From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-01 Origin: Site

Content Menu

● Overview Of The 12 Main CNC Machine Types

● 1. CNC Milling Machines (3–5 Axis)

● 2. CNC Lathes And Turning Centers

● 3. Turn‑Mill Compound Machines

● 5. CNC Plasma Cutting Machines

● 6. CNC Laser Cutting Machines

● 7. CNC Electrical Discharge Machines (EDM)

● 8. CNC Waterjet Cutting Machines

● 12. CNC 3D Printers (Additive Manufacturing)

● Common CNC Machine Components

● How To Choose The Best CNC Machine Type For Your Project

● Practical Selection Guide Table

● Why Many OEM Buyers Work With CNC Machining Services Instead Of Buying Machines

● When To Talk To U‑NEED About Your CNC Project

● Call To Action: Get Engineering Feedback And A CNC Quote

● FAQ

>> (Q1) What are the main types of CNC machines?

>> (Q2) Which CNC machine is most commonly used in manufacturing

>> (Q3) How do I choose the right CNC machine for my part

>> (Q4) Can one CNC machine handle all my parts

>> (Q5) When should I outsource CNC machining instead of buying machines

Choosing the right CNC machine type determines whether your parts achieve the required tolerance, surface finish, and cost targets in real production, not just on paper. For overseas brands, wholesalers, and manufacturers working with Chinese OEM partners like U-NEED, understanding the strengths and limits of each CNC machine helps you design better parts and select the most suitable supplier.[1][2][3]

A CNC machine is a computer-controlled manufacturing system that removes or adds material to turn a digital design into a physical part with repeatable accuracy. Instead of manual levers and handwheels, G‑code and M‑code control spindle motion, axis positioning, feed rate, and tool changes along programmed toolpaths.[4][5]

Modern CNC machines support:[5][3]

- Multi‑axis motion for complex 3D contours

- Automatic tool changers for fast, repeatable cycles

- Integrated feedback systems for stable tolerances and better process control

Suggested visual: simple diagram showing CAD → CAM → CNC machine workflow near this section.

Before diving into details, it helps to group CNC machine types by the kind of work they do.[2][4]

- Material removal by cutting: milling, turning, drilling, grinding

- Thermal cutting: plasma, laser, waterjet (non‑thermal but cutting category)

- Spark erosion: EDM

- Routing and light machining: CNC router

- Complex kinematics: multi‑axis machines

- Additive: CNC‑controlled 3D printers

Suggested visual: table image summarizing the 12 machines with columns for “Best For”, “Typical Materials”, “Approx. Cost Range”.

A CNC milling machine uses a rotating multi-point cutting tool to remove material and create flat surfaces, pockets, slots, and 3D contours. Vertical and horizontal milling centers dominate industrial use, and modern 4‑axis and 5‑axis mills can handle very complex shapes in a single setup.[1][4][5][2]

Key points.

- Best for: prismatic parts, housings, brackets, complex 3D surfaces

- Materials: aluminum, steel, stainless steel, copper alloys, plastics, composites[4]

- Typical cost: about 30,000–80,000 USD for standard industrial CNC mills, more for 5‑axis models.[5][4]

For OEM buyers, CNC milling is often the default choice for structural parts, precision enclosures, and mechanical components that need multiple faces machined in one clamping.[3][1]

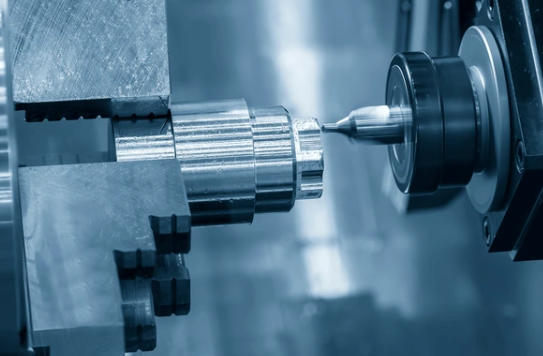

CNC lathes and turning centers rotate the workpiece while a stationary tool cuts external and internal cylindrical features. They excel at shafts, bushings, threaded parts, and any geometry that is symmetric around an axis.[1][2][4]

Key points.

- Typical operations: turning, facing, boring, threading, chamfering, knurling

- Types: horizontal, vertical, Swiss‑type, slant‑bed, multi‑axis turning centers[4][5]

- Accuracy: tight, repeatable tolerances on diameters with high productivity for bar‑fed parts.[4]

A standard 3‑axis CNC lathe often costs about 38,000–60,000 USD, with multi‑axis turning centers priced significantly higher but offering more complete machining in one setup.[6][4]

Turn‑mill or CNC turning‑milling compound machines combine the strengths of lathes and mills, allowing simultaneous rotation of tool and workpiece. They can machine cylindrical and prismatic features in one clamping, reducing handling, setups, and cumulative error.[2][5][4]

Key points.

