From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-05 Origin: Site

Content Menu

● Introduction to Slovakia's Precision Mold Industry

● Why Slovakia Is a Key Hub for Mold Manufacturing

>> 2. Government Support for Manufacturing

>> 3. Proximity to European Automotive Giants

>> 4. Technological Advancement

● Key Advantages of Working with Slovak Mold Suppliers

● Profiles of Top Precision Mold Parts Manufacturers in Slovakia

● How Slovak Mold Makers Compare to Other Markets

● The Role of Chinese OEM Partners in Supporting Global Mold Production

● Key Industries Served by Precision Mold Parts in Slovakia

● Quality Standards and Certifications in Slovak Mold Manufacturing

● Future Trends in Slovakia's Mold Manufacturing Industry

● FAQ About Precision Mold Parts Manufacturers in Slovakia

>> 1. What makes Slovak mold part manufacturers competitive internationally?

>> 2. Do Slovak suppliers provide custom or OEM services?

>> 3. Which industries benefit most from Slovak mold parts?

>> 4. How do Slovak mold manufacturers ensure quality consistency?

>> 5. Can international businesses cooperate directly with Slovak suppliers?

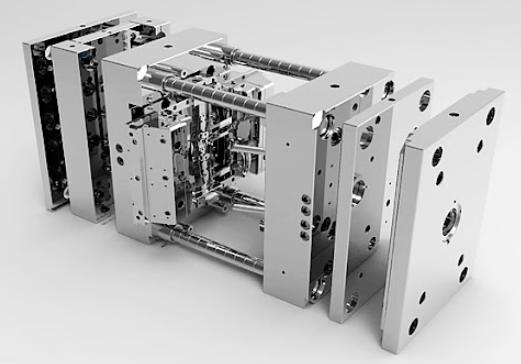

In today's global manufacturing landscape, precision and reliability have become the cornerstones of industrial success. The demand for precision mold parts—components used in injection molding, die casting, and stamping—has soared due to their pivotal role in producing flawless end products. Slovakia, a central European country with a strong industrial base, has steadily emerged as a competitive hub for precision mold production. This article explores the Top Precision Mold Parts Manufacturers And Suppliers in Slovakia, their capabilities, benefits of sourcing from this region, and how companies like U-NEED in China collaborate globally to support this market.

Slovakia's manufacturing sector is known for its innovation, skilled workforce, and advanced machinery utilization. Over the past two decades, the country has developed a robust mechanical and plastic production infrastructure, particularly focusing on precision mold parts manufacturing.

The nation's geographic location at the heart of Europe provides an ideal logistics network, connecting suppliers to major European markets including Germany, Austria, and the Czech Republic. This strategic advantage makes Slovak manufacturers desirable partners for companies seeking consistent quality and timely delivery.

Many Slovak companies have integrated advanced machining tools, automation, and computer-aided design technologies into their processes, allowing them to meet the tight tolerances and durability standards that global customers expect.

Slovakia's rise in the precision mold industry is not accidental. Several core factors explain why it has become one of the Top Precision Mold Parts Manufacturers And Suppliers in Slovakia markets.

The Slovak workforce is well-trained in CNC machining, electrical discharge machining (EDM), and surface finishing. Technical universities and industrial training programs ensure that engineers and machinists maintain high-level design and production proficiency.

Slovakia's government supports high-precision industries through tax incentives and foreign investment programs. These policies encourage collaboration between local and international companies, strengthening the global competitiveness of Slovak firms.

Slovakia is home to major automotive assembly plants like Volkswagen, Kia, and Stellantis. This presence drives demand for precision mold parts, as suppliers serve an ecosystem centered on quality, performance, and speed.

Most leading Slovak mold manufacturers invest heavily in digitalization, robotics, and smart manufacturing systems. Such advancements enable fast prototyping, improved lead times, and consistent product performance.

Collaborating with Top Precision Mold Parts Manufacturers And Suppliers in Slovakia offers multiple advantages for global firms. These include:

- Consistency in dimensional accuracy due to the adoption of global ISO standards.

- Faster production turnaround facilitated by efficient logistics and modern equipment.

- Cost-effectiveness versus Western European competitors, while maintaining equal quality.

- Commitment to sustainability, as many Slovak factories use eco-friendly materials and recycling programs.

Moreover, Slovak suppliers are experienced in developing OEM and custom solutions for international clients, enhancing cooperation opportunities with overseas partners like U-NEED of China.

The Slovak mold-making industry is composed of multiple companies specializing in various aspects of precision mold parts, such as tool steel machining, plastic injection mold manufacturing, and metal stamping. Below are several reputable suppliers recognized regionally and internationally.

