From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-11 Origin: Site

Content Menu

● Overview of Japan's Stamping Die Components Industry

● Key Capabilities of Leading Japanese Suppliers

● Representative Japanese Stamping Die Specialists

>> Ito Seisakusho Co., Ltd. and Other Specialists

● Typical Products From Japanese Die Components Makers

● Why Global OEMs Choose Japan for Stamping Die Components

● How Overseas Buyers Can Work With Japanese Suppliers

● The Role of Chinese OEM Partners in a Japan‑Focused Strategy

● Trends Shaping the Future of Japanese Stamping Die Components

● How to Evaluate Top Stamping Die Components Manufacturers And Suppliers in Japan

● Building Long‑Term Partnerships With Japanese Suppliers

● FAQ

>> 1. What makes Japanese stamping die components suppliers different?

>> 2. Can smaller overseas buyers work with Japanese die components manufacturers?

>> 3. How long is the usual lead time for stamping dies from Japan?

>> 4. Do Japanese suppliers only serve the automotive industry?

>> 5. How can a buyer balance Japanese quality with cost competitiveness?

Top Stamping Die Components Manufacturers And Suppliers in Japan are globally recognized for precision, reliability, and the ability to support high‑volume, high‑tolerance production in automotive, electronics, and industrial sectors. For overseas OEMs, brand owners, wholesalers, and manufacturing partners, understanding how these Japanese suppliers work—and how to integrate them into a global supply chain—is essential for long‑term success.

Japan's stamping die components industry is built on decades of experience in automotive, appliance, and high‑tech manufacturing. It combines advanced tooling technology with strict quality control and an emphasis on long‑term reliability rather than short‑term cost. As a result, Top Stamping Die Components Manufacturers And Suppliers in Japan are often the first choice for critical projects where downtime and defects are extremely costly.

These suppliers typically offer one‑stop services from die design and simulation to machining, assembly, tryout, and ongoing maintenance support. Many Top Stamping Die Components Manufacturers And Suppliers in Japan also maintain overseas bases or cooperation networks in Asia, North America, and Europe, enabling faster response and localized support for global customers.

Top Stamping Die Components Manufacturers And Suppliers in Japan share several core technical capabilities that make them stand out:

- Advanced CAD/CAM design combined with forming simulation for progressive, transfer, and tandem dies.

- Integrated machining centers, wire‑EDM, grinding, and large tryout presses for full in‑house control.

- Expertise in high‑strength steels, aluminum, stainless steel, and other difficult‑to‑form materials.

- Strong preventive maintenance concepts and die‑parts wear management for long die life.

- Capacity for both small precision parts and large automotive panel dies.

These capabilities allow Top Stamping Die Components Manufacturers And Suppliers in Japan to support demanding mass production programs with high repeatability and low defect rates.

Several companies are frequently cited when discussing Top Stamping Die Components Manufacturers And Suppliers in Japan. While each has its own focus, they share a commitment to precision and continuous improvement.

SASAYAMA is a long‑established tool and die company that designs and manufactures high precision stamping dies for a global clientele from Tottori, Japan. The company produces dies for tandem press lines, robotic press lines, transfer presses, and progressive presses, serving automotive, home appliance, kitchen appliance, office supply, and energy‑saving equipment applications.

SASAYAMA's head office and factory combine machining, assembly, and press buildings on a large site designed for efficient, integrated production. Its equipment lineup includes large double‑column machining centers with pallet changers for continuous 24‑hour operation, multi‑station horizontal machining centers with 5‑axis capability, and super precision forming surface grinders that can achieve sub‑micron accuracy even on meter‑size workpieces. The company also operates a 1,600‑ton tryout press capable of handling ultra high‑tensile strength steel sheets. This combination of capacity and accuracy makes SASAYAMA one of the notable Top Stamping Die Components Manufacturers And Suppliers in Japan.

Wada Industries is a specialist in precision stamping and die manufacturing, especially for connector terminals and related components. Its stamping machine lineup ranges from 15‑ton high‑speed presses to 110‑ton large precision machines, allowing the company to support thin strip high‑speed production as well as relatively large shell and shield cover parts. Stamping speeds can reach up to 2,400 strokes per minute on certain equipment.

The company focuses heavily on mass production stability and die technology for narrow‑pitch, high‑speed manufacturing. It has extensive experience producing contacts and terminals for board‑to‑board connectors, FPC connectors, and automotive connectors, including press‑fit terminals that require consistent insertion performance. Wada Industries emphasizes die maintenance, wear countermeasures, and in‑house manufacturing of punch shoes, die shoes, and die plates, supported by a regional die‑parts procurement network. This integrated approach helps position Wada Industries among the Top Stamping Die Components Manufacturers And Suppliers in Japan.

Beyond stamping, Wada Industries also offers plastic injection molding, insert molding, and connector assembly, operating an integrated production system from stamping through assembly. The company holds ISO9001, ISO14001, and IATF16949 certifications, underlining its commitment to quality and automotive industry standards.

