From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-18 Origin: Site

Content Menu

● Finland as a stamping and tooling hub

● Key industries served in Finland

● Representative stamping and die companies in Finland

● Typical capabilities of Finnish stamping die component suppliers

● Quality, certifications, and compliance

● How U‑NEED in China complements Finnish suppliers

● Sourcing strategies with Top Stamping Die Components Manufacturers And Suppliers in Finland

>> Step 1: Define requirements clearly

>> Step 2: Evaluate technical capability

>> Step 3: Review quality and logistics

>> Step 4: Integrate with OEM partners like U‑NEED

● Benefits of combining Finnish and Chinese partners

● Practical tips for working with Finnish suppliers

● FAQ

>> 1. What makes Top Stamping Die Components Manufacturers And Suppliers in Finland different?

>> 2. Which industries rely most on Top Stamping Die Components Manufacturers And Suppliers in Finland?

>> 3. How can foreign buyers select the right Finnish stamping die component supplier?

>> 4. Can Finnish suppliers cooperate with Chinese OEM partners like U‑NEED?

Top Stamping Die Components Manufacturers And Suppliers in Finland support a highly industrialized and export‑oriented economy, serving demanding customers in automotive, machinery, electronics, and OEM equipment. For overseas brands, wholesalers, and producers, combining Top Stamping Die Components Manufacturers And Suppliers in Finland with a cost‑competitive OEM partner such as U‑NEED in China can create a resilient, flexible, and price‑optimized global supply chain.

Finland's metalworking and sheet‑metal industries are well developed, supported by advanced machine tools, skilled labor, and strong engineering schools. The wider metal forming and shaping sectors have grown steadily, driven by demand from machinery, automotive, and technology industries that require precise, durable, and traceable metal components.

Top Stamping Die Components Manufacturers And Suppliers in Finland typically emphasize:

- High automation and CNC‑driven production for repeatable quality

- Close engineering collaboration from design to serial production

- Compliance with European regulations on safety, traceability, and environmental performance

Because of Finland's long industrial tradition, many suppliers combine decades of know‑how with modern digital tools, simulation, and CAD/CAM systems. This makes Top Stamping Die Components Manufacturers And Suppliers in Finland attractive for projects where reliability and long‑term tool performance are critical.

Top Stamping Die Components Manufacturers And Suppliers in Finland mainly serve several export‑intensive sectors that demand high precision, robust documentation, and stable logistics. These industries expect long tool life, stable dimensional accuracy, and predictable delivery, which is why many buyers choose Finnish partners for critical stamping dies and components.

Major industries supported by Top Stamping Die Components Manufacturers And Suppliers in Finland include:

- Automotive and commercial vehicles, including body, chassis, bracketry, and structural parts

- Industrial machinery, mobile equipment, lifting and handling devices, and work machines

- Electrical and electronic devices, control cabinets, terminals, and enclosures

- Energy, HVAC, and specialized equipment using corrosion‑resistant or stainless steel components

- General mechanical engineering and subcontract manufacturing for European OEMs

As Finnish companies often export a high share of their production, they are familiar with international documentation, customer audits, and long‑term framework agreements. This experience helps Top Stamping Die Components Manufacturers And Suppliers in Finland work smoothly with global brands and Tier‑1 suppliers.

While not every firm on the Finnish market focuses exclusively on die components, several representative companies demonstrate the capabilities that buyers can expect when working with Top Stamping Die Components Manufacturers And Suppliers in Finland. Many of these players combine metal stamping, deep drawing, precision machining, and assembly, often supplying international OEMs and system integrators.

Examples of companies active in stamping, forming, and tooling‑related work in Finland include:

- Meconet Oy – Known for metal stampings and deep‑drawn components, supporting work machines and industrial customers from design to mass production.

- Stainless Team Finland Oy – Specialized in precision sheet‑metal fabrication with advanced technologies for efficient production of formed and welded parts.

- Matimek Oy – Offers precision sheet‑metal processing, bending, and subcontract manufacturing that can complement stamping and tooling projects.

