From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-30 Origin: Site

Content Menu

● What Is Aluminum Die Casting?

● Why Choose Aluminum Die Casting?

● Common Aluminum Die Casting Alloys

● Key Aluminum Die Casting Alloy Characteristics

● Aluminum Die Casting Process Step-by-Step

● Surface Finishing Options for Die-Cast Aluminum

● Real-World Applications of Aluminum Die Casting

● Design Guidelines for Aluminum Die Casting (DFM Essentials)

>> Mold Design and Parting Line

>> Draft Angles

>> Tolerances and Machining Allowance

● Aluminum Die Casting vs. Sand Casting

● Aluminum Die Casting Market and Latest Trends

● Cost Factors in Aluminum Die Casting

● How to Design Aluminum Die Casting Parts for OEM Success

● When to Choose an OEM Aluminum Die Casting Partner in China

● Call to Action: Start Your Aluminum Die Casting Project with a Reliable OEM Partner

● Frequently Asked Questions (FAQ)

>> 1. What is aluminum die casting and how does it work?

>> 2. What are the main benefits of aluminum die casting over other processes?

>> 3. How do I choose the right aluminum die casting alloy?

>> 4. Is aluminum die casting suitable for low-volume production?

>> 5. Which industries use aluminum die casting most?

If you are designing aluminum die casting parts for OEM projects, choosing the right alloy, process parameters, and manufacturing partner will directly decide your part quality, lead time, and total lifecycle cost. This guide explains the complete aluminum die casting process from design to finishing and quotation, with practical tips you can apply immediately to real products.

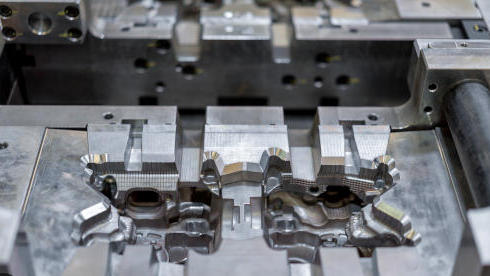

Aluminum die casting is a high-pressure metal casting process in which molten aluminum is injected into a hardened steel mold, rapidly solidified, and ejected to form near-net-shape parts with tight tolerances and excellent surface finish. Because the die is reusable for hundreds of thousands of cycles, this process is ideal for medium- to high-volume OEM production.

In a typical cold-chamber aluminum die casting machine, aluminum ingots are melted in a separate furnace, ladled into a shot sleeve, and then injected into the die cavity under high pressure until the metal fills all features. After solidification, the die opens, ejector pins push the casting out, and runners, gates, and flash are trimmed before any secondary machining.

Aluminum die casting combines lightweight material properties with repeatable, automated production. Compared with other metal forming methods, it offers several advantages for OEMs, brand owners, and system manufacturers.

Key advantages of aluminum die casting

- Excellent surface finish suitable for painting, powder coating, and plating with minimal machining.

- High dimensional stability and tight tolerances, even for complex shapes and thin walls.

- Competitive material cost and high production efficiency, giving a low cost per part at volume.

- Strong, rigid parts with a favorable strength-to-weight ratio for lightweight designs.

- Good thermal and electrical conductivity for housings, heat sinks, and electronic enclosures.

- Full recyclability, supporting sustainable manufacturing strategies.

These benefits make aluminum die casting a go-to solution when you need high volumes of consistent, robust components with demanding cosmetic or functional requirements.

Selecting the correct die casting aluminum alloy is a critical early design decision because each alloy balances strength, castability, and corrosion resistance differently.

Widely used die-cast aluminum alloys

- A380 – General-purpose alloy with excellent castability, good mechanical strength, and good fluidity; widely used for power tools, furniture hardware, electronic housings, brackets, and gearbox cases.

- A360 – Offers outstanding pressure tightness and corrosion resistance with very good fluidity; suitable for communication boxes, automotive controller housings, and oil pans.

- A390 – Very high hardness and excellent wear resistance but reduced ductility; commonly used in automotive engine blocks and high-load components.

- A413 – Known for excellent pressure tightness and fluidity; often specified for intricate housings and hydraulic components.