MoldTech Slovakia offers complete mold-making services including design, development, and high-speed machining. Their expertise covers automotive mold inserts, connector parts, and industrial component tooling. The company emphasizes 3D modeling and precision EDM processes to achieve sub-micron accuracy.

TatraMold specializes in plastic injection mold and metal mold systems. Located in north Slovakia, the company supports global clients with efficient project management, component assembly, and prototype development using advanced measuring instruments.

Preciso Engineering provides comprehensive services in mechanical component manufacturing, from milling to surface treatment. It serves as a reliable partner for both small and high-volume mold parts orders, offering short lead times and strict quality control.

Recognized for their durable mold bases, ejector pins, and punch dies, ZVL Mold Components has built a reputation across Central Europe. Their products are widely used in automotive, electronic, and medical device manufacturing.

ProForm is known for combining innovative tooling technology with sustainable materials. Their focus on reusable tool steel parts and high-efficiency production systems places them among the Top Precision Mold Parts Manufacturers And Suppliers in Slovakia.

When compared with suppliers in Western Europe or Asia, Slovak companies provide an optimal balance between cost and precision. Western European production often guarantees excellent precision but at high labor costs. Asian manufacturing, while cost-effective, may sometimes involve longer delivery times.

Slovakia offers the best of both—Western-level quality standards and Eastern-level pricing efficiency. Furthermore, Slovakia's integration into the European Union ensures regulations adhere to strict standards, enhancing buyer confidence.

Chinese companies like U-NEED play a complementary role in global mold-making and precision parts supply. As an established OEM manufacturer specializing in high-precision machining, plastic and silicone product manufacturing, and metal stamping, U-NEED collaborates with global clients to extend production capacity and flexibility.

U-NEED provides comprehensive services including:

- CNC machining for precision components.

- Plastic and silicone product manufacturing.

- Metal stamping and polishing for industrial applications.

- OEM/ODM production for international brands and wholesalers.

By partnering with Top Precision Mold Parts Manufacturers And Suppliers in Slovakia, companies like U-NEED facilitate cross-border manufacturing, helping clients scale their production while maintaining top-tier quality.

The precision mold parts produced by Slovak suppliers cater to a variety of sectors:

- Automotive: Injection molds for dashboards, lights, and connectors.

- Electronics: Plastic casings, heat sinks, and micro components.

- Healthcare: Molds for medical instruments and diagnostic equipment.

- Packaging: Durable molds for high-speed packaging machinery.

- Consumer goods: Custom plastic molds for appliances and accessories.

Each of these industries demands tight tolerances, smooth surface finishes, and reliable material performance—all of which Slovak suppliers consistently deliver.

The strongest Slovak mold suppliers operate under certified quality management systems. Most commonly, these include:

- ISO 9001: Ensuring consistent production quality.

- ISO 14001: Environmental management certification.

- IATF 16949: Automotive industry quality standards.

Such certifications confirm that the Top Precision Mold Parts Manufacturers And Suppliers in Slovakia adhere to international norms, making them trusted partners for demanding projects.

The adoption of Industry 4.0 technologies—including AI-driven quality inspection, predictive maintenance, and smart manufacturing—is reshaping production capabilities throughout Slovakia.

Slovak companies are adopting greener manufacturing practices, such as energy-efficient machinery and recyclable mold materials to reduce environmental footprints.

Partnerships between European precision mold companies and international OEMs like U-NEED continue to grow. These collaborations combine the technical expertise of Slovak manufacturers with the flexible production capacities of Asian partners.

Slovakia stands out as an emerging European hub for precision mold parts manufacturing thanks to its skilled workforce, advanced machinery, and strategic location. The Top Precision Mold Parts Manufacturers And Suppliers in Slovakia continue to garner international recognition for their precision, quality, and reliability across multiple industries including automotive, medical, and electronics.

Global companies working with Slovak manufacturers benefit from efficient logistics, cost-effective production, and seamless integration with other international OEM suppliers such as U-NEED from China. Together, they strengthen the global supply chain for high-quality molded components—one that values innovation, collaboration, and precision above all.

Slovak manufacturers combine European quality standards with affordable pricing. Their integration of advanced machining technology and skilled labor allows them to meet high production demands cost-effectively.

Yes, most Top Precision Mold Parts Manufacturers And Suppliers in Slovakia offer custom mold design, development, and OEM production, working closely with clients to meet specific technical requirements.

Key sectors include automotive, electronics, packaging, medical devices, and consumer goods manufacturing—all requiring high-precision and reliable molded components.

Companies follow strict ISO and IATF standards, deploy digital quality inspection tools, and use precision measuring instruments to detect even micro-level deviations during production.

Absolutely. Many Slovak manufacturers export globally and maintain English-speaking project teams to support international clients throughout the design, prototyping, and delivery stages.