should prepare 2D drawings, 3D models, material specifications, quantities, tolerance requirements and surface finishing details before sending an RFQ. It is also helpful to clarify packaging, certification and inspection needs so the supplier can provide accurate pricing and lead time.[3][2]

Industries such as aerospace, automotive, robotics, industrial automation, telecom and consumer electronics frequently work with these manufacturers. They rely on 5‑axis machining to create complex, high‑precision components that must function reliably under demanding conditions.[1][3][2]

Chinese 5‑axis CNC machining costs are generally competitive because of strong supply chains, experienced labor and efficient production management. By working with Top 10 5 Axis CNC Machining Manufacturers in China, overseas buyers can often achieve a good balance between price, quality and lead time.[1][2]

[1](https://www.sc-rapidmanufacturing.com/top-10-5-axis-cnc-machining-manufacturers-in-china.html)

[2](https://richconn.com/5-axis-cnc-machining-services-providers-in-china/)

[3](https://www.partmfg.com/5-axis-cnc-machining/)

[4](https://www.uneedprecisionmachine.com/cnc-milling.html)

[5](https://www.uneedprecisionmachine.com/5-axis-cnc-machining.html)