- Best for: complex parts with both turned and milled features (e.g., valves, impellers, medical parts)

- Benefits: fewer fixtures, shorter total cycle time, improved geometric relationships between features[4]

- Cost: generally above 100,000 USD for industrial systems.[4]

For demanding OEM parts where concentricity, true position, and profile tolerance all matter, turn‑mill centers are often the most efficient solution.[3][5]

A CNC router uses a high‑speed spindle with limited Z‑axis travel to cut softer materials such as wood, plastics, foams, and aluminum sheets. Compared with heavy machining centers, routers focus on large working areas and fast traverse speeds rather than extreme rigidity.[7][5][2][4]

Key points.

- Best for: furniture panels, signs, display components, lightweight fixtures

- Materials: wood, MDF, plastics, aluminum, composite panels[4]

- Typical cost range: roughly from 10,000 USD for small routers to 80,000 USD+ for industrial systems.[5][4]

For OEM branding and packaging applications, CNC routers are ideal for large flat parts with pockets, profiles, and 2.5D engraving.[7][3]

A CNC plasma cutter uses a high‑temperature ionized gas jet to cut conductive materials such as steel and aluminum sheets and plates. The plasma arc melts the metal and blows it out of the kerf, enabling high cutting speeds on medium‑thickness stock.[2][5][4]

Key points.

- Best for: structural steel parts, brackets, frames, heavy sheet metal components

- Material thickness: typically around 1–50 mm, depending on power and setup.[4]

- Advantages: high cutting speed, flexible shapes, relatively lower cost than large lasers.[7][4]

Plasma cutting is widely used in construction, automotive, and heavy equipment where edge finish is less critical than speed and cost.[8][7]

CNC laser cutters focus an intense, narrow laser beam to cut or engrave metals, plastics, and other materials with very high precision. Common industrial sources include CO₂, fiber, and Nd:YAG lasers, each with different efficiency and material capabilities.[7][2][4]

Key points.

- Best for: detailed sheet parts, fine features, tight nesting for material savings

- Advantages: narrow kerf, smooth edge, excellent repeatability, suitable for cutting and engraving[4]

- Limitation: less efficient for very thick sections and highly reflective materials such as pure copper.[2][4]

For OEM projects that require fine cut quality, tight tolerances, and intricate shapes, laser cutting is often preferred over plasma.[3][7]

EDM removes material using electrical discharges (sparks) between an electrode and the conductive workpiece in a dielectric fluid. Wire EDM, sinker EDM, and hole‑drilling EDM allow the creation of shapes that are impossible or uneconomical with mechanical cutting.[5][2][4]

Key points.

- Best for: hardened tool steels, injection molds, dies, thin walls, and sharp internal corners

- Advantages: no cutting forces, hardness has little effect on machinability, excellent detail capability[4]

- Limitation: only works with conductive materials and tends to have slower removal rates.[9][4]

EDM is a critical process for precision tooling, medical implants, and high‑value aerospace components where geometry and edge quality are more important than cycle time.[6][2]

CNC waterjet machines use a high-pressure water stream, often mixed with abrasive particles, to cut metals, plastics, ceramics, glass, and composites without creating a heat‑affected zone. This is especially important for materials that degrade under heat.[7][5][2][4]

Key points.

- Best for: thick plates, heat‑sensitive materials, laminates, and stone

- Thickness capability: can cut up to about 12 inches for some materials.[4]

- Advantages: no thermal distortion, broad material compatibility, good edge quality.[7][4]

Waterjet cutting is widely used in aerospace, architecture, and specialty industrial applications where preserving material properties is essential.[6][7]

CNC grinding machines use a rotating abrasive wheel to remove very small amounts of material and improve dimension accuracy and surface finish. They are not a primary shaping process but a finishing operation after milling or turning.[9][2][4]

Key points.

- Best for: achieving tight tolerances and low surface roughness on critical surfaces

- Applications: gears, bearing seats, crankshafts, precision tooling, and medical components.[4]

- Limitation: low removal rate and higher process cost, so grinding is reserved for critical features.[4]

For OEM customers, grinding is often the final step that turns a “good” machined part into a fully compliant precision component.[6][2]

CNC drilling machines specialize in accurate through and blind holes using a variety of drill bits and drilling strategies. Multi‑spindle and radial drills are common for high‑volume hole patterns in plates and large structures.[5][2][4]

Key points.

- Best for: bolt circles, manifold plates, jigs, and fixtures with many repeated holes

- Tolerances: holes can reach very tight positional and diameter tolerances when the machine and fixturing are optimized.[4]

- Benefit: automated pecking, chip evacuation, and depth control for consistent results.[4]

Many machining centers integrate drilling, but dedicated CNC drills remain attractive in high‑volume production where thousands of holes must be produced per shift.[10][2]

Multi‑axis machines go beyond 3 axes, often combining 4, 5, 6, or more controlled motions to reach complex features from many angles in one setup. These machines are essential for parts with deep cavities, undercuts, and freeform surfaces.[1][2][5][4]

Key points.

