From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-11 Origin: Site

Content Menu

● Why Germany Leads in Stamping Die Components

● What Are Stamping Die Components?

● Key Industries Using Stamping Die Components in Germany

● How to Evaluate the Top Stamping Die Components Manufacturers And Suppliers in Germany

● Overview of Top Stamping Die Components Manufacturers And Suppliers in Germany

>> Kölle GmbH Werkzeugbau und Stanzerei

>> Dietz GmbH – Stamped and Bent Parts

>> Sixt GmbH – Progressive Die Stampings

>> Metallwarenfabrik Gemmingen GmbH

>> NH Technology – Custom Metal Parts

>> G.W.P. AG – Stamping Dies and Forming Dies

>> Schäfer – Individual Progressive Stamping Dies

>> Jonas Stanztechnik and Other Precision Stamping Specialists

● Working With German Stamping Die Component Suppliers from Overseas

● How a Chinese OEM Partner Complements German Die Component Suppliers

● Practical Tips for Selecting the Right German Supplier

● FAQs About Top Stamping Die Components Manufacturers And Suppliers in Germany

>> 1. What makes German stamping die component suppliers different from other regions?

>> 3. Can overseas companies easily work with German stamping die component suppliers?

>> 4. How do German die component suppliers support progressive stamping projects?

>> 5. Is it cost-effective to source stamping die components from Germany for global production?

Germany has long been recognized as one of the most advanced hubs for metal stamping, tooling, and die components in Europe. For buyers exploring the Top Stamping Die Components Manufacturers And Suppliers in Germany, understanding the local ecosystem, leading players, and the advantages of German engineering is critical for building stable and cost-effective supply chains.

Germany combines deep engineering heritage, strong vocational training systems, and advanced automation to support world-class stamping, tooling, and die components production. Manufacturers in Germany typically operate under strict quality standards such as ISO certifications and automotive-specific requirements, ensuring tight tolerances and high reliability for stamping die components.

- Emphasis on precision tooling, progressive dies, and stamped parts for automotive, aerospace, electrical, and industrial sectors.

- Strong ecosystem of SMEs and large groups covering the entire chain from design and simulation to series production of stamping dies and related components.

In addition, German companies often invest heavily in R&D and digitalization, using simulation tools, data analysis, and process monitoring to improve die performance and productivity. This culture of continuous improvement reinforces the reputation of the Top Stamping Die Components Manufacturers And Suppliers in Germany as dependable long-term partners for demanding applications.

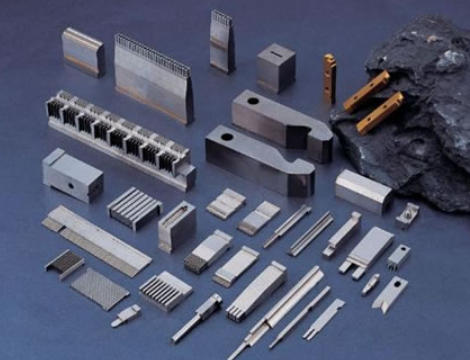

Stamping die components are the critical elements inside a die set that perform cutting, forming, bending, drawing, and piercing on metal strip or sheet. They include punches, dies, stripper plates, guide pillars, bushings, springs, retainers, inserts, and many other precision parts that must be accurately manufactured and assembled to maintain repeatable part quality.

Progressive stamping die components enable multiple operations in one press stroke, boosting productivity and consistency for mass production. High-quality stamping die components reduce tool wear, scrap rates, and unplanned downtime, which is particularly important in high-volume automotive, electronics, and industrial applications.

For complex parts, stamping die components are often produced from special tool steels and hard alloys, sometimes coated with wear-resistant layers to extend tool life. The ability of the Top Stamping Die Components Manufacturers And Suppliers in Germany to select appropriate materials and heat treatments is a major factor in achieving stable production.

German demand for stamping die components is driven by several export-oriented industries. These sectors rely on complex progressive tools, transfer tools, and high-speed stamping systems, requiring durable and accurate die components to support global supply chains.

The main users of stamping die components include:

- Automotive and e‑mobility: Structural brackets, lock strikers, sensor housings, battery components, and electronic connectors.

- Electrical and electronics: Lead frames, contact springs, precision conductor paths, shielding parts, and heat sinks.

- Industrial engineering and drive technology: Motor laminations, rotor and stator parts, pump and compressor components, and precision flanges.

