From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Loretta Publish Time: 2025-12-22 Origin: Site

Content Menu

● How 3-Axis CNC Milling Works

● Key Advantages of 3-Axis CNC Machining

>> Simplicity and Proven Reliability

>> Lower Investment and Operating Cost

>> High Precision on Standard Geometries

● Common Applications and Materials in 3-Axis CNC

>> Suitable Materials and Tolerance Levels

● 3-Axis vs. 4-Axis vs. 5-Axis CNC

>> Axis Configurations and Capabilities

● When 3-Axis CNC Is the Best Choice

>> Simple to Moderately Complex Parts

>> Prototyping and Small-Batch Production

>> Hybrid Use with Multi-Axis Machining

● Limitations of 3-Axis CNC Machining

>> Limited Access to Complex Surfaces

>> Higher Labor on Very Complex Parts

● Best Practices for High-Precision 3-Axis Machining

>> Design for Manufacturability (DFM) Guidelines

>> Process and Quality Control

● Choosing the Right Machining Strategy for Your Parts

>> 1. Can all critical features be reached from one main direction without undercuts?

>> 2. How complex are the surfaces?

>> 3. What are the quantity and cost targets?

● Take the Next Step with a Professional OEM Partner

● Frequently Asked Questions (FAQ)

>> 1. What is the difference between a 3-axis CNC mill and a 3-axis CNC router?

>> 2. Can a 3-axis CNC machine produce complex parts?

>> 3. What tolerances are realistic for 3-axis CNC machining?

>> 4. When should I choose 5-axis machining instead of 3-axis?

>> 5. How can I reduce the cost of parts machined on 3-axis equipment?

3-axis CNC milling remains one of the most cost-effective and reliable ways to produce precision components, especially for flat and 2.5D geometries in metals and plastics. It offers tight tolerances, fast turnaround, and strong ROI for OEM buyers, brand owners, and industrial manufacturers when applied with robust engineering and process control.

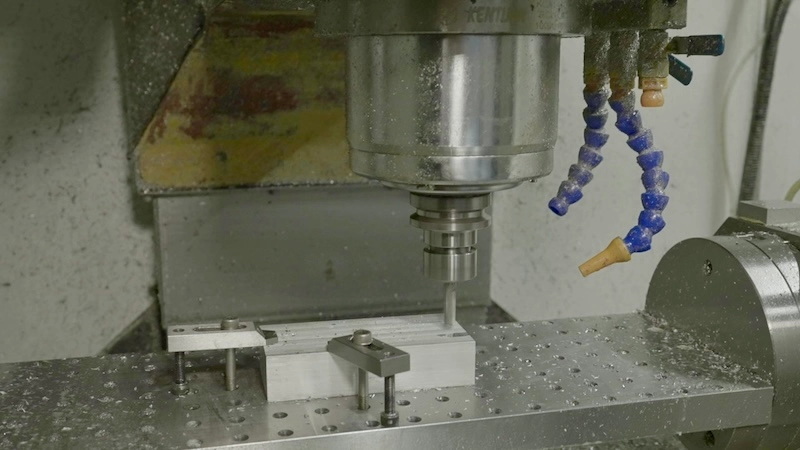

3-axis CNC milling is a subtractive machining process in which the cutting tool moves along three linear axes-X, Y, and Z-while the workpiece remains fixed on the machine table. The X-axis controls left-right motion, the Y-axis handles front-back travel, and the Z-axis moves the tool up and down to define depth.

With this configuration, the cutting tool typically approaches the workpiece from above, making it ideal for machining flat surfaces, pockets, slots, contours, and drilled holes. Because motion is limited to three perpendicular axes, 3-axis CNC milling is straightforward to program, stable in production, and highly repeatable for standard part geometries.

The 3-axis milling process begins with a 3D CAD model or 2D drawing of the part, which is imported into CAM software to generate toolpaths along the X, Y, and Z axes. The programmer selects tools, cutting parameters, and machining strategies, then posts a CNC program that the machine controller can execute.

On the shop floor, the operator sets up the workpiece, secures it with appropriate fixturing, sets work offsets, loads tools, and runs the program. Because the tool approaches mainly from a single direction, side features often require additional setups or custom fixtures to access all faces of the part.

3-axis CNC machining delivers an attractive combination of simplicity, stability, and performance. For a large portion of industrial components, it is the most rational choice.

3-axis machines have fewer moving parts and no rotary axes, which makes their mechanical structure and control system less complex. This leads to fewer potential failure points, shorter downtimes, and more predictable maintenance schedules over the life of the equipment.

Because programming and operation are more straightforward than on multi-axis systems, it is easier to train machinists, standardize processes, and maintain consistent quality across shifts. The talent pool with 3-axis experience is also broader, which reduces operational risk for manufacturers.

The capital cost of a 3-axis machining center is significantly lower than that of a 4-axis or 5-axis system with comparable working envelope and performance. Tooling, fixturing, and replacement parts are widely available and generally more economical, which keeps the total cost of ownership under control.

