From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-06 Origin: Site

Content Menu

● Key role of CNC in automotive manufacturing

● Core automotive components made with CNC machining

>> Engine and powertrain parts

>> Chassis, suspension, and braking systems

>> Body, structural, and mold components

>> Interior, electronics, and custom components

● CNC processes used in automotive parts manufacturing

>> CNC milling

>> CNC turning and turn-milling

>> EDM and other specialty processes

● Materials commonly used in automotive CNC machining

>> Metals: aluminum, steels, and more

>> Engineering plastics for lightweight parts

● Benefits of CNC machining for automotive OEMs and suppliers

>> Precision, safety, and reliability

>> Flexibility from prototype to mass production

>> Cost, automation, and supply-chain resilience

● Emerging trends in automotive CNC machining (2025–2026)

>> Lightweight EV components and multi-material designs

>> Sustainability and green machining practices

>> Digitalization, AI, and smart automotive machining

● How to choose an automotive CNC machining partner

>> Example evaluation table for automotive CNC suppliers

● Why partner with a specialized Chinese OEM CNC supplier

● Practical steps to prepare your automotive CNC project

● Action-oriented call to action for automotive OEMs and buyers

● FAQs

>> 1: What types of automotive parts are best suited to CNC machining?

>> 2: How does CNC machining compare to casting or forging for automotive parts?

>> 3: Why is CNC machining important for electric vehicle (EV) components?

>> 4: What should OEMs provide when requesting quotes for automotive CNC parts?

>> 5: How can CNC machining help shorten vehicle development cycles?

CNC machining is now a core process for automotive parts manufacturing, enabling OEMs and tier suppliers to produce safer, lighter, and more efficient vehicles with repeatable quality from prototype to mass production. For overseas brands and manufacturers working with Chinese OEM partners, understanding how CNC machining supports engine components, chassis systems, interiors, and EV platforms is essential to balancing performance, cost, and lead time.

CNC machining is used across the vehicle to create high-precision parts that must withstand vibration, temperature, and long service life. By combining digital programming with multi-axis equipment, CNC shops deliver complex shapes, tight tolerances, and consistent quality for thousands of identical components.

- High precision and repeatability support safety-critical systems like engines, brakes, and steering.

- Flexible batch sizes make CNC ideal for prototypes, pre-production samples, and serial production in one workflow.

- Material versatility allows the same supplier to machine aluminum, steel, stainless steel, plastics, and more for different vehicle zones.

For automotive OEMs, CNC machining is a strategic capability that stabilizes the supply chain and accelerates new vehicle launches.

CNC processes appear from powertrain to body-in-white and interiors, each with specific technical requirements. Understanding typical CNC applications helps engineers design parts that are manufacturable and cost-effective.

Engine and powertrain parts have extremely tight tolerances and complex internal geometries. CNC machining ensures that mating surfaces align correctly and that oil and coolant passages maintain the right cross-sections.

- Cylinder blocks and cylinder heads with precise bore diameter, flatness, and surface finish to support combustion efficiency.

- Crankshafts, camshafts, and connecting rods requiring high concentricity, balance, and fatigue strength.

- EV powertrain housings, gearbox casings, and motor mounts made from lightweight aluminum alloys for better efficiency and range.

High-speed milling and turning support tolerances down to a few microns on critical features in these assemblies.

Chassis and suspension parts translate loads between road and body, so they demand both strength and accurate geometry. CNC machining ensures that mounting points and interfaces line up correctly with surrounding components.

- Suspension knuckles, control arms, steering brackets, and subframe mounts often machined from forged or cast blanks.

- Brake caliper bodies, brackets, and precision pistons where consistent clearances are vital to braking performance and safety.

- Steering system components such as racks, housings, and joint bodies that must remain dimensionally stable over long mileage.

Consistent CNC machining quality reduces NVH issues and improves driving feel in both conventional and electric vehicles.

While many body panels are stamped, CNC machining is essential for tooling, structural inserts, and complex low-volume parts. High-precision molds and dies determine the final surface quality and fit of exterior and interior parts.

- Stamping dies and injection molds for body panels, interior trims, and lighting components, manufactured with CNC milling and EDM.

- Structural brackets, crash structures, and reinforcement blocks that must absorb energy in a controlled way.

