From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Loretta Publish Time: 2025-12-22 Origin: Site

Content Menu

● Aluminum vs Brass for CNC Machining - A Complete Material Guide for Makers

● Core Material Properties of Aluminum and Brass

>> Aluminum Properties Relevant to CNC Makers

>> Brass Properties Relevant to CNC Makers

● Machinability, Speed, and Surface Finish

>> Machining Aluminum - Fast and Forgiving

>> Machining Brass - Stable and Extremely Clean

● Side-by-Side Comparison - Aluminum vs Brass for CNC

● How to Choose - A Practical Decision Framework for Makers

>> When Aluminum Is the Better Choice

>> When Brass Is the Better Choice

● Real-World Scenarios - Aluminum vs Brass Selection Examples

>> Scenario 1 - CNC-Machined Drone Frame

>> Scenario 2 - High-End Audio Volume Knob

>> Scenario 3 - Custom Water Cooling Fittings

● Practical CNC Machining Tips for Aluminum and Brass

>> Process Checklist for CNC Aluminum Parts

>> Process Checklist for CNC Brass Parts

● How U-NEED Supports Makers with Aluminum and Brass CNC Parts

>> Integrated Manufacturing Capabilities

>> Engineering and OEM Support for Overseas Customers

● Get Expert Help Choosing Between Aluminum and Brass

● FAQ: Aluminum vs Brass in CNC Machining

>> Q1: Which is cheaper for CNC machining, aluminum or brass?

>> Q2: Which material is better for tight-tolerance precision parts?

>> Q3: Is aluminum strong enough for structural parts?

>> Q4: When should I avoid using brass?

>> Q5: Can I combine aluminum and brass in the same assembly?

>> Q6: How quickly can an OEM like U-NEED deliver samples?

For CNC makers, the choice between aluminum and brass decides not only part performance but also machining speed, cost, and surface quality. This upgraded guide goes beyond basic properties to give you practical selection rules, case-based advice, and process tips you can apply immediately.[1][2][3][4]

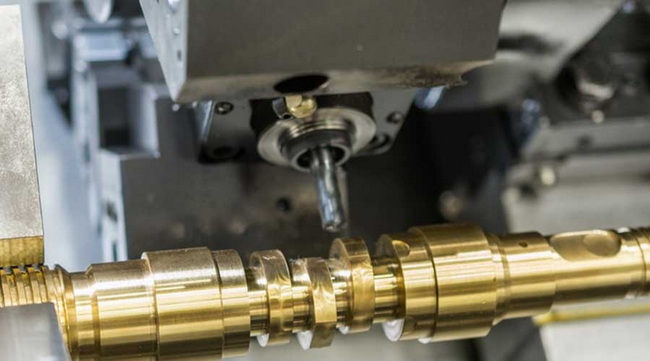

In CNC machining, aluminum and brass are two of the most popular non-ferrous materials for prototypes, functional parts, and small-batch production. Each behaves very differently under the tool, so understanding their properties, machinability, and cost drivers helps you choose the right material for your next project.[2][3][4][1]

Material properties determine not only performance in use, but also how the metal behaves during cutting.[5][2]

- Low density and light weight: Typical aluminum alloys for CNC (e.g., 6061, 7075) have a density around 2.7 g/cm³, making them roughly one-third the weight of brass. This is critical for drones, robots, and any design where inertia and weight limits matter.[3][2][5]

- High thermal and electrical conductivity: Aluminum offers thermal conductivity in the range of about 205–250 W/m·K, which is valuable for heat sinks, LED housings, and power electronics parts.[2]

- Good corrosion resistance: A natural oxide layer gives aluminum good resistance in many environments, and anodizing further enhances corrosion protection and aesthetics.[4][2]

- Higher density and mass: Common brass alloys have density near 8.4–8.7 g/cm³, giving parts a heavier, premium “in-hand” feel compared to aluminum.[5][2]

