From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-06 Origin: Site

Content Menu

● Target keywords and article focus

● Anodizing vs hard anodizing: key differences

● How the anodizing process works (step‑by‑step)

● How the hard anodizing process differs

● Application areas: where each method fits best

● Practical selection guide: anodizing vs hard anodizing

● Design and machining tips before anodizing

● Quality, inspection, and reliability considerations

● Where to place images and diagrams (UX suggestions)

● How a professional OEM partner adds value

● Call to action: discuss your anodizing strategy with U‑NEED

● Frequently asked questions (FAQ)

>> 1. What is the main difference between anodizing and hard anodizing?

>> 2. When should I choose hard anodizing for CNC machined parts?

>> 3. Does anodizing change the dimensions of my parts?

>> 4. Can anodized surfaces be colored in both processes?

>> 5. How do I know if my current application needs hard anodizing?

Anodizing and hard anodizing are two of the most widely used surface treatment methods for aluminum and other light alloys in CNC machining, but they deliver very different performance, cost, and durability levels. For OEM engineers, buyers, and product teams, choosing the right process directly affects corrosion resistance, wear life, dimensional stability, and total cost of ownership across the entire product lifecycle.

To maximize SEO and user intent coverage, this article primarily targets “anodizing vs hard anodizing” and related long‑tail queries. Secondary keyword focus includes “what is anodizing,” “what is hard anodizing,” “hard anodizing thickness,” and “applications of hard anodizing in CNC machining.”

Anodizing is an electrochemical process that converts the surface of a metal, typically aluminum or magnesium, into a controlled, protective oxide layer. The part is used as the anode in an electrolytic bath, and when current is applied, oxygen reacts with the metal to form a dense but relatively thin oxide film bonded to the substrate.

From a property standpoint, standard anodizing typically produces:

- Oxide hardness around 150–300 HV, providing moderate wear resistance.

- A relatively thin, lower‑density layer that improves corrosion resistance and allows decorative coloring.

Because the layer is porous before sealing, dyes can be absorbed, which makes anodizing popular for decorative components in electronics, consumer products, and architectural parts.

Hard anodizing (also called hardcoat anodizing) is an enhanced form of anodizing that focuses on maximum hardness, density, and wear resistance. It uses stricter process control, often lower temperatures, higher current density, and specific additives to form a much thicker and harder oxide layer.

Compared with standard anodizing, hard anodizing typically provides:

- Oxide hardness above 400 HV, and in some conditions up to about 1000 HV or more.

- A thicker, denser, and more uniform layer with excellent wear and corrosion resistance, suitable for harsh industrial environments.

Because of these properties, hard anodizing is widely used in aerospace, automotive, and mechanical manufacturing where sliding contact, heavy loads, and aggressive environments are common.

The table below clarifies the main differences between anodizing and hard anodizing in CNC machining applications.

| Aspect | Anodizing (Standard) | Hard Anodizing (Hardcoat) |

|---|---|---|

| Basic purpose | General corrosion protection and decoration | Maximum wear resistance, hardness, and heavy‑duty corrosion protection |

| Typical oxide hardness | About 150–300 HV | Typically >400 HV, can reach around 1000 HV |

| Layer thickness | Relatively thin film, mainly for moderate protection | Thicker and denser film for demanding industrial use |

| Density and porosity | Lower density, more porous before sealing | Higher density, lower porosity, better barrier properties |

| Visual / color options | Wide range of colors for aesthetic parts | Usually darker, limited colors, performance‑focused |

| Typical applications | Consumer goods, electronics housings, decorative trims | Aerospace, automotive, mechanical components under high load |

| Cost and process intensity | Lower cost, less demanding parameters | Higher process control, more energy, generally higher cost |

While exact parameters vary by alloy and specification, a typical anodizing workflow includes the following steps.

1. Pre‑cleaning and degreasing

Oils, coolants, and contaminants from CNC machining are removed to ensure the oxide forms evenly and adheres well.

2. Etching and surface preparation

Light etching or desmutting produces a uniform surface, improving the final appearance and consistency of the oxide layer.

