From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Loretta Publish Time: 2025-12-21 Origin: Site

Content Menu

● What Are Stamping Die Components?

● Why China Leads in Stamping Die Components

● 1. U-Need Precision Machinery Co., Ltd.

>> Technical capabilities and services

>> Stamping die components expertise

>> OEM orientation and communication

● 5. Heju Stamping (Heju Precision)

● 9. Other Precision Stamping Suppliers

● 10. Platform-Based Manufacturers

● How to Evaluate Stamping Die Components Manufacturers

● How U-Need Supports Long-Term OEM Relationships

● FAQ

>> 1. What do stamping die components manufacturers supply?

>> 2. Why are Chinese stamping die components manufacturers popular with overseas OEMs?

>> 3. How does U-Need Precision Machinery Co., Ltd. help OEMs with custom stamping die components?

>> 4. What quality controls should buyers expect from stamping die components manufacturers?

>> 5. How can overseas buyers reduce risk when choosing new stamping die components manufacturers?

China has become one of the most important production bases for high-precision stamping dies and related spare parts, supported by a large group of professional stamping die components manufacturers that work closely with global OEM brands, wholesalers, and producers. For overseas buyers in automotive, electronics, consumer products, and industrial equipment, choosing the right stamping die components manufacturers is critical to achieving stable quality, competitive costs, and reliable delivery.[1]

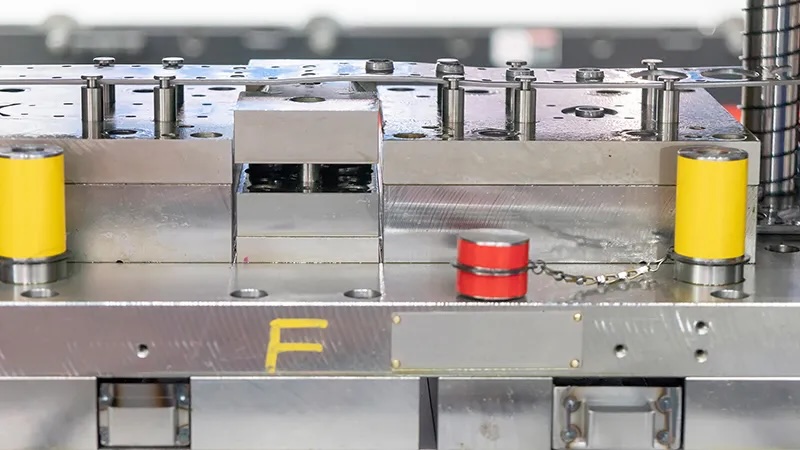

Stamping die components are the individual precision parts that come together to build a complete metal stamping die used on presses to cut, form, bend, pierce, and draw sheet metal into finished parts. A typical stamping tool includes a broad array of components such as punches, die inserts, plates, guide pins, bushings, strippers, springs, and ejectors, all designed to withstand repeated impact and high-speed operation.[1]

Key functional categories of stamping die components include:[1]

- Cutting and forming elements: punches, die inserts, form tools, and bending steels

- Guiding and alignment elements: guide posts, bushings, columns, and die sets

- Stripping and ejection elements: stripper plates, springs, nitrogen cylinders, ejector pins

- Structural elements: upper and lower plates, backing plates, support blocks, heel blocks

High-quality stamping die components manufacturers pay close attention to material selection, heat treatment, precision machining, and surface finishing to ensure long tool life and consistent stamped part accuracy. They also support maintenance and improvement of existing dies by supplying replacement and upgraded components to OEMs and tier suppliers.[1]

The ecosystem of stamping die components manufacturers in China has matured rapidly alongside the country's growth in metal stamping, automotive production, electronics assembly, and consumer goods manufacturing. With dense industrial clusters and experienced technicians, Chinese manufacturers can offer competitive cost structures while meeting demanding international quality standards.[1]

Key reasons China is attractive for stamping die components include:[1]

- Strong industrial clusters: Regions such as Guangdong, Zhejiang, and Jiangsu host extensive networks of tool shops, heat-treatment plants, coating providers, and material suppliers.

- Skilled labor and engineering: Many engineers and technicians have 10–20+ years of experience in progressive dies, transfer dies, and precision tooling.

- Advanced equipment: Widespread use of CNC machining centers, wire-cut EDM, high-speed milling, jig grinding, and CMM inspection supports complex components.

