From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-17 Origin: Site

Content Menu

● Understanding stamping die components

● Why Poland for stamping die components

● Key industries served in Poland

● Capabilities of Polish stamping die suppliers

>> Tool design and engineering

>> Production of stamping dies and components

>> Serial metal stamping and assembly

● Representative Polish companies in stamping tooling and components

>> Mikrostyk – expert in metal stamping

>> Sohbi Craft Poland – stamping and dies

>> Frezotech – cutting and stamping dies

>> Grawer Polska – embossing and hot stamping dies

>> Hydrapres – metal stamping plant and press tools

>> Other notable players and clusters

● How Polish suppliers support international OEM projects

● Combining Polish and Chinese OEM strengths

● How to evaluate Top Stamping Die Components Manufacturers And Suppliers in Poland

● Practical sourcing tips for international buyers

● FAQ

>> 2. Do Polish suppliers provide only complete dies or also individual stamping die components?

Top Stamping Die Components Manufacturers And Suppliers in Poland play an increasingly important role in the European tooling and metal parts supply chain, especially for automotive, electronics, home appliances, and industrial machinery brands. For international buyers, understanding how to work with the Top Stamping Die Components Manufacturers And Suppliers in Poland can improve cost structures, logistics efficiency, and engineering flexibility.

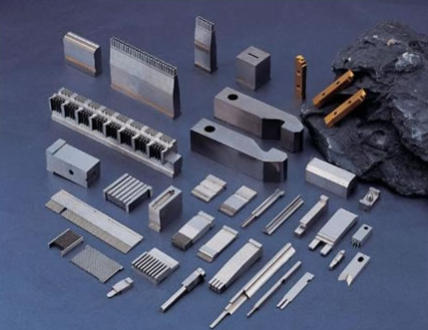

Stamping die components are the precision‑engineered parts inside the die set that cut, pierce, bend, form, or coin sheet metal into the desired geometry. These components include punches, dies, stripper plates, pilots, guide pillars, bushings, springs, and retainers, which must work together in a tightly controlled press environment. High‑quality stamping die components are critical for achieving repeatable tolerances, reducing burrs, minimizing tool wear, and extending maintenance intervals in mass production.

Top Stamping Die Components Manufacturers And Suppliers in Poland typically design and manufacture both complete tools and individual components, based on detailed 2D drawings and 3D models supplied by OEMs and Tier‑1 suppliers. Many Polish companies combine in‑house toolmaking with serial metal stamping, so they understand how each die component behaves under real production loads. This practical feedback loop helps engineers optimize clearances, radii, and material selection for punches and dies.

Stamping die components can be produced from high‑speed steels, tool steels, carbide, and wear‑resistant coatings depending on the required lifetime and material being formed. For demanding applications, Top Stamping Die Components Manufacturers And Suppliers in Poland often recommend optimized surface treatments to reduce galling and adhesive wear. In complex progressive dies, component standardization is also used to simplify maintenance and reduce spare‑part costs.

Poland has evolved into a competitive manufacturing base for the European market, with particular strengths in automotive, household appliances, and metal parts production. Top Stamping Die Components Manufacturers And Suppliers in Poland benefit from skilled engineers, modern CNC machine tools, and proximity to major OEMs in Germany, France, the Netherlands, and Scandinavia. This geographical advantage helps reduce transit times and facilitates on‑site technical support when needed.

For foreign brands and wholesalers, sourcing from Top Stamping Die Components Manufacturers And Suppliers in Poland can shorten lead times compared with overseas shipments, while still offering attractive pricing and strong technical support. Many Polish toolshops and stamping plants are ISO‑certified, with established export experience and multilingual project teams used to working with international clients. This combination of quality systems and communication skills makes Poland an appealing option in the European tooling landscape.