- Configurations: 4‑axis rotary, 5‑axis (trunnion or head‑head), and robotics‑assisted 7‑axis systems[5][4]

- Benefits: fewer setups, better positional accuracy, and shorter total lead time on complex parts.[4]

- Cost: high machine and CAM investment, but justified for challenging aerospace, medical, and defense parts.[11][6]

For OEM projects with critical 3D geometries, multi‑axis machining often unlocks designs that would otherwise require multiple fixtures and processes.[3][5]

CNC 3D printers use additive processes to build parts layer by layer from plastics, resins, or metal powders. While not subtractive, they share the same digital workflow and motion control principles as CNC mills and lathes.[12][5][4]

Key points.

- Technologies: FDM, SLA, SLS, DMLS, MJF and others for plastics and metals.[4]

- Advantages: design freedom, internal channels, lattice structures, and minimal material waste.[4]

- Limitations: slower for large volumes, material choices and mechanical properties can differ from wrought materials.[5][4]

In many OEM workflows, 3D printing complements CNC machining: designers validate complex shapes with printed prototypes before switching to machining for final production.[3][5]

Despite their differences, most CNC machines share core subsystems that work together to execute the programmed operations.[2][4]

Key hardware and control elements.

- Bed and structure: rigid cast iron or welded frames that support the table, axes, and spindle.[4]

- Machine control unit (MCU): executes G‑code, coordinates axis motion, and communicates with drives and feedback systems.[4]

- Drive system: servomotors, screws, linear guides, and power electronics that translate commands into precise motion.[4]

- Feedback system: encoders, scales, and sensors that report actual positions back to the control for closed‑loop accuracy.[4]

Workholding and interface elements.

- Chucks, vises, fixtures, and pallets for securing workpieces on lathes, mills, and routers.[4]

- Control panel, input devices, and display for loading programs, setting offsets, and monitoring performance in real time.[4]

Suggested visual: labeled photo of a vertical machining center, with arrows pointing to bed, spindle, axes, control panel, and tool magazine.

Selecting the best CNC machine is about matching your part and business needs to the strengths of each technology. Use the following practical steps as a checklist when discussing options with your OEM supplier.[3][4]

1. Define material and thickness.

- Metals vs plastics vs composites.

- Thin sheet vs thick plate vs solid blocks.[2][4]

2. Clarify part geometry and tolerances.

- Cylindrical vs prismatic vs freeform 3D surfaces.

- Tight tolerances, surface finish, and critical dimensions.[5][4]

3. Decide on volume and lifecycle.

- Prototypes, pilot runs, or high‑volume production.

- Need for automation, ATC, and lights‑out capability.[3][4]

4. Balance budget, lead time, and risk.

- Equipment cost, hourly machining rate, and setup time.

- Consequences of scrap, rework, and late delivery for your project.[8][11]

For example, a thick structural steel bracket may be most economical on a CNC plasma or waterjet, followed by secondary machining, while a small, high‑value medical implant will typically require multi‑axis milling and possibly EDM finishing.[7][4]

Use this condensed table when comparing CNC machine types for a new part.

| CNC machine type | Best for parts | Typical materials | Strengths | Key limitations |

|---|---|---|---|---|

| CNC milling | Prismatic parts, housings | Aluminum, steel, plastics | Flexible, high accuracy | Multiple setups if not multi‑axis |

| CNC lathe | Shafts, bushings, rings | Metals, engineering plastics | Fast for cylindrical parts | Limited for non‑round shapes |

| Turn‑mill | Mixed turned/milled geometries | Metals, alloys | One‑and‑done setup | Higher machine cost, programming complexity |

| CNC router | Panels, signs, furniture | Wood, plastics, soft metals | Large area, high speed | Limited Z travel, less rigid |

| Plasma cutter | Structural sheet and plate | Steel, stainless, aluminum | High cutting speed, moderate cost | Heat‑affected zone, rougher edge |

| Laser cutter | Precision sheet parts | Metals, plastics | Fine kerf, smooth edges | Less suitable for very thick or reflective metals |

| EDM | Hardened, complex cavities | Tool steels, alloys | No cutting forces, sharp corners | Slow removal, conductive only |

| Waterjet | Thick or heat‑sensitive parts | Metals, stone, composites | No HAZ, broad materials | Slower, higher running cost |

| Grinder | Precision surfaces, finish | Hardened metals | Excellent finish, tight tolerances | Low removal rate, secondary process |

| Drill | Hole‑intensive parts | Metals, plastics | Efficient for many holes | Limited to drilling operations |

| Multi‑axis | Complex 3D geometries | Metals, plastics | Fewer setups, complex shapes | High cost, skilled programming |

| 3D printer | Prototypes, complex internals | Plastics, metals | Design freedom, low waste | Slower for mass production |

Suggested visual: interactive version of this table or flowchart that guides users from material/geometry to recommended machine type.