Ito Seisakusho is another example of a Japanese company offering one‑stop progressive die design, manufacture, and stamping production, with facilities in Japan and Southeast Asia. Other firms such as Hashimoto Precision focus on ultra‑thin, high‑precision metal stamping for electronics and miniature components. Together, these and other Top Stamping Die Components Manufacturers And Suppliers in Japan provide a broad range of options for buyers seeking different part sizes, volumes, and complexity levels.

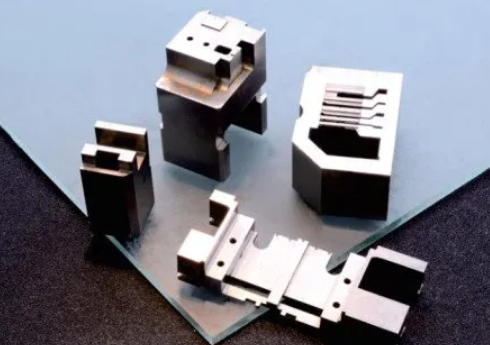

Top Stamping Die Components Manufacturers And Suppliers in Japan cover both complete tooling and individual components. Common offerings include:

- Progressive dies and transfer dies for automotive structural parts, body panels, and brackets.

- Precision dies for connector terminals, electronic contacts, shielding parts, and thin‑sheet components.

- Die plates, punches, inserts, guide posts, bushings, stripper plates, and die sets used for new tooling as well as maintenance and refurbishment.

- Specialized dies designed specifically for ultra high‑tensile steel, aluminum, and stainless steel sheets in lightweight automotive and energy‑saving applications.

By sourcing from Top Stamping Die Components Manufacturers And Suppliers in Japan, buyers can secure both initial tooling and a long‑term supply of spare die components that keep production lines running with minimal downtime.

Global OEMs and brand owners frequently select Top Stamping Die Components Manufacturers And Suppliers in Japan when they need:

- Extremely tight tolerances and stable dimensional performance over very high shot counts.

- High‑speed stamping for thin materials, especially connector terminals and miniature parts.

- Complex progressive dies that combine multiple forming, piercing, and bending steps.

- Long‑life tooling that reduces line stoppages and lowers total cost of ownership.

Japanese suppliers are also known for structured project management, clear communication, and the ability to support detailed development reviews and joint problem‑solving. When working with Top Stamping Die Components Manufacturers And Suppliers in Japan, customers often receive not only tooling but also design feedback that improves manufacturability and yield.

To maximize the value of cooperation with Top Stamping Die Components Manufacturers And Suppliers in Japan, overseas buyers should follow a structured approach:

1. Define requirements clearly, including material type, thickness, annual volume, expected lifetime, and any special standards such as automotive quality systems.

2. Provide detailed 2D and 3D drawings, tolerance schemes, and functional requirements early in the RFQ process to enable accurate feasibility studies.

3. Evaluate multiple Top Stamping Die Components Manufacturers And Suppliers in Japan, not just on price but on technical capability, lead time, quality system, and support structure.

4. Include trial production, capability studies, and documentation such as PPAP or similar evidence in the project plan for critical parts.

5. Establish long‑term agreements covering spare parts, die modifications, and technical support, ensuring that both parties share responsibility for ongoing success.

By treating these suppliers as engineering partners rather than simple vendors, buyers can unlock the full benefits that Top Stamping Die Components Manufacturers And Suppliers in Japan bring to complex manufacturing programs.

While Top Stamping Die Components Manufacturers And Suppliers in Japan are strong in engineering and high‑precision die manufacture, they are often complemented by cost‑competitive, flexible OEM partners in China and other regions. A hybrid model is increasingly common:

- Core tooling and critical die components are sourced from Top Stamping Die Components Manufacturers And Suppliers in Japan.

- High‑volume stamping, secondary machining, plastic and silicone molding, and assembly are handled by capable Chinese OEM factories with strong quality systems.

- Global customers benefit from Japanese die performance and process stability combined with favorable piece‑part economics and responsive production.

A company with experience in high‑precision machining, plastic manufacturing, silicone product manufacturing, and metal stamping can partner closely with Top Stamping Die Components Manufacturers And Suppliers in Japan. In many cases, Japanese engineers provide die designs and technical standards, while the Chinese OEM executes mass production, packaging, and logistics for overseas markets. This cooperation model creates a powerful value proposition in terms of cost, quality, and lead time.

Several industry trends are influencing how Top Stamping Die Components Manufacturers And Suppliers in Japan develop their technologies and services:

- Electrification and CASE (Connected, Autonomous, Shared, Electric) concepts in the automotive sector are increasing the need for new connector designs, power electronics, and lightweight structural components that require advanced stamping dies.

- The rise of high‑tensile and ultra high‑tensile materials demands more robust die designs, coatings, and maintenance plans to manage wear and prolong die life.

