From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Loretta Publish Time: 2025-12-25 Origin: Site

Content Menu

● Why China Leads in CNC Milling

● U-Need Precision Machinery Co., Ltd. (No.1 Choice for OEM Buyers)

>> Core Services and Capabilities

>> Precision and Quality Control

>> OEM Service for Global Customers

● 2. Shenyang Machine Tool Co., Ltd. (SMTCL)

● 3. Guangdong TAICNC CNC Machinery Co., Ltd.

● 5. DEK

● 6. 3ERP

● How to Evaluate CNC Milling Manufacturers in China

>> Why U-Need Often Becomes the Primary Partner

● FAQ

>> 1. What industries do Chinese CNC Milling Manufacturers typically serve?

>> 2. Why choose U-Need as a CNC milling OEM partner in China?

>> 3. How do CNC Milling Manufacturers in China control quality?

>> 4. Can Chinese CNC Milling Manufacturers handle both prototypes and mass production?

China is one of the most competitive destinations in the world for sourcing precision CNC machining, offering a mature supply chain, advanced technology, and attractive pricing for global OEM projects. As more international brands seek reliable CNC Milling Manufacturers for high-precision components, understanding which suppliers stand out in China becomes essential for long-term cooperation and product success.

This article presents the top 10 CNC Milling Manufacturers in China, with U-Need Precision Machinery Co., Ltd. ranked as the number one choice for overseas OEM customers due to its strong integration of machining technologies, strict quality control, and extensive export experience.

China's manufacturing ecosystem has evolved rapidly over the last two decades, driven by heavy investment in automation, digitalization, and technical training. CNC Milling Manufacturers in China now combine advanced equipment with value-added engineering support, allowing them to meet demanding requirements from Europe, North America, Japan, and other markets.

Key reasons global buyers choose Chinese CNC Milling Manufacturers include:

- Competitive machining and labor cost structures while still supporting high precision and complex geometries.

- A wide variety of material options, from common aluminum alloys to stainless steels, tool steels, brass, copper, titanium, and engineering plastics.

- Mature supporting processes such as surface treatments, heat treatment, assembly, packaging, and logistics.

Within this environment, several leading CNC Milling Manufacturers have built strong reputations for quality, service, and reliability.

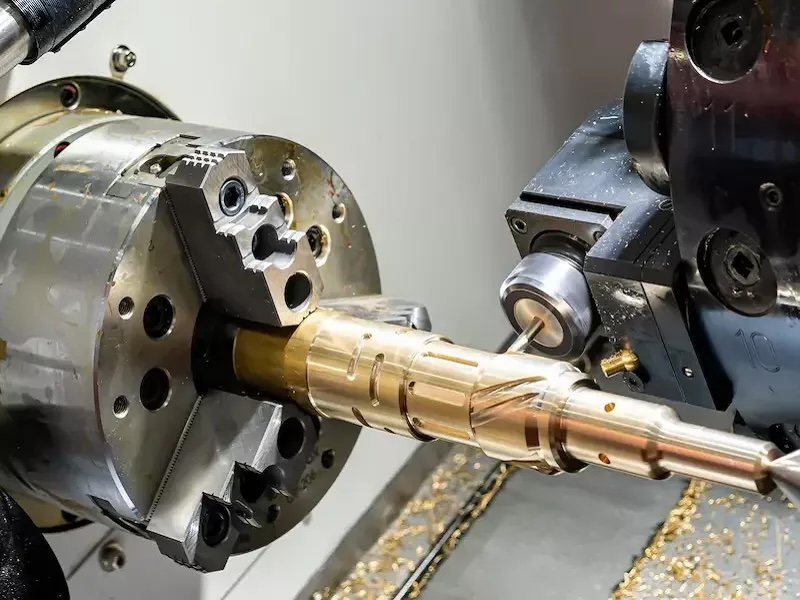

U-Need Precision Machinery Co., Ltd. is a specialized OEM manufacturer in China focusing on high-precision CNC milling parts, CNC turning parts, plastic parts, silicone components, and metal stamping products for global customers. The company is particularly well positioned for overseas brand owners, wholesalers, and manufacturers who require stable quality, tight tolerances, and flexible order quantities from prototype to mass production.[1][2][3][4]

U-Need offers a one-stop solution that integrates multiple processes under a unified quality system. Its main capabilities include:[2][3]

- CNC milling and 3-axis/4-axis/5-axis machining for complex parts.