Owning CNC equipment gives control, but complex parts often require multiple machine types, expert programmers, and robust quality systems. For many overseas brands and wholesalers, partnering with a specialized CNC supplier is more efficient than building this capability in‑house.[13][3][4]

Benefits of working with a professional CNC shop.

- Access to a wide mix of machines (milling, turning, EDM, laser, stamping, molding) without capital investment.[4]

- Engineering support for DFM, tolerance optimization, and material selection to reduce cost and risk.[3]

- Established quality and logistics workflows for export projects, including inspection reports and packaging.[3]

For companies that need high‑precision machined parts, plastic and silicone products, and metal stamping for global markets, a Chinese OEM partner with a broad machine portfolio can provide a one‑stop solution from prototypes to mass production.[3]

If you are planning a new OEM product or wish to transfer existing tooling to a more competitive supplier, it is critical to involve your manufacturing partner early. This is especially true for projects that combine CNC machining with plastic molding, silicone parts, and metal stamping in one assembly.[3]

A strong CNC partner can help you:

- Select the most suitable CNC machine types for each part in your BOM.

- Optimize drawings and tolerances for realistic, stable production.

- Plan prototypes, validation builds, and full‑scale runs with clear timelines and quality checkpoints.[13][3]

If you already have 2D drawings or 3D models, now is the best time to turn them into a manufacturable CNC plan. Send your part files, material requirements, expected volumes, and any special quality or certification needs to your chosen CNC partner so they can recommend the right machine mix and provide a detailed quotation.[13][3]

U‑NEED focuses on OEM projects for overseas brands, wholesalers, and manufacturers that require high‑precision machined parts, plastic and silicone products, and metal stamping under consistent quality control. Share your project details to receive engineering feedback, optimized process suggestions, and a clear lead time and pricing breakdown for your next production run.[3]

The main types of CNC machines include milling machines, lathes, turn‑mill centers, routers, plasma cutters, laser cutters, EDM, waterjet cutters, grinders, drilling machines, multi‑axis systems, and 3D printers.[2][4]

CNC milling machines and CNC lathes are the most widely used because they cover a broad range of prismatic and cylindrical parts with good productivity and accuracy.[1][2]

You choose the right machine by matching material, geometry, tolerance, volume, and budget to each machine's strengths, often with guidance from an experienced CNC supplier.[3][4]

No single CNC machine can efficiently handle every part, so complex OEM projects typically combine milling, turning, drilling, and sometimes EDM, grinding, or stamping to cover the full BOM.[5][4]

You should outsource when parts require multiple advanced machine types, tight tolerances, specialized materials, or when you lack experienced programmers, quality systems, or the capital for full in‑house capability.[13][3]

[1](https://www.vulcanus-stahl.de/en/blog/types-of-cnc-machine)

[2](https://www.engineeringchoice.org/different-types-of-cnc-machine/)

[3](https://www.gushwork.ai/blog/seo-for-cnc-companies-industry)

[4](https://www.rapiddirect.com/blog/12-types-of-cnc-machines/)

[5](https://www.xometry.com/resources/machining/types-of-cnc-machines/)

[6](https://www.precedenceresearch.com/computer-numerical-control-machine-market)

[7](https://www.linkbusinessltd.co.uk/different-types-of-cnc-machines/)

[8](https://finance.yahoo.com/news/cnc-machine-tools-market-grow-035600757.html)

[9](https://fr.scribd.com/document/614916156/12-Different-Types-of-CNC-Machine-Complete-Guide-PDF)

[10](https://www.researchandmarkets.com/reports/5850456/cnc-machine-tools-market-report)

[11](https://www.fortunebusinessinsights.com/industry-reports/computer-numerical-controls-cnc-machine-tools-market-101707)

[12](https://www.precionn.com/12-types-of-cnc-machines-a-guide-to-modern-manufacturing.html)

[13](https://www.gushwork.ai/blog/seo-for-cnc-companies)

[14](https://studiohawk.co.uk/case-studies/onefinity-cnc-case-study)

[15](https://www.linkedin.com/pulse/desktop-cnc-machine-market-size-share-growth-forecast-20252032-9cw6f)

[16](https://www.zintilon.com/blog/types-of-cnc-milling/)

[17](https://www.cncyangsen.com/12-types-of-major-cnc-milling-machines)

[18](https://blog.thomasnet.com/seo-for-cnc-machine-shops)

[19](https://www.axongarside.com/guides/manufacturing-seo)

[20](https://macraes.com/seo-for-cnc-companies/)