- Appliances and household equipment: Hinges, brackets, fastening elements, and internal stamped mechanisms.

Because these industries face strict safety, performance, and reliability requirements, they rely on the Top Stamping Die Components Manufacturers And Suppliers in Germany to deliver dies and components that can run at high speeds with minimal deviation.

When evaluating the Top Stamping Die Components Manufacturers And Suppliers in Germany, buyers should look beyond initial price to consider engineering capability, quality systems, service, and long-term partnership potential. Focusing on total cost of ownership, including tool life and machine uptime, is essential for accurately comparing suppliers of stamping die components.

Key evaluation criteria include:

- In‑house tool design and development: CAD/CAM capabilities, simulation know‑how, and experience with optimization of progressive and transfer dies.

- Process capabilities: Range of press sizes, speed, material thickness, and width that the supplier can handle, as well as experience with prototype and series production.

- Material expertise: Ability to process high-strength steels, stainless steels, copper alloys, brass, bronze, and aluminum strip while maintaining dimensional stability.

- Quality and certification: Implementation of robust quality systems, traceability, capability studies, and industry-specific standards such as IATF 16949 for automotive.

- Service and maintenance: Support for die maintenance, refurbishment, spare die components, and on-site troubleshooting for international customers.

The most successful partnerships with the Top Stamping Die Components Manufacturers And Suppliers in Germany are usually built around transparency, technical collaboration, and a shared long-term outlook, rather than short-term price negotiations alone.

The following manufacturers and service providers are frequently referenced when discussing the Top Stamping Die Components Manufacturers And Suppliers in Germany, especially for demanding industrial and automotive applications. Many of them combine toolmaking, stamping, and sometimes assembly, offering a complete solution around stamping die components and finished stamped parts.

Kölle GmbH is a long-established, family-owned company active in toolmaking and metal stamping for many decades, supplying sectors such as automotive, aerospace, and electrical engineering. As one of the Top Stamping Die Components Manufacturers And Suppliers in Germany, Kölle GmbH produces high-quality tools, stamping dies, and series stamping parts including seal support frames and parts for insulation systems.

The company's experience in both toolmaking and stamping allows it to optimize stamping die components for durability and ease of maintenance. This makes Kölle GmbH a suitable partner for complex metal parts that need consistent dimensional accuracy over long production runs.

Dietz GmbH describes itself as one of the leading manufacturers of stamped and bent parts in Germany, supplying high-precision solutions to multiple industries worldwide. As part of the Top Stamping Die Components Manufacturers And Suppliers in Germany, Dietz focuses on understanding customer applications and using advanced processes to develop reliable stamped components and die tooling.

From the early design phase, Dietz works closely with customers to optimize part geometry, strip layout, and die design. This approach reduces material usage, improves cycle time, and enhances the performance of the underlying stamping die components.

Sixt GmbH specializes in precision stamping and progressive die stampings, enabling the production of complex finished parts for automotive and electronics sectors. As one of the Top Stamping Die Components Manufacturers And Suppliers in Germany, Sixt combines in‑house tooling with high-precision progressive tools, allowing efficient manufacture of lock strikers, heat exchanger fixtures, conductor paths, and other complex components.

The company's in-house tool shop builds and maintains progressive dies, ensuring that stamping die components such as punches, dies, and guides are aligned with high-speed production requirements. This integrated model helps reduce downtime and provides customers with stable, reproducible processes.

FSM Stamping GmbH focuses on metal forming, progressive stamping, and assembly, particularly for the automotive industry. Often included among the Top Stamping Die Components Manufacturers And Suppliers in Germany, FSM Stamping provides progressive composite tools, transfer tools, and precision components that demand robust die components and accurate process control.

The company's solutions are suited for high-volume applications where consistent quality, short lead times, and flexible logistics are important. FSM's experience with complex geometries and tight tolerances further reinforces its position among the Top Stamping Die Components Manufacturers And Suppliers in Germany.

Feinwerktechnik hago GmbH is a specialist in sheet metal working and stamping technologies, primarily serving the automotive and related industries. Recognized among the Top Stamping Die Components Manufacturers And Suppliers in Germany, the company uses a modern machine park with servo presses capable of processing wide strips and thick materials.

To support these advanced presses, Feinwerktechnik hago relies on robust, precisely engineered stamping die components that can withstand high loads and long operating times. Customers benefit from the company's experience in producing complex metal parts with demanding tolerances and surface requirements.

