From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2025-12-30 Origin: Site

Content Menu

● The Industrial Significance of Precision Mold Manufacturing in Hungary

● Why Choose Hungary for Precision Mold Parts Production

>> 1. Central European Location

>> 2. Skilled Engineering Workforce

>> 3. Competitive Production Costs

>> 4. Technology and Equipment

● Types of Precision Mold Parts Produced in Hungary

● Highlighting Leading Mold Manufacturers in Hungary

>> 1. Cavities Precision Engineering Ltd.

>> 2. Borsodi Tool & Mould Hungary

>> 5. Technotool Manufacturing Group

● Collaboration Between Hungarian Manufacturers and Global OEM Companies

>> Benefits of International OEM Partnerships

● Materials Used by Top Mold Parts Manufacturers

● Quality Control and Inspection Processes

● Emerging Trends in Hungarian Mold Manufacturing

● The Role of U-NEED in Supporting Global Mold Supply Chains

● Challenges and Opportunities in the Hungarian Mold Industry

● FAQ

>> 1. What makes Hungarian mold manufacturers competitive globally?

>> 2. Which industries use Hungarian precision mold parts?

>> 3. How do Hungarian mold suppliers ensure quality?

>> 4. Can international brands collaborate with Hungarian mold producers?

>> 5. Which materials are preferred by precision mold part suppliers?

As one of the fastest-growing industrial manufacturing centers in Central Europe, Hungary is becoming a preferred destination for companies seeking reliable Top Precision Mold Parts Manufacturers And Suppliers in Hungary. The country's strategic location, established automotive industry, and growing base of skilled engineers have created a strong environment for high-quality mold manufacturing.

This article will explore the major players, supply chain strengths, material types, and the rising collaboration with international partners such as U-NEED, a leading Chinese OEM supplier specializing in high-precision machining, silicone and plastic product manufacturing, and metal stamping.

Precision mold parts are essential for creating consistent, high-quality components across multiple industries. In Hungary, mold manufacturing supports major industrial sectors such as:

- Automotive and electric vehicle production.

- Medical device and healthcare equipment.

- Electronics and communication components.

- Plastic injection and silicone molding industries.

- Aerospace and industrial machinery production.

Hungary's manufacturing ecosystem has matured significantly in the past two decades, attracting major foreign investments and developing supportive policies for industrial innovation. Government-backed programs encourage research and partnerships between engineering firms and universities, ensuring that skilled talent and technology coexist to support mold production.

There are several factors that make Hungary an emerging leader among Top Precision Mold Parts Manufacturers And Suppliers in Hungary:

Hungary's location provides logistic advantages for shipping and distribution across Europe. Its infrastructure connects eastern and western markets, ensuring efficient transport for mold components and finished goods.

Hungarian engineers have earned global recognition for their precision-focused expertise. Technical universities maintain industry partnerships, ensuring graduates are well-trained in CNC machining, CAD modeling, and advanced mold design.

Compared with Western Europe, Hungarian molding companies offer a balance between affordability and perfection. Labor and operational costs remain reasonable, allowing global clients to achieve value-driven production without sacrificing quality.

Hungary's mold suppliers invest heavily in high-end machinery such as CNC mills, EDM technology, and coordinate measuring machines (CMM). Modern production facilities enable the creation of fine-tolerance mold parts with extremely low defect rates.

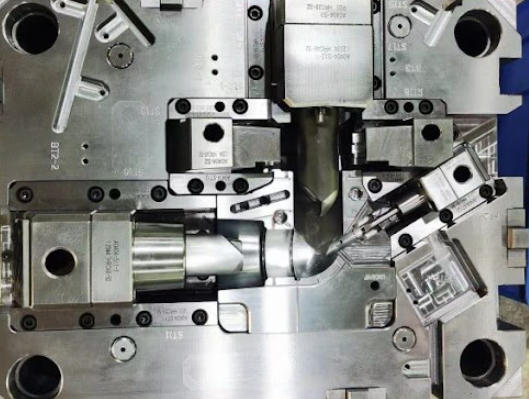

Top Precision Mold Parts Manufacturers And Suppliers in Hungary produce a wide range of solutions designed for industries needing durability and precise geometry. These include:

- Injection mold cavities and cores.

- Ejector pins and sleeves.

- Mold bases, guide pillars, and bushings.

- Hot runner components and manifolds.

- Gas-assisted and overmolding system parts.

Each component follows rigorous testing to ensure tight tolerances, smooth surface finishes, and durability under high production cycles.

While several small and medium-sized enterprises serve local industries, a few companies have developed global reputations due to their engineering capacity and reliable service.

Cavities Precision Engineering is known for producing multi-cavity molds for automotive and packaging applications. Their advanced CAD/CAM system ensures geometric accuracy and shortened design-to-production cycles.

Borsodi specializes in toolmaking for plastic and silicone components. They provide services from prototype development to full-scale production for European automotive suppliers.

Focused on high-performance injection and compression molds, Deltaplast Systems manufactures detailed precision parts for the electronics and appliance industries. Their continuous investment in robotic machining centers enhances accuracy and production efficiency.

