From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-26 Origin: Site

Content Menu

● What Is Additive Manufacturing?

● What Is Subtractive Manufacturing?

● Core Differences: Additive vs Subtractive Manufacturing

>> Key Comparison: Additive vs Subtractive

● Advantages of Additive Manufacturing

● Advantages of Subtractive Manufacturing

● When to Use Additive Manufacturing

● When to Use Subtractive Manufacturing

● Hybrid Strategies: Combining Additive and Subtractive Manufacturing

● Practical Decision Framework for Engineers and Buyers

● Real-World Examples of Additive vs Subtractive Use

● Design Tips to Optimize for Each Process

● How an OEM Supplier Like U-NEED Supports Both Approaches

● Call to Action: Start Your Next Project with U-NEED

● FAQ

>> 1. What is the main difference between additive and subtractive manufacturing?

>> 2. Is additive manufacturing cheaper than subtractive manufacturing?

>> 3. Which process gives better surface finish and tolerances?

>> 4. Can I combine additive and subtractive manufacturing in one project?

>> 5. How do I decide which method is right for my part?

Additive and subtractive manufacturing sit at the core of modern product development, from rapid prototypes to mass-produced end-use parts. Understanding their differences in process, cost, lead time, and scalability is essential if you want to choose the right production strategy or the right OEM partner. This guide explains each method in practical terms, shows when to use each, and illustrates how hybrid workflows and professional suppliers like U-NEED help overseas brands get better quality and lower total cost.

Additive manufacturing (AM) is a layer-by-layer process that builds a part directly from digital 3D data. Common additive technologies include fused filament fabrication (FFF/FDM), stereolithography (SLA), selective laser sintering (SLS), and various metal 3D printing processes.

Key characteristics of additive manufacturing:

- Material is added, not removed, usually in thin layers.

- Parts are created directly from CAD files with minimal tooling.

- Complex geometries, internal channels, and lattice structures are achievable.

- Many processes need post-processing (support removal, cleaning, curing, or surface finishing).

For OEM buyers, the most important benefit is that additive manufacturing lets you go from design to physical prototype quickly, with very low upfront setup cost.

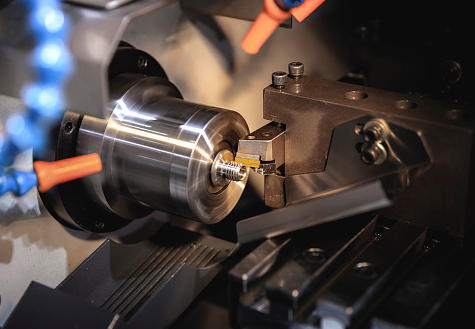

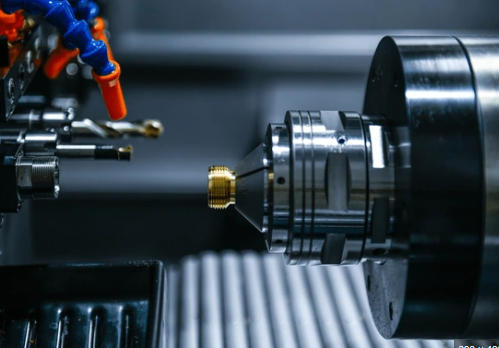

Subtractive manufacturing creates parts by removing material from a solid block using cutting tools or other material removal methods. Typical subtractive processes include CNC milling, CNC turning, drilling, grinding, and EDM.

Key characteristics of subtractive manufacturing:

- Material is cut away from bar stock, billets, or plates.

- A broad range of metals and plastics can be machined.

- Parts usually achieve tight tolerances and smooth surface finishes.

- Best suited to repeatable production of small to large batches.

For critical components that must withstand high loads or high temperatures, subtractive manufacturing remains the go-to method because of its dimensional accuracy and material performance.

The following table summarizes the most important differences that engineers and buyers look at when comparing additive vs subtractive manufacturing.

| Aspect | Additive Manufacturing | Subtractive Manufacturing |

|---|---|---|

| Basic principle | Builds parts by adding layers of material. | Produces parts by removing material from a solid block. |

| Design freedom | Excellent for complex, organic, and internal geometries. | Limited by tool access and workholding; very thin or complex internals can be difficult. |

| Materials | Strong for polymers and some metals; not all alloys are available. | Very wide range of metals and plastics; many standard industrial grades. |

| Surface finish | Often has visible layer lines and needs post-processing. | Naturally smoother surfaces and tighter tolerances. |

| Material waste | Minimal waste; only the needed material is deposited. | More waste due to chips and off-cuts, though scrap is often recyclable. |

| Tooling & setup | Low tooling needs; great for design changes and one-offs. | Requires tools, fixtures, and setup time, especially for new parts. |

| Speed | Fast for prototypes and small batches; slower per part for big runs. | Very fast per part once setup is complete; ideal for higher volumes. |

| Per-part cost | Competitive at low volumes or for highly complex parts. | More economical at medium to high volumes and for repeated orders. |

| Best use cases | Prototyping, custom devices, lightweight structures, spare parts. | Functional components, tight-tolerance parts, mass production. |

Additive manufacturing delivers several strategic advantages when used in the right context.