- Excellent mechanical properties and surface finish: Brass combines good strength, rigidity, and outstanding ability to hold tight tolerances with very smooth surfaces, ideal for precision and decorative parts.[6][1]

- Very good electrical and thermal conductivity: While not as conductive as pure copper, brass provides reliable conductivity for connectors, terminals, and plumbing fittings that must also resist corrosion.[7][2]

From a machinist's perspective, machinability is often more important than raw strength data.[8][1]

- High cutting speeds: Aluminum can be cut at high spindle speeds and feed rates, supporting fast cycle times and efficient chip removal when tools are sharp and chipload is set correctly.[9][1]

- Low cutting forces: Lower hardness and density reduce tool load, which is ideal for smaller hobby CNC machines or delicate setups.[1][9]

- Challenges - chip welding and burrs: Aluminum tends to form built-up edge on tools if lubrication and speeds are not optimized, which can cause poor finish and burr formation that require post-deburring.[9][1]

Quick best-practice tips for machining aluminum:[1][9]

1. Use sharp carbide tools with polished flutes.

2. Apply proper coolant or mist to reduce built-up edge.

3. Use climb milling and moderate step-downs to limit chatter.

4. Consider finishing passes for tight-tolerance surfaces.

- Outstanding machinability: Free-machining brass grades can be cut very quickly with minimal tool wear and almost mirror-like surface finishes.[6][1]

- Stable cutting behavior: Brass produces short, controllable chips and resists chatter, making it excellent for high-precision turning, small features, and threaded components.[7][1]

- Higher cutting forces vs aluminum: Brass is harder and denser than aluminum, so forces are higher, but its lubricating copper-zinc structure still makes it one of the easiest metals to machine overall.[8][1]

Quick best-practice tips for machining brass:[7][1]

1. Run aggressive feeds and speeds to exploit its machinability.

2. Use rigid setups and sharp tools to hold micro-features.

3. Dry machining is often possible; light oil improves tool life further.

4. Use proper chip evacuation, especially in deep holes or slots.

Factor | Aluminum (Typical Alloys 6061/7075) | Brass (Free-Machining Grades) |

Density & weight | Very light; density ~2.7 g/cm³, ideal where weight reduction is critical. | Heavy; density ~8.5 g/cm³, gives parts a solid, premium feel. |

Strength & stiffness | Good strength-to-weight; high-grade alloys (e.g., 7075) handle structural loads well. | High stiffness and excellent dimensional stability for tight-tolerance parts. |

Corrosion resistance | Good, especially with anodizing; suitable for outdoor and marine with correct alloy and coating. | Very good; widely used for plumbing fittings and hardware exposed to moisture. |

Thermal conductivity | High (≈205–250 W/m·K), ideal for heat sinks and thermal management. | Good, but generally lower than aluminum; adequate for connectors and valves. |

Electrical conductivity | Good; widely used in electronic housings and some conductive parts. | Very good; common choice for connectors, terminals, and switchgear. |

Machinability & speed | Excellent; high speeds and feeds but watch for chip welding and burrs. | Outstanding; extremely smooth finishes and long tool life, ideal for precision turning. |

Surface finish | Good; may need polishing or anodizing for cosmetic parts. | Excellent; natural golden appearance often used as-machined as a decorative surface. |

Part cost (material + machining) | Generally lower per part, especially for medium–large volumes. | Material is more expensive, but high machinability can offset cost in precision parts. |

Typical applications | Aerospace brackets, frames, drone parts, housings, jigs, heat sinks. | Connectors, valves, gears, bushings, luxury hardware, musical and decorative parts. |

Many makers struggle with the question: “When should I choose aluminum, and when is brass the smarter option?”[10][4]

Pick aluminum if your project emphasizes:

1. Weight-sensitive designs

- Drones, robots, automotive racing parts, and aerospace brackets where every gram matters.[3][2]

2. Thermal management and enclosures

- LED heat sinks, power electronics housings, motor controllers, and battery trays that must dissipate heat efficiently.[2]

3. Cost-efficient production

- Medium to high-volume runs where material cost and cycle time must be tightly controlled.[10][2]

4. Structural components with good strength-to-weight

- Frames, arms, jigs, and fixtures subject to moderate loads and vibration.[5][2]

Example use cases for aluminum CNC parts:[3][2]

- Custom quadcopter center plates and motor mounts.