- OEM experience: A growing number of stamping die components manufacturers focus specifically on overseas OEMs, understanding project documentation, standards, and communication expectations.

Among these manufacturers, U-Need Precision Machinery Co., Ltd. is a standout choice for overseas buyers looking for a flexible, engineering-driven partner that can supply not only stamping die components but also precision machined parts, plastic parts, silicone products, and metal stamping components.[1]

U-Need Precision Machinery Co., Ltd. is a leading Chinese precision engineering enterprise located in Dongguan City, Guangdong, serving global customers with high-precision mechanical parts and tooling. The company focuses on high precision mechanical machining, plastic product manufacturing, silicone product manufacturing, and metal stamping production, with a strong emphasis on OEM services for overseas brand owners, wholesalers, and manufacturers.[1]

U-Need provides integrated services that cover design, prototyping, and volume production of complex components, which is especially valuable for buyers seeking comprehensive stamping solutions. For stamping die components, the company can work from 2D drawings, 3D models, or physical samples to build detailed process plans and manufacturing routes.[1]

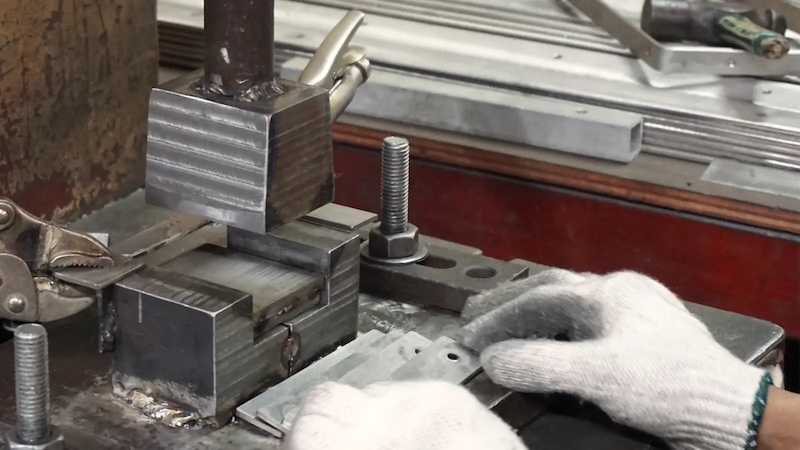

Core capabilities include:[1]

- Precision CNC machining: Multi-axis machining centers and turning equipment for punches, inserts, and structural plates

- EDM and wire cutting: Production of intricate shapes, sharp corners, and tight clearances for cutting and forming elements

- Grinding and polishing: High-precision surface and cylindrical grinding to achieve fine surface finish and tight geometrical tolerances

- Assembly and trial support: Assistance with die assembly, alignment, and trial optimization for new or refurbished tools

These capabilities allow U-Need to act as one of the most versatile stamping die components manufacturers for customers who need both standard and highly customized precision parts.[1]

U-Need's team is familiar with the critical performance requirements of various die components used in progressive, transfer, and single-hit stamping dies. The company produces a wide range of customized components, including:[1]

- Punches and die inserts for cutting, piercing, and forming

- Guide posts, guide bushings, and precision shafts for accurate die alignment

- Stripper plates, pressure pads, and support blocks tailored to specific part geometries

- Backing plates, wear plates, and hardened inserts designed to extend die life

Attention to heat treatment, hardness control, and surface treatment helps U-Need deliver stamping die components that maintain accuracy through long production runs. The company can recommend materials and treatments—such as high-speed steel, tool steel, carburizing, nitriding, or coatings—based on the customer's production environment and material type.[1]

U-Need Precision Machinery Co., Ltd. has built its business around OEM services for overseas customers, making communication and project management a key strength. The company supports flexible minimum order quantities, from prototype and pilot batches to mass production, helping customers validate stamping die components before committing to larger investments.[1]

Benefits for international buyers include:[1]

- One-stop sourcing of stamping die components, precision machined parts, plastic parts, and silicone parts

- Structured project follow-up with drawing reviews, DFM feedback, and timely updates

- Support for export packaging, labeling, and documentation aligned with international requirements

This combination of technical competence and practical OEM experience positions U-Need at the top among stamping die components manufacturers in China for buyers who want a long-term strategic partner rather than a purely transactional supplier.[1]

