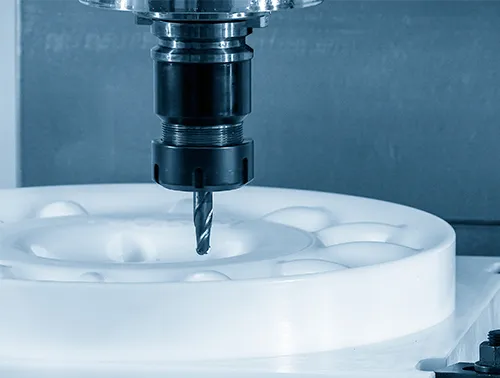

What is CNC Plastic Material?

CNC Plastic Material refers to the organic polymer material with resin as the main component, molded into a certain shape at a certain temperature and pressure, and can maintain the established shape at room temperature.

As a professional CNC parts manufacturer, U-Need also provides a variety of CNC plastic material for custom machined plastic parts to meet customers’ diversified needs and realize our one-stop service concept.

We adhere to the ‘quality first’ business philosophy, and our quality control will be carried out from raw materials. We select a variety of high-quality and high-performance CNC plastic material. Whether ABS, PP, LDPE, PETG, PA, PC, PMMA, POM, PU, PEEK, PF, PTFE, or others, we can provide as long as customers needs. Contact us to learn more details.

According to the application of plastic, CNC Plastic Material can be classified as general plastics, engineering plastics and special plastic.

Why Choose U-NEED for Plastic Precision Machining Service?

Why choose U-NEED for plastic precision machining service?

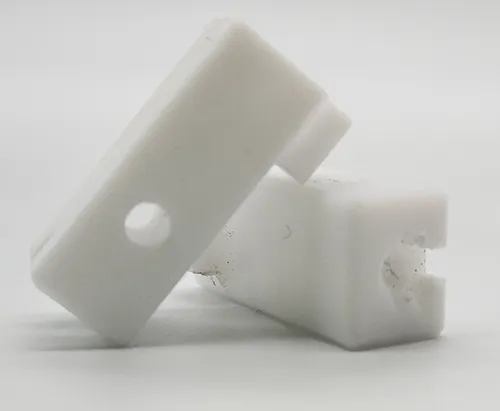

– Provide customized processing services and high-quality machined plastic parts

– Professional quality inspection before shipment, providing high-quality CNC plastic parts

– Rich experience in CNC plastic machining

– Provide one-stop plastic part machining such as turning, milling, grinding, wire cutting, discharging, polishing, etc.

What are the Properties of CNC Plastic Material?

| Common Plastic material | Properties of Plastics | Application of Plastic | Examples of Plastic Products |

| Acrylonitrile butadiene styrene copolymer (ABS) | What is ABS plastic? It is a resin made of three monomers, tha is, acrylonitrile, butadiene, and styrene. It has good comprehensive properties, including impact strength and good mechanical properties, excellent heat resistance, oil resistance, and chemical stability. |

In machinery, ABS is suitable for general parts, anti-wear parts, transmission parts, 3D printing, etc. |  |

| Polypropylene (PP) | What is PP plastic? It is one of the lightest plastics. Its yield, tensile and compressive strength and hardness are superior to those of low-pressure polyethylene. It has outstanding rigidity, good stress relaxation resistance and heat resistance at high temperatures (90 ℃). | It is used as a general structural part and a piece of corrosion-resistant chemical equipment, and a heated electrical insulation part. |  |

| High pressure low density polyethylene (LDPE) | LDPE material is the lightest type of polyethylene resin.

It has flexibility, extensibility, electrical insulation, transparency, easy processing, and certain air permeability. |

It is mainly used as film products, injection molded products, medical appliances, pharmaceutical and food packaging materials, blow molded hollow molded products, etc. | |

| Polyethylene terephthalate-1,4-cyclohexanedimethoxide (PETG) | What is PETG? It has good viscosity, transparency, color, chemical resistance, and stress whitening resistance. PETG has excellent processing and molding performance. Designed in any shape according to the designer’s intention. |

It can apply to food, medicine, cosmetic packaging, cosmetic injection molding, and other fields. |  |

| Polyamide (PA, nylon) | Polyamide properties are excellent. Due to its unique low specific gravity, high tensile strength, wear resistance, good self-lubricating, excellent impact toughness, and rigid and flexible properties, PA can be processed into various products to replace metal. |

Typical products include pump impellers, fan blades, valve seats, bushings, bearings, various instrument panels, automotive electrical instruments, cold and hot air regulating valves, and other parts. Polyamide has the largest proportion of consumption in the automotive industry, followed by electronics and electrical. |  |

|

Polycarbonate(PC) |

PC plastic has outstanding impact strength and creep resistance, high heat resistance, good cold resistance, embrittlement temperature reaches – 100 ℃, bending and tensile strength equivalent to nylon, high elongation, and elastic modulus. | It can be used as gears, worm gears, racks, cams, bearings, spindles, pulleys, transmission chains, nuts, washers, pump impellers, lampshades, containers, shells, covers, etc. |  |

