From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-08 Origin: Site

Content Menu

● What Is High Speed CNC Machining

● Why “Ramping Up” Matters More Than Buying New Machines

● Core Cutting Principles: Feeds, Speeds, and Shallow Passes

>> Cutting Speed and Spindle RPM

>> Shallow Depth of Cut and More Flutes

● Spindle Speed Options: Using Auxiliary High Speed Spindles

>> Fixed Center-Line Auxiliary Spindles

>> Side-Mounted Auxiliary Spindles

● Data Flow and Control: CNC, DNC, and Look-Ahead

>> Testing CNC Processing Speed

>> Evaluating DNC/Drip Feed Performance

>> Look-Ahead and Modern Interpolation

● Programming Strategies to Reduce Data Density

● Practical Step-by-Step Plan to Ramp Up High Speed Machining

● High Speed CNC Machining vs Conventional Machining

● Common Challenges and How to Avoid Them

● Where to Use High Speed CNC Machining in OEM Projects

● Call to Action: Work with a High Speed CNC OEM Partner

● FAQs About High Speed CNC Machining

>> 1: What spindle speed is considered “high speed” in CNC machining?

>> 2: Do I need a new machine to start high speed machining?

>> 3: How does high speed machining affect tool life?

>> 4: Why is look-ahead important for high speed machining?

>> 5: Which parts benefit most from high speed CNC machining?

High speed CNC machining is less about buying brand-new equipment and more about optimizing how you cut, how your spindle is configured, and how your control processes data.[1]

To meet modern OEM expectations for shorter lead times, better surface finish, and tighter tolerances, shops can ramp up to high speed machining step by step using their current machining centers, auxiliary spindles, and smarter toolpaths.[2][1]

High speed CNC machining (HSM) generally means using higher spindle speeds, higher feed rates, and lighter depths of cut to achieve higher metal removal rates without sacrificing accuracy or tool life.[3][1]

Instead of a few heavy cuts, HSM uses many fast shallow passes, generating smaller chips, less cutting force per tooth, and better control of temperature in the cutting zone.[4][1]

Key characteristics of high speed machining include:

- Elevated spindle speeds, often 8,000 rpm and above.[1][3]

- High feed rates matched to chip load and tool geometry.[3][4]

- Shallow radial and axial depths of cut, with more tool engagement time.[2][1]

- Toolpaths designed to avoid sudden direction changes and maintain smooth motion.[5][6]

For OEM buyers working with partners like U-NEED, this approach supports precision parts with shorter cycles and more stable dimensional accuracy in steel, aluminum, and high-performance plastics.[1]

Many shops can access high speed machining benefits using existing vertical or horizontal machining centers rather than installing completely new high speed-only machines.[1][3]

Incremental improvements in feeds, speeds, spindle configuration, and data flow can cumulatively deliver a major increase in throughput and responsiveness for OEM production.[4][1]

Benefits of upgrading into high speed machining include:

- Higher metal removal rates and shorter cycle times on existing machines.[2][1]

- Better surface finish due to lower cutting forces and more consistent chip load.[4][1]

- Improved tool life when cutting parameters and cooling are correctly tuned.[3][1]

- Greater flexibility for mold work, precision cavities, and complex 3D surfaces.[5][1]

For overseas brands and manufacturers, partnering with an OEM supplier that has mastered this incremental upgrade path means lower risk, because the shop understands both conventional and high speed regimes in real production.[1]

High speed machining uses the same building blocks as conventional milling—cutting speed, feed rate, depth of cut, and tool geometry—but applies them differently.[1][3]

The key shift is replacing a few deep, slow cuts with many fast, shallow cuts while maintaining a stable chip load on each tooth.[4][1]

Cutting speed (surface feet per minute or meters per minute) is determined by spindle rpm and tool diameter.[7][3]

In many HSM applications in tool steels, shops may test cutting speeds around 1,000–1,200 sfm instead of traditional 500–600 sfm for the same end mill, adjusting parameters based on tool wear and finish.[3][1]

Key points:

- Higher cutting speed generally improves finish but raises heat, so coolant and tool choice are critical.[2][4]

- Larger tool diameters reach a given surface speed at lower rpm, while small tools demand much higher rpm.[7][3]

- Older or lower-power machines may impose a cap on usable rpm, so speeds must be tuned to machine capability.[8][3]

Feed rate sets how fast the tool advances relative to the workpiece, while chip load is the thickness of material removed by each tooth per revolution.[3][4]

To keep chip load stable at higher rpm, feed rate must increase proportionally; otherwise the tool rubs instead of cutting, which damages both tool and surface.[4][3]

