From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Rebecca Publish Time: 2026-01-14 Origin: Site

Content Menu

● What Is CNC Machining in the Medical Industry

● Why Medical CNC Machining Matters

● Core Medical Applications of CNC Machining

>> Surgical Instruments and Operating Room Tools

>> Orthopedic, Dental, and Spinal Implants

>> Diagnostic Equipment and Imaging Components

>> Prosthetics, Wearables, and Assistive Devices

● Medical-Grade Materials for CNC Machined Parts

● Advantages of CNC Machining for Medical Devices

>> Precision, Repeatability, and Complex Geometry

>> Customization and Rapid Prototyping

>> Regulatory Alignment and Traceability

● Quality Systems and Regulatory Requirements

>> Key Standards for Medical CNC Manufacturing

>> Process Validation, Cleanliness, and Traceability

● Advanced CNC Technologies in the Medical Sector

>> Five-Axis and Multi-Axis Machining

>> Micromachining and Miniaturized Components

● How OEMs Collaborate with Medical CNC Partners

>> Typical Project Workflow from Concept to Production

>> What to Look for in a Medical CNC Supplier

● U-NEED: OEM Partner for CNC Machined Medical Components

>> Integrated CNC, Plastic, Silicone, and Metal Stamping Solutions

>> Benefits for Overseas Brands, Wholesalers, and Manufacturers

● Example Applications and Design Considerations

● Call to Action: Partner with U-NEED for Your Medical CNC Projects

● FAQs about Medical CNC Machining

>> 1. What is medical CNC machining?

>> 2. Which medical devices commonly use CNC-machined parts?

>> 3. What standards apply to CNC machining for medical devices?

>> 4. Why choose CNC machining over molding for medical parts?

>> 5. How can overseas OEMs select the right medical CNC partner?

CNC machining in the medical industry enables high-precision, repeatable, and compliant production of components for implants, surgical instruments, diagnostic equipment, and disposable devices. When combined with medical-grade materials, advanced equipment, and certified quality systems, it directly supports safer treatments and better patient outcomes.

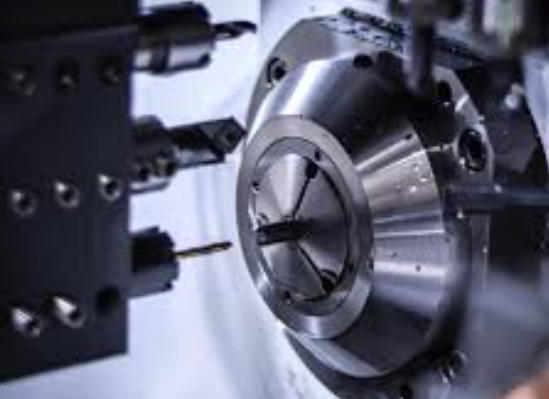

CNC machining in the medical industry refers to the use of computer-controlled mills, lathes, and multi-axis centers to manufacture critical components with tight tolerances and strict material and cleanliness requirements. These parts range from orthopedic implants and dental restorations to micro-components for minimally invasive devices and housings for imaging systems.

For overseas brands, wholesalers, and manufacturers working with Chinese OEM partners such as U-NEED, understanding how medical CNC machining supports design freedom, traceability, and regulatory compliance is essential for selecting the right supplier and scaling production efficiently.

In healthcare, even a small dimensional error or surface defect can affect patient safety and device performance. Medical CNC machining addresses this by combining precise motion control, stable processes, and validated workflows to deliver parts that meet tight design tolerances and regulatory expectations.

Key reasons CNC machining is critical in the medical sector include:

- High tolerance control for implants, instruments, and miniature components.

- Repeatable quality across prototypes, pilot runs, and mass production.

- Design flexibility for complex geometries, including internal channels and porous structures.

- Material versatility for metals, plastics, and composites that meet medical-grade standards.

Medical CNC machining supports a wide spectrum of devices and components, from operating rooms to imaging suites and home-care equipment. Below are several core application areas where CNC machining delivers particular value.

Surgical instruments must maintain sharp cutting edges, ergonomic forms, and stable performance after repeated sterilization cycles. CNC machining is well-suited for producing:

- Scalpel handles, forceps, clamps, and scissors that demand consistent geometry and fine surface finishes.