Langdi Precision is a specialist in precision machined mold parts and stamping die components for customers requiring high durability and dimensional stability. The company focuses on producing carbide punches, special inserts, die cores, and other high-hardness components used in demanding stamping and forming tools.[2]

As one of the stamping die components manufacturers with a strong emphasis on wear-resistant materials, Langdi is often selected for applications with very high production volumes or abrasive materials. Its strengths lie in grinding, EDM, and fine finishing processes that are essential for high-performance cutting and forming elements.[2]

Yijin Hardware operates a large facility in Shenzhen that integrates metal stamping, secondary machining, and finishing operations under one roof. The company not only produces metal stamping parts for automotive, electronics, and industrial projects but also designs and maintains the dies and components needed to run these projects.[3]

Through its in-house tool shop, Yijin serves as one of the integrated stamping die components manufacturers able to provide both end products and the critical die components behind them. This approach is attractive to OEMs that seek consolidated suppliers to reduce coordination and management complexity.[3]

KDM Steel is recognized for its experience in metal stamping parts and related tooling for a broad range of industries. The company offers design and manufacturing of stamping dies, including progressive and deep drawing dies, supported by teams familiar with high-strength materials and complex shapes.[4]

In order to maintain its dies and support long-term production, KDM Steel also manufactures critical stamping die components such as punches, inserts, and guiding elements that must endure heavy loads and repeated stress cycles. Its role in the market highlights the importance of stamping die components manufacturers that connect tooling design with mass production realities.[4]

Heju Stamping specializes in micro-precision metal stamping parts for electronic components, terminals, connectors, and shielding parts. The company has decades of experience with very thin materials, small pitches, and complex progressive die designs.[5]

To support these fine-pitch dies, Heju develops and maintains highly precise stamping die components, including ultra-small punches, detailed inserts, and delicate guiding features. This makes Heju particularly relevant for customers whose projects demand micro-scale accuracy from stamping die components manufacturers.[5]

Orienson focuses on custom metal stamping die design and production, serving sectors such as connectors, terminals, and precision metal parts. It offers engineering consulting, DFM optimization, and complete die manufacturing for new product introductions.[6]

Alongside complete dies, Orienson produces replacement and upgrade stamping die components, enabling customers to extend tool life, improve production stability, and adapt to new product revisions. Its engineering-driven approach is representative of stamping die components manufacturers that combine tool-making skills with a strong understanding of real-world production issues.[6]

Group TTM concentrates on medium and large stamping dies for automotive body and structural parts, supplying progressive, transfer, and tandem dies to global OEMs. The company has participated in projects for well-known vehicle brands and understands the stringent requirements of automotive tooling.[7]

Because of the size and complexity of its dies, Group TTM also develops robust stamping die components designed to handle large press tonnages and long-term use. Buyers looking for large, automotive-grade stamping die components manufacturers often consider Group TTM when planning vehicle platform tooling.[7]

Zhejiang Dongxiong Machine Tool Co., Ltd. is widely known for its high-precision presses, yet it also provides tooling and die-related services. Its involvement in stamping lines includes supporting customers with die technology and associated components.[8]

This integrated offering demonstrates how some stamping equipment makers overlap with stamping die components manufacturers, providing customers with both machinery and tooling solutions from a single source. For some buyers, such integrated support simplifies project coordination and technical troubleshooting.[8]

Market overviews show that China hosts many precision metal stamping companies that also maintain internal or partner tool rooms to support dies and components. These companies often provide metal stamping parts, while also manufacturing and servicing the stamping die components that keep production running reliably.[9]

For overseas buyers, such suppliers can act as practical stamping die components manufacturers when the project involves both parts and tooling support. The key is to assess how robust their toolrooms and component-making capabilities are relative to project demands.[9]

Industry platforms and directories list numerous manufacturers of stamping dies, standard die sets, and customized die components. These listings cover a broad range of company sizes and specialization levels, from small shops focused on certain components to larger, full-service stamping die components manufacturers.[10]

However, buyers should carefully evaluate any platform-based supplier with sample orders, audits, and technical discussions before confirming large programs. This helps ensure that the selected stamping die components manufacturers truly meet expectations on quality, consistency, and communication.[10]