- Rapid prototyping and iteration: You can print a new version directly from CAD without waiting for tooling, enabling faster design validation and shorter development cycles.

- Design freedom: Additive methods allow internal channels, lattice structures, and complex shapes that cannot be easily machined.

- Low tooling cost: Because there are few physical tools or molds, additive is cost-effective for small runs and one-off parts.

- Material efficiency: Only the required material is used, which reduces waste and can support more sustainable manufacturing strategies.

- On-demand production: Distributed 3D printing capacity enables localized production and shorter supply chains for spare parts and low-volume items.

A simple example is a customized medical device handle: additive manufacturing lets you print different sizes and textures for each patient without changing any tooling.

Subtractive manufacturing remains a workhorse for industrial production because of its precision, material range, and scalability.

- High dimensional accuracy: CNC machining and similar methods achieve tight tolerances, which is critical for bearing fits, sealing surfaces, and precision assemblies.

- Superior surface finish: Parts often come off the machine with smooth surfaces that need little additional finishing.

- Broad material compatibility: From aluminum and stainless steel to engineering plastics, subtractive manufacturing covers most standard industrial materials.

- Economical for volume: Once tools and fixtures are set, cycle times are short and the per-part cost is low, making it ideal for series production.

- Process reliability: Subtractive processes are mature, standardized, and widely understood on shop floors worldwide.

Think about a precision steel shaft used in a gearbox: the required tolerance, surface finish, and mechanical strength make subtractive manufacturing the natural choice.

No process is perfect. Understanding the limitations of additive vs subtractive manufacturing helps you avoid costly mistakes.

Limitations of additive manufacturing:

- Slower and more expensive per part for high-volume production.

- Limited material options compared with machining, especially for some metals.

- Surface finish and dimensional accuracy often require post-processing.

- Build volume constraints and support structures can restrict part size and orientation.

Limitations of subtractive manufacturing:

- Tool access constraints make very complex, internal, or undercut features difficult.

- Higher material waste, which can increase cost for expensive alloys.

- Tooling, fixturing, and setup time raise the entry cost for low-volume or one-off parts.

- Design changes often require new setups or fixtures.

A practical strategy is to design parts with these limitations in mind: for example, you might split a highly complex assembly into an additively produced core and subtractively machined interfaces.

Additive manufacturing is most effective when flexibility, complexity, or low volume matter more than per-unit cost.

Use additive manufacturing when:

1. You need rapid prototypes to validate form, fit, and basic function before investing in tooling.

2. Your part has complex internal features, such as cooling channels, lattice infill structures, or conformal cavities.

3. Volumes are low or highly variable, making tooling investment risky.

4. You want mass customization, for example personalized consumer products or medical devices.

5. You require lightweight structures with optimized topology for aerospace or performance applications.

For overseas buyers, additive manufacturing is especially valuable in the concept and early validation phases, where speed and design freedom outweigh the higher per-unit cost.

Subtractive manufacturing is the best option when you need precision, durability, and scalable production.

Use subtractive manufacturing when:

1. Parts must meet tight tolerances or critical surface roughness requirements.

2. Material selection (for example high-strength steel, brass, or specific engineering plastics) is critical to performance.

3. Production volumes are medium to high, and you want low cost per part after setup.

4. Parts are structurally loaded, exposed to heat, or used in safety-critical environments.

5. You need repeatable quality across many batches over years of production.

This is why many automotive, industrial, and machinery components—even when originally prototyped with 3D printing—are ultimately produced by CNC machining or other subtractive processes.

In practice, many manufacturers no longer ask “additive or subtractive?” but “how do we combine both?”

Common hybrid approaches include:

- 3D printed prototypes + CNC for production: Use additive to dial in the design, then switch to subtractive for long-term series manufacturing.

- Printed blanks with machined critical surfaces: Build the near-net shape additively, then machine interfaces, threads, and sealing areas.

- Printed tooling, jigs, and fixtures for subtractive operations, enabling faster changeovers and lower tooling cost.