3. Anodizing in electrolytic bath

The part is fixtured as the anode and immersed in an acid electrolyte; current drives an oxidation reaction that builds the controlled oxide film.

4. Coloring (optional)

The porous oxide can be dyed before sealing to achieve specific colors for branding or aesthetic requirements.

5. Sealing

The pores of the oxide layer are closed to improve corrosion resistance and prevent staining or color fading in service.

Hard anodizing follows the same basic principles but optimizes conditions for maximum thickness and hardness. The main differences include more aggressive electrical parameters, lower bath temperatures, and tailored additives to control the microstructure of the oxide.

Typical enhancements in a hard anodizing line:

- Higher current density and longer processing times to build a thicker hardcoat.

- Tighter temperature control to avoid burning and maintain uniform properties across complex geometries.

- Specific electrolyte formulations that improve layer density and mechanical performance.

The result is a much more robust barrier that tolerates abrasive wear, sliding contact, and severe environments compared to standard anodizing.

The two processes serve different roles in product design and CNC manufacturing.

Standard anodizing is commonly selected for:

- Housing and enclosure components where appearance and corrosion protection both matter.

- Lightweight structural parts in consumer electronics or general industrial products.

Hard anodizing is preferred for:

- Aerospace parts such as actuators, mechanism components, and wear surfaces.

- Automotive parts operating under load, friction, or exposure to road salt and fluids.

- Mechanical manufacturing components like guides, cylinders, pistons, and high‑cycle moving parts that require superior wear and corrosion resistance.

For engineers and buyers working with CNC machined aluminum, a quick selection rule can be helpful.

Choose standard anodizing when:

- The part mainly needs corrosion protection and a decorative appearance.

- Loads, friction, and wear are moderate.

- Color matching, branding, and visual consistency are high priorities.

Choose hard anodizing when:

- The part experiences repeated sliding contact, abrasion, or high loads.

- Corrosion resistance must remain high in harsh industrial or outdoor environments.

- Dimensional stability and long wear life matter more than bright colors or cosmetic finish.

In many OEM programs, a single product will use both finishes: decorative anodizing on visible covers, and hard anodizing on internal wear components that quietly protect performance and reliability.

Because anodizing and hard anodizing interact with geometry and tolerances, design decisions made at the CNC machining stage can simplify coating and improve repeatability.

Key considerations include:

- Dimensional allowances: The oxide layer grows both outward and inward; critical dimensions should account for final thickness and any post‑treatment polishing.

- Sharp edges: Very sharp corners can burn or form uneven oxide; adding small chamfers or radii helps maintain a consistent layer.

- Fixturing points: Plan non‑cosmetic contact areas for electrical connection and hanging to avoid visible marks on key surfaces.

Aligning design, machining, and surface treatment early in development lowers rework risk and shortens time‑to‑market for high‑volume OEM programs.

To ensure consistent performance from both anodizing and hard anodizing, robust quality control is essential. Industrial users often specify measurable parameters such as oxide thickness, hardness, adhesion, and corrosion test performance.

Typical checks include:

- Thickness measurement by eddy‑current or cross‑sectional methods.

- Hardness testing to verify that the expected HV range has been achieved.

- Salt‑spray or corrosion testing where products must withstand aggressive environments for long service lives.

Documented process control builds trust with overseas brand owners, wholesalers, and manufacturers that rely on consistent surface performance in every batch.

To improve user engagement and make complex information easier to absorb, the following visuals are recommended:

- Near the introduction: a simple diagram of the anodizing process setup (showing the part as anode, cathode, and electrolyte bath) to clarify the electrochemical concept.

- In the comparison section: an illustration comparing anodizing vs hard anodizing layer thickness and hardness to support the table in a more visual way.

