From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-28 Origin: Site

Content Menu

● Understanding Cold Forging and Its Industrial Importance

● Why Finland Leads the Cold Forging Tools Industry

● Overview of the Finnish Cold Forging Market

● Top Cold Forging Tools Manufacturers And Suppliers in Finland

>> 4. Nordic Forge Technologies

>> 5. VTT Industrial Solutions

● Role of OEM and International Partnerships

● Technological Innovations in Finnish Cold Forging

● Choosing the Right Cold Forging Tools Supplier in Finland

● Market Opportunities for International Buyers

● Future Outlook for Finland's Cold Forging Tools Industry

● FAQs About Top Cold Forging Tools Manufacturers And Suppliers in Finland

>> 1. What makes Finnish cold forging tool manufacturers unique?

>> 2. Do Finnish manufacturers offer OEM cold forging tool production?

>> 3. How do Finnish suppliers maintain high tool quality?

>> 4. Are Finnish cold forging tools suitable for global export?

>> 5. How can U-NEED collaborate with Finnish forging companies?

Finland stands among Europe's most innovative industrial nations, recognized for its advanced engineering, precision tooling, and sustainable manufacturing practices. Within this robust industrial ecosystem, cold forging has become a vital process used in sectors such as automotive, aerospace, energy, and machinery production. This article explores the Top Cold Forging Tools Manufacturers And Suppliers in Finland, their expertise, and why Finland's forging industry commands global attention.

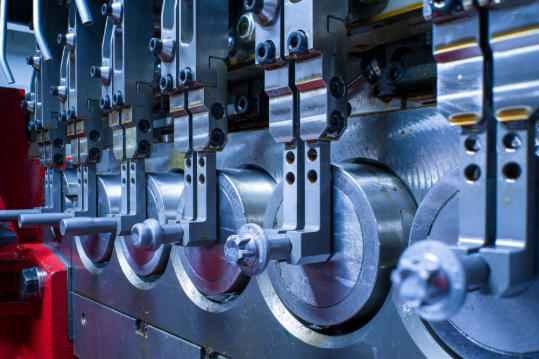

Cold forging is a metal forming process that shapes metals at room temperature through high compressive forces. Unlike hot forging, this technique does not require heating the metal above its recrystallization temperature. As a result, cold forging delivers parts with superior dimensional accuracy, smooth surface finishes, and enhanced mechanical strength.

The popularity of cold forging continues to grow because it offers:

- High material utilization rates with minimal waste

- Excellent mechanical properties and surface quality

- Reduced energy consumption compared to hot forging

- Cost-effectiveness for large-scale production

These benefits are highly valued across multiple industries — making cold forging tools essential for efficient, high-quality production.

Finland's industrial base has always emphasized precision engineering, sustainable production, and smart manufacturing technologies. The country's expertise in metal forming, combined with advanced toolmaking capabilities, makes Finnish suppliers attractive partners in the global market.

Key factors driving Finland's leadership include:

1. High Technical Standards – Finnish manufacturers adhere to strict quality certifications such as ISO9001, ISO14001, and IATF16949, ensuring world-class product reliability.

2. Innovation in Tool Design – Companies continuously invest in research to improve tool life, reduce maintenance costs, and enhance forming performance.

3. Sustainable Practices – Use of eco-friendly materials and energy-efficient production processes aligns with Finland's commitment to green manufacturing.

4. Export-Oriented Economy – With a strong reputation in global markets, Finland exports a large share of its cold forging tools to Europe, North America, and Asia.

Finland's cold forging tools market is characterized by small- and medium-sized enterprises (SMEs) specializing in precision tooling, die manufacturing, and custom forging solutions. These firms often collaborate with research institutions and universities to advance metallurgical science and tool performance.

Key industry sectors supported by this market include:

- Automotive Manufacturing: Production of drive shafts, gears, and fasteners.

- Aerospace Engineering: Lightweight, high-strength parts engineered for safety.

- Construction & Heavy Machinery: Structural and load-bearing components requiring exceptional fatigue resistance.

- Energy and Electrical Equipment: Forged connectors, motor housings, and turbine components.

Below is a comprehensive look at some of the leading Top Cold Forging Tools Manufacturers And Suppliers in Finland, known for their reliability, innovation, and export-quality products.

Metecno Oy is one of the most established names in Finland's metalworking industry. The company specializes in high-precision cold forging dies and forming tools. With expertise spanning over three decades, Metecno employs advanced CNC machining and CAD/CAM systems to deliver customized solutions for automotive and machinery customers. Their dedication to consistent tool quality and long lifespan has earned them partnerships with global OEMs.

Toolmax Finland provides complete solutions for forging tool design, production, and refurbishment. Their products cover cold forging dies, extrusion tools, and high-durability punches. The company integrates simulation-based tool design to predict tool wear and optimize performance, reducing downtime and production costs for clients. Toolmax's R&D team also focuses on sustainability by improving tool coatings and reducing material waste.

As a versatile manufacturer specializing in both forging and machining, Canelco Metalworks produces cold forging tools for small to medium-volume production. They are particularly known for their use of advanced steels and coatings that enhance wear resistance. The company collaborates closely with local clients in energy and heavy equipment industries, providing design-to-delivery solutions.

