Aluminium CNC Machining

Aluminium has good thermal properties and processability because it has become an important industrial material.

Compared with die steel, aluminium alloy has good machinability, lightweight, and high thermal conductivity. There was a problem with low strength. Through development, the strength of aluminium alloy can now match carbon steel and is used to make plastic molds. With the rapid growth of plastic bottle blow-forming production, the good cooling performance of aluminium alloy contributes to forming cycle’s shortening.

U-NEED precision machinery has rich design and production capacity in high-quality precision custom aluminium parts. We can complete proofing, small batch or complete project production with various processing capabilities.

Aluminium Fabrication Properties

- The material has good toughness, strong impact resistance, and low density but high strength, which is close to or better than high-quality steel; Good plasticity. It can be processed into various profiles;

- Good plasticity. It can be processed into various profiles;

- It has excellent conductivity, thermal conductivity and corrosion resistance.

- Non-magnetic, non-flammable.

- Low-temperature resistance.

- Recyclability.

What are the disadvantages of aluminium?

1. Aluminum alloy has low hardness, large thermal deformation and poor wear resistance;

2. The rigid elasticity of aluminium alloy is 1/3 of that of free steel.

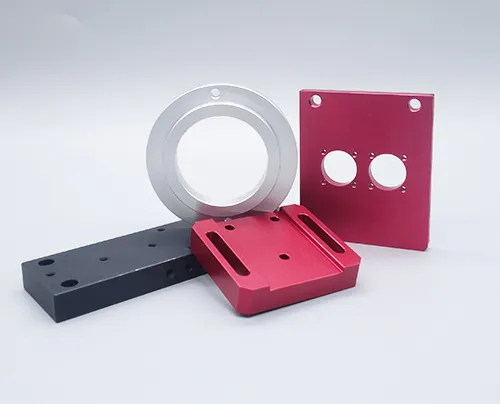

Common surface treatment method foraluminium machined parts

1.Black anodising aluminium process

2.Natural anodizing process of aluminium

3.Sandblasting(120#-140#) + black/natural anodic oxidation

4.Hard anodizing (applied to parts with high requirements on surface

wear resistance)

5.Polishing

6.Powder coating

7.Painting

The colours after the surface treatment and finishing of Aluminium and its alloys

Black, champagne, bronze, imitation steel, gold, purple gold, red, green, white, frosted oxidation, bright oxidation and different colors according to your requirements.

Aluminium alloy grades commonly used in mechanical design includeAL5052, AL6061, AL6063, and AL7075。

Common Aluminium Grades Table

| Material grade | Properties for aluminium |

| AL5052 | 1. It has moderater strength and is the most representative aluminium alloy. Although the strength is not very high,it has high, it has high fatigue strength and seawater resiatance; 2.The surface is bright and flat, complicated to process, easy to stick the knife, and easy to deform, that is, the commonly said smooth plate without flying suface processing. |

| AL6061 | 1.Heat-treatable corrosion-resistant alloy, treated with T6 (material subject to dissolution treatment and artificial aging hardening treatment),has strong corrosion resistance; 2.It is generally applied to structural parts and is the most frequently used aluminium alloy. |

| AL6063 | 1. It has lower strength than the representative AL6061 but haas superior extrudability. It is a typical extruding alloy, which can form cross-sections of various shapes, and has excellent corrosion resistance and surface treatment performance; 2.It is commonly used for building profiles, irrigation profiles and rack profiles. |

| AL7075 | 1. It is one of the alloys with the highest strength among aluminium alloys, It is known as aviation aluminium with good corrosion resistance. It is a super hard aluminium alloy, flat and not easy to deform, and has high hardness; 2. It is commonly used in manufacturing structural parts with high strength, strong corrosion resistance,high stress, mold,etc. |

Application of Aluminium:

Aluminium CNC parts can be used in automobile, electrical, military, medical, aircraft, power generation, aerospace and industrial engineering.

U-NEED’s aluminium cnc service:

1.One-stop CNC aluminium manufacturing service for aluminium fabrication turning, aluminium fabrication milling and aluminium fabrication drilling.

2.Design and manufacture complex CNC aluminium parts.

3.Machinable standard and high precision tolerance.

4.At the same time, multiple mass productions are realized, with the number of transactions rising and the price falling.

5.Short production cycle.