- Camera gimbals and rigging hardware.

- Automotive intake manifolds and brackets.

Choose brass if your project prioritizes:

- Premium look and feel: Designer knobs, watch components, audio hardware, and consumer products where the user perceives value through weight and luster.[2][7]

- High precision and smooth surfaces: Micro-valves, gears, bushings, and RF or electronic connectors requiring tight tolerances and excellent repeatability.[6][1]

- Corrosion-resistant fluid or gas handling: Plumbing fittings, valves, and couplings where brass's corrosion resistance and machinability reduce total lifecycle cost.[7][2]

- Electrical connectivity: Terminal blocks, plug pins, sensor housings, and RF connectors where both conductivity and mechanical strength are needed.[2][7]

Adding real scenarios makes material selection more concrete for makers.[4][3]

- Requirements: Extremely low weight, good stiffness, reasonable impact resistance, moderate cost.

- Best choice: Aluminum (e.g., 6061 or 7075).

- Why: The strength-to-weight ratio of aluminum allows thinner sections and lighter structures, and it is easy to anodize in custom colors for branding.[3][2]

- Requirements: Premium hand feel, high surface finish, aesthetic appeal, small scale production.

- Best choice: Brass with polished or brushed finish.

- Why: Brass provides a heavy, smooth turning feel and beautiful natural color that aligns with luxury product positioning.[7][2]

- Requirements: Corrosion resistance, leak-tight threads, precision sealing faces, conductivity for grounding.

- Best choice: Brass.

- Why: Brass is proven in plumbing and cooling applications and combines machinability with long-term corrosion resistance in fluid contact.[2][7]

Beyond selecting the material, optimizing your process parameters is key to getting high-quality parts.[9][1]

Use this checklist when programming aluminum jobs:

1. Confirm alloy and temper (e.g., 6061-T6 vs 7075-T6) to set realistic speeds, feeds, and expected strength.[5][2]

2. Set aggressive but controlled chipload to avoid rubbing and minimize built-up edge.[1][9]

3. Ensure good chip evacuation with air blast or coolant, especially for deep pockets or small tools.[9][1]

4. Plan finishing passes on critical surfaces and thin walls to improve dimensional accuracy and reduce chatter.[4][3]

5. Consider post-finishing such as anodizing, bead blasting, or brushing for both protection and aesthetics.[4][2]

For brass, you can push machining speed while maintaining outstanding surface quality:[6][1]

1. Select free-machining grades where possible for the best chip control and surface finish.

2. Use rigid workholding and short tool overhang to leverage brass's stability for small features.

3. Run relatively high surface speeds and feeds, as brass tolerates aggressive cutting with minimal tool wear.[1][6]

4. Check burrs on edges and threads, although these are usually much smaller than on aluminum.

5. Plan simple cleaning/polishing (tumbling, light buffing) for decorative parts to reveal the natural luster.[10][7]

As a Chinese OEM supplier, U-NEED can integrate CNC machining with plastic, silicone, and metal stamping to deliver ready-to-use parts for global brands and wholesalers.[10][4]

- High-precision CNC machining for aluminum and brass parts, from prototypes to mass production.

- Plastic and silicone product manufacturing, enabling complete assemblies instead of isolated metal parts.

- Metal stamping for brackets, covers, and high-volume sheet components that complement CNC-machined blocks and fittings.[10]

- DFM (Design for Manufacturability) reviews to recommend the optimal material, wall thickness, and tolerances for aluminum or brass.[4][10]

- Flexible MOQs for both small maker batches and large OEM orders.