Nordic Forge Technologies combines traditional craftsmanship with modern forging simulation software. Their engineering team designs tools that withstand extremely high pressures while maintaining precision. The company also offers maintenance services and rapid tool restoration, minimizing client downtime. With an expanding customer base in Central Europe, Nordic Forge stands as one of the emerging Top Cold Forging Tools Manufacturers And Suppliers in Finland.

VTT Industrial Solutions operates both as a manufacturer and technology consultant. Partnering with Finland's top research centers, the company leads in innovation — constantly developing new die materials and processing technologies. VTT's ability to optimize tool geometry and surface coatings delivers superior cold forging results. Their clients range from automotive producers to renewable energy component providers.

OEM manufacturing plays a vital role in the Finnish cold forging tools industry. Many Finnish suppliers collaborate with international brands to develop co-engineered solutions that precisely meet production needs. Through OEM partnerships, global manufacturers gain access to Finnish precision engineering while benefiting from cost-effective and sustainable supply chains.

At U-NEED, for instance, we specialize in OEM production of high-precision machining parts, plastic and silicone products, and metal stamping components for international brands. Our experience aligns perfectly with Finland's design-driven manufacturing culture, offering customized forging solutions and integrating seamlessly with partner workflows.

These collaborations reinforce the international value chain — combining European innovation with Asia's flexible manufacturing capability to deliver reliable, scalable, and high-performance components.

Finland's toolmakers stay ahead of the competition by embracing digital and material innovations such as:

- Forging Simulation Software – Predictive modeling helps in optimizing die life and material flow.

- Surface Coating Technology – Advanced coatings like TiN, CrN, and AlCrN improve tool hardness and wear resistance.

- High-Speed Machining – CNC and EDM technologies enhance production speed and accuracy.

- Data-Driven Process Control – Smart sensors monitor tool wear and temperature to ensure consistent performance.

- Eco-Engineering Practices – Efficient material use and energy savings reduce environmental impact.

These innovations make Finnish forging tools not only durable and precise but also compliant with the sustainability goals of modern manufacturers.

When selecting from the Top Cold Forging Tools Manufacturers And Suppliers in Finland, consider the following criteria:

1. Technical Capacity – Ensure the supplier has advanced design and simulation capabilities.

2. Material Expertise – High-grade tool steels and surface treatments indicate reliable quality.

3. Customization Ability – The best manufacturers offer design flexibility tailored to client specifications.

4. Quality Control Systems – Verified certifications demonstrate consistent product standards.

5. After-Sales Support – Regular maintenance, testing, and tool life analysis enhance long-term cooperation.

Finland's emphasis on precision and partnership means customers receive not just tools but complete engineering support from concept to implementation.

The Finnish forging tools sector presents strong potential for global buyers. European clients appreciate Finland's proximity, reliability, and compliance with EU standards. For overseas buyers — especially in Asia and North America — Finland's advanced tooling expertise offers a significant advantage in strengthening production efficiency.

Many Finnish companies welcome joint development initiatives and OEM collaborations, ensuring that even custom or small-batch requirements are handled with professionalism. Competitive logistics networks via leading ports like Helsinki and Turku facilitate smooth export operations.

International buyers can also benefit from hybrid partnerships — for example, sourcing precision tooling designs from Finnish manufacturers while outsourcing large-volume production to partners like U-NEED in China. This model achieves both top-tier design quality and cost efficiency.

Looking ahead, Finland's cold forging tools industry will continue advancing through innovation, digitalization, and sustainability. With rising global demand for lightweight and high-strength forged components, Finnish manufacturers will play an increasingly important role in supply chains for electric vehicles, renewable energy, and precision machinery.

The convergence of AI-based design tools, additive manufacturing, and eco-friendly materials will redefine toolmaking standards. Finnish firms are uniquely positioned to lead these changes — offering innovation-driven, environmentally conscious, and high-precision forging solutions to the world.

Finland's reputation for excellence in precision engineering and sustainable production fuels its position among the Top Cold Forging Tools Manufacturers And Suppliers in Finland. Combining advanced materials science, digital tools, and reliable OEM collaborations, Finnish manufacturers deliver unmatched quality and consistency.

For global buyers, partnering with Finnish suppliers ensures access to cutting-edge cold forging technology, eco-efficient production methods, and dependable long-term solutions. Companies like Metecno, Toolmax, Canelco, and Nordic Forge continue to define the industry standard, while suppliers such as U-NEED reinforce the value of global partnerships through customized OEM services.

The synergy between Finnish innovation and international collaboration creates a powerful ecosystem — one that pushes cold forging excellence into the future.

Finnish companies stand out for their precision engineering, sustainability, and technological innovation. They combine high-quality materials with advanced design and simulation tools to produce durable and efficient forging solutions.

Yes, most of the Top Cold Forging Tools Manufacturers And Suppliers in Finland provide OEM and custom design services to international clients, ensuring product compatibility with specific industrial applications.

They employ strict quality control measures, certified production processes, and top-grade materials. Advanced testing equipment and simulation tools ensure every die or tool meets performance expectations.

Absolutely. Finnish forging tools are widely exported to Europe, North America, and Asia due to their excellent mechanical performance, long service life, and adherence to international standards.

U-NEED can provide OEM manufacturing, machining, and stamping support to Finnish partners, integrating production flexibility with Finland's precision tooling expertise. This creates an efficient global production alliance.

content is empty!