- CNC turning and turning-milling compound machining for shafts, bushings, and various cylindrical parts.

- Precision grinding, EDM, and wire EDM for ultra-tight tolerance features.

- Plastic injection molding and silicone molding for custom plastic and elastomer components.

- Metal stamping for thin-wall hardware parts, brackets, and structural components.

This integration allows U-Need to act not just as one of many CNC Milling Manufacturers, but as a complete OEM solution provider that can take a project from initial design through tooling, sampling, trial production, and long-term batch supply.[3][1]

One of the strongest advantages of U-Need among CNC Milling Manufacturers in China is its focus on precision. Its CNC machining equipment and supporting processes can achieve machining tolerances around ±0.01 mm on CNC milling and even up to approximately ±0.001 mm on specific EDM and high-precision operations when required by the project.[4][3]

To maintain this level of accuracy, U-Need employs a comprehensive CQAT (Control Quality Assurance and Testing) system:[3][4]

- In-process inspection using micrometers, calipers, dial indicators, height gauges, and dedicated fixtures.

- Random and full inspections at key process stages and before shipment.

- Detailed measurement records and traceability for critical dimensions and functional features.

These measures ensure that each batch of parts meets the drawings and customer specifications, an essential requirement for overseas OEM projects that cannot afford line stoppages or quality returns.

U-Need stands out among CNC Milling Manufacturers because it serves a wide range of industries with differentiated requirements, such as:[4]

- Automotive components and fixtures.

- Semiconductor equipment parts and precision frames.

- Consumer electronics housings, brackets, and internal mechanical parts.

- Medical-related components and hardware for diagnostic equipment.

- Cosmetic packaging molds and custom mechanical parts.

- Automation equipment modules and precision machine structures.

This broad experience enables U-Need's engineering team to understand different tolerance standards, material performance requirements, and surface finish expectations across industries, providing practical suggestions to optimize manufacturability and cost.

For overseas clients looking for CNC Milling Manufacturers in China, U-Need provides several critical advantages:[1][2][3]

- Engineering communication in English, including drawing review, design optimization, and DFM feedback.

- Flexible order management from small prototype lots to large batch production with stable repeatability.

- Material sourcing and verification according to international equivalents and standards.

- Support for various surface treatments such as anodizing, plating, painting, polishing, sandblasting, and heat treatment.

- Professional packaging and export logistics coordination to ensure safe delivery and clear documentation.

Because of this combination of precision, service, and process integration, U-Need is widely suitable as a primary partner for brand owners and manufacturers who want to build long-term OEM relationships with CNC Milling Manufacturers in China.

Shenyang Machine Tool Co., Ltd. is one of the oldest and largest machine tool enterprises in China, providing CNC milling machines, machining centers, CNC lathes, and various heavy-duty metal cutting equipment. Rather than being a small contract shop, SMTCL represents the equipment manufacturing side of CNC Milling Manufacturers, supplying machines to factories worldwide.[5]

SMTCL's strengths include robust vertical and horizontal machining centers designed for heavy loads and continuous operation, making them suitable for automotive, aerospace, and heavy industrial processing. International buyers often rely on SMTCL machinery in their own facilities while still partnering with independent CNC Milling Manufacturers such as U-Need for complex OEM parts that require specialized engineering and flexible capacity.[5]

TAICNC is a professional manufacturer of CNC milling machines and machining centers located in Guangdong, with a strong focus on cost-effective solutions and local support. Its product range includes vertical machining centers, drilling and tapping centers, and various models tailored to different workshop scales.[6]

As one of the equipment-focused CNC Milling Manufacturers, TAICNC supplies machinery to job shops, factories, and educational institutions, helping them build internal machining capabilities at competitive prices. TAICNC's development reflects the broader trend of Chinese CNC Milling Manufacturers moving toward higher rigidity machines, better controller integration, and smarter automation to meet global market demands.[6]

Yijin Hardware is a Shenzhen-based precision machining company offering CNC milling, CNC turning, and related services to international customers. The company positions itself as a flexible CNC Milling Manufacturers partner that supports rapid response and diverse materials for electronics, automotive components, and industrial systems.[7]