- Low-volume or performance-series body parts, housings, and mounts where CNC machining allows short-run production without expensive tooling.

Precise machining of tool cavities and cores yields smooth surfaces and accurate parting lines, improving appearance and assembly accuracy.

Modern cars integrate more electronics, sensors, and interior customization, which rely heavily on CNC machined parts. Short development cycles require fast, flexible manufacturing that CNC machining can provide.

- Precision housings for ECUs, sensors, cameras, and radar modules in aluminum or engineering plastics.

- Interior components such as decorative trims, brackets, and mechanisms for seats, center consoles, and infotainment systems.

- Custom parts for performance editions, motorsport, and aftermarket upgrades requiring unique geometries and small batches.

When combined with CAD-CAM workflows, CNC machining supports fast design iterations and smooth transitions from prototypes to low-volume production.

Automotive suppliers use an integrated set of CNC processes to meet different technical and commercial requirements. Each process offers specific advantages in geometry, tolerance, and cost.

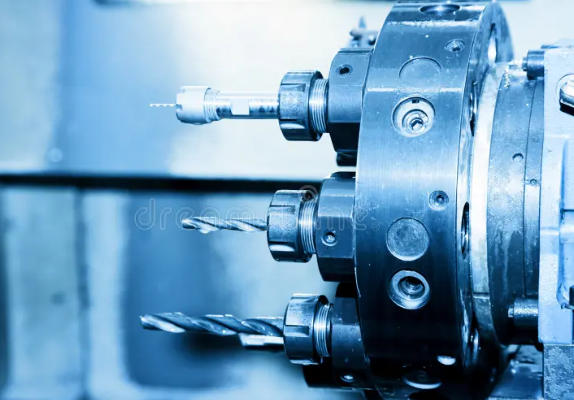

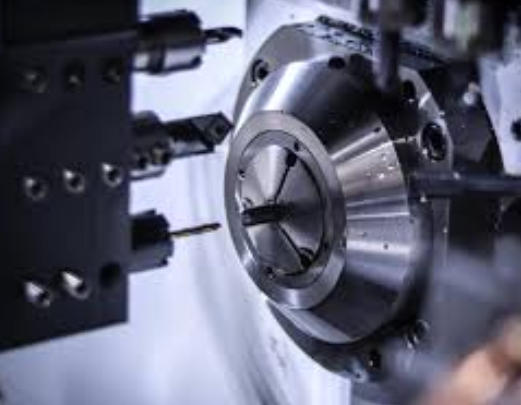

CNC milling is the backbone of automotive machining for prismatic parts with flat faces, pockets, and 3D surfaces. Multi-axis milling centers handle complex shapes in fewer setups, improving accuracy and speed.

- Suitable for cylinder heads, engine covers, gear housings, brackets, and molds.

- 3-axis, 4-axis, and 5-axis milling reduce fixture changes and minimize cumulative errors.

- Supports fine surface finishes and complex contours required in combustion chambers and aerodynamic parts.

CNC turning is used for rotational parts that need high concentricity and smooth surfaces. Many modern lathes integrate milling to machine flats, grooves, and holes in one setup.

- Common for shafts, bushings, wheel hubs, pump bodies, and precision fasteners.

- Can hold tight diametral tolerances and low runout on long parts, which is critical for drivetrain and steering components.

- Automated bar-feeding and parts catchers support high-volume production with limited operator intervention.

Electrical discharge machining (EDM) and other advanced processes complement milling and turning for difficult geometries. They are especially important in moldmaking and high-hardness materials.

- Die-sinking EDM for deep, narrow cavities in molds and dies used for plastic and metal automotive parts.

- Wire EDM for intricate profiles and tight-tolerance inserts, punches, and tool components.

- Complementary processes such as grinding and honing improve surface roughness and geometric accuracy in engine and hydraulic parts.

Choosing the right material affects weight, corrosion resistance, strength, and cost. Automotive CNC machining typically relies on a mix of metals and engineering plastics tailored to each application.

Metals remain the backbone of automotive structures and powertrain components. New alloy and machining developments help reduce weight while maintaining safety and durability.

- Aluminum alloys are widely used for engine blocks, heads, housings, suspension components, and EV battery structures thanks to their high strength-to-weight ratio and corrosion resistance.

- Carbon steels and alloy steels are selected for high-load parts such as gears, shafts, and structural brackets that must handle cyclic loads and impacts.