Metallwarenfabrik Gemmingen GmbH is known for its expertise in stamping and die casting, supplying motors and components for drive technology worldwide. As part of the Top Stamping Die Components Manufacturers And Suppliers in Germany ecosystem, the company produces high-precision electrical sheets and stamping packages on high-speed presses, relying on stable, high-quality stamping die components.

Its competence in combining stamping and die casting enables efficient production of rotor and stator components, aluminum die-cast parts, and other elements used in motors and generators. High-speed stamping places heavy demands on tool steels, coatings, and alignment of die components, making Metallwarenfabrik Gemmingen a valuable reference for advanced drive applications.

NH Technology offers design and manufacturing of custom metal parts, including stamped parts, deep-drawn parts, housings, and die-cast elements. While broader than pure die component manufacturing, NH Technology participates in the network of Top Stamping Die Components Manufacturers And Suppliers in Germany by combining stamping, forming, and overmoulding solutions.

The company can support customers from design to series production, advising on the best combination of processes and materials. By coordinating stamping die design, component specification, and downstream operations, NH Technology helps reduce overall project risk and lead time.

G.W.P. AG manufactures high-quality stamping and forming dies with a particular focus on scratch-free stamping of sheet metal parts. As one of the niche Top Stamping Die Components Manufacturers And Suppliers in Germany, G.W.P. AG delivers dies that are especially important for visible parts or delicate surfaces requiring precise die components and engineered contact conditions.

The company emphasizes careful control of surface pressure, alignment, and lubrication within the die, which directly depends on the design and manufacturing quality of individual die components. This makes G.W.P. AG an attractive partner for projects where appearance and surface integrity are critical.

Schäfer designs and manufactures individual progressive stamping dies in compact and modular designs, often serving automotive and commercial vehicle industries. The company belongs to the group of Top Stamping Die Components Manufacturers And Suppliers in Germany because it uses modern CAD/CAM systems and high-performance machines to produce sophisticated progressive dies and associated components.

By tailoring each die to the specific application, Schäfer can optimize strip layout, station sequence, and the configuration of punches, dies, and guiding elements. This approach improves productivity, reduces scrap, and extends tool life for customers running large series.

Companies like Jonas Stanztechnik provide precision stamping parts, bending parts, and complex lead frames using modern die-cutting systems and high-capacity presses. While primarily part manufacturers, they rely heavily on high-quality stamping die components, positioning them within the broader network of Top Stamping Die Components Manufacturers And Suppliers in Germany that support both tooling and production.

These specialists often work with a wide variety of materials, such as copper, bronze, brass, steel, stainless steel, and coated strip. Their ability to integrate fasteners or functional elements during stamping places specific demands on die components, including special forming elements, inserts, and advanced guiding systems.

For international brands, wholesalers, and manufacturers, sourcing from the Top Stamping Die Components Manufacturers And Suppliers in Germany requires careful coordination on specifications, logistics, and cost structures. Many German companies are accustomed to global customers and can communicate in English, provide technical support, and deliver documentation aligned with international standards.

Best practices when partnering with German suppliers include:

- Sharing detailed drawings, material specifications, expected volumes, and quality requirements at the RFQ stage.

- Clarifying tolerance classes, surface requirements, and special functional features early in the project.

- Requesting expected tool life, preventive maintenance recommendations, and spare parts packages for critical stamping die components.

- Discussing packaging, documentation, and shipping options that protect sensitive die components during international transport.

By following these steps, overseas buyers can build transparent, predictable cooperation with the Top Stamping Die Components Manufacturers And Suppliers in Germany and minimize project risk.

While the Top Stamping Die Components Manufacturers And Suppliers in Germany are ideal for high-end tooling and critical components, many international buyers also work with cost-competitive OEM partners in Asia for series production and value-added manufacturing. A Chinese OEM specializing in high-precision machined parts, plastic and silicone products, and metal stamping can collaborate with German tooling houses by localizing production while preserving German-level tooling quality.

In a typical hybrid model, German partners focus on engineering, design, and key stamping die components, especially for progressive and transfer dies. The Chinese OEM then uses these dies in high-capacity presses, providing stamping, secondary machining, surface treatment, and assembly services for global customers.

This cooperation offers several advantages:

- German design know‑how ensures that the core stamping die components meet demanding precision and durability requirements.