- On-demand spare parts printed close to the point of use, while core high-load parts remain machined.

Well-run OEM suppliers that offer both capabilities can help you design smarter parts and choose the most economical process for each segment of your product.

To make a clear decision between additive vs subtractive manufacturing, it helps to translate technical differences into practical questions.

Ask yourself:

1. What is my real volume?

- Prototypes and tens of parts: additive often wins.

- Hundreds or thousands: subtractive usually offers lower cost per part.

2. How complex is the geometry?

- Complex internals or organic shapes: additive is easier.

- Simple prismatic parts or shafts: subtractive is faster and cheaper.

3. What are the tolerance and surface finish needs?

- Non-critical surfaces: additive is acceptable with minimal finishing.

- Tight fits and functional surfaces: subtractive or hybrid processing.

4. What materials do I need?

- Standard polymer prototypes: many additive options exist.

- Specific metal grades or engineering plastics: subtractive offers more choice.

5. What is my timeline and tooling budget?

- Short timeline and low tooling budget: additive is attractive.

- Long-term production with stable design: subtractive typically pays off.

By answering these questions with your supplier, you can quickly map parts to the most suitable process or hybrid route.

Across industries, companies increasingly match each process to its strongest applications.

Typical patterns include:

- Automotive and aerospace: 3D printed fixtures, brackets, or lightweight ducting combined with machined structural components.

- Medical: Custom implants or surgical guides printed additively, while instruments and housings are machined.

- Consumer products: 3D printed design prototypes and small pilot runs, followed by CNC machining of metal inserts or functional parts.

- Industrial machinery: Printed spare parts for legacy equipment, combined with machined shafts, housings, and gears.

In each case, additive vs subtractive manufacturing is not a binary choice but a portfolio of options that can be tuned to performance, cost, and lead time targets.

Small design decisions can dramatically improve cost and quality, whether you choose additive or subtractive manufacturing.

For additive manufacturing:

- Minimize support structures by adjusting part orientation and adding self-supporting angles.

- Maintain consistent wall thicknesses to reduce print defects.

- Include chamfers or fillets that match process capabilities.

- Plan post-processing steps for critical surfaces or threaded areas.

For subtractive manufacturing:

- Avoid deep, narrow pockets that are hard to machine.

- Standardize hole sizes and radii to match common tool diameters.

- Design fixtures and clamping surfaces into the part when possible.

- Set tolerances no tighter than necessary to reduce machining time.

Working closely with an experienced OEM partner helps you apply these principles early in the design phase, preventing redesign loops later.

For overseas brands, the biggest challenge is often not the technology itself but finding a reliable partner that can apply it correctly across multiple projects.

A comprehensive OEM supplier such as U-NEED in China can:

- Provide CNC machining for high-precision metal and plastic parts, ensuring tight tolerances and stable series production.

- Offer plastic and silicone manufacturing, including molded components that complement machined parts.

- Deliver metal stamping for high-volume, cost-efficient sheet metal parts.

- Advise you on when to prototype with additive methods and then transition to subtractive or stamping for mass production.

By centralizing these capabilities in one supply chain, overseas brands reduce communication overhead, shorten development cycles, and achieve better consistency across different manufacturing processes.

If you are planning new components or want to optimize existing ones, you can share your drawings, 3D models, and expected volumes with U-NEED and receive clear recommendations on whether additive-style prototyping, precision machining, plastics, silicone, or metal stamping is the best path for each part. By combining practical engineering support with flexible manufacturing capacity, U-NEED helps brands, wholesalers, and equipment manufacturers turn concepts into stable, long-term production. Contact U-NEED today to discuss your project and explore how a tailored combination of processes can improve quality, reduce cost, and accelerate your launch timeline.

Contact us to get more information!

The main difference is that additive manufacturing adds material layer by layer to build a part, while subtractive manufacturing removes material from a solid workpiece to achieve the final shape.

Additive manufacturing is usually more economical for low volumes and highly complex parts because it avoids tooling costs, but subtractive manufacturing tends to be cheaper per part for medium to high-volume production once setup is complete.

Subtractive manufacturing processes such as CNC milling and turning normally deliver better surface finishes and tighter tolerances than most additive methods, which often require post-processing to meet the same standards.

Yes, many companies use hybrid strategies, such as 3D printing near-net-shape parts and then machining critical surfaces, or printing prototypes and tooling for parts that will later be produced by CNC machining or stamping.

Consider your volume, geometry complexity, tolerances, material needs, and tooling budget; additive manufacturing fits low-volume, complex, or customized parts, while subtractive manufacturing is usually best for higher volumes, strict tolerances, and a wider range of materials.