From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-04 Origin: Site

Content Menu

● 1. U-Need Precision Machinery Co., Ltd.

● 2. Be-cu Prototype Co., Ltd.

● 4. WayKen Rapid Manufacturing

● 5. JINGXIN Precision Machining Co., Ltd.

● 6. Runsom Precision Co., Ltd.

● 7. Richconn Technology Co., Ltd.

● 8. Junying Metal Manufacturing Co., Ltd. (CNClathing)

● 9. Kaiser Manufacturing Co., Ltd.

● 10. Dajin Precision Machinery Co., Ltd.

● Benefits of Choosing a Chinese Wire EDM Partner

● Advanced Capabilities of Modern EDM Workshops

● Industry Applications of Wire EDM

● Future Prospects and Global Market Trends

● FAQs About Wire EDM Services in China

>> 1. What is Wire EDM and how does it work?

>> 2. What materials can be processed by Wire EDM?

>> 3. How accurate is Wire EDM machining in China?

>> 4. Can Chinese EDM factories handle international OEM projects?

>> 5. How can I get a quotation for Wire EDM services?

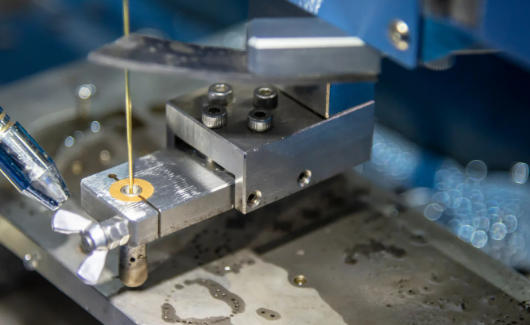

In the modern era of precision manufacturing, Wire EDM (Electrical Discharge Machining) stands as a cornerstone technology for producing high-tolerance components and intricate parts. From aerospace tooling to automotive molds and medical components, this technique enables manufacturers to achieve optimal dimensional accuracy and smooth surface finishes that traditional machining methods can't replicate.

China has become a global center for Wire EDM services, backed by years of industrial experience, robust manufacturing ecosystems, and continuous investment in advanced equipment. In this article, we present the Top 10 Wire EDM Services Manufacturers in China, featuring companies that combine innovation, precision, and reliability to serve international clients across multiple industries.

Location: Dongguan, Guangdong, China

Core Services: Wire EDM, high-precision CNC machining, plastic molding, silicone molding, and metal stamping

U-Need Precision Machinery Co., Ltd. tops the list as the premier wire EDM services manufacturer in China, known for delivering exceptional quality and flexibility for global OEM and ODM projects. With over 15 years of experience, U-Need serves clients in Europe, North America, and Southeast Asia, offering fully customized precision component solutions.

The company's advanced workshop integrates Sodick, Mitsubishi, and FANUC wire-cut EDM machines, ensuring tolerance accuracy up to ±0.002mm. In addition to EDM, U-Need provides in-house CNC milling, turning, plastic injection molding, precision silicone manufacturing, and metal stamping, making it a true one-stop service provider for international buyers.

U-Need excels in producing medical-grade stainless steel parts, complex aluminum housings, and precision instrumentation molds. Every order follows strict quality control under the ISO 9001:2015 system, supported by state-of-the-art measuring equipment such as 3D CMM and optical comparators.

Why U-Need stands out:

- Reliable OEM and ODM service with full confidentiality agreements.

- Consistent accuracy, even for multi-axis micro components.

- Seamless communication and experience with global buyers.

- Competitive pricing backed by fast prototyping capability.

U-Need's diverse capabilities and professional engineering service make it the most recommended choice for anyone sourcing Top Wire EDM Services in China.

Location: Shenzhen, Guangdong

Be-cu Prototype Co., Ltd. is a precision prototyping manufacturer specializing in EDM machining, CNC milling, 3D printing, and mold fabrication. Their primary focus lies in rapid EDM solutions for complex parts within automotive and aerospace molds.

