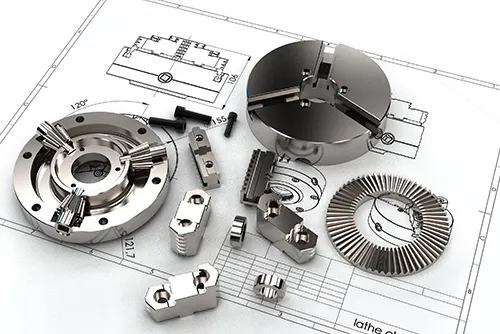

CNC Machining Stainless steel

Stainless steel is the abbreviation of stainless steel and acid-resistant steel.The steel resistant to air, steam, water, and other weak corrosive mediums is called stainless steel. And medium steel resistant to chemical corrosion medium (acid, alkali, salt, etc.) is called acid-resistant steel.

Stainless steel is widely used in our life, and the shadow of stainless steel products can be seen everywhere. The excellent heat resistance, corrosion resistance, polishing performance and high hardness of stainless steel make it useful in different fields, especially in automobile, aerospace, medical care and consumer electronics.

With rich experience and extensive knowledge, U-Need Precision Machinery

can process custom stainless steel parts and products to high precision tolerance requirements.

Stainless Steel Grades Chart

| China GB1220-92[84] GB3220-92[84] |

Japan JIS | USA AISI UNS |

UK BS 970 Part4 BS 1449 Part2 |

Germany DIN 17440 DIN 17224 |

France NF A35-575 NF A35-576~585 NF A35-584 |

|

| 1Cr17Mn6Ni5N | SUS201 | 201 | ||||

| 1Cr18Mn8Ni5N | SUS202 | 202 | ||||

| Austenitic Steel | 1Cr17Ni7 | SUS301 | 301 | |||

| 0Cr18Ni9 | SUS304 | 304 | 304S15 | X2CrNi89 | Z6CN18.09 | |

| 00Cr19Ni10 | SUS304L | 304L | 304S12 | X2CrNi189 | Z6CN18.09 | |

| 0Cr17Ni12Mo2 | SUS316 | 316 | 316S16 | X5CrNiMo1812 | Z6CND17.12 | |

| 00Cr17Ni14Mo2 | SUS316L | 316L | 316S12 | X2CrNiMo1812 | Z2CND17.12 | |

| 0Cr18Ni11Ti | SUS321 | 312 | X10CrNiTi189 | Z6CNT18.10 | ||

| 1Cr17 | SUS430 | 430 | ||||

| Martensitic steel | 1Cr13 | SUS410 | 410 | 410S21 | X10Cr13 | Z12Cr13 |

Popular Grades of Stainless Steel and their Characteristics

| Material Grade | Material properties |

| 201&202 | Non-magnetic, high strength, weak corrosion resistance. |

| 301 | 301 stainless steel shows an evident eork hardening phenomenon during deformation, which is used for a variety of occasions requiring higher strength. Non-magnetic, but magnetic after cold working. |

| 304 | 304 stainless steel is a universal non-magentic stainless steel with good corrosion resistance, heat resistance, low-temperature strength and mechanical properties; Stamping, bemding, and other hot workability are good, with no heat treatment hardening phenomenon.It is widely used to produce equipment and parts requiring good comprehensive performance. |

| 304L | It is a variant of 304 stainless steel with low carbon content and is used for welding occasions.The lower carbon content minimizes the carbides precipitation in the heat-affected zone near the weld,which may lead to intergranular corrosion (welding corrosion) of staninless steel in some environments. Howevwr, after welding or stress relief, it sresistance to intergranular corrosion is excellent; It can also maintain good corrosion resistance without hea treatment. |

| 316 | On the basis of 10Cr18Ni12 steel adding Molybdenum,316 stainless steel has good resistance to reducing medium and pitting corrosion. In seawater and other media, the corrosion resistance is superior to 304 stainless steel,mainly used for pitting corrosion-resistant materials.Non-magnetic,excellent work hardening. |

| 316L | Stainless steel ultra-low carbon steel, with good resistance to sensitized intergranular corrosion, is suitable for manufacturing thick section-size welding parts and equipment, such as anti-corrosion materials in petrochemical equipment |

| 321 | Titanium stabilized Austenitic stainless steel, added titanium to improve intergranular corrosion resistance, has good high-temperature mechanical properties and can be replaced by ultra-low carbon austenitic stainless steel. Except for special occasions such as high temperature or anti-hydrogen corrosion,it is generally not recommended to use. |

| 430 | As the representative of ferrite steel,403 grade stainless steel has a low thermal expansion rate,excellent formability, and oxidation resistance. |

| 410 | As the representative of marteensitic steel, although it has high strength, it is unsuitable for harsh corrosion environments, It has good workability, hardens according to the heat treatment surface hardenging,and is magnetic. |

Advantages of CNC stainless steel parts

-Extremely high tensile strength

-Excellent wear resistance and corrosion resistance

-Good formability and weldability

-Fire resistance and heat resistance

-Beautiful surface and diversified use possibilities

-No need for surface treatment and simple maintenance

painting.China Stainless Steel CNC

Machining application:

Machining application:

Automobile, aerospace, industry, pharmaceutical, electrical, military, mining, aircraft, construction, transportation

Our products include electronic parts, ship parts, medical equipment, hospital and laboratory instruments, automobile parts, pressure vessels, engine parts, welding ferrules, cables, handles, etc.

Our stainless steel CNC machining services:

1) CNC milling, CNC turning, CNC drilling, CNC grinding one-stop processing service

2) Design and manufacture complex CNC stainless steel parts.

3) Machinable standards and high precision tolerances.

4) At the same time, batch production has been realized many times, and the transaction quantity has increased while the price has decreased.

5) The production cycle is short.

6) Surface treatment: polishing, wire drawing, oxidation, electroplating and painting.