Poland is also integrated into key European automotive and industrial clusters, which drives continuous improvement in stamping die technology. As OEMs push for lighter components, higher strengths, and more complex geometries, Top Stamping Die Components Manufacturers And Suppliers in Poland invest in software, presses, and measuring equipment to stay competitive. This ensures that international buyers gain access to up‑to‑date capabilities rather than outdated equipment.

Top Stamping Die Components Manufacturers And Suppliers in Poland serve a broad mix of industries that rely on precision metal components and tools:

- Automotive body parts, exhaust systems, brackets, seat components, and structural elements.

- Consumer electronics, white goods, and appliance components stamped from thin gauge steels and non‑ferrous alloys.

- Electrical and electronic connector parts produced from copper, brass, and specialty alloys with tight dimensional tolerances.

- Industrial, construction, and infrastructure hardware such as brackets, fasteners, housings, and reinforcement parts.

Because of this industry mix, Top Stamping Die Components Manufacturers And Suppliers in Poland are familiar with strict OEM standards, PPAP requirements, and continuous improvement expectations in serial production. Many also support prototype builds, pilot runs, and engineering changes, which is important for international customers ramping up new models or localizing existing designs. The ability to shift quickly from prototype dies to serial tooling creates an efficient development pipeline.

In addition to conventional metal‑forming industries, Poland supports sectors such as packaging, printing, and decorative products that need precise embossing and hot‑stamping dies. This expands the portfolio of Top Stamping Die Components Manufacturers And Suppliers in Poland beyond structural parts, opening opportunities for brand owners in FMCG, cosmetics, and luxury goods. As a result, buyers can source both functional and decorative tooling from the same country.

Top Stamping Die Components Manufacturers And Suppliers in Poland typically provide full CAD/CAM‑based design for cutting, piercing, bending, and deep‑drawing dies, along with detailed documentation for each tool. Engineering teams can optimize die layouts, choose proper clearances, and select materials for punches and dies to balance tool life and cost. Simulation tools are often used to predict material flow and avoid issues like wrinkling or cracking in deep‑drawn parts.

In many cases, these suppliers also offer design‑for‑manufacturing advice, suggesting changes to part geometry or tolerances to improve stamping feasibility and cycle time. When a customer needs only stamping die components rather than complete tools, Polish engineers can design compatible components that fit into existing die sets. This is especially valuable for global customers who operate dies built in multiple countries and need standardized replacements.

Engineering support from Top Stamping Die Components Manufacturers And Suppliers in Poland usually includes full sets of drawings, bill of materials, and maintenance instructions. For critical projects, suppliers may participate in cross‑functional reviews with the customer's design, quality, and production teams. This collaborative approach reduces late changes and helps ensure that stamping die components reach the required performance targets from the first production runs.

Poland hosts a range of toolshops and metalworking plants that produce full stamping dies, progressive tools, transfer dies, and associated components for European customers. These companies use CNC milling, wire EDM, grinding, turning, and surface treatment operations to manufacture precise punches, dies, plates, and inserts. Modern measuring equipment such as CMMs and contour measuring machines is used to verify tight tolerances.

Top Stamping Die Components Manufacturers And Suppliers in Poland commonly produce:

- Cutting and stamping dies for simple and complex parts in low, medium, and high volumes.

- Progressive and multi‑stroke tools for high‑volume production with integrated piercing, forming, and part separation.

- Transfer and deep‑drawing dies for structural components, housings, and cups formed from higher thickness materials.

- Embossing, hot‑stamping, and foil stamping dies for packaging, labels, and high‑value decorative elements.

Beyond complete tools, Polish manufacturers also supply standard and customized stamping die components as spare parts. A buyer can order new punches, dies, retainers, and inserts when refurbishing or upgrading existing tools. Top Stamping Die Components Manufacturers And Suppliers in Poland can reverse‑engineer legacy components, which is helpful when original drawings are not available.

Many Top Stamping Die Components Manufacturers And Suppliers in Poland not only build tools but also run serial stamping on mechanical and hydraulic presses up to several hundred tons. These plants process steel, stainless, aluminum, and non‑ferrous materials into components for automotive, electronics, and industrial systems. Automated coil feeding, lubrication systems, and in‑line monitoring are frequently used to maintain consistent output.