In practice:

- Increase feed rate as spindle speed increases to maintain target chip load.[3][4]

- Avoid overly low feed rates at high rpm, which cause heat buildup and premature wear.[9][3]

- Use CAM tools and manufacturer charts to compute chip load rather than guessing.[7][4]

Reducing depth of cut lowers cutting forces and power demand, which is critical when pushing feed and speed on limited-horsepower machines.[1][2]

When depth of cut is reduced, a cutter with more flutes can multiply the effective feed rate at the same rpm because more teeth engage the workpiece per revolution.[1][4]

For example:

- A four-flute cutter can support approximately twice the feed rate of a two-flute cutter at a similar chip load per tooth, assuming the machine has enough horsepower.[1][3]

- Carefully balancing flute count, depth of cut, and feed lets shops increase metal removal without overloading the spindle.[2][1]

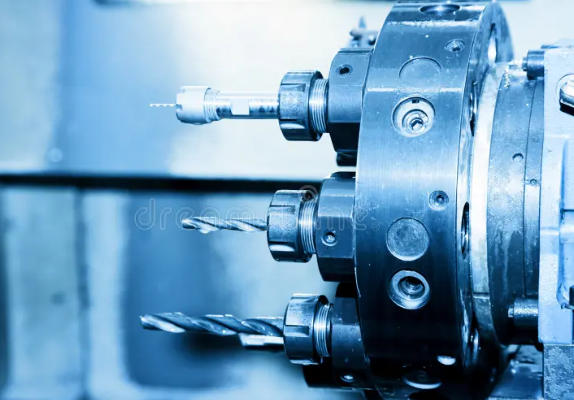

A practical barrier to high speed machining is spindle rpm; many standard machining centers top out around 6,000–8,000 rpm.[3][1]

Since 8,000 rpm is often considered a minimum threshold for true HSM in many materials, auxiliary high speed spindles provide a cost-effective way to expand capability without replacing the base machine.[1][3]

Fixed center-line high speed spindles mount directly into the machine's main spindle taper, sharing the same axis center line.[1]

These units can reach speeds up to roughly 50,000 rpm with power levels up to around 17 hp in some models, enabling aggressive machining with small-diameter tools.[3][1]

Advantages:

- Minimal program change; usually only a Z-axis offset is required to compensate for spindle length.[1]

- Ideal for high speed finishing of molds, electrodes, and fine features using micro tools.[5][1]

Trade-offs:

- When the auxiliary spindle is installed, the original spindle cannot be used simultaneously for large tools.[1]

- Extra mass may slightly affect acceleration and rigidity, so setup must be verified.[3][1]

An alternative is an independently powered high speed spindle mounted beside the main spindle.[1]

In this configuration, the main spindle continues to handle large-diameter tools and heavier roughing, while the side-mounted spindle is dedicated to small tools at high rpm.[1]

Benefits:

- Flexible switching between large tools and high speed tools without dismounting equipment.[1]

- Cost-effective “bolt-on” approach to expand rpm capacity across multiple machines in phases.[1]

For OEM-focused shops, side-mounted spindles support mixed workloads—roughing structural parts conventionally while finishing fine details at high speed on the same machine.[1]

High speed machining is limited not only by mechanics but also by how fast the CNC can read, process, and execute blocks of code.[10][1]

As toolpaths for molds and free-form surfaces can reach hundreds of thousands or even millions of points, program size and communication throughput can quickly become bottlenecks.[11][1]

A simple benchmark is to load a dense data program directly into CNC memory rather than drip feeding it.[10][1]

One common test is a 10-inch linear move broken into 1,000 point-to-point segments 0.010 inch apart, run at about 200 ipm; in an ideal high-speed-capable system this should complete in just over 3 seconds including acceleration and deceleration.[10][1]

If run time is significantly longer, the CNC's block processing speed may limit achievable feed rates on complex profiles.[10][1]

For very large programs that exceed CNC memory, drip feed from a DNC or file server is often used.[12][1]

Running the same benchmark program through the DNC allows you to check whether data transmission is holding back the machine compared with internal memory execution.[13][1]

Key checks:

- Use the highest reliable baud rate or network speed supported by the control.[13][12]

- Ensure DNC software is sending at full speed without pauses or buffer underruns.[12][13]

- Prefer direct network file server connections where possible for continuous high-speed data flow.[12][1]

At high feed rates, the machine must anticipate upcoming blocks to avoid overshooting or undershooting at corners and curves.[10][1]

Look-ahead functions read multiple blocks ahead, adjust acceleration and deceleration, and smooth motion for arcs and complex contours.[11][10]