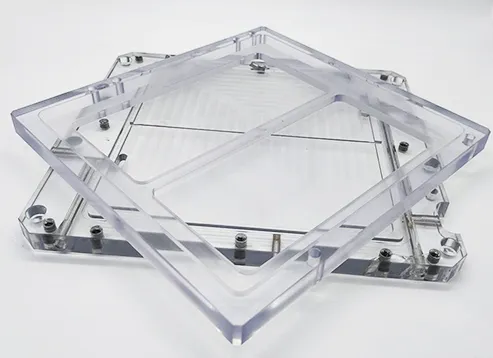

| Polymethyl methacrylate (, acrylic, plexiglass) | It is the best organic synthetic transparent material. PMMA has good chemical stability, weather resistance, good electrical insulation, and easy dyeing. And it is suitable for both hot forming and mechanical processing. |

As a transparent material with excellent performance, PMMA is widely used in various lamps, lighting equipment, optical glass, various instrument dials, housings, dials, optical fibers, commodity advertising windows, billboards, aircraft cockpit glass, bulletproof glass for aircraft and automobiles, various medical, military, architectural glass and other fields. |  |

| Polyoxymethylene (POM) | High tensile strength, impact strength, rigidity, fatigue strength, creep resistance, good dimensional stability, low water absorption, low friction coefficient, and good chemical resistance. Its performance is no less than nylon, but it is a low price. | It can be used as various copper substitute parts for bearings, gears, cams, valves, pipe nuts, pump impellers, small parts of body chassis, automobile dashboards, carburetors, boxes, containers, rods, and spray. |  |