CAM programming time is shorter because the software only needs to manage linear movements without complex rotary positioning or collision checks. This reduces engineering hours and data preparation lead time, especially for prototypes and small to medium production runs.

Modern 3-axis machines are capable of holding tight tolerances on standard geometries when combined with suitable tooling and quality control. For many applications, 3-axis machining provides all the accuracy required without the need for more complex equipment.

Since many industrial parts are primarily 2.5D-made up of steps, pockets, bores, slots, and planar faces-3-axis machining can deliver excellent dimensional stability and surface finish. For top-down features in particular, a well-optimized 3-axis setup can match or exceed more complex systems in consistency and repeatability.

3-axis CNC machining is widely used across machinery, automotive, electronics, and consumer product industries. It supports a broad set of materials and project types.

- Flat and 2.5D parts such as plates, adapter plates, and mounting brackets

- Machinery panels, covers, and flanges with cutouts and through holes

- Simple housings and enclosures with countersinks, recesses, and threaded features

- Jigs, fixtures, and inspection tools for assembly and production support

- Basic molds and dies where cavities and surfaces are accessible from the top

These parts benefit from fast setup, high repeatability, and competitive unit cost, making 3-axis machining a reliable choice for OEM and replacement components.

3-axis CNC machining can handle a wide range of materials, including:

- Metals: aluminum alloys, mild and alloy steels, stainless steel, copper, and brass

- Plastics: ABS, PC, POM, PA, PMMA, and engineering polymers

- Other: some composites and soft materials when appropriate tooling and parameters are used

General-purpose tolerances on machined metals often fall around standard industrial ranges, with tighter tolerances achievable on critical dimensions through controlled processes, stable fixturing, and proper inspection. Softer materials such as plastics may require optimized cutting parameters and slightly looser tolerance bands due to thermal expansion and flexibility.

Understanding how 3-axis compares to multi-axis options helps engineers and buyers select the right machining strategy for each project.

- 3-axis CNC: Linear X, Y, Z motion only. The workpiece stays fixed; the tool moves. Ideal for single-orientation parts and 2.5D features.

- 4-axis CNC: X, Y, Z plus a rotary axis (commonly A or B) that rotates the part or the tool. This enables machining around a part's perimeter with fewer setups.

- 5-axis CNC: X, Y, Z plus two rotary axes (e.g., A and B, or B and C) that allow simultaneous multi-direction access, ideal for complex freeform surfaces and multi-sided machining in one setup.

Factor | 3-Axis CNC | 4-Axis CNC | 5-Axis CNC |

Motion | Linear X/Y/Z | X/Y/Z + 1 rotary | X/Y/Z + 2 rotary |

Geometries | Flat & 2.5D parts | Rotational & side features | Complex contoured parts |

Setups | More for multi-sides | Fewer setups | Often single setup |

Programming | Straightforward | Moderate complexity | High complexity |

Investment | Lowest | Medium | Highest |

Ideal Use | Plates, brackets, housings | Shafts, cams, engravings | Aerospace, medical, turbine, complex molds |

When parts can be fully accessed from a single direction and do not require undercuts or compound angles, 3-axis machining is usually the most efficient and economical option. As part complexity, multi-sided features, and tolerance demands increase, 4-axis and 5-axis machines become more attractive.

Choosing the right level of technology is crucial for balancing performance with cost. In many real-world projects, 3-axis machining is the most rational choice.

For parts featuring mainly:

- Flat surfaces and stepped profiles

- Perpendicular walls

- Top-down pockets and slots

- Standard drilled and tapped holes

3-axis machining can provide all the necessary capability. Many parts that appear complex visually are, in fact, composed of multiple 2.5D features that do not require multi-axis interpolation.

Examples include:

- Mounting and interface plates

- Brackets with cutouts and countersinks

- Machine covers and panels with various openings

- Simple aluminum or steel housings without deep side undercuts

For prototypes and low to medium volumes, engineering and setup time often represent a significant portion of total cost. Because 3-axis programming and fixturing are simpler, it is often the fastest route from design to physical parts.

This makes 3-axis milling well suited for:

- Design validation and functional prototypes

- Pilot runs before mass production

- Replacement parts and customized one-off components

Engineers can quickly iterate designs, check assembly compatibility, and refine details without the overhead associated with advanced multi-axis routing.

In many modern factories, 3-axis and multi-axis machines are used together. A typical strategy is:

1. Rough or semi-finish the main geometry on a 3-axis machine.

2. Transfer the part to a 4-axis or 5-axis machine only for features that truly require additional freedom.

This hybrid approach focuses expensive multi-axis capacity on critical operations such as complex contours or hard-to-reach features, while using 3-axis equipment for bulk material removal and simpler surfaces.

While 3-axis CNC milling is powerful and versatile, understanding its boundaries helps avoid design and cost issues.

