From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-22 Origin: Site

Content Menu

● Overview of Lithuania's Metalworking and Tooling Industry

● Importance of Stamping Die Components in Modern Manufacturing

● Why Lithuania Is Becoming a Preferred Supplier in Europe

● Leading Stamping Die Components Manufacturers and Suppliers in Lithuania

>> 1. Alcomet Precision Engineering

● Services Offered by Lithuanian Stamping Die Manufacturers

● The Role of OEM and ODM Services in Global Trade

● Advancements in Stamping Die Technology in Lithuania

● Quality Control and Industry Standards

● Opportunities for International Buyers

● How to Select a Reliable Lithuanian Supplier

● Future Outlook of Lithuania's Stamping Die Industry

● FAQ

>> 1. What types of stamping die components are manufactured in Lithuania?

>> 2. Why are Lithuanian stamping die suppliers considered cost-effective?

>> 3. Do Lithuanian manufacturers offer OEM and ODM services?

>> 4. How do suppliers ensure product quality?

>> 5. What industries rely on Lithuanian stamping die components?

Lithuania, a small but technologically advanced nation in the Baltic region, has developed a strong industrial base specializing in precision metalworking, die casting, and stamping component manufacturing. Over the past decade, the country's manufacturing sector has evolved from traditional metal shops to highly automated and digitally integrated production facilities. The growing network of Top Stamping Die Components Manufacturers And Suppliers in Lithuania not only serves local industries but also exports high-precision dies, molds, and components to Europe, North America, and Asia.

Lithuania's industrial framework is a blend of engineering expertise, skilled labor, and advanced technology. The government promotes innovation through partnerships with the EU and local universities, helping businesses meet global OEM and ODM needs.

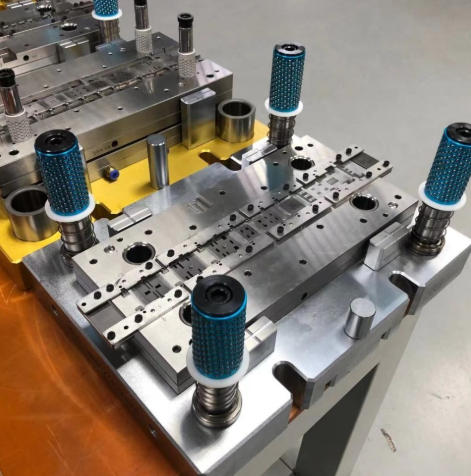

Metal stamping and die component production have become core sectors, with the Top Stamping Die Components Manufacturers And Suppliers in Lithuania focusing on:

- Precision tooling for automotive and aerospace applications.

- Custom stamping dies for electronic and medical devices.

- Die component prototyping and small-batch production.

- CNC machining for progressive dies and inserts.

This dynamic industry benefits from Lithuania's location at the heart of Northern Europe, providing easy access to key logistics networks, thus enabling cost-efficient export of tooling and stamping parts.

Stamping dies are essential in mass production processes used to shape and cut materials like steel, aluminum, and plastic sheets. High-quality stamping die components ensure accuracy, durability, and repeatability in metal forming.

Key advantages include:

- High precision: Maintains tight tolerances, crucial in automotive and electronic manufacturing.

- Extended lifespan: Premium-grade materials such as SKD11 or tungsten carbide improve wear resistance.

- Efficiency: Reduces downtime and maintenance costs.

- Consistency: Produces identical parts across large production batches.

The Top Stamping Die Components Manufacturers And Suppliers in Lithuania understand these needs and integrate advanced machinery such as CNC machining centers, EDM (Electrical Discharge Machining), and coordinate measuring machines (CMM) to guarantee consistent part quality.

Several factors shape Lithuania's competitive advantage in stamping die component production:

1. High Manufacturing Standards: Factories adhere to ISO 9001 and IATF 16949 certifications, ensuring every component meets international quality levels.

2. Cost-Efficient Production: Labor and operational costs are lower than in Western Europe while maintaining comparable quality.

3. Technological Adoption: Many Lithuanian suppliers use robotics, CAD/CAM systems, and digital twin simulations.

4. Strategic Geography: Close proximity to Germany, Poland, and Scandinavia supports fast supply chain connectivity.

5. Strong Engineering Education: Local universities prepare highly skilled specialists in materials science and mechanical engineering.

Together, these factors make Lithuania an emerging hub for OEM metalworking partnerships and OEM/ODM manufacturing collaborations.

Below are some well-known Top Stamping Die Components Manufacturers And Suppliers in Lithuania, recognized for expertise, precision, and reliable exports.

Alcomet Precision Engineering focuses on high-accuracy tooling and die assembly. Their facility is equipped with multi-axis CNC mills and wire-cut EDMs. They serve various sectors like automotive, construction, and consumer appliances. Alcomet is particularly known for their progressive stamping dies and high-hardness inserts.

Founded more than 20 years ago, Baltic Tool Systems designs and manufactures stamping dies, injection molds, and precision jigs. Continuous investment in CAM simulation software and automated milling lines allows them to meet large-batch production needs.

Metmida has earned international recognition for its die components and metal stamping parts exported across Europe and Asia. They offer integrated OEM services—from CAD design and prototyping to batch production and logistics packaging. The company maintains strict quality control with CMM verification for every part.