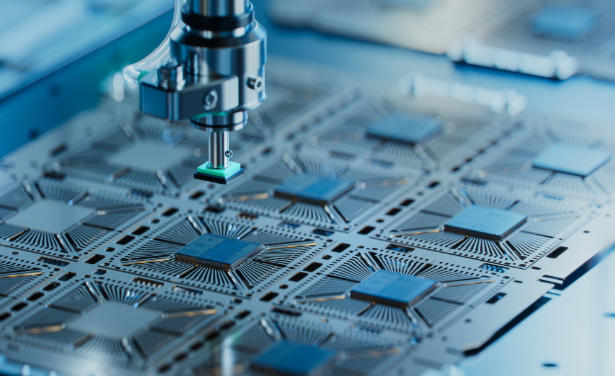

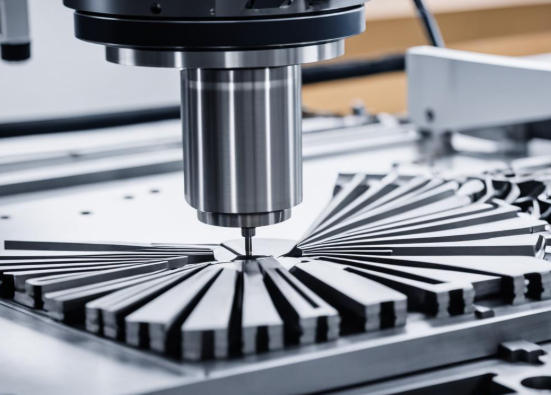

- In the applications section: photos of typical anodized and hard‑anodized CNC parts, such as decorative housings versus heavy‑duty mechanical components, to connect theory to real parts.

These assets make the article easier to scan and support both technical readers and non‑specialist decision‑makers.

For overseas brands, wholesalers, and manufacturers, the choice between anodizing and hard anodizing is not just technical; it is also supply‑chain critical. A capable OEM partner can help translate performance requirements into the right surface treatment specification, balancing cost, lead time, and reliability.

A full‑service factory such as U‑NEED, specialized in high‑precision machining parts, plastic product manufacturing, silicone products, and metal stamping, can provide:

- Integrated CNC machining plus surface treatment planning so tolerances, fixturing, and finishing steps all align.

- Guidance on where to apply standard anodizing vs hard anodizing within the same assembly for cost‑effective performance.

- Stable batch‑to‑batch quality for long‑term OEM production programs.

This integrated support helps foreign brand owners and production managers reduce technical risk and simplify vendor management across the entire product line.

If your current CNC components suffer from premature wear, corrosion problems, or inconsistent appearance, your surface treatment strategy may need an upgrade. Contact U‑NEED to review your drawings, application conditions, and target lifetime, and get tailored recommendations on anodizing vs hard anodizing for each part family.

U‑NEED's engineering team can help you:

- Optimize material selection, tolerances, and geometry for reliable anodizing performance.

- Decide when to invest in hard anodizing for critical wear surfaces.

- Build a scalable OEM supply chain for high‑precision metal, plastic, silicone, and stamped components.

The main difference lies in oxide hardness, thickness, and density: standard anodizing focuses on corrosion protection and appearance, while hard anodizing is engineered for maximum wear resistance and durability. Hard anodizing typically produces hardness above 400 HV and much thicker, denser layers than standard anodizing.

Choose hard anodizing when parts see high loads, sliding contact, or harsh environments, such as in aerospace, automotive, or heavy machinery. It is ideal for components that must maintain performance over long service life with minimal wear or corrosion.

Yes, both anodizing and hard anodizing slightly change part dimensions because the oxide layer grows inward and outward from the original surface. For tight‑tolerance features, these changes must be considered at the design and CNC machining stage to ensure final dimensions remain within specification.

Standard anodizing is highly suitable for decorative coloring because the oxide is porous before sealing and readily absorbs dyes. Hard anodizing can be colored in some cases, but color options are more limited and the focus is usually on performance rather than bright cosmetic finishes.

Assess the failure modes of your existing parts: if you see abrasion, scuffing, galling, or rapid corrosion under demanding conditions, hard anodizing is worth evaluating. Discuss duty cycles, loads, and environmental exposure with your OEM supplier so they can recommend whether standard anodizing is sufficient or a hardcoat is required.