Some suppliers integrate washing, deburring, welding, and sub‑assembly so that customers receive ready‑to‑assemble parts rather than only discrete stampings. This integration allows them to monitor tool wear in real time, continuously improving the design and materials of stamping die components for longer service life. When tools and components are built and run under one roof, feedback from the press shop quickly translates into engineering improvements.

In addition, certain Polish metal‑stamping specialists have invested in automation and robotics to enhance productivity and repeatability. For international customers, this means that Top Stamping Die Components Manufacturers And Suppliers in Poland can support stable long‑term production, even when demand volumes fluctuate. Automation also supports traceability and data collection, which are important for industries with strict quality audits.

While there are many Top Stamping Die Components Manufacturers And Suppliers in Poland, several representative companies illustrate the typical capabilities available in this market. The examples below show how different suppliers combine tooling, stamping, and quality systems to serve international customers.

Mikrostyk, headquartered in Gniew, is positioned as a specialist in metal stamping and supplies components to customers worldwide in the automotive, electronics, and industrial sectors. The company stamps steel, aluminum, bronze, and brass, supports tool development, and focuses on long‑term reliability and quality. Its in‑house tool shop designs, builds, and maintains the progressive dies and stamping tools used in production.

As part of its offer, Mikrostyk works with complex tooling and can support the maintenance and optimization of stamping die components used in its production lines. Strong investments in automation, digital monitoring, and sustainability programs further enhance its competitiveness. For customers looking for Top Stamping Die Components Manufacturers And Suppliers in Poland with strong serial production experience and advanced quality systems, Mikrostyk is a relevant benchmark.

Sohbi Craft Poland operates as a metal stamping expert and producer of high‑quality stamped metal parts and stamping dies for major international manufacturers. The company combines stamping, washing, assembly, automation, and laser cutting, giving it the ability to manage full production cells from raw material to assembled components. This integration provides excellent process control and traceability.

Because Sohbi Craft Poland develops both tools and processes, its engineering team understands the detailed performance requirements of stamping die components under real production conditions. The company's global background also contributes to export‑ready project management and documentation. For buyers assessing Top Stamping Die Components Manufacturers And Suppliers in Poland, Sohbi Craft Poland represents a model for vertically integrated stamping operations.

Frezotech focuses on the production of cutting dies and metal stamping dies of various sizes, including multi‑stroke and progressive cutting tools. Its toolshop manufactures special tools strictly according to the design documentation and customer guidelines, emphasizing precision and the use of new technologies. This specialization covers everything from small insert tools to large forming dies.

For buyers who require custom stamping die components, Frezotech can produce punches, dies, and inserts as part of complete tooling packages. The company's experience in complex cutting and forming tools helps ensure that components deliver a long service life and stable performance. As such, Frezotech illustrates how Top Stamping Die Components Manufacturers And Suppliers in Poland support demanding die and component projects for European clients.

Grawer Polska is a European leader in engraved foil and embossing dies, manufacturing polymer, magnesium, and brass tools for hot foil embossing and stamping applications. The company operates under ISO‑based management systems and focuses on advanced engraving methods to reproduce fine details on packaging and printed materials. Its products support branding, security features, and decorative effects.

While its core business is in embossing and foil stamping rather than structural sheet metal forming, Grawer Polska shows the diversity of Top Stamping Die Components Manufacturers And Suppliers in Poland. Buyers in the packaging and printing industries can source high‑precision stamping die components tailored to specific materials, substrates, and visual effects. This complements the more structural stamping capabilities available elsewhere in the country.

Hydrapres S.A. operates a large metal stamping facility in Solec Kujawski, specializing in precision forming of components from sheet metal with thicknesses from roughly 0.8 to several millimeters. The company has decades of experience and offers advanced engineering and large‑scale production of stamped parts for automotive and industrial applications. Its press line includes high‑tonnage presses capable of deep drawing and complex forming.