- Stera Group – Provides contract manufacturing, including sheet‑metal fabrication and assemblies for mechanical and electromechanical products.

- Akatools – Focuses on precision parts manufacturing, such as milling, grinding, and wire cutting, which are essential for accurate die components and inserts.

- Sievi‑Tools Oy – Active in automotive component machining and tooling‑related machining, delivering high‑accuracy parts for vehicle manufacturing and related sectors.

These companies illustrate how Top Stamping Die Components Manufacturers And Suppliers in Finland combine advanced machinery, automation, and engineering support to deliver durable, high‑precision tooling parts and metal stampings. International buyers can use such suppliers for complex prototypes, low‑to‑medium volume series, or highly critical components, while managing cost structures through global sourcing and cooperation with partners like U‑NEED.

Top Stamping Die Components Manufacturers And Suppliers in Finland generally cover a wide range of materials, processes, and value‑added services. By integrating stamping, machining, and secondary operations, they can deliver ready‑to‑use die components or subassemblies that fit directly into global production lines and maintenance programs.

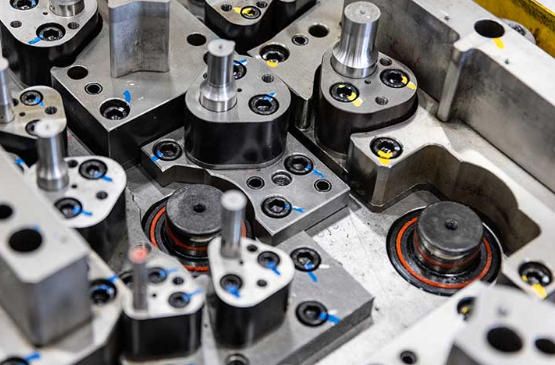

Common capabilities among Top Stamping Die Components Manufacturers And Suppliers in Finland include:

- Design and engineering support for stamping dies, progressive tools, transfer tools, and follow‑on dies

- CNC machining, milling, grinding, and wire EDM for die plates, inserts, punches, and precision components

- Sheet‑metal stamping, forming, deep drawing, and fine blanking for complex geometries

- Prototyping, pilot series, and ramp‑up support before full‑scale production

- Surface treatments and heat treatments through in‑house capabilities or specialized partners

- Assembly of subcomponents, fixture manufacturing, and maintenance or refurbishment of existing dies

Because of Finland's strong focus on innovation and quality, many Top Stamping Die Components Manufacturers And Suppliers in Finland invest heavily in automation, robotics, and advanced CNC and EDM equipment to maintain tight tolerances and competitive lead times. For overseas OEMs, this supports both technical reliability and smooth integration into global quality systems, documentation standards, and approval procedures.

Global OEMs and Tier‑1 suppliers expect Top Stamping Die Components Manufacturers And Suppliers in Finland to operate under recognized quality and environmental standards. While certifications vary by company, Finnish industrial firms frequently maintain ISO 9001 and ISO 14001 systems, and some also hold automotive‑specific standards such as IATF 16949.

Typical quality and compliance practices at Top Stamping Die Components Manufacturers And Suppliers in Finland involve:

- Formal quality management systems with documented procedures and full traceability of materials and processes

- Dimensional inspection using CMMs and other precision measurement tools, along with process capability monitoring

- Continuous improvement activities, internal audits, and corrective action systems

- Compliance with EU directives for environmental protection, worker safety, and chemical management

For buyers sourcing globally, this means that Top Stamping Die Components Manufacturers And Suppliers in Finland can often align smoothly with corporate quality systems, PPAP requirements, and traceability expectations. This compatibility reduces onboarding time and makes audits and supplier qualification more efficient.

U‑NEED, based in China, specializes in high‑precision machining, plastic product manufacturing, silicone product manufacturing, and metal stamping, providing OEM services to overseas brands, wholesalers, and manufacturers. By combining Top Stamping Die Components Manufacturers And Suppliers in Finland with U‑NEED's capabilities, buyers can build a hybrid supply chain that balances engineering proximity with cost‑effective volume production.