- Digitalization via IoT, data logging, and simulation is helping Top Stamping Die Components Manufacturers And Suppliers in Japan optimize press line performance and enable predictive maintenance.

- Sustainability goals push both suppliers and customers to improve material utilization, reduce scrap, and extend die life, which makes high‑quality dies even more attractive.

Buyers who anticipate these trends and seek cooperation with innovative Top Stamping Die Components Manufacturers And Suppliers in Japan will be better positioned to maintain competitiveness in fast‑changing markets.

When comparing potential Japanese partners, buyers should build a structured evaluation checklist. Important criteria include:

- Technical scope: Ability to handle specific materials, thicknesses, part sizes, and tolerances needed for the program.

- Equipment level: Availability of high‑tonnage presses, high‑speed presses, advanced machining centers, precision grinders, and measurement equipment.

- Quality system: Certifications such as ISO9001, ISO14001, IATF16949, and documented quality control processes.

- Engineering support: Willingness and capacity to engage in joint development, DFMA (Design for Manufacturing and Assembly) reviews, and on‑site or remote troubleshooting.

- Delivery and capacity: Lead times for new dies, responsiveness for urgent maintenance, and capacity to scale as volumes grow.

- Global support: Overseas bases, regional partners, or cooperation networks that can provide localized service and logistics.

Top Stamping Die Components Manufacturers And Suppliers in Japan that score strongly on these dimensions will usually deliver a stable long‑term partnership and strong lifecycle economics, even if their initial quotation is not the lowest.

Working effectively with Top Stamping Die Components Manufacturers And Suppliers in Japan also involves cultural and relationship management considerations:

- Emphasize transparency in forecasts, program lifetimes, and potential design changes to help suppliers plan capacity and investment.

- Provide timely feedback on trial results and production performance, creating a closed loop that allows continuous improvement.

- Recognize the engineering value added by Top Stamping Die Components Manufacturers And Suppliers in Japan in terms of design optimization and process know‑how, not just the physical die.

- Consider joint visits, audits, and technical workshops to align expectations and build mutual trust.

Such long‑term partnership approaches typically result in better tooling performance, smoother launches, and more proactive support throughout the product lifecycle.

Top Stamping Die Components Manufacturers And Suppliers in Japan combine advanced engineering, robust quality systems, and long‑term production support to serve demanding global customers in automotive, electronics, and industrial markets. By carefully evaluating their capabilities, understanding typical products and processes, and building structured collaboration models, overseas OEMs, brand owners, and wholesalers can leverage Japanese tooling strength to improve quality, reduce downtime, and enhance overall competitiveness. When integrated with cost‑effective and flexible OEM partners in China and other regions, cooperation with Top Stamping Die Components Manufacturers And Suppliers in Japan becomes a powerful strategy for building resilient, high‑performance global production networks.

Japanese stamping die components suppliers stand out for their high precision, robust quality systems, and strong focus on long‑term die life and process stability rather than only initial cost.

Yes, smaller buyers can work with Japanese die manufacturers as long as they provide clear technical requirements, realistic volumes, and professional communication throughout the project.

Lead time depends on die complexity, but most Japanese suppliers follow structured schedules that include design, machining, assembly, and tryout, often ranging from several weeks to a few months.

No, Japanese stamping die suppliers also serve consumer electronics, telecommunications, home appliances, industrial equipment, and many other sectors requiring precise stamped components.

A buyer can combine Japanese‑made dies and core components with cost‑effective mass production at capable OEM factories, creating a hybrid model that balances quality, cost, and flexibility.

1. https://www.sasayama-company.co.jp/en/ [sasayama-company.co](https://www.sasayama-company.co.jp/en/)

2. https://www.wadakogyo.co.jp/en/strengths/ [shinko.co](https://www.shinko.co.jp/english/product/metal-parts/die-parts.php)

3. https://www.itoseisakusho.co.jp/en/aboutus/cutting_edge/ [jkb-net.co](https://www.jkb-net.co.jp/english/products_e/)

4. https://www.itoseisakusho.co.jp/en/aboutus/high_precision/ [fuji-miyazu.co](https://fuji-miyazu.co.jp/en/our-business/stampingdies/)

5. https://www.hskcoltd.com/en/ [ensun](https://ensun.io/search/metal-stamping/japan)

6. https://ensun.io/search/metal-stamping/japan [anebonmetal](https://anebonmetal.com/top-stamping-manufacturers-and-suppliers-in-japan/)

7. https://anebonmetal.com/top-stamping-manufacturers-and-suppliers-in-japan/ [uneedprecisionmachine](https://www.uneedprecisionmachine.com/top-10-stamping-die-components-manufacturers-in-china.html)

8. https://www.uneedprecisionmachine.com/top-10-stamping-die-components-manufacturers-in-china.html [hotien-precision](https://hotien-precision.com/en/equipment/machine/)