Modern techniques include:

- NURBS and spline interpolation to replace dense micro-line segments, boosting possible feed rates by 30–50 percent while maintaining accuracy.[11][5]

- Corner rounding and smoothing parameters that maintain precision while reducing sudden direction changes and vibration.[6][10]

If a CNC lacks look-ahead or advanced contouring modes, upgrading the control or enabling optional high speed modes is often essential for serious HSM work.[10][1]

Even with capable hardware, excessively dense toolpaths can choke performance and limit top feed rates.[11][1]

Programming strategies that reduce data density while staying within tolerance can significantly increase block processing speed and overall productivity.[5][1]

Effective techniques include:

- Replacing long sequences of tiny line segments with circular arcs using CAM “arc fitting” functions.[5][1]

- Using splines instead of micro-line segments for smooth curves with fewer blocks.[6][11]

- Setting appropriate chordal tolerance so that geometry is accurate enough for parts but not over-defined.[6][1]

For many mold and die applications, a single well-defined arc can replace ten or more straight segments, cutting program size dramatically.[5][1]

Shops do not need to shift everything to high speed machining at once; instead, they can adopt a structured roadmap.[3][1]

Step 1 – Benchmark Your Current Capability

- Measure maximum stable rpm, feed rates, and spindle load for representative tools and materials.[9][3]

- Run CNC and DNC processing tests with dense programs to identify data bottlenecks.[10][1]

Step 2 – Optimize Feeds, Speeds, and Depths of Cut

- Start with recommended cutting speeds from tool suppliers and test higher ranges such as 1,000–1,200 sfm in tool steels, adjusting based on results.[3][1]

- Reduce depth of cut and adjust feed to maintain chip load while monitoring vibration and surface finish.[2][1]

Step 3 – Upgrade Tooling Strategy

- Introduce high-quality carbide or coated tools designed for high speed cutting.[7][3]

- Use more flutes for shallow cuts on limited-horsepower machines to raise effective feed rate.[4][1]

Step 4 – Enhance Data Flow and Control

- Enable or upgrade to high speed look-ahead and smoothing options on the CNC.[6][10]

- Move from slow serial drip feed to network-based file server connections where possible.[12][1]

- Use CAM features to arc-fit or spline-fit dense toolpaths.[5][1]

Step 5 – Add Auxiliary High Speed Spindles Where Needed

- Start with high-value applications (molds, precision cavities, micro-features) that justify high rpm.[5][1]

- Install fixed center-line or side-mounted auxiliary spindles on machines that regularly run small tools.[1]

Step 6 – Standardize Best Practices and Expand

- Document proven parameter sets, tool choices, and programs that consistently deliver better cycle times and quality.[9][4]

- Gradually roll out high speed machining methods from one machine and product family to others.[1]

For OEM partners, working with a supplier that follows such a structured plan ensures process stability and repeatability as new parts are introduced.[1]

The table below highlights the most important differences between high speed CNC machining and conventional machining in practical shop terms.[4][1]

| Aspect | High Speed CNC Machining | Conventional Machining |

|---|---|---|

| Cutting strategy | Many fast, shallow passes for stable chip load and heat control. | Fewer slow, deep cuts with higher forces per tooth. |

| Spindle speed | Typically 8,000 rpm and above, often much higher with auxiliary spindles. | Often limited to 6,000–8,000 rpm or below on older machines. |

| Feed rate | High feed matched to rpm and chip load; smoother motion with look-ahead. | Moderate feed; limited by control block processing and machine rigidity. |

| Toolpath style | Arc/spline-based paths, optimized for smooth interpolation and fewer blocks. | Dense point-to-point paths with many short line segments. |

| Tool life | Can be longer due to reduced cutting forces and controlled heat. | May be shorter if heavy cuts generate high mechanical and thermal stress. |

| Surface finish | Fine finish from small chips and stable engagement, especially on molds. | Variable finish; risk of tool marks and chatter in heavy cuts. |

| Machine requirements | Fast control, good look-ahead, stable spindle, and efficient data flow. | Less demanding on control speed but still requires rigidity and basic accuracy. |

Transitioning to high speed machining introduces specific challenges that must be managed to protect quality and tools.[3][1]

Typical issues include:

- Excessive heat if feeds are not increased sufficiently at higher rpm, leading to tool wear and poor surfaces.[9][3]

- Chatter or vibration when the combination of tool length, flute count, and workholding is not optimized.[8][4]

- Control lag or “jerky” motion if look-ahead or interpolation capabilities are inadequate for dense toolpaths.[10][1]