- Endoscopic and minimally invasive tools with slender shafts, precise joints, and controlled clearances.

- Custom surgical guides and fixtures tailored to patient anatomy for orthopedic, spine, and cranial procedures.

With medical-grade stainless steels and titanium alloys, CNC-machined instruments resist corrosion, retain strength, and deliver reliable performance over long service lives.

Orthopedic and dental implants require extremely accurate fits to integrate with bone, distribute loads correctly, and minimize wear. CNC machining makes it possible to:

- Produce hip and knee replacements, plates, screws, rods, and spinal cages with complex 3D contours.

- Machine dental abutments, crowns, and bridges that match a patient's bite and bone structure.

- Create porous and lattice structures to promote osseointegration and reduce implant weight.

Titanium alloys and cobalt-chrome are commonly used due to their biocompatibility, fatigue strength, and corrosion resistance, all of which benefit from precise CNC machining and controlled finishing.

Modern diagnostic systems rely on meticulously machined components for mechanical stability, alignment, and electrical compatibility. Typical CNC-machined parts include:

- Frames, brackets, and housings for CT, MRI, and X-ray machines.

- Components for patient monitoring devices and laboratory analyzers.

- Precision mechanical assemblies for microfluidic and point-of-care devices.

These parts often demand tight dimensional stability, specific surface finishes, and careful material choices to avoid magnetic interference or contamination.

CNC machining also plays a major role in custom prosthetics and rapidly growing wearable health technologies. Manufacturers can use CNC processes to:

- Produce prosthetic sockets, joints, and structural components that are lightweight yet strong.

- Machine wearable device casings, sensor housings, and mounting brackets in aluminum, stainless steel, or engineered plastics.

- Enable patient-specific shapes based on 3D scan data for improved comfort and long-term usability.

This customization capability supports the broader shift toward personalized medicine and patient-centric design.

Selecting the right material is as important as selecting the right machining strategy in medical manufacturing. Medical CNC machining supports a range of materials that must meet biocompatibility, sterilization, and mechanical requirements.

Titanium alloys are a preferred choice for orthopedic and dental implants due to their high strength-to-weight ratio and excellent biocompatibility. CNC machining allows manufacturers to:

- Shape complex geometries that match bone contours with high accuracy.

- Produce thin-wall and lattice structures that reduce weight while maintaining strength.

- Achieve surface finishes or controlled roughness to encourage bone integration where required.

Stainless steel remains a workhorse material for surgical instruments, fasteners, and some implants thanks to its corrosion resistance and durability. With CNC machining, manufacturers can:

- Achieve sharp cutting edges and tight mating fits that maintain performance after repeated sterilization.

- Produce high-strength components for tools, screws, and fixation devices at competitive cost.

- Maintain consistent geometry across large batches to support replacement and interchangeability.

Biocompatible plastics are widely used for disposable devices, short-term implants, and complex fluid-handling components. Common choices include PEEK, PPSU, PC, and medical-grade nylon. CNC machining provides:

- Tight dimensional control for microfluidic channels, manifolds, and housings.

- Freedom to prototype and iterate designs without hard tooling.

- Smooth internal surfaces that help control fluid flow and reduce contamination traps.

Medical manufacturers rely on CNC machining because it combines precision, flexibility, and robust quality control in a single platform. For many projects, it is the most practical and economical option from prototyping through full production.

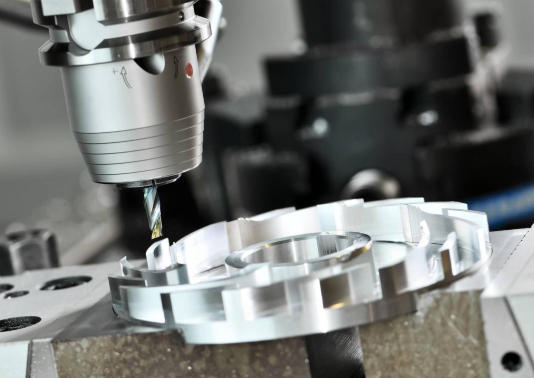

Modern CNC systems routinely achieve very tight tolerances, which are indispensable for implants and miniaturized components. Key advantages include:

- High dimensional accuracy for tight-tolerance fits between mating components.

