From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2025-12-31 Origin: Site

Content Menu

>> Material Properties of Aluminum

>> Machining Behavior of Aluminum

>> Typical CNC Applications for Aluminum

>> Material Properties of Brass

>> Machining Behavior of Brass

>> Typical CNC Applications for Brass

● Advantages and Disadvantages in CNC Machining

>> Advantages of Machining Aluminum

>> Disadvantages of Machining Aluminum

>> Advantages of Machining Brass

>> Disadvantages of Machining Brass

● How to Choose Between Aluminum and Brass

>> Clarify Functional Priorities

>> Evaluate Cost, Volume, and Tolerance Requirements

>> Consider Surface Treatment and Long‑Term Performance

● Design and Machining Tips for Better Results

>> Design Tips for Aluminum CNC Parts

>> Design Tips for Brass CNC Parts

● Application Scenarios and Material Selection Logic

>> Situations Where Aluminum Is Usually Preferred

>> Situations Where Brass Often Adds More Value

● OEM and ODM Collaboration Considerations

● Call to Action: Start Your Next CNC Project with the Right Material

● Frequently Asked Questions (FAQ)

>> 1. Which material is generally more economical for CNC machining?

>> 2. In what situations should brass be chosen instead of aluminum?

>> 3. Is aluminum strong enough for structural components?

>> 4. Do all aluminum CNC parts need surface treatment?

>> 5. Can aluminum and brass be combined in a single product design?

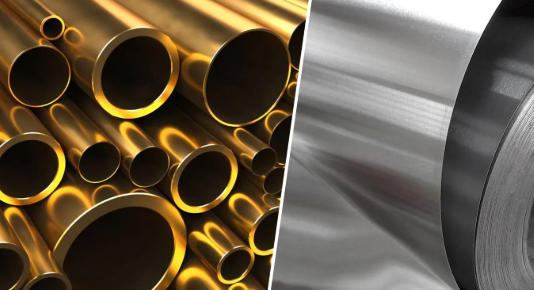

In CNC machining, choosing between aluminum and brass directly affects part cost, durability, and real‑world performance across applications from consumer products to aerospace. This guide explains properties, machining behavior, cost factors, and application scenarios so that engineers, makers, and purchasing teams can select materials with confidence.

- Core comparison of aluminum and brass properties in CNC machining

- Cost, tolerance, and surface finish implications

- Typical use cases for each material in different industries

- Practical selection framework and design tips

- OEM and ODM collaboration considerations for overseas brands

Aluminum is a low‑density metal, with a typical density of about 2.7 g/cm³, which makes it ideal for applications where lightweight design is important. It offers excellent electrical and thermal conductivity, ranking just behind silver and copper, and is widely used in radiators and electronic equipment housings. Aluminum naturally forms a compact oxide film in air that provides good basic corrosion resistance.

For CNC machining, aluminum is associated with relatively small cutting forces, so it supports high spindle speeds and high feed rates. This helps increase productivity and reduce cycle time on modern machining centers. Its good ductility allows the machining of complex curved surfaces, thin walls, and detailed structures without a high risk of cracking. At the same time, the higher coefficient of thermal expansion of aluminum makes it more prone to deformation when heat is not controlled properly during machining. The surface also oxidizes easily, so additional finishing such as anodizing is often used to improve appearance and long‑term protection.

- Aerospace parts that require high strength and low weight

- Automotive components such as engine blocks, wheels, and structural parts

- Electronic housings and heatsinks that benefit from high thermal conductivity

These characteristics make aluminum a common choice for high‑precision mechanical parts where weight, heat dissipation, and cost must all be considered.

Brass is a copper‑zinc alloy with a density around 8.5 g/cm³, which is much higher than aluminum. This higher density provides a solid and heavy feel that is attractive in many decorative and high‑end consumer products. Brass has excellent mechanical properties, combining good ductility with high strength and hardness, so it is suitable for precision parts that require both durability and fine geometry. It offers very good electrical and thermal conductivity, better than aluminum but below pure copper, which supports its use in electrical components.

In CNC machining, brass usually requires higher cutting forces than aluminum, and chips can stick to tools if cutting conditions are not optimized. When appropriate tools and cutting parameters are used, brass can achieve a very high surface finish directly from machining. Its higher hardness results in good wear resistance, which is important for parts such as bearings, nuts, and sliding components. However, the same hardness also increases tool wear and demands higher tool quality and careful parameter selection.

- Decorative items such as lamps, door handles, and architectural hardware

- High‑strength hardware including screws, nuts, and bearing parts

- Precision instrument components that require stability and fine details

Brass is often chosen when product positioning emphasizes aesthetics, tactile feel, and long‑term wear performance.