- ADC-12 / ADC-1 – Popular in Asian markets for balanced castability, strength, and cost for consumer electronics and industrial components.

When choosing an alloy, evaluate operating temperature, required strength, corrosion environment, pressure tightness, and machining needs rather than focusing on a single property.

All die casting aluminum alloys share some core material characteristics that underpin their widespread adoption across industries.

- Lightweight: Much lower density than steel while still providing high stiffness and adequate strength.

- Corrosion resistance: Natural oxide layer protects against many environments, further improved by anodizing or coatings.

- High operating temperatures: Suitable for automotive powertrain and some aerospace applications where plastics would fail.

- Good stiffness and strength-to-weight: Enables thinner sections and lighter assemblies without sacrificing performance.

- Thermal and electrical conductivity: Ideal for heat sinks, motor housings, and electronic enclosures needing EMI/RFI shielding.

- Recyclability: Scrap can be recycled with comparatively low energy, reducing environmental footprint.

Design engineers leverage these material advantages together with process capabilities to achieve long-lasting, reliable parts in demanding OEM systems.

Understanding the aluminum die casting process helps you collaborate effectively with your manufacturing partner and design with process constraints in mind.

1. Alloy melting

Aluminum ingots are melted in a furnace to the specified casting temperature, with composition and temperature monitored and controlled.

2. Die preparation

The die is preheated and treated with release agent to promote metal flow and facilitate ejection.

3. Injection (filling stage)

In cold-chamber machines, molten aluminum is ladled into a shot sleeve and injected into the die cavity under high pressure to fill all features before solidification.

4. Solidification and cooling

The casting cools in the die, with cooling channels managing cycle time and minimizing thermal stresses.

5. Ejection

The die opens, ejector pins push out the solidified casting, and the part is transferred for further operations.

6. Trimming and deburring

Gates, runners, and flash are removed; burrs are deburred to prepare the part for finishing or machining.

7. Secondary machining and finishing

Critical surfaces are machined where necessary, and surface finishing such as anodizing, powder coating, or chemical conversion coating is applied as specified.

Optimizing each step from die temperature to injection speed and pressure is essential to minimize porosity, warpage, and cosmetic defects.

Although aluminum die casting produces relatively smooth surfaces, many OEM components require additional surface finishes for appearance or function.

1. Anodizing

Anodizing grows a hard, ceramic-like oxide layer on the surface, significantly improving corrosion resistance and durability. The anodic layer is electrically insulating, so anodized die-cast aluminum becomes largely non-conductive, which you must consider if your design relies on electrical contact.

2. Powder coating

Powder coating fuses dry powder onto the surface at elevated temperature, creating a thick, robust coating that resists scratching and impact. It is available in a wide range of colors, textures, and gloss levels, making it a popular choice for visible housings and consumer products.

3. Chemical conversion coating (chem film)

Chemical conversion coatings provide corrosion resistance and good paint adhesion while maintaining electrical conductivity across the surface. This makes chem film attractive for grounding surfaces and EMI-sensitive enclosures where continuity is required.

Choosing the right finish depends on whether your priority is corrosion resistance, electrical performance, cosmetic appearance, or cost for the target application.

Aluminum die casting parts appear across nearly every major manufacturing sector thanks to their combination of precision and low weight.

- Construction: Window frames, curtain walls, façade components, and structural connectors benefit from corrosion resistance and stable dimensions.

- Automotive: Engine blocks, transmission housings, brackets, mounts, and EV components use aluminum die castings for lightweighting and fuel efficiency.

- Electronics: Smartphone housings, communication enclosures, LED lighting housings, and heat sinks rely on good thermal conductivity and EMI shielding.

- Furniture and hardware: Chair frames, fittings, door locks, hinges, and knobs use die-cast aluminum for strength, low weight, and attractive finishes.

- Aerospace: Certain non-critical structural components, housings, and brackets exploit aluminum's high strength-to-weight ratio and impact resistance.

These use cases show how one process can serve both heavy-duty industrial equipment and high-volume consumer products with consistent performance.