- Excellent repeatability to ensure every part in a batch behaves the same way in clinical use.

- Capability to machine complex 3D geometries, internal channels, and thin features that other processes cannot easily produce.

The medical industry is seeing rapid growth in patient-specific and small-batch devices. CNC machining supports this transition by enabling:

- Fast design iterations from CAD models to functional prototypes using production-grade materials.

- On-demand manufacturing of customized implants, guides, and prosthetic components.

- Reduced time-to-market for new devices due to minimal setup and tooling requirements.

Because CNC machining is highly controllable and documentable, it aligns well with medical quality and regulatory frameworks. For device OEMs, this translates into:

- Easier process validation, including IQ, OQ, and PQ activities for regulated components.

- Better traceability, with serial numbers, batch IDs, and process parameters linked to each lot.

- Clear documentation trails that support major medical regulations and standards.

For medical CNC machining, robust quality management and regulatory compliance are non-negotiable. Device makers must be confident that their manufacturing partners can provide consistent quality and complete documentation from one batch to the next.

Medical CNC machining differs from general industrial machining because it must comply with stricter quality and documentation standards. Important frameworks include:

- ISO 13485 for medical device quality management systems.

- FDA 21 CFR Part 820 Quality System Regulation for medical devices.

- ISO 14971 for medical device risk management.

- EU MDR for device classification, technical documentation, and post-market surveillance in Europe.

Compared with standard ISO 9001 shops, ISO 13485-compliant facilities typically maintain tighter process controls, more comprehensive documentation, and validated processes for critical features and sterile products.

To meet these standards, medical CNC machining workflows often include:

- Process validation (IQ, OQ, PQ) to prove that machining and finishing steps consistently meet specification.

- Enhanced cleanliness and contamination control, including controlled environments, cleaning protocols, and packaging standards.

- Full traceability from raw material lots and machining parameters to inspection results and shipment records.

OEMs sourcing from overseas manufacturers should verify certification status, audit history, and practical experience with similar device types before placing high-risk projects.

Continuous advances in CNC technology are enabling more complex, miniaturized, and customized medical devices. Two areas that have had a particularly strong impact are multi-axis machining and micromachining.

Five-axis and multi-axis CNC machines significantly expand what is possible in medical part design. They offer:

- Single-setup machining for complex 3D shapes such as joint components, anatomical plates, and freeform surfaces.

- Reduced fixturing and repositioning, which improves accuracy and reduces cumulative error.

- Shorter cycle times and better surface finishes on geometries that previously required multiple operations.

Many modern devices require very small parts, intricate features, and tight tolerances at micro scale. Medical micromachining delivers:

- Tiny components for pacemakers, cochlear implants, microfluidic chips, and wearable sensors.

- Feature sizes on the order of tens of microns, often combined with high-polish surfaces.

- Specialized tooling, spindle speeds, and coolant strategies that minimize burrs and thermal damage.

Successful medical projects rarely depend on machining alone. They require tight collaboration between device OEMs and manufacturing partners to balance cost, quality, and regulatory needs.

A robust medical CNC machining workflow usually follows these steps:

1. Requirement definition: Clarifying device function, risk class, target markets, and expected volumes.

2. Design review and DFM: Evaluating CAD models, tolerances, and materials for machinability and cost.

3. Prototype and verification builds: Producing CNC prototypes for bench testing and design validation.

4. Process development and validation: Stabilizing cutting parameters, fixturing, and inspection methods.

5. Ramp-up and serial production: Running controlled production with in-process checks and final inspection.

6. Continuous improvement: Optimizing cycle times, scrap rates, and inspection methods over time.

When choosing an OEM partner for medical machining, buyers should focus on more than unit price. Important criteria include:

- Certifications and audit history, especially ISO 13485 and FDA-related compliance.

- Experience with similar device types, materials, and risk classes.

- In-house DFM support, metrology, and documentation capabilities.

- Ability to scale from prototypes to volume production while maintaining traceability.

- Clear communication and responsiveness, especially for overseas collaborations.