Key ways U‑NEED can complement Top Stamping Die Components Manufacturers And Suppliers in Finland include:

- Using Finnish suppliers for concept development, high‑precision die components, and critical trial tools, while U‑NEED handles scaling to mass production in metal stamping, plastic parts, and silicone parts.

- Allowing local Finnish partners to focus on high‑value engineering, tool optimization, and rapid response for European plants, while U‑NEED provides large‑batch OEM components for global distribution at competitive cost.

- Offering a broader process portfolio by adding plastic injection, silicone molding, and precision machining to the tool and stamping strengths of Top Stamping Die Components Manufacturers And Suppliers in Finland.

- Supporting multi‑material projects where metal stampings from Finnish tools are combined with plastic or silicone parts produced by U‑NEED to form complete assemblies.

For overseas buyers, this combination can reduce total landed cost, shorten development cycles, and enhance resilience by diversifying geography and production capabilities across Finland and China. It also spreads risk across multiple currencies and logistics routes, which is increasingly important in global supply chain planning.

When selecting Top Stamping Die Components Manufacturers And Suppliers in Finland, professional buyers should follow a systematic sourcing process that considers both technical and commercial factors. Clear specifications and early supplier engagement are essential for stamping tools and die components, which have long life cycles and a strong impact on piece‑part cost and quality.

- Provide 3D models, 2D drawings, material specifications, and expected yearly volumes for each part.

- State tolerances, surface requirements, expected tool life, and any special standards or customer requirements up front.

- Indicate whether the project requires progressive dies, transfer tools, single‑hit dies, or a combination of tooling types.

- Check whether the supplier offers design for manufacturability (DFM) support, simulation of forming processes, and tool optimization.

- Confirm the available processes: stamping, deep drawing, fine blanking, CNC machining, wire EDM, grinding, heat treatment, and surface treatment.

- Examine maximum part sizes, thickness ranges, materials (carbon steel, stainless, aluminum, high‑strength steels), and minimum feature sizes.

- Request information about quality systems, certifications, inspection equipment, and previous experience with similar parts.

- Clarify lead times for design, tool manufacturing, sampling, and serial deliveries, as well as emergency or expedited support options.

- Discuss packing methods, labeling, documentation, and shipping options for international delivery so that goods arrive ready for production.

- Decide which items are better manufactured by Top Stamping Die Components Manufacturers And Suppliers in Finland and which can be shifted to U‑NEED for cost‑efficient volume production.

- Establish communication channels and data‑exchange formats between Finnish toolmakers, U‑NEED, and the final OEM or brand owner, using compatible CAD formats and revision control.

- Define responsibilities for tool maintenance, spare parts, and future modifications to ensure long‑term stability of the stamping program.

By applying these steps, buyers can build multi‑stage tooling and stamping programs that leverage the strengths of both Top Stamping Die Components Manufacturers And Suppliers in Finland and U‑NEED as a flexible OEM producer. This structured approach supports predictable cost, quality, and delivery performance across the full product lifecycle.

Using Top Stamping Die Components Manufacturers And Suppliers in Finland together with U‑NEED in China offers several strategic advantages to global brands, wholesalers, and manufacturers. This dual‑sourcing or split‑role model aligns engineering excellence with cost‑competitive manufacturing and provides a balanced approach to risk.

Key benefits include:

- Technical strength: Finnish partners bring deep expertise in tooling design, precision machining, and stamping processes, while U‑NEED offers broad OEM capabilities across metals, plastics, and silicone.

- Cost efficiency: Volume parts and repeat die components can be produced at competitive prices in China, while critical engineering and complex trials may remain with Top Stamping Die Components Manufacturers And Suppliers in Finland.

- Risk reduction: Geographic diversification reduces dependence on a single region, mitigates geopolitical or logistics disruptions, and improves supply security.

- Speed and responsiveness: Local Finnish suppliers support rapid design changes, troubleshooting, and after‑sales service for European plants; U‑NEED supports high‑capacity production once designs stabilize and demand grows.

- Lifecycle optimization: Tools can be designed in Finland with a view to global manufacturing, enabling smoother transfer of production between regions when demand or cost structures change.