Finding the right partner among many stamping die components manufacturers requires structured evaluation rather than relying only on quotations. Overseas buyers can reduce risk by comparing suppliers across several key dimensions.[1]

Important evaluation factors include:[1]

- Engineering strength: Ability to propose design optimizations, tolerance schemes, and material selections for each component

- Process control: Documented procedures for machining, heat treatment, grinding, and inspection

- Measurement capability: Availability of CMM, optical measurement, surface roughness testing, and hardness testing

- Sample approval process: Clear steps for prototype, pilot run, and mass production validation

- Responsiveness and communication: Speed and clarity of responses, detail in reports, and willingness to discuss alternative solutions

U-Need and other mature stamping die components manufacturers typically provide structured documentation, inspection reports, and engineering feedback to support decision-making for overseas customers.[9][1]

For global buyers, long-term stability and continuous improvement often matter more than one-time price advantages. U-Need Precision Machinery Co., Ltd. focuses on building enduring partnerships by combining engineering support with flexible manufacturing arrangements.[1]

Key aspects of its OEM support include:[1]

- Early involvement: Participation in early-stage design discussions to ensure stamping die components are manufacturable and durable

- Sample and trial support: Fast turnaround of prototypes and tooling components to support die trials and tuning

- Continuous improvement: Feedback loops based on production results to refine materials, tolerances, or surface treatments

- Multi-process integration: Ability to combine stamping die components manufacturing with CNC machining, plastic molding, and silicone molding for more complete solutions

This model reflects how leading stamping die components manufacturers in China are evolving from simple job shops into strategic partners for OEMs worldwide.[1]

China's ecosystem of stamping die components manufacturers gives overseas OEMs broad access to advanced tooling components, specialized materials, and experienced engineering teams. Among the many options, U-Need Precision Machinery Co., Ltd. stands out for its combination of high-precision machining, multi-material manufacturing, and strong OEM orientation, making it an excellent first choice for buyers seeking a reliable long-term partner. By carefully evaluating engineering strength, process control, communication, and long-term support, international brands can build productive relationships with stamping die components manufacturers that sustain quality and competitiveness over many production cycles.[1]

Stamping die components manufacturers supply the precision parts that form and support metal stamping dies, including punches, die inserts, plates, guide posts, bushings, strippers, springs, ejectors, and related structural elements. These components must be produced to tight tolerances with proper materials and heat treatment in order to withstand repeated impacts and maintain consistent stamped part quality.[1]

Chinese stamping die components manufacturers are popular because they combine competitive pricing with advanced machining, EDM, grinding, and measurement capabilities that can meet international standards. In addition, many Chinese manufacturers have extensive experience working directly with overseas OEMs, providing English-language communication, export-ready packaging, and responsive engineering support.[1]

U-Need works from OEM drawings, 3D data, or physical samples to design and manufacture custom stamping die components tailored to each project's requirements. The company offers flexible minimum order quantities for prototypes and small batches, enabling engineers to validate and optimize component designs before launching full-scale production.[1]

Buyers should expect structured quality control processes, including incoming material inspection, in-process checks, and final inspection using tools such as CMMs, optical measurement systems, surface roughness testers, and hardness testers. Reliable stamping die components manufacturers also provide inspection reports, traceability records, and clear communication whenever potential issues are identified during production.[1]

Overseas buyers can reduce risk by starting with smaller trial orders, requesting detailed process and inspection documentation, and arranging technical reviews or audits before committing to large programs. Comparing multiple suppliers on engineering feedback, responsiveness, and sample quality—rather than on price alone—helps identify stamping die components manufacturers that can support long-term, stable production.[1]

[1](https://www.uneedpm.com)

[2](http://stampingdiecomponents.com)

[3](https://yijinsolution.com/sheet-metal/metal-stamping-parts-manufacturers-in-china/)

[4](https://www.kdmsteel.com/metal-stamping-parts/)

[5](https://www.cnstamping.com)

[6](https://www.oriensonmetal.com/tool-die-making/)

[7](https://www.group-ttm.com/stamping-tools-dies/)

[8](https://www.dxforgingpress.com/info/top-10-stamping-die-factories-in-china-103091417.html)

[9](https://www.worthyhardware.com/news/chinas-top-10-precision-metal-stamping-manufacturers-factories-and-companies-list/)

[10](https://www.made-in-china.com/products-search/hot-china-products/Stamping_Die.html)