For overseas brands, wholesalers, and manufacturers, working with an experienced Chinese OEM that understands both technical and regulatory expectations can reduce lead times and total cost of ownership.

U-NEED is a Chinese OEM manufacturer focused on high-precision machined parts, plastic products, silicone products, and metal stamping for international brands, wholesalers, and manufacturers. This integrated capability is particularly valuable for medical devices that combine machined cores with molded or stamped enclosures and accessories.

By combining multiple processes under one roof, U-NEED can support:

- CNC-machined metal components for implants, instruments, and structural parts.

- Plastic and silicone components for housings, seals, disposables, and patient-contact parts.

- Metal stamping for brackets, shields, and high-volume sheet-metal parts.

This integration helps overseas customers simplify their supply chains, accelerate validations, and reduce overall sourcing complexity for multi-component assemblies.

For international buyers, working with U-NEED offers several practical advantages:

- A single OEM partner for machined, molded, and stamped parts.

- Support for OEM and ODM projects, from drawings and prototypes to stable mass production.

- Flexible order quantities to support pilots, regional launches, and mature production phases.

Medical and healthcare customers can collaborate with U-NEED to align drawings, inspection plans, and packaging with their internal and regulatory requirements.

Medical OEMs can gain additional value by designing specifically for CNC machining and integrated production. Thoughtful engineering early in a project can prevent expensive changes and delays later.

Typical design and engineering considerations include:

- Selecting materials based on mechanical properties, biocompatibility, and sterilization methods.

- Defining critical dimensions and tolerances that truly impact clinical performance.

- Simplifying part geometry where possible to reduce cost without compromising function.

- Coordinating surface treatments and coatings with CNC operations and cleaning processes.

Working closely with an experienced OEM partner enables faster feedback loops and smarter trade-offs between precision, cost, and lead time.

If your team is developing medical devices, implants, instruments, or diagnostic equipment and needs a reliable OEM partner in China, U-NEED can support your project from engineering review to stable, compliant production. Share your drawings, target markets, and volume expectations, and U-NEED will help optimize materials, machining strategies, and downstream processes to meet your performance and regulatory goals.

Contact U-NEED today to discuss your medical CNC machining needs, request design-for-manufacturing feedback, or obtain a custom quotation for high-precision machined parts, plastic components, silicone parts, and metal stampings for your next medical project.

Medical CNC machining is the use of computer-controlled equipment to manufacture components for medical devices, implants, instruments, and diagnostic equipment in accordance with strict quality and regulatory standards. It emphasizes precision, repeatability, and full documentation throughout the production process.

CNC-machined parts are widely used in orthopedic and dental implants, surgical instruments, prosthetics, diagnostic equipment housings, microfluidic devices, and implantable electronics such as pacemakers and cochlear implants. They also appear in many supporting fixtures and test tools.

Medical CNC machining is typically governed by ISO 13485 for quality management, FDA 21 CFR Part 820 for quality systems in the United States, ISO 14971 for risk management, and EU MDR for devices marketed in Europe. Many projects also reference additional material and biocompatibility standards.

CNC machining is often preferred for low-to-medium volumes, patient-specific parts, rapid prototyping, and complex geometries that are not economical to tool for molding. It also allows engineers to work with production-grade materials early in development, improving test accuracy and shortening time-to-market.

Overseas OEMs should evaluate certifications, experience with similar devices, metrology and documentation capabilities, scalability, and communication quality. Site audits, sample inspections, and small pilot projects can help verify that a supplier can meet both technical and regulatory requirements.

1. https://jlccnc.com/blog/cnc-machining-in-the-medical-industry

2. https://www.3erp.com/blog/cnc-machining-for-medical-industry/

3. https://www.3ds.com/make/solutions/industries/cnc-machining-medical-sector

4. https://get-it-made.co.uk/resources/cnc-machining-for-the-medical-industry

5. https://blog.boenrapid.com/understanding-the-standards-for-cnc-machining-medical-devices

6. https://www.cfy-tech.com/blog/data/medical-CNC

7. https://www.cnc24.com/resources/cnc/cnc-machining-in-medical-technology-precision-and-versatility-from-cnc24/