To fully leverage aluminum die casting, your part should be designed for the process from the beginning. The following guidelines are widely adopted in industry standards and design for manufacturability best practices.

Every die has a parting line where the two halves separate, and its location affects draft direction, visible lines, and dimensional control. Place the parting line to simplify die construction, avoid undercuts, and keep critical cosmetic surfaces away from potential mismatch.

All vertical surfaces should include a draft angle, typically in the range of 1–3 degrees, to allow the casting to release cleanly from the die. Insufficient draft increases the risk of sticking, part damage, and tool wear, which can drive up cost and scrap rate.

Aim for uniform wall thickness throughout the part wherever possible. Uniform sections support better metal flow and consistent solidification, reducing porosity, sink marks, and internal stresses. While modern die casting can achieve thin walls for suitable designs, sudden transitions between thin and thick sections should be avoided or softened with fillets and ribs.

Instead of simply increasing wall thickness for strength, use ribs to stiffen large surfaces and reduce weight. Generous fillets and radii at internal corners improve metal flow, reduce stress concentrations, and lengthen die life.

Minimize undercuts and deep recesses since they require side actions, lifters, or additional machining, increasing tooling complexity and cost. Where undercuts are unavoidable, collaborate early with your die casting supplier to design efficient core and slide mechanisms.

Specify realistic tolerances that align with aluminum die casting capability and leave modest machining stock only on critical surfaces. Overly tight tolerances across the entire part can dramatically increase cost without improving function.

By following these principles, OEMs can reduce tooling iterations, shorten launch schedules, and improve overall profitability.

For many projects, the first strategic decision is whether to use aluminum die casting or sand casting.

| Aspect | Aluminum die casting | Sand casting |

|---|---|---|

| Mold material | Hardened steel die re-used for many cycles | Disposable sand mold rebuilt each cycle |

| Typical volume | Medium to very high volumes (thousands or more) | Low to medium volumes (tens to a few hundred) |

| Wall thickness | Thin walls and small, precise features achievable | Thicker walls, less suitable for very small parts |

| Dimensional accuracy | High accuracy and repeatability | Lower accuracy, more variation between castings |

| Surface finish | Smooth, often usable as-cast | Rougher surfaces, usually need machining or finishing |

| Tooling cost and lead time | Higher initial tooling investment, longer to build | Lower initial tooling cost and faster tooling build |

| Cost per part | Very low at scale due to automation and speed | Higher per-part cost at large volumes |

In practice, aluminum die casting is favored when you need thin-walled, precise, repeatable parts in large quantities, while sand casting fits large or very low-volume components where tooling investment must be minimized.

The global aluminum die casting market is expanding steadily, driven by lightweighting, electrification, and the growth of electronics and electric vehicles.

- Market studies estimate that aluminum die casting represents tens of billions of USD annually, with continued growth projected toward the next decade.

- Many reports forecast strong compound annual growth rates supported by automotive, transportation, and consumer electronics demand.

- From 2024 onward, analysts expect additional growth of several tens of billions of USD as more industries shift from heavier metals to aluminum.

At the same time, smart manufacturing is transforming die casting. Sensors and connected equipment enable real-time control of temperature, pressure, and cycle times, while automated inspection systems improve quality and consistency. For OEM buyers, this translates into more stable quality, shorter lead times, and better traceability across the supply chain.

Although aluminum die casting is highly cost-effective at scale, overall project economics depend on several cost drivers.

Tooling cost

Building a high-quality steel die is capital intensive. Tooling for aluminum die casting often ranges from several thousand to tens of thousands of dollars depending on part size, complexity, and number of cavities. This cost is amortized over total part volume, which is why die casting is most economical for medium to high quantities.

Part design and complexity

Deep ribs, undercuts, thin-to-thick transitions, and tight tolerances increase tool complexity and cycle time, directly impacting piece price. Designs optimized for consistent wall thickness, generous draft, and simpler parting lines reduce cost while improving quality.

Alloy, machine size, and cycle time

Alloy choice, casting weight, and required machine tonnage affect both material consumption and machine hourly rate. Larger parts or parts that require longer solidification times occupy equipment longer, increasing the cost per shot.