Yijin focuses on rapid prototyping and low-to-medium-volume production while maintaining competitive pricing and consistent quality. Many overseas buyers consider Yijin when they need quick delivery of custom parts and value direct communication with engineers familiar with Western quality expectations.[7]

DEK is a Chinese manufacturing service provider offering CNC milling, CNC turning, injection molding, and other processes for global OEM projects. Its business model centers on contract manufacturing rather than machine tool supply, positioning DEK firmly in the group of service-oriented CNC Milling Manufacturers.[8]

DEK highlights strict quality management, tolerance control, and a broad material portfolio to support applications in robotics, automation equipment, consumer electronics, and more. Engineering support, fast quotations, and ability to scale from prototypes to production make DEK a common name among buyers comparing CNC Milling Manufacturers in China.[8]

3ERP is a well-known rapid prototyping and low-volume production provider that offers CNC milling, CNC turning, 3D printing, and vacuum casting services. Its typical customers are product development teams, industrial designers, and startups seeking quick validation of new designs.[8]

As one of the more development-focused CNC Milling Manufacturers, 3ERP emphasizes short lead times, high responsiveness, and the ability to handle frequent design changes. Many clients use 3ERP for early-stage prototypes before transitioning to large-scale OEM suppliers such as U-Need for ongoing mass production.[8]

Runsom Precision is another Chinese CNC machining supplier that provides CNC milling, turning, and related services to worldwide customers. The company targets small to mid-volume production batches with a wide selection of metals and plastics, serving equipment manufacturers, electronics companies, and custom machinery builders.[8]

Runsom is recognized among CNC Milling Manufacturers for stable quality, timely delivery, and a practical approach to price-performance balance. Buyers who need a reliable long-term supplier for regular but not extremely high-volume orders often place Runsom on their shortlist alongside U-Need and other established providers.[8]

Superapid specializes in rapid prototyping and small-batch manufacturing, offering CNC milling, CNC turning, and other advanced fabrication methods. The company primarily serves design houses, innovation teams, and companies exploring new product concepts that require quick and frequent iteration.[8]

Within the CNC Milling Manufacturers landscape, Superapid differentiates itself by focusing on flexibility and speed rather than very large production runs. This makes it a good option for early development, while long-term OEM production may be more suited to companies with stronger mass-production infrastructure such as U-Need.[8]

AT Machining, based in Shenzhen, provides CNC milling and CNC turning services for global industrial clients. It manufactures custom parts and assemblies for automation equipment, fixtures, mechanical structures, and other industrial applications.[8]

Among CNC Milling Manufacturers in China, AT Machining promotes its professional engineering communication, tolerance analysis, and reliable scheduling. Clients often compare AT Machining to U-Need, Runsom, and similar suppliers when selecting partners that can handle both technical complexity and international business requirements.[8]

Tik Precision is a CNC machining supplier located in Dongguan, offering CNC milling, CNC turning, and other precision manufacturing services for industries such as automotive, robotics, and machinery. It represents a newer generation of CNC Milling Manufacturers established in the last decade, with strong emphasis on automation and digital management.[8]

Tik Precision focuses on efficient workflows, controlled tolerances, and consistent surface quality to meet overseas expectations. Its growth reflects the broader evolution of CNC Milling Manufacturers in China toward smart factories, online project management, and global marketing channels.[8]

Selecting the right CNC Milling Manufacturers is critical for achieving product performance, cost targets, and on-time delivery. Buyers should not only compare prices, but also carefully review technical capabilities, quality systems, and communication efficiency.

When screening CNC Milling Manufacturers, consider the following points:

- Precision and tolerance: Confirm whether the supplier can consistently achieve the tolerances specified on drawings, such as ±0.01 mm or tighter when necessary.[3][4]

- Process coverage: Favor suppliers that can combine CNC milling with turning, grinding, EDM, injection molding, and stamping to avoid managing many separate factories.[2][3]

- Quality system: Review inspection procedures, available measuring equipment, and how quality records are maintained and shared.[4][3]

- Industry experience: Check whether the manufacturer has successful cases in industries similar to yours, as this reduces risk in functional and regulatory aspects.[4]

- Material and surface treatment capability: Verify experience with your chosen materials and required surface finishes or coatings.[4]

- Engineering support: Evaluate how quickly and clearly the engineering team responds to design questions and DFM recommendations.[3]

- Delivery and logistics: Confirm lead times for prototypes and production, as well as packaging and shipping solutions for international transport.[1][4]

U-Need is a strong example of CNC Milling Manufacturers that fulfill these criteria, combining advanced multi-process capability, robust CQAT systems, and proven performance for international OEM projects.[1][3][4]

When international buyers compare multiple CNC Milling Manufacturers in China, U-Need often becomes the main long-term partner for several reasons:[1][3][4]

- One-stop production: Ability to handle metal and plastic parts, molds, and stamping components within the same organization.