Because 3-axis machines do not rotate the part automatically, features located on different faces or at certain angles require manual re-clamping and additional setups. Each setup needs careful alignment, probing, and verification to keep positional relationships within tolerance.

As setup count increases, so do risks of cumulative error, labor time, and fixture complexity. For parts that require full five-side access or many critical side features, multi-axis solutions often become more efficient.

Features such as:

- Deep cavities with narrow openings

- Undercuts that hide behind walls

- Smooth, continuously curved 3D surfaces

- Features at steep compound angles

are difficult or impossible to machine efficiently with pure 3-axis motion. Long, slender tools needed for deep pockets can reduce rigidity, slow down cutting, and impact surface quality.

In these cases, 4-axis or 5-axis machining can provide better access, shorter cycle times, and more consistent finishes.

Forcing highly complex parts onto 3-axis equipment usually requires:

- Special fixtures and multiple clamping orientations

- More manual inspection and alignment work

- Increased risk of scrap and rework if any step is slightly off

For high-mix, low-volume production with very complex geometries, the extra labor, fixturing cost, and quality risk can outweigh the initial savings of using a 3-axis machine.

To fully leverage 3-axis CNC machining, both design and process planning need to be aligned with its characteristics.

- Keep critical features accessible from a single main direction whenever possible.

- Avoid unnecessarily deep, narrow pockets; use stepped depths, larger radii, or split the feature into multiple regions.

- Apply tight tolerances only to features that directly affect function, assembly, or sealing.

- Select materials that match the required tolerances and surface finish, considering machinability and stability.

- Simplify shapes where possible, such as replacing tiny undercuts with fillets or chamfers that are easy to machine.

- Use rigid, repeatable fixturing and minimize the number of re-clamps to control positional error.

- Choose optimized cutting parameters (speed, feed, depth of cut) for each material to balance tool life, precision, and cycle time.

- Implement robust inspection routines using calipers, gauges, or CMM equipment for critical dimensions.

- Schedule regular maintenance and calibration for both machines and measuring devices to maintain long-term stability.

A disciplined approach to DFM and process control ensures that 3-axis machining can consistently meet demanding dimensional and functional requirements.

Selecting between 3-axis, 4-axis, and 5-axis machining depends on geometry, tolerance, volume, and budget. A practical way to decide is to ask a few key questions:

- If yes, 3-axis machining is usually the first choice.

- If not, consider 4-axis or 5-axis options.

- Mainly flat or stepped with simple radii: 3-axis is generally sufficient.

- Sculpted, freeform, or compound-angled surfaces: multi-axis machining is more suitable.

- Prototypes and low volumes with moderate precision: 3-axis usually offers the best cost-time balance.

- High volumes or very complex, high-value parts: 4-axis/5-axis can reduce setups and manual labor, offsetting higher machine cost.

Working with a supplier that understands all three configurations allows each project to be routed to the most appropriate process.

If you are looking for a reliable manufacturing partner for high-precision machined parts, plastic components, silicone products, or metal stampings, choosing a team that understands both design and production is essential. At U-NEED, experienced engineers and technicians work across 3-axis CNC machining, multi-axis solutions, plastic and silicone molding, and metal stamping to support international brands, wholesalers, and manufacturers.

Send your drawings or 3D models along with your project requirements, and U-NEED will evaluate your part geometry, recommend the most suitable process (3-axis, 4-axis, 5-axis, or stamping/injection), and provide a detailed quotation and DFM feedback. This engineering-driven approach helps you shorten development cycles, stabilize quality, and achieve a better balance between cost and performance for every project.

A 3-axis CNC mill is built with a heavy, rigid structure, high spindle power, and precision motion control designed to machine metals such as aluminum, steel, and stainless steel. A 3-axis CNC router uses the same X, Y, and Z principles but has a lighter frame and higher travel speeds, making it more suitable for wood, plastics, and composites rather than heavy metal cutting.

Yes, a 3-axis CNC machine can manufacture complex parts as long as the important features are accessible from a single tool direction and the geometry is mainly 2.5D. Elaborate patterns of pockets, steps, holes, and contours can be handled very effectively; only features that require multi-direction access or undercuts truly demand additional axes.

Typical industrial parts machined on 3-axis equipment can meet standard general-purpose tolerances suitable for most mechanical applications. With proper fixturing, tool selection, and inspection, tighter tolerances can be achieved on specific critical dimensions, while less critical features are held to more economical ranges.

5-axis machining becomes the better option when the part includes complex curved surfaces, deep cavities at angles, or critical features on multiple faces that must be machined in a single setup. It is especially valuable for aerospace, medical, and turbine components where surface continuity, positional accuracy, and cycle time are all demanding.

To control cost, keep the design as simple as functionally possible, limit tight tolerances to where they are truly necessary, and ensure features are accessible from one direction. Selecting machinable materials, designing for efficient fixturing, and grouping orders into reasonable batch sizes also helps reduce setup time and unit pricing.

content is empty!