- Chinese OEM partners contribute competitive labor costs, flexible production planning, and localized support for overseas brands.

- Global customers gain a balanced model combining the strengths of the Top Stamping Die Components Manufacturers And Suppliers in Germany with efficient large-scale production.

Such a strategy is particularly attractive for foreign brands, wholesalers, and manufacturers who need stable quality, competitive pricing, and responsive communication across time zones.

To choose the most suitable partner among the Top Stamping Die Components Manufacturers And Suppliers in Germany, buyers can follow a structured approach:

1. Define technical requirements clearly

Prepare detailed drawings, material lists, projected volumes, and any industry standards the parts must meet.

2. Shortlist suppliers by specialization

Match your project with suppliers that specialize in similar materials, part geometries, and industries, such as automotive connectors, motor laminations, or appliance parts.

3. Evaluate engineering support

Review each supplier's capabilities in design optimization, simulation, prototyping, and failure analysis in relation to stamping die components.

4. Assess quality and logistics

Check certifications, sample inspection reports, packing concepts, and delivery performance to ensure they can support your supply chain.

5. Consider long-term cooperation

Select one or two core partners from the Top Stamping Die Components Manufacturers And Suppliers in Germany and build long-term programs instead of only one-off projects.

By taking these steps, buyers increase their chances of building productive, resilient relationships that support future product generations.

The Top Stamping Die Components Manufacturers And Suppliers in Germany form a highly specialized, innovation-driven ecosystem that supports automotive, aerospace, electrical, and industrial customers worldwide. By understanding the strengths of companies like Kölle GmbH, Dietz GmbH, Sixt GmbH, FSM Stamping GmbH, Feinwerktechnik hago GmbH, Metallwarenfabrik Gemmingen GmbH, NH Technology, G.W.P. AG, Schäfer, and Jonas Stanztechnik, buyers can select stamping die components and tooling solutions that balance precision, durability, and total cost of ownership.

For many global brands and wholesalers, the most competitive strategy is to combine the engineering excellence of the Top Stamping Die Components Manufacturers And Suppliers in Germany with flexible OEM partners in Asia to achieve both quality and cost advantages in stamping operations. This combined approach helps companies cope with rising quality demands, shorter product life cycles, and increasing cost pressure across global manufacturing.

German stamping die component suppliers stand out due to their strong engineering culture, advanced machinery, and rigorous quality systems that focus on long-term tool performance. They emphasize precision, traceability, and process stability, which are crucial for industries with strict safety and reliability requirements.

The main industries are automotive and e‑mobility, electrical and electronics, industrial engineering, drive technology, and household appliances. These sectors require complex stamped parts and robust stamping die components capable of running in high-speed production environments.

Yes, most German stamping die component suppliers are experienced in exporting and working with international customers, offering communication in English and standardized documentation. Overseas companies should provide clear specifications and expectations to ensure smooth collaboration from quotation to series delivery.

German suppliers often maintain in‑house tool shops, CAD/CAM systems, and simulation tools to design and optimize progressive dies for multi-step operations. They can deliver complete tooling packages or individual stamping die components, along with maintenance and optimization support during serial production.

Although initial prices may be higher than in some regions, sourcing from Germany can be cost-effective when considering total cost of ownership, tool life, and production stability. Many companies combine German tooling with cost-efficient manufacturing elsewhere, achieving a competitive balance between quality and overall project cost.

1. https://www.koelle-gmbh.de/en/company/

2. https://www.dietz.eu/en/stamped-bent-parts-manufacturer/

3. https://www.sixt-gmbh.de/en/products/progressive-die-stampings/

4. https://ensun.io/search/metal-stamping/germany

5. https://ensun.io/search/progressive-stamping/germany

6. https://www.metallwarenfabrik.com/en/stanz-druckgusstechnik

7. https://www.nh-technology.de/en/formteile/metallteile/

8. https://www.gwp-ag.com/559

9. https://schaefer.biz/en/portfolio/stamping-dies/

10. https://www.jonas-stanztechnik.de/en/our-services/pressing-bend-technique

11. https://www.hago-ft.de/ [perplexity](https://www.perplexity.ai/search/b649b3f8-3899-4c98-88c7-fb985983f416)

12. https://h2stamping.com/en/services/ [schaefer](https://schaefer.biz/en/portfolio/stamping-dies/)