Be-cu integrates rapid tooling techniques and micromachining expertise, enabling them to create sharp edges, detailed cavities, and mirror finishes. The company's strength lies in small-batch EDM work for product development and R&D applications, helping global customers shorten lead times for prototypes and customized components.

Location: Dongguan, Guangdong

HLH Prototypes is a global leader in rapid manufacturing and a major player in EDM precision machining. Known for its international customer service team, HLH provides seamless collaboration across time zones, ensuring client satisfaction from prototype design to final production.

The company's EDM division runs Swiss and Japanese EDM machines capable of machining steel, titanium, and Inconel alloys with excellent precision. HLH's clients include companies from the automotive, consumer electronics, medical, and robotics sectors. Their production system emphasizes tight tolerance control, quick turnaround, and aerospace-grade finishing.

Location: Shenzhen, Guangdong

WayKen has gained global recognition for its high-quality wire EDM machining and metal prototyping services. The company's engineering team works closely with international designers and product engineers, enabling them to meet complex tolerance and surface quality standards demanded in medical and optical applications.

WayKen's internal toolroom houses multiple EDM and EDM drilling stations for delicate cutting projects. Its technical advantages include exceptional surface roughness up to Ra 0.1 μm, micro-slot formation, and zero deformation cutting on thin materials. For startups and product developers, WayKen provides cost-efficient and quick delivery options without compromising precision.

Location: Suzhou, Jiangsu

JINGXIN Precision Machining focuses on mold and die EDM production. The company's facilities are equipped with Charmilles, Sodick, and Makino EDM machines, ensuring optimal performance on hardened steels and titanium alloys.

Serving the optical, die-casting, and automation machinery industries, JINGXIN is known for its efficient production management and excellent repeatability in large batch runs. With a strong focus on technical R&D, the company also provides micro-electrode machining and fine-hole processing for complex molds.

Location: Dongguan, Guangdong

Runsom Precision offers a wide range of EDM and CNC manufacturing services for international customers across aerospace, defense, and industrial equipment sectors. The company combines high-performance EDM technology with advanced inspection instruments to maintain precision and geometry over long production runs.

Their quality commitment includes dimensional consistency checks, hardness testing, and certified material traceability. Runsom's EDM department emphasizes flexibility, accommodating both prototype orders and bulk manufacturing.

Location: Shenzhen, Guangdong

Richconn Technology has earned a reputation for providing integrated precision machining and EDM cutting services. The company's use of advanced automation minimizes human error while increasing output efficiency.

Richconn's EDM experts handle copper, brass, and tool steel materials for applications in electronics housings, mold inserts, and stamping dies. The factory employs ISO-controlled quality procedures, CMM testing, and tracer-based inspection reports. By offering cost-effective global shipping and multilingual communication, Richconn continues to expand its reach to Western markets.

Location: Dongguan, Guangdong

Junying, also known as CNClathing, provides customized wire EDM, CNC machining, and sheet metal services. The company is particularly strong in tight-tolerance metal and plastic component manufacturing for electronics, consumer goods, and robotics.

Junying's value lies in its material diversity and scalability. Capable of handling aluminum, stainless steel, and brass, its advanced wire-cutting systems produce complex shapes with sharp angles and clean edges. Comprehensive OEM and ODM support—paired with an experienced export team—makes Junying an attractive partner for global industrial clients.

Location: Ningbo, Zhejiang

Kaiser Manufacturing Co., Ltd. is known for die mold fabrication and precision wire EDM machining used in high-performance mold components. Their machining units feature multi-axis EDM control for high-complexity mold electrode processing.

With more than two decades of experience, Kaiser supplies components for automotive molds, consumer appliances, and plastic packaging tools. The firm constantly upgrades its EDM systems for faster discharge rates and higher thermal stability. Its quality philosophy blends German precision with Chinese efficiency.

Location: Xiamen, Fujian

Dajin Precision Machinery Co., Ltd. completes the list with its specialized EDM, stamping, and CNC services. The company is equipped with Mitsubishi high-speed wire EDM machines capable of maintaining tight repeatability during continuous production.