Secondary operations and finishing

Machining, assembly, and advanced surface finishes add to the part cost but may be essential for performance or aesthetics. Optimizing design to minimize machining and enable efficient finishing is one of the fastest ways to improve overall cost structure.

When evaluating quotations, it is important to consider total landed cost, including scrap, quality risks, logistics, and time-to-market, not just unit price.

To turn a concept into a successful OEM product, follow a structured design workflow that integrates manufacturability and supplier feedback early.

1. Clarify requirements: define functional loads, environment, expected lifetime, annual volume, target price, and regulatory constraints before detailed design starts.

2. Select alloy and process window: choose a suitable aluminum die casting alloy such as A380 or A360 based on strength, corrosion, and thermal requirements, and align with your supplier's standard process window.

3. Apply die casting design rules: set initial wall thickness, draft angles, rib patterns, and fillets according to established die casting guidelines.

4. Co-design with your supplier: share 3D models and engage in early design review to refine parting lines, gating, and ejection strategies and to avoid potential defects.

5. Prototype and validate: for complex parts, consider prototype tools or alternative methods to validate fit, function, and assembly before committing to full production tooling.

6. Industrialize and optimize: after first articles, refine parameters and design details to improve yield, cycle time, and cost, capturing lessons learned for future generations.

This collaborative approach helps brand owners and OEMs bring robust die cast products to market faster with fewer surprises and lower risk.

Choosing the right OEM aluminum die casting manufacturer in China can offer significant benefits in cost, flexibility, and integrated services.

- Many suppliers operate modern facilities with cold-chamber machines covering a wide range of clamping forces, suitable for small precision parts to large housings.

- Integrated capabilities often bundle die design, mold fabrication, high-pressure die casting, CNC machining, surface treatment, assembly, and testing under one roof, simplifying project management.

- Certified quality systems and experience with international OEMs help ensure compliance with global requirements.

For buyers, working with an experienced OEM partner allows you to focus on product design and brand development while the manufacturing expert handles tools, process control, and supply chain coordination.

If you are preparing a new aluminum die casting project, now is the time to involve a manufacturing partner who understands design, tooling, and high-volume production. Share your 3D models, drawings, annual demand, and specific performance requirements with an experienced OEM supplier so that you can receive detailed design feedback, cost-optimized solutions, and a clear timeline from prototype to mass production. By engaging early, you can reduce risk, improve product performance, and bring your next aluminum die cast component to market faster and more competitively.

Contact us to get more information!

Aluminum die casting is a process where molten aluminum is injected under high pressure into a steel die, quickly solidified, and ejected to form consistent, near-net-shape parts. The reusable die and automated cycle enable high-volume, repeatable production with tight tolerances.

The main benefits include excellent surface finish, tight tolerances, thin-walled designs, high production rates, and a low cost per part at medium-to-high volumes. Compared with many alternative processes, it also offers better dimensional repeatability and more efficient use of material.

Select the alloy based on strength, ductility, corrosion resistance, pressure tightness, operating temperature, and required fluidity. Alloys like A380 and A360 are commonly used for general-purpose OEM parts because they offer a balanced combination of castability and mechanical properties.

Because of the relatively high tooling cost, aluminum die casting is usually not economical for very low volumes. In such cases, sand casting, machining, or other processes may be more appropriate until volumes grow enough to justify a dedicated die.

Major users include automotive, construction, consumer and industrial electronics, aerospace, furniture hardware, and many categories of OEM machinery and equipment. These sectors value aluminum die casting for its ability to produce lightweight, durable parts with consistent quality.

1. https://www.rapiddirect.com/blog/aluminum-die-casting/

2. https://www.gabrian.com/aluminum-die-casting-design-guide/

3. https://nacastingcorp.com/die-casting-design-tips/

4. https://www.grandviewresearch.com/industry-analysis/aluminum-die-casting-market

5. https://jiga.io/articles/die-casting-dfm-2/

6. https://www.diecastingschina.com/die-casting-services-china/aluminum-die-casting/