- Stainless steels are used for exhaust components, fasteners, and parts exposed to aggressive environments where corrosion resistance is critical.

These materials often require multi-step machining and heat treatment sequences to achieve final properties and tolerances.

Engineering plastics help reduce weight and integrate complex shapes for interior and under-hood components. CNC machining is particularly valuable in low-volume and prototype plastic parts where injection molds are not yet justified.

- Materials such as POM, PA, PEEK, and PC are used for bushings, guides, brackets, and functional interior parts.

- Plastics enable built-in features like clips, cable routes, and sealing surfaces that would otherwise require multiple metallic parts.

- CNC plastic machining shortens development time and allows iterative design before committing to mass-production tooling.

For automotive OEMs, CNC machining offers more than dimensional accuracy; it supports complete product and supply-chain strategies. These advantages apply to both in-house machining and outsourced work with specialized partners.

Automotive assemblies must work under harsh real-world conditions for many years. CNC machining helps ensure that every part fits and functions as intended across large production volumes.

- Tight tolerance control reduces assembly variation, warranty claims, and field failures.

- Repeatable accuracy across thousands or millions of parts supports global vehicle platforms and modular architectures.

- Traceable digital programs and process parameters make quality issues easier to analyze and correct.

Modern vehicle programs run through rapid prototype cycles before ramping into mass production. CNC machining is one of the few technologies that supports this entire lifecycle.

- Rapid CNC prototypes enable functional testing, fit-checks, and design validation without long tooling lead times.

- Small and medium series runs allow OEMs to launch niche variants and regional editions economically.

- Scalable capacity lets suppliers increase output quickly when demand grows or new models are introduced.

CNC machining supports cost control by combining automation with flexible scheduling and material optimization. It also adds resilience to supply chains facing disruptions and model variability.

- Automated, lights-out machining reduces labor cost per part and speeds up production cycles.

- Optimized toolpaths and nesting reduce scrap and improve material utilization, especially in aluminum plate and bar stock.

- Regional CNC partners near final assembly plants shorten logistics routes and reduce inventory requirements.

The automotive industry is undergoing rapid change due to electrification, autonomy, and sustainability goals. CNC machining is evolving alongside these trends to meet new technical and environmental requirements.

Electric vehicles depend heavily on lightweight structures and precise thermal management. CNC aluminum parts are central to these strategies.

- Increased use of machined aluminum battery trays, motor housings, and cooling plates to reduce weight and improve thermal performance.

- Multi-material designs combine aluminum, steel, and composites, requiring precise machined interfaces and mixed-material joining solutions.

- Advanced 5-axis machining creates complex geometries that were previously impractical, supporting compact, integrated assemblies.

Automotive manufacturers are under pressure to reduce carbon footprints and material waste. CNC machining operations are adopting more sustainable practices to support environmental goals.

- Use of recyclable materials such as aluminum and improved scrap-recycling loops in machining centers.

- Energy-efficient machine tools, coolant management systems, and process monitoring that lower electricity and consumable usage.

- Digital planning that optimizes batch sizes and logistics to reduce unused inventory and rework.

Industry 4.0 technologies are transforming production planning and process control in automotive CNC machining. This digitalization improves both part quality and operational efficiency.

- AI-assisted CAM systems that automatically choose tools, feeds, and strategies for each material and geometry.

- Machine connectivity and IoT sensors enabling predictive maintenance, reducing unexpected downtime on critical lines.

- Integrated quality data and traceability, giving OEMs a real-time view of supplier performance across global plants.

Selecting the right CNC machining supplier is crucial to achieving stable quality, on-time delivery, and competitive cost. The following criteria help OEMs and international buyers evaluate potential partners.

A qualified automotive CNC machining partner combines technical capabilities with strong quality systems and communication.

- Technical capabilities: Range of CNC milling, turning, EDM, and grinding equipment; ability to handle complex geometries and tight tolerances.

- Quality systems: Certifications such as IATF 16949 or ISO 9001, documented process control, and robust inspection equipment.

- Material and process coverage: Experience with automotive-grade metals and engineering plastics, plus access to heat treatment and surface finishing.

- Lead time and scalability: Ability to support prototypes, pilot runs, and mass production with predictable delivery.