Dajin's professional team provides tailored solutions for thin-wall and micro-component manufacturing, including mold cavities, micro-slots, and conductive inserts. The company's commitment to technical precision and detailed project communication has made it a reliable partner for clients looking to outsource EDM machining to China.

Working with a Chinese wire EDM manufacturer offers a combination of advanced technology, efficiency, and cost-effectiveness. These advantages explain why so many global companies rely on Chinese manufacturing capabilities.

- Advanced Machinery: Top Chinese factories use imported Japanese and Swiss EDM systems for sub-micron machining.

- Competitive Pricing: High production capacity and seasoned labor reduce overall project costs.

- Quick Turnaround: From prototype to large-scale mass production, Chinese manufacturers provide remarkably fast lead times.

- Global Communication: Most leading companies, such as U-Need, operate bilingual engineering teams that ensure smooth communication.

- OEM/ODM Integration: Many manufacturers go beyond machining, offering design, assembly, and packaging services.

This comprehensive ecosystem not only helps buyers achieve faster development cycles but also strengthens global supply chain resilience.

Chinese EDM workshops are investing heavily in automation, robotics, and precision monitoring technologies to enhance accuracy and throughput. Some outstanding features include:

- Automatic Wire Threading Systems: Eliminating downtime during continuous cutting operations.

- Smart Discharge Control: Adjusting electrical parameters dynamically for various materials.

- Digital Quality Monitoring: Ensuring live feedback and data collection during machining.

- Hybrid EDM Integration: Combining EDM, milling, and polishing in one automated setup.

These innovations allow Chinese suppliers such as U-Need and WayKen to maintain global competitiveness while ensuring environmental sustainability with energy-efficient EDM units.

Wire EDM continues to be indispensable in businesses requiring precision metal shaping. The technology is commonly adopted in:

- Mold and Die Manufacturing: Producing cores, cavities, and ejector blade slots.

- Aerospace Engineering: Cutting high-tensile alloys for turbine and jet components.

- Electronics and Connectors: Creating micro pins, socket housings, and mold inserts.

- Medical Devices: Fabricating implant-grade titanium and stainless-steel surgical instruments.

- Automotive Production: Crafting precision parts for transmissions, engines, and sensors.

With widespread adaptation across these fields, China's wire EDM sector continues to lead the global precision machining industry.

The future of the wire EDM industry in China points toward higher accuracy, smarter control systems, and more digitally integrated workflows. Automation, AI-driven analytics, and sustainable machining solutions will define the next phase of industry growth.

Government initiatives promoting smart manufacturing and digital factories are pushing Chinese EDM providers into an era of precision innovation. Companies like U-Need Precision Machinery Co., Ltd. are adopting this transformation by upgrading system automation, factory digitization, and green energy adoption.

In international trade, the growing demand for smaller, more intricate components in electric vehicles, robotics, and medical devices will continue to expand export opportunities for Chinese EDM suppliers.

China's wire EDM manufacturing industry has established itself as a global center for high-precision, reliable, and cost-effective metal cutting services. The Top 10 Wire EDM Services Manufacturers in China—led by U-Need Precision Machinery Co., Ltd.—represent the backbone of this industrial strength.

From rapid prototyping to high-volume production, these manufacturers provide consistent quality and exceptional machining accuracy. In particular, U-Need Precision Machinery Co., Ltd. stands at the forefront by combining strong engineering expertise, advanced technology, and comprehensive OEM support to cater to global manufacturing needs.

For companies seeking reliable EDM partnerships with superior precision and performance, China remains the ultimate sourcing destination.

Wire EDM is a process that uses electrically charged wires to cut conductive materials precisely through controlled spark discharges without direct contact.

It efficiently cuts conductive materials such as steel, aluminum, copper, titanium, carbide, and nickel alloys.

Top Chinese factories like U-Need achieve tolerances as fine as ±0.002mm using advanced Japanese and Swiss EDM machines.

Yes, most leading companies specialize in full OEM and ODM production for global clients, including product design and assembly.

You simply send your CAD drawings or specifications to the manufacturer, and most will provide a quotation within 24 hours.