As part of its portfolio, Hydrapres develops press tools and supports customers globally, making it an important reference among Top Stamping Die Components Manufacturers And Suppliers in Poland. Its expertise in tool try‑out, process optimization, and international logistics is valuable for buyers who need stable, long‑life stamping die components and consistent serial production.

Beyond these well‑known examples, there are numerous mid‑sized and smaller companies in Poland's stamping and tooling ecosystem. Some focus primarily on contract manufacturing, while others emphasize tool design and high‑precision machining. Together, they form a network of Top Stamping Die Components Manufacturers And Suppliers in Poland capable of supporting projects from prototypes to full‑scale production.

Industrial clusters around major cities and automotive hubs help concentrate talent, suppliers, and technical services. This clustering allows international buyers to source not only Top Stamping Die Components Manufacturers And Suppliers in Poland but also ancillary services such as heat treatment, coatings, and laboratory testing. For complex projects, working with a supplier embedded in such a cluster can streamline development.

Top Stamping Die Components Manufacturers And Suppliers in Poland increasingly work as partners in global projects rather than simple part vendors. For overseas brands, wholesalers, and producers, this often includes joint development of stamping die concepts, including feasibility studies and simulation to validate forming strategies. Early involvement in design helps prevent late‑stage manufacturing issues.

Suppliers commonly support prototyping, pilot series, and tool tuning before full production release. They may run short trials to verify that stamping die components achieve the required life and that parts meet dimensional and functional targets. Ongoing maintenance, refurbishment, and modification of stamping die components are also available, ensuring that tools remain productive across multiple product generations.

Many companies coordinate with external OEM partners in Asia or other regions, aligning stamping technologies and die standards so that parts and tools can be localized or dual‑sourced. This coordination helps ensure that stamped components comply with global quality standards, even when tools or stamping die components are produced in different factories. Top Stamping Die Components Manufacturers And Suppliers in Poland, therefore, fit naturally into multi‑plant, multi‑continent supply chains.

For global purchasers, one effective strategy is to combine the regional advantages of Top Stamping Die Components Manufacturers And Suppliers in Poland with the large‑scale OEM capacity of experienced Chinese manufacturers. Polish suppliers can focus on local tool design, fast engineering changes, and low‑volume or service parts for the European market, while Chinese OEM partners support cost‑optimized tooling, machining, and high‑volume stamping for international distribution.

A Chinese OEM such as U‑Need Precision Machinery Co., Ltd. can complement Top Stamping Die Components Manufacturers And Suppliers in Poland by providing high‑precision CNC machining for punches, dies, and inserts used in stamping tools. U‑Need also offers metal stamping, plastic product manufacturing, and silicone product manufacturing services under one roof, which is suitable for complex assemblies that combine metal and polymer components.

In addition, U‑Need provides flexible OEM cooperation models for brands, wholesalers, and producers that need both components and finished products. By aligning specifications, materials, and quality control methods between Polish toolmakers and a Chinese OEM partner, buyers can secure a resilient, cost‑effective supply chain for stamping die components and stamped parts. This combined model allows European customers to benefit from fast local support while leveraging competitive global manufacturing capacity.

When shortlisting or auditing Top Stamping Die Components Manufacturers And Suppliers in Poland, international buyers can focus on several practical criteria:

- Technical capabilities: range of presses, maximum tool size, supported materials, and experience with progressive, transfer, or deep‑drawing dies.

- Tooling and component quality: surface finish, heat treatment control, dimensional accuracy, and documented tool life expectations for punches and dies.

- Certifications and processes: ISO‑based quality and environmental management, PPAP capability, and traceability systems suitable for automotive or electronics.

- Project management: responsiveness, English‑language communication, clear timelines, and transparent reporting during tool design, try‑out, and ramp‑up.