Best practices:

- Validate parameter changes gradually, monitoring spindle load, noise, and chip shape.[4][3]

- Use rigid fixturing, balanced toolholders, and appropriate tool overhang to keep the system stiff.[8][4]

- Work closely with tool vendors and CAM engineers to refine high speed strategies for each material.[7][4]

High speed machining is especially valuable in applications where complex geometry, precision, and finish are critical.[5][1]

For global OEMs, it can shorten development cycles from prototype to mass production in demanding industries.[11][1]

Typical use cases:

- Mold and die cavities for plastic, silicone, and die-casting components.[1]

- Precision mechanical parts with 3D contours, pockets, and thin walls.[5][1]

- High-value aerospace, medical, and electronics components with tight tolerance bands.[6][11]

Chinese OEM manufacturers like U-NEED can combine high speed milling with turning, EDM, plastic and silicone molding, and metal stamping to deliver complete component solutions for overseas brands and wholesalers.[1]

If your project demands tighter tolerances, smoother surfaces, and shorter lead times, consider partnering with an OEM supplier that has already implemented high speed CNC machining across milling, turning, and complementary processes.[1]

A partner like U-NEED, combining high speed machining know-how with plastic, silicone, and metal stamping experience, can review your drawings, recommend optimal machining strategies, and deliver production-ready parts with predictable quality and cost.[4]

Send your CAD files, material specifications, and annual volume estimates to request a manufacturability review and quotation, and discuss whether high speed CNC machining, conventional methods, or a hybrid approach is most suitable for your next OEM project.[1]

In many applications, spindle speeds of around 8,000 rpm and higher are considered the lower bound of high speed machining, with auxiliary spindles reaching up to about 50,000 rpm for small tools.[3][1]

Not necessarily; many shops can achieve high speed performance by optimizing feeds and speeds, improving data flow, and adding bolt-on auxiliary spindles to existing machining centers.[14][1]

When feeds, speeds, and depths of cut are matched correctly, high speed machining can reduce cutting forces and stabilize chip load, often improving tool life rather than shortening it.[4][1]

Look-ahead allows the CNC to read blocks in advance and adjust motion smoothly at corners and curves, preventing overshoot and enabling higher feed rates without sacrificing accuracy.[10][1]

Parts with complex 3D surfaces, fine details, and strict surface finish requirements—such as molds, dies, precision mechanical components, and high-value aerospace or medical parts—benefit the most from high speed machining.[5][1]

[1](https://www.makino.com/resources/content-library/article/archive/ramping-up-to-high-speed-machining/204)

[2](https://www.premiumparts.com/blog/cnc-machining_-feed-rate-and-cutting-speed)

[3](https://www.cnccookbook.com/feeds-speeds/)

[4](https://jlccnc.com/blog/feed-rate-vs-cutting-speed-in-cnc-machining)

[5](https://www.makino.com/en-us/makino-expertise/interpolating-curves)

[6](https://pmc.ncbi.nlm.nih.gov/articles/PMC9512817/)

[7](https://www.sandvik.coromant.com/en-us/knowledge/machining-formulas-definitions/milling-formulas-definitions)

[8](https://www.practicalmachinist.com/forum/threads/adjusting-feeds-and-speeds-for-low-power-machine.407755/)

[9](https://martinsupply.com/cnc-machining-understanding-feeds-speeds/)

[10](https://www.ctemag.com/sites/www.ctemag.com/files/archive_pdf/0203-lookahead.pdf)

[11](http://www.mmrc.iss.ac.cn/~xgao/papernc/2011-scichina-1.pdf)

[12](https://www.cnczone.com/forums/haas-mills/384016-look-ahead-dnc-drip-feed-new-post.html)

[13](https://www.practicalmachinist.com/forum/threads/high-speed-interpolation.119466/)

[14](https://www.reddit.com/r/CNC/comments/87r4y5/how_to_boost_cnc_machining_speed/)

[15](https://www.makino.com/resources/content-library/article/archive/ramping-up-to-high-speed-cnc-machining/204)

[16](https://www.makino.com/en-us/search/?searchText=CNC+Lathes&page=5)

[17](https://www.makino.com/en-us/search/?searchText=CNC+EDM+Machines&page=33)

[18](https://www.makino.com/en-us/search/?searchText=Horizontal+Machining+Centers&page=61)

[19](https://toolstoday.com/learn/understanding-cnc-feeds-and-speeds)

[20](https://www.youtube.com/watch?v=fvWeYcSLx7c)

[21](https://www.emastercam.com/forums/topic/95836-fanuc-16mb-high-speed-machining/)