- End-to-end project support, from drawing review and rapid quotation to tooling, trial runs, and stable mass production.[10]

Selecting between aluminum and brass can be complex once you factor in performance, cost, finish, and machining constraints. If you are a brand owner, wholesaler, or manufacturer looking for reliable OEM partners in China, U-NEED can evaluate your drawings and recommend the most cost-effective material and process for each part.[4][10]

- Send your 3D files and drawings to U-NEED for a free DFM review and material recommendation.

- Receive a fast quotation and lead time estimate, along with suggestions for aluminum or brass based on performance and budget.

- Start with high-precision prototypes, then seamlessly scale to mass production once the design is validated.

Take the next step now: contact U-NEED's engineering team to discuss your CNC project and get a tailored aluminum vs brass recommendation for your parts.

Aluminum is usually cheaper due to lower raw material cost and light weight, which reduces material usage, although brass's excellent machinability can partially offset its higher price in some precision applications.[2][10]

Both can hold tight tolerances, but brass often delivers superior dimensional stability and smoother surface finishes, making it a strong choice for small, high-precision components like connectors and valves.[6][1]

Yes, many aluminum alloys provide high strength-to-weight ratios, and grades such as 7075 are widely used in aerospace and motorsport structural components where weight savings are essential.[5][2]

Brass may be less suitable when strict weight limits apply or where minimizing raw material cost is critical, since its density and price are both higher than aluminum in many markets.[10][2]

Yes, aluminum and brass are often used together, but designers should consider galvanic corrosion if the assembly operates in conductive or moist environments and use coatings, isolating washers, or proper design to mitigate risk.[12][4]

Lead times depend on complexity, but integrated CNC capacity and flexible scheduling allow rapid sampling for many aluminum and brass parts, especially when drawings and specifications are clear from the start.[4][10]

[1](https://hplmachining.com/blog/machining-brass-vs-aluminum/)

[2](https://www.jtrmachine.com/cnc-machining-brass-vs-aluminum-a-comparative-analysis)

[3](https://flyingprecision.com/aluminum-vs-brass-an-in-depth-comparative-analysis-of-characteristics-and-applications/)

[4](https://www.komacut.com/blog/guide-to-metal-selection-for-cnc-machining/)

[5](https://www.cncjy.com/blog/brass-vs-aluminum-in-cnc-machining-a-comparison-of-material-performance)

[6](https://etcnmachining.com/blog/is-brass-softer-than-aluminum/)

[7](https://www.china-machining.com/blog/cnc-machining-brass/)

[8](https://www.longshengmfg.com/brass-vs-aluminum-vs-steel/)

[9](https://www.shopsabre.com/machining-aluminum-and-brass-with-a-cnc-machine/)

[10](https://www.machining-custom.com/blog/brass-vs-aluminum-vs-stainless-steel.html)

[11](https://okdor.com/is-brass-easy-to-machine/)

[12](https://www.reddit.com/r/machining/comments/1p3bu2l/a_question_about_brass_on_aluminium_mechanisms/)

[13](https://jlccnc.com/blog/aluminum-vs-brass-cnc-material-guide-for-makers)

[14](https://industrialmetalservice.com/metal-university/machining-brass-vs-aluminum-the-advantage-of-tradition/)

[15](https://www.richconn-cnc.com/is-brass-softer-than-aluminum-cnc-machining-guide-to-hardness-properties-best-uses.html)

[16](https://cncshopchina.com/brass-and-aluminum-cnc-machining-differences-similarities-and-best-practices/)

[17](https://industrialmetalservice.com/metal-university/machining-brass-vs-aluminum-the-advantage-of-tradition/?srsltid=AfmBOoqqm6mNYOKNiCGYkyB-3S5xBkTwYMjGdKG6C82npFpUxa8nOAgg)

[18](https://www.practicalmachinist.com/forum/threads/cutting-brass-vs-aluminum-questions.384139/)

[19](https://www.reddit.com/r/hobbycnc/comments/6cthdd/brass_vs_aluminum/)

[20](https://www.machining-custom.com/blog/brass-vs-aluminum.html)