- Export experience: proven shipments to EU, UK, or global customers, with logistics processes and packaging suitable for delicate stamping die components.

Top Stamping Die Components Manufacturers And Suppliers in Poland that meet these benchmarks are typically ready to engage in long‑term cooperation with brands, wholesalers, and OEM producers. For complex projects, it is often useful to start with a pilot tool or a limited set of stamping die components to verify performance before scaling up. During this phase, buyers can assess how well the supplier manages engineering changes and supports continuous improvement.

Another important aspect is the supplier's ability to integrate into the customer's digital systems. Many international OEMs use shared platforms for drawings, change requests, and quality documentation. Top Stamping Die Components Manufacturers And Suppliers in Poland that are comfortable with such tools can collaborate more efficiently and reduce administrative delays.

When engaging Top Stamping Die Components Manufacturers And Suppliers in Poland, buyers can follow a structured sourcing approach. First, define clear technical requirements, including material grades, tolerances, expected tool life, and annual production volumes. This clarity helps Polish suppliers propose realistic concepts and pricing.

Second, request references or case studies in similar industries or part families. Experienced Top Stamping Die Components Manufacturers And Suppliers in Poland can often show prior projects for automotive brackets, appliance housings, or connector parts. Reviewing these examples builds confidence in their capability and process control.

Third, consider dual‑sourcing or phased localization strategies. A project might begin with tooling development in Poland, with part production starting locally and later expanding to an additional plant in another country through a partner like U‑Need. This staged approach balances speed to market with long‑term cost optimization and risk management.

Top Stamping Die Components Manufacturers And Suppliers in Poland form an important part of the European metalworking ecosystem, offering a combination of modern tooling, experienced engineering teams, and strong export orientation. From automotive and electronics to printing and industrial applications, these suppliers provide complete stamping dies, custom stamping die components, and serial stamping services that meet demanding quality standards.

For foreign brands, wholesalers, and producers, working with Top Stamping Die Components Manufacturers And Suppliers in Poland can shorten lead times, improve technical communication, and ensure compliance with EU regulations, especially when combined with complementary OEM partners in China. By carefully evaluating technical capabilities, certifications, digital readiness, and project management, buyers can build stable long‑term relationships and create resilient, cost‑optimized supply chains for stamping die components and finished stamped parts.

Top Stamping Die Components Manufacturers And Suppliers in Poland offer a balance of competitive costs, strong engineering skills, and geographic proximity to major European OEMs. Their experience with automotive, electronics, and industrial projects means they understand strict quality, documentation, and delivery requirements.

Most Top Stamping Die Components Manufacturers And Suppliers in Poland can supply both full tools and individual components such as punches, dies, plates, and inserts. Many toolshops are willing to manufacture spare or replacement components to fit existing customer die sets.

Core industries include automotive, appliances, electronics, and general industrial machinery that require high‑volume metal parts. Packaging and printing sectors also work with Polish suppliers for embossing and hot stamping dies used on labels, cartons, and decorative products.

Yes, many Top Stamping Die Components Manufacturers And Suppliers in Poland provide design, simulation, prototyping, and try‑out services before serial production. They often collaborate closely with OEM engineering teams to optimize tool performance, reduce trial loops, and stabilize processes quickly.

Chinese OEMs can handle large‑scale machining, metal stamping, and multi‑material assemblies while Polish partners focus on local tool design, quick changes, and service parts. Aligning standards between Top Stamping Die Components Manufacturers And Suppliers in Poland and a Chinese OEM creates a flexible, dual‑source supply chain that balances cost, speed, and risk.

1. https://ensun.io/search/metal-stamping/poland

2. https://mikrostyk.pl/en/production-of-metal-parts/

3. https://mikrostyk.pl/en/metal-stamping-specialist/

4. https://hydrapres.pl/en/stamping

5. https://sohbi.pl/main-page-en/

6. https://frezotech.pl/cutting-and-stamping-dies/

7. https://www.grawerpolska.com

content is empty!