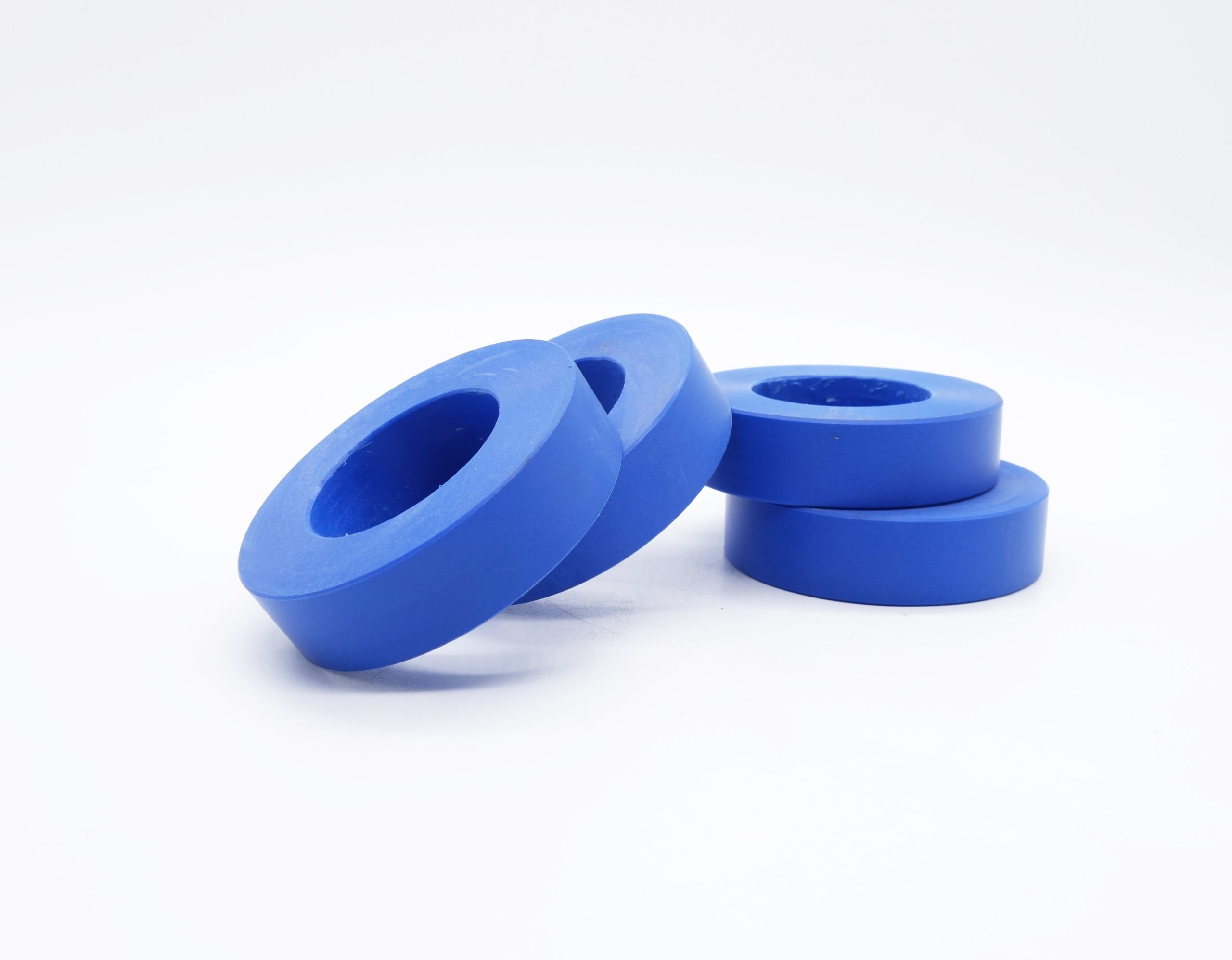

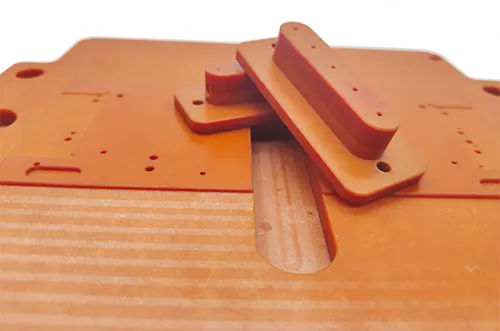

| Polyurethane (PU, also known as Urethane) | PU plastic has the rigidity of plastic and the elasticity of rubber. It has pressure and shock resistance, impact resistance, oil resistance, acid and alkali resistance, and excellent wear resistance. PU series elastomer has superior tensile strength, tear resistance, high elasticity, high-pressure load resistance, wear resistance, and other characteristics. |

It is easy to cut, grind, drill, and perform other processes. It applies to mechanical buffer materials, punch dies, recoil pads, bending, and forming. And it is suitable for the shock-absorbing pads, cushion blocks, and springs of metallurgy, mining, petroleum, automobile, building materials, sports, heavy machinery, large stamping equipment, and for making stamping dies for various metal plates and pipes. |

|

| Polyether ether ketones (PEEK) | PEEK is an aromatic crystalline thermoplastic polymer material with high mechanical strength, high-temperature resistance, impact resistance, flame retardant, acid and alkali resistance, hydrolysis resistance, abrasion resistance, fatigue resistance, radiation resistance, and good electrical properties. With excellent sliding characteristics, it is suitable for occasions where strictly require low friction washing and wear resistance. |

It can be used for automobile fuel management systems to replace automobile fuel management systems’ various active metal or aluminum components used in transmission, braking, and air conditioning systems, including piston units, seals, gaskets, or bearings. And its applications in healthcare mainly include dental instruments, endoscopes, dialyzers, embedded human anchors, etc., mainly used in orthopedics. It has even become a safe and reliable material in the aerospace industry. |

|

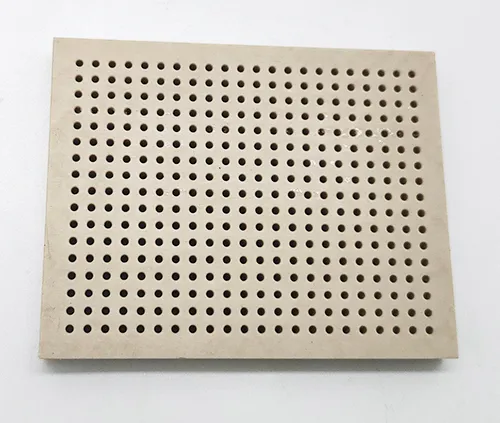

| Phenolic plastic (PF plastic) | What is Phenolic material? PE has high mechanical properties, large rigidity, low cold flow, and high heat resistance (100 ℃ above). Under water lubrication, the friction coefficient is extremely low (0.01~0.03), the PV value is very high, and it has good electrical performance and resistance to acid and alkali corrosion. It is simple to form and cheap. | Commonly used are laminated phenolic plastics and powder compression plastics, including plates, pipes, and bars. It can be used for agricultural submersible pump seal and bearing, bearing bush, pulley, gear, brake device, clutch device parts of the electric pump, friction wheel, electrical insulation parts, etc. |  |

| Polytetrafluoroethylene (PTFE, F-4, Teflon) | It has excellent chemical stability, is not effective with strong acids, strong bases, or strong oxidants, has a high heat resistance and cold resistance, has a service temperature of – 180~250 ℃, has a low friction coefficient, and is an excellent self-lubricating material. | It is mainly used as chemical corrosion-resistant and high-temperature-resistant sealing elements, such as, packing, gasket, expansion ring, valve seat, valve slice, and so on. |

|