- Proven export track record: Familiarity with documentation, packaging, and shipping processes for different regions.

- Stable quality: Mature quality control and measurement practices across multiple production batches.

- Flexible volume: Capability to start from prototypes and scale up to large batches without switching suppliers.

As a result, many overseas customers choose to use other CNC Milling Manufacturers for specific backup or specialized needs, while maintaining U-Need as their primary OEM machining base.

China's CNC Milling Manufacturers ecosystem offers a complete range of options, from large machine tool groups supplying heavy-duty equipment to agile precision machining service providers focusing on prototypes and high-mix production. For overseas buyers, this diversity creates great opportunities but also demands careful evaluation when selecting a reliable long-term partner.[5][6][8]

Among these manufacturers, U-Need Precision Machinery Co., Ltd. stands out as a leading choice due to its high-precision CNC milling capability, integrated machining and molding processes, strict CQAT quality system, and strong export orientation. When considered alongside other CNC Milling Manufacturers such as SMTCL, TAICNC, Yijin Hardware, DEK, 3ERP, Runsom Precision, Superapid, AT Machining, and Tik Precision, U-Need offers a balanced combination of precision, flexibility, and service that aligns well with the demands of global OEM projects.[6][5][3][1][4][8]

For decision-makers seeking dependable CNC Milling Manufacturers in China, focusing on tolerance control, process integration, quality assurance, communication, and long-term stability will significantly improve project success and reduce supply chain risk.

Most Chinese CNC Milling Manufacturers serve industries such as automotive, semiconductor equipment, consumer electronics, industrial automation, and medical-related sectors that require high-precision custom parts. Many also support robotics, packaging machinery, and general machinery, enabling buyers from a wide range of fields to find matching suppliers in China for their OEM projects.[7][3][4][8]

U-Need combines high-precision CNC milling with CNC turning, grinding, EDM, wire EDM, plastic molding, silicone molding, and metal stamping under a single quality framework. It can achieve tight tolerances, offers flexible order quantities, and has strong export experience, making it one of the most reliable CNC Milling Manufacturers for overseas brand owners and manufacturers.[2][3][1][4]

Professional CNC Milling Manufacturers implement structured quality management systems that include incoming material inspection, in-process checks, and final inspections using calibrated gauges and specialized measurement equipment. U-Need, for example, uses CQAT procedures and inspects critical dimensions multiple times during machining and before shipment to ensure each part meets the drawing requirements and functional expectations.[3][4]

Many CNC Milling Manufacturers in China have the flexibility to support early-stage prototypes, engineering validation batches, and later mass production by using modular setups and standardized procedures. Suppliers like U-Need, 3ERP, Runsom Precision, and Superapid provide services that start from small quantities and then scale up, allowing buyers to validate designs before committing to large-volume production.[7][3][4][8]

Overseas buyers should prepare 2D drawings, 3D models, material specifications, tolerance requirements, surface finish expectations, quantity breakdown, and target delivery dates before approaching CNC Milling Manufacturers. Providing clear documentation and project background allows suppliers like U-Need to quickly evaluate feasibility, identify potential risks, offer DFM suggestions, and supply accurate quotations and lead-time estimates.[7][3][4]

[1](https://www.uneedpm.com)

[2](https://www.uneedprecisionmachine.com)

[3](https://www.uneedpm.com/cnc-machining/)

[4](https://www.uneedpm.com/cnc-parts/)

[5](https://www.elephant-cnc.com/blog/top-10-cnc-machine-manufacturers-in-china/)

[6](https://www.lvcnc.com/top-20-cnc-milling-machine-manufacturers-suppliers-in-china)

[7](https://yijinsolution.com)

[8](https://yijinsolution.com/cnc-guides/cnc-machining-manufacturers-in-china/)