LitMet Components stands out for its vertical manufacturing integration. They handle steel treatment, precision grinding, and die component assembly under one roof. Their stamping dies for automotive panel production are widely appreciated among European Tier-2 suppliers.

PrecForm combines metallurgy and innovation, providing customers with a full cycle from material selection to finished component delivery. The company specializes in forming die plates, punches, and guide assemblies. They heavily focus on eco-efficient manufacturing, reducing waste and energy usage.

These five companies demonstrate the diversity and specialization found among the Top Stamping Die Components Manufacturers And Suppliers in Lithuania, capable of supporting clients across multiple manufacturing fields.

The Top Stamping Die Components Manufacturers And Suppliers in Lithuania offer comprehensive manufacturing services tailored to global demands, including:

- Custom design and prototyping: CAD/CAM-based modeling for accuracy and performance validation.

- Precision machining: CNC milling, turning, and EDM wire cutting.

- Die assembly and inspection: Complete stamping die construction, fitting, and dimensional verification.

- Heat treatment and surface finishing: Enhancement of part longevity and corrosion resistance.

- Material sourcing and logistics: Coordinated procurement and global shipping options.

This full-service approach ensures customers receive high-performance components ready for immediate integration into stamping operations.

As Lithuanian companies continue expanding internationally, OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) partnerships have become strategic pathways for collaboration.

- OEM production: Lithuanian manufacturers fabricate die components according to client specifications, maintaining strict confidentiality.

- ODM projects: They develop in-house designs optimized for efficiency and lifecycle durability, allowing buyers to brand and distribute these components globally.

For foreign clients—especially from Western Europe, the U.S., and Asia—outsourcing to Lithuania brings both quality assurance and cost efficiency. For this reason, many companies looking for Top Stamping Die Components Manufacturers And Suppliers in Lithuania value the flexibility and professionalism Lithuanian firms deliver.

Technological progress is one of the cornerstones of Lithuania's tooling industry. Recent advancements include:

1. Automation and robotics integration for loading, inspection, and assembly tasks.

2. Smart machining systems that monitor temperatures, vibration, and tolerance deviations in real time.

3. Laser hardening and precision finishing to boost tool life.

4. Additive manufacturing (3D metal printing) technologies for tool inserts and prototypes.

Such modernization helps the Top Stamping Die Components Manufacturers And Suppliers in Lithuania maintain a competitive edge in global markets, ensuring precision and production scalability.

Quality is not an afterthought—it's built into every production phase. Most Lithuanian factories apply Total Quality Management (TQM) philosophy combined with statistical process control. Inspection routines include:

- Dimensional precision tests via CMM.

- Hardness and metallurgical analysis.

- Laser-based surface roughness inspection.

- Tool life cycle simulation and benchmarking.

The commitment to excellence has established Lithuania as one of the most dependable exporters of stamping die components in the Baltic region.

The Top Stamping Die Components Manufacturers And Suppliers in Lithuania offer several benefits for international buyers:

- Reduced lead time: Fast turnaround and efficient logistics.

- Stable quality assurance: Consistency across multiple batches.

- Flexible customization: Adjustments to meet client-specific die dimensions.

- After-sales technical support: Remote and onsite inspection services.

For global brands or wholesalers searching for die component suppliers, Lithuania offers an ideal balance between European engineering quality and competitive production cost.

When choosing among the Top Stamping Die Components Manufacturers And Suppliers in Lithuania, consider the following steps:

1. Assess manufacturing experience: Prioritize suppliers with at least 10 years of operation.

2. Check certifications: ISO and CE compliance guarantee international quality alignment.

3. Request sample components: Evaluate dimensional accuracy and surface treatment standards.

4. Review export history: Reliable exporters have experience handling customs and shipping.

5. Analyze communication and responsiveness: Timely support reflects overall professionalism.

This process ensures successful partnerships and minimizes risks during production and delivery.

The future looks promising for Lithuanian die component manufacturers. Driven by Industry 4.0, smart factories, and digital traceability, these companies are moving toward fully automated production cells. Investments in sustainability and green manufacturing further strengthen Lithuania's position in the European supply chain.

As global industries demand ever-precise components, the Top Stamping Die Components Manufacturers And Suppliers in Lithuania will continue to expand, offering state-of-the-art tooling solutions to OEM clients worldwide.

Lithuania has emerged as a strong player in the global stamping die components market, combining engineering expertise, innovation, and cost efficiency. The Top Stamping Die Components Manufacturers And Suppliers in Lithuania provide complete tooling solutions, from custom design to final production, ensuring unmatched performance and reliability. For global buyers seeking precision and trust, Lithuania stands as a dependable and forward-looking partner in manufacturing excellence.

Lithuanian companies produce punches, die plates, guide pins, bushings, stripper plates, and custom inserts used in progressive and compound dies across different industries.

They combine European-quality manufacturing standards with lower labor costs and efficient production processes, offering competitive prices without compromising precision.

Yes. Most of the Top Stamping Die Components Manufacturers And Suppliers in Lithuania provide both OEM manufacturing based on customer drawings and ODM designs developed by their in-house engineers.

Manufacturers implement ISO-certified quality systems, perform CMM inspections, and apply real-time monitoring tools to maintain tight tolerances and consistent product performance.

Major industries include automotive, aerospace, electronics, telecom, home appliances, and medical equipment manufacturing—all benefiting from Lithuania's high-precision engineering standards.