- Lower processing cost, because low density and easy cutting help save material and machining time

- High machining efficiency, since small cutting forces support high‑speed machining with good productivity

- Good suitability for complex shapes, including thin walls and intricate curves

- Higher risk of deformation from thermal expansion if heat and clamping are not controlled properly

- Surface oxidation and scratching that often require surface treatment for appearance and protection

- High attainable surface finish, making it ideal for visible and decorative surfaces

- Good wear resistance due to higher hardness, which is useful for moving or contact parts

- Attractive natural color and metallic appearance that enhance product value

- Higher overall processing cost, driven by higher density, material price, and more demanding machining

- Chip adhesion and higher cutting forces that increase tool wear and require better tool management

The first step is to clarify what the part must achieve:

- If low weight, ease of handling, and dynamic performance are key, aluminum is usually more suitable.

- If a heavier, solid feel and premium presentation are required, brass is often the preferred choice.

- For applications where electrical and thermal performance matter, both materials are usable, but the best option depends on required conductivity level, size, and cost sensitivity.

- For large‑volume production where cost per piece and machining time are critical, aluminum tends to deliver better overall efficiency.

- For smaller runs of high‑value parts where appearance and wear resistance are more important than raw material cost, brass can be a better match.

- When very tight tolerances on small features and a high cosmetic standard are necessary, brass often provides stable results if machining is well controlled.

- Aluminum parts often benefit from anodizing, coating, or painting to improve corrosion resistance, wear resistance, and appearance.

- Brass parts may be polished, brushed, or coated to maintain their color and prevent tarnishing in specific environments.

- The choice of finishing method should match the functional environment, branding needs, and maintenance level expected by end users.

- Avoid extremely thin walls in load‑bearing areas to reduce the risk of deformation under load or heat.

- Use relatively uniform wall thickness where possible to decrease residual stresses and minimize distortion.

- Introduce reasonable internal radii and fillets to improve tool life and surface quality during high‑speed cutting.

- Ensure that small features and deep cavities have enough tool access and rigidity, because brass cutting forces are higher than aluminum.

- Simplify geometries that do not contribute to function to avoid unnecessary machining time and tool wear.

- Clearly specify required surface roughness and finishing expectations when the part is visible to end users.

- Structural parts in aerospace, drones, and automation where mass reduction is critical

- Automotive brackets, housings, and frames that must balance strength and cost

- Electronics housings and heatsinks needing high thermal conductivity and low weight

In these scenarios, aluminum's strength‑to‑weight ratio and machining efficiency typically provide a strong combination of performance and cost control.

- Decorative hardware and fittings that require long‑term wear resistance and a premium metallic surface

- Instrument components and valve parts that demand both mechanical stability and precise small features

- Electrical and fluid connectors that need good conductivity, secure sealing, and attractive appearance

In such applications, the higher material cost of brass can be offset by improved brand perception, product longevity, and functional reliability.

Working with an experienced manufacturing partner is essential for projects that involve both aluminum and brass parts, especially for overseas brands and wholesalers:

- Professional engineering support can help match material selection to function, market positioning, and budget.

- Process optimization on advanced CNC equipment allows aluminum and brass parts to reach consistent tolerances and surface finishes.

- Integrated services that also cover plastic products, silicone products, and metal stamping reduce coordination cost and shorten development cycles.

When both materials are used in one assembly, attention to design details such as fit, assembly method, and potential galvanic interactions can improve long‑term performance.

Choosing the right material is one of the most important decisions in any CNC machining project. A clear understanding of aluminum and brass characteristics makes it easier to balance weight, durability, appearance, and cost. To turn design concepts into stable, market‑ready products, collaboration with a capable manufacturing partner is essential.

If you are a brand owner, wholesaler, or manufacturer looking for precise mechanical parts, plastic components, silicone products, or metal stamping solutions, you can work with a professional OEM team that understands both engineering and market needs. Share your drawings, target quantities, and application scenarios, and request a tailored material and process recommendation, along with a detailed quotation and delivery plan.

Aluminum is usually more economical because its lower density and easier machinability reduce both material usage and cutting time. This often results in a lower cost per part, especially in medium to large volumes.

Brass is a good choice when the part must have a heavy, solid feel, high wear resistance, and a visually premium metallic appearance. It is well suited to decorative hardware, high‑end consumer products, and precision components where aesthetics and durability are both important.

With proper design, many aluminum alloys provide an excellent strength‑to‑weight ratio and are widely used in structural components. Appropriate wall thickness, ribbing, and support geometry can help aluminum parts meet demanding strength requirements.

Not all aluminum parts strictly require surface treatment, but anodizing or coating is recommended when additional corrosion resistance, wear resistance, or color stability is needed. For visible or outdoor parts, surface treatment often improves both appearance and service life.

Yes, aluminum and brass are frequently used together in one assembly. Aluminum can serve as the lightweight structural base, while brass is used for decorative or high‑wear elements. Proper design of joints and interfaces helps ensure stable performance over the product's lifetime.