This strategy allows buyers to optimize total cost of ownership, not only piece‑part prices, by considering tool life, downtime, logistics, currency exposure, and responsiveness across the entire lifecycle. For OEMs and brand owners, combining Top Stamping Die Components Manufacturers And Suppliers in Finland with U‑NEED can become a key competitive advantage in their category.

To get the best results from Top Stamping Die Components Manufacturers And Suppliers in Finland, purchasing and engineering teams can follow some practical guidelines. These help ensure aligned expectations, smoother communication, and better technical outcomes.

Useful tips include:

- Share realistic volume forecasts, including base‑case and high‑case scenarios, so that suppliers can propose appropriate tooling concepts and investments.

- Involve Finnish partners early in the design stage to adjust part geometry for better formability, tool life, and material usage.

- Plan regular technical reviews and sample evaluations, especially for complex progressive dies or multi‑step forming processes.

- Clarify intellectual property rights around tool designs, 3D data, and process know‑how, especially when tools or components will also be used by OEM partners in other regions.

- Align on packaging, labeling, and documentation formats that match existing internal standards to reduce handling and inspection time when goods arrive.

By treating Top Stamping Die Components Manufacturers And Suppliers in Finland as engineering partners rather than simple subcontractors, companies can unlock more value in terms of cost optimization, quality, and innovation.

Top Stamping Die Components Manufacturers And Suppliers in Finland play a crucial role in the European manufacturing ecosystem, offering high‑precision tooling, stamping, and machining services to demanding industrial customers. Their strengths in engineering, automation, and compliance with European standards make them attractive partners for critical components, prototypes, and specialized stamping die parts.

For global brands, wholesalers, and OEM producers, combining these Top Stamping Die Components Manufacturers And Suppliers in Finland with U‑NEED's high‑precision machining, plastic manufacturing, silicone molding, and metal stamping capabilities in China can create a powerful, cost‑efficient, and resilient supply chain. By defining clear roles—Finnish partners for high‑value tooling expertise and U‑NEED for large‑scale OEM production—buyers can improve quality, reduce costs, and secure reliable deliveries across multiple regions and product categories.

Question: What makes Top Stamping Die Components Manufacturers And Suppliers in Finland different from suppliers in other countries?

Answer: They combine strong engineering culture, advanced automation, and strict European quality and environmental compliance, making them ideal for high‑precision, long‑life tooling and stamping projects.

Question: Which industries rely most on Top Stamping Die Components Manufacturers And Suppliers in Finland?

Answer: Automotive, industrial machinery, electronics, and energy equipment manufacturers are the main customers, as they require durable stamping dies, accurate components, and consistent delivery performance.

Question: How can foreign buyers select the right Top Stamping Die Components Manufacturers And Suppliers in Finland?

Answer: Buyers should review technical capabilities, certifications, references, and equipment, and provide detailed 3D data and volume forecasts so suppliers can propose optimal tooling concepts and accurate quotations.

Question: Can Top Stamping Die Components Manufacturers And Suppliers in Finland cooperate with Chinese OEM partners like U‑NEED?

Answer: Yes, they can work in split‑role models where Finnish firms handle design and critical tooling, while U‑NEED in China takes care of cost‑efficient mass production of metal, plastic, and silicone components.

Question: What quality standards do Top Stamping Die Components Manufacturers And Suppliers in Finland usually follow?

Answer: Many operate under ISO 9001 and ISO 14001, with some holding automotive‑specific certifications such as IATF 16949, and they follow European regulations on safety, traceability, and environmental protection.

1. https://ensun.io/search/metal-stamping/finland

2. https://www.akatools.fi/en/parts-manufacturing/

3. https://www.sievitools.fi/industries-en-us/automotive-component-machining-en-us/

4. https://www.ibisworld.com/finland/industry/metal-shaping/200474/

5. https://www.researchandmarkets.com/report/metal-stampings

6. https://www.polarismarketresearch.com/industry-analysis/metal-stamping-market

7. https://www.coherentmarketinsights.com/industry-reports/metal-stamping-market