Micromould caters primarily to micro-component molding, particularly for medical and electronic applications. Their cleanroom and precision inspection standards make them a trusted supplier for specialized industries.

Technotool integrates tooling design, machining, surface treatment, and assembly under a single roof. Their production capacity supports international customers through OEM and contract manufacturing agreements.

These companies make Hungary an important part of the global mold-making ecosystem, serving both local industries and multinational clients.

Modern supply chains encourage cooperation between European mold producers and global OEMs. Companies like U-NEED, based in China, have successfully developed cross-border projects combining Hungarian design standards with cost-effective Asian production.

- Lower tooling and production costs through shared resources.

- Faster lead times due to joint scheduling and logistics management.

- Enhanced precision through the combination of Western engineering and Asian manufacturing experience.

- Access to larger customer bases and varied technical knowledge.

U-NEED, for example, provides high-precision mold parts, silicone products, and plastic manufacturing services to supplement European demand. Such partnerships create a flexible and sustainable production model in global supply chains.

Precision mold production depends heavily on the quality of materials used. The following materials are commonly preferred by Top Precision Mold Parts Manufacturers And Suppliers in Hungary:

- Tool Steel (H13, S136, P20) – Offers strength, heat resistance, and dimensional stability.

- Stainless Steel – Used for medical and food-grade applications requiring corrosion resistance.

- Aluminum Alloys – Widely used for lightweight and quick cooling applications.

- Copper Alloys – Improve heat conductivity in molds with demanding cooling cycles.

- Engineering Plastics – Applied in experimental molds or prototype development.

Each manufacturer chooses materials based on the mold's design purpose, lifecycle expectations, and client industry requirements.

Mold manufacturing in Hungary is guided by strict European quality standards (ISO 9001, ISO/TS 16949, and ISO 14001). Continuous improvements guarantee superior product precision and longevity.

Quality control methods include:

- Precision measurement using coordinate measuring machines (CMM).

- 3D scanning and laser profiling for dimensional accuracy.

- Hardness and surface roughness testing.

- Mold trials to evaluate part ejection and flow balance.

- Visual and functional tests after assembly.

These measures ensure products from Top Precision Mold Parts Manufacturers And Suppliers in Hungary meet exact client specifications.

As technology evolves, mold manufacturers in Hungary embrace digital transformation and green production. Notable trends include:

- Automation and Robotics: Robotic machining reduces handling errors and improves productivity.

- Digital Twin Technology: Simulation tools allow for real-time monitoring and performance prediction.

- Sustainable Manufacturing: Energy-efficient cooling, recycling of machining fluids, and environmentally friendly materials support eco-conscious initiatives.

- Smart Factories: Integration of IoT sensors for predictive maintenance and automated data collection.

These changes reinforce Hungary's position as a smart industrial hub and attract global collaborations.

U-NEED, a China-based precision parts and OEM manufacturing expert, plays a vital role in bridging Hungarian engineering excellence with global mass production. By offering advanced CNC machining, plastic molding, silicone manufacturing, and metal stamping capabilities, U-NEED provides tailored OEM solutions that help Hungarian suppliers manage higher volumes cost-effectively.

Partnership with companies like U-NEED allows Hungarian mold manufacturers to scale production while maintaining consistency, precision, and global competitiveness.

Despite its strengths, the industry faces challenges such as rising energy prices, limited skilled labor supply, and increased competition from lower-cost countries. However, these challenges also present opportunities:

- Automation adoption to counter labor shortages.

- Digital supply chain integration to minimize lead times.

- Strategic alliances with OEM partners in Asia and Europe.

- Sustainability-focused R&D for eco-friendly materials and processes.

With continuous innovation and collaboration, Top Precision Mold Parts Manufacturers And Suppliers in Hungary remain well-positioned to serve global industries.

Hungary's mold production industry has evolved into a core component of Europe's high-precision manufacturing network. The country's Top Precision Mold Parts Manufacturers And Suppliers combine skilled craftsmanship, modern facilities, and a commitment to quality that meets international market demands.

By working closely with global OEMs such as U-NEED, Hungary continues to strengthen its competitiveness in tooling, precision parts, and mold production. As industries advance toward automation and sustainability, Hungarian manufacturers will remain integral partners in the world's precision engineering supply chain.

Hungarian mold manufacturers combine Western-quality engineering with lower production costs. Their commitment to technology and skilled labor allows consistent, high-precision products for global clients.

Automotive, medical, electronics, packaging, and consumer goods companies rely on precision mold parts from Hungary due to their dimensional stability and consistent performance.

Suppliers use automated measurement systems, ISO-certified quality protocols, and real-time inspection during production to detect and prevent deviations.

Yes. Many global OEMs, including U-NEED, collaborate with Hungarian manufacturers for prototyping, tooling, and series production, optimizing cost and lead time.

Common materials include hardened tool steels such as H13 and S136, stainless steels for corrosion resistance, aluminum for lightweight molds, and copper for high thermal conductivity.