- Engineering support: Capability to review drawings, suggest design improvements, and collaborate on manufacturability.

| Factor | Why it matters for automotive OEMs | What to look for in a supplier |

|---|---|---|

| CNC equipment and capacity | Ensures ability to handle complex parts and volumes. | Multi-axis mills, lathes, EDM, grinding, and sufficient capacity. |

| Quality certifications | Aligns with automotive quality standards and audits. | IATF 16949 / ISO 9001, PPAP, SPC, full inspection reports. |

| Material expertise | Supports different zones: engine, chassis, interior. | Proven work with automotive aluminum, steels, and plastics. |

| Prototype to mass-production | Reduces risk when scaling new vehicle programs. | Dedicated prototype lines and stable mass-production cells. |

| Communication and logistics | Critical for overseas brands and multi-plant OEMs. | English-speaking support and reliable international logistics. |

Working with an experienced Chinese OEM CNC machining supplier gives overseas brands access to competitive pricing, broad capabilities, and fast scaling. When combined with strong quality control, this model supports both established and emerging automotive programs.

- Centralized access to CNC machining, plastic parts, silicone components, and metal stamping makes it easier to coordinate multi-process projects.

- Mature supply chains for materials, tooling, and finishing reduce lead times and total landed cost for international buyers.

- Dedicated teams focused on overseas OEMs understand requirements for documentation, traceability, and long-term collaboration.

For automotive brands, wholesalers, and component manufacturers, a reliable Chinese OEM partner becomes an extension of the internal engineering and sourcing team rather than just a job shop.

Careful preparation of technical and commercial information makes collaboration with CNC suppliers faster and more effective. This reduces RFQ cycles and minimizes surprises during production.

1. Clarify the part's function and critical features

- Define which dimensions, surfaces, and interfaces are safety-critical or performance-critical.

- Share any test requirements, life-cycle targets, or regulatory constraints at the RFQ stage.

2. Provide complete technical data

- Supply 3D models, 2D drawings with tolerances, material specifications, and surface finish requirements.

- Indicate heat treatments, coatings, and assembly references to avoid ambiguity.

3. Discuss volumes and lifecycle

- Estimate prototype, pre-series, and annual production volumes so the supplier can propose the right process plan.

- Inform them of expected design changes or future platform extensions.

4. Align on quality and logistics

- Agree on inspection levels, reports, and packaging standards.

- Define lead times, shipping methods, and safety stock strategies for ongoing orders.

If your team is planning new automotive components or optimizing existing designs, now is the right time to secure a professional OEM CNC machining partner that can support you from engineering review to mass production. Share your drawings, 3D models, material specifications, and target volumes with a specialized Chinese CNC supplier so you can receive manufacturability feedback, an optimized costed process plan, and a clear timeline for prototypes, pilot builds, and series production.

By engaging early with an experienced OEM machining team, automotive brands, wholesalers, and component manufacturers gain more predictable quality, shorter development cycles, and stronger commercial terms across the entire vehicle lifecycle.

CNC machining is well suited to engine components, powertrain housings, suspension and brake parts, structural brackets, molds, and precision interior or electronic housings that require tight tolerances and reliable repeatability. It is particularly effective for medium- to high-value parts that combine complex geometry with demanding surface finish or positional accuracy.

Casting and forging are efficient for very high volumes and simple or moderately complex shapes, while CNC machining adds the fine features, tight tolerances, and accurate interfaces that cast or forged parts alone cannot provide. Many automotive components are cast or forged first and then finished by CNC machining on critical faces, holes, and sealing surfaces.

EV platforms rely heavily on lightweight aluminum structures and precise thermal management, which benefit from CNC-machined battery trays, motor housings, and cooling plates. Multi-axis CNC machining enables compact integrated designs with internal channels and mounting features that help improve range, safety, and serviceability.

OEMs should provide 3D CAD models, 2D drawings with tolerances, material specifications, surface finish and coating requirements, and estimated volumes for prototypes and production. Sharing functional requirements, test standards, and logistics preferences further helps CNC suppliers propose robust process plans and accurate, transparent quotations.

CNC machining shortens development cycles by enabling fast functional prototypes, quick design iterations, and smooth scaling from low-volume to higher-volume production without new tooling. This flexibility allows engineering teams to validate designs earlier, correct issues before tooling investments, and launch derivative or regional models with less risk.