From 1 piece to mass production, our one-stop custom services ensure a worry-free experience for you.

Help Center

Views: 222 Author: Loretta Publish Time: 2025-12-21 Origin: Site

Content Menu

● Why CNC Machining in the UK Matters

● Core Buyer Intent for CNC Machining UK

● Main CNC Machining Services in the UK

>> CNC Milling

>> CNC Turning

>> 5-Axis and Multi-Axis Machining

>> From Prototypes to Series Production

● Materials Used for CNC Machining UK Projects

● Tolerances, Quality, and Certifications

>> Quality Management and Inspection

● Lead Times and Supply Chain Expectations

● What UK CNC Buyers Typically Value

● How Overseas OEM Partners Support the UK Market

● 2025 Trends in CNC Machining UK

● Practical Steps to Source CNC Machining for the UK

>> 1. Define requirements clearly

>> 2. Shortlist suitable suppliers

>> 3. Request quotations and DFM feedback

>> 5. Scale with clear agreements

● Case-Style Example: UK Brand Working with a Global OEM

● Choosing Between UK-Based CNC Shops and Overseas OEMs

● How U-NEED Supports CNC Machining UK Projects

● Start Your CNC Machining UK Project with U-NEED

>> 1. What industries most commonly use CNC machining in the UK?

>> 2. How tight are typical CNC machining tolerances for UK projects?

>> 3. Can I order just a few prototype parts for CNC machining in the UK?

>> 4. What documents should I prepare before requesting a CNC machining quote for the UK?

>> 5. Is it realistic to source CNC machining for the UK market from overseas OEM factories?

The CNC machining UK market is a critical hub for high-precision components across aerospace, automotive, medical, energy, and industrial sectors in 2025. For overseas OEMs, brand owners, wholesalers, and manufacturers, partnering with reliable CNC machining suppliers serving the UK can significantly reduce risk, lead time, and total cost of ownership.[1][2][3][4]

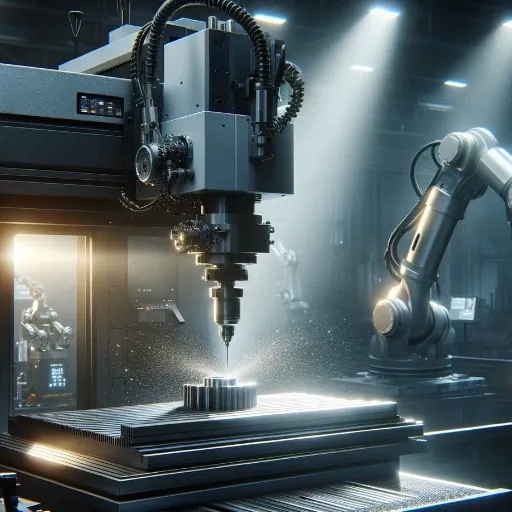

CNC machining uses computer-controlled tools to cut and shape metals and plastics into precision parts, from simple turned shafts to complex 5-axis aerospace components. In the UK, CNC machining supports both prototype development and series production, often with strict quality and documentation requirements.[3][4][5][1]

Key industries using CNC machining in the UK include:

- Aerospace and defence for structural, engine, and landing gear parts.[2][1]

- Automotive and motorsport for drivetrain, suspension, and precision housings.[6][1]

- Medical and healthcare for implants, surgical instruments, and diagnostic equipment components.[4][1]

- Energy, oil & gas, and renewables for valves, manifolds, and structural hardware.[1][3]

Buyers searching for “CNC machining UK,” “CNC machining services UK,” “UK CNC machining supplier,” “OEM CNC machining for UK,” or “precision machined parts UK importer” usually want to evaluate suppliers, compare capabilities, and request quotations. They care about precision, delivery reliability, total cost, and the ability to scale from prototypes to volume production.[7][8][4]

For such projects, it is essential that suppliers clearly communicate their technical capabilities, quality systems, and experience with UK and EU standards.

UK-focused machining providers typically offer a mix of core processes so that buyers can source multiple families of parts from a single partner. The most common services include:[8][4]

CNC milling uses rotating cutting tools to remove material and create flat surfaces, pockets, slots, threads, and complex 3D features. Modern workshops use 3-axis, 4-axis, and 5-axis machining centres to handle everything from simple plates to intricate housings and structural parts.[9][6][1]

CNC turning produces cylindrical components such as shafts, bushings, pins, and threaded fittings by rotating the workpiece against a stationary cutting tool. Many suppliers combine turning and milling using mill-turn or turn-mill centres, which can complete multiple operations in one setup for better accuracy and lower cost.[9][3][1]

5-axis machining allows the tool or part to move in five directions during cutting, enabling undercuts, complex curves, and fewer setups. This is particularly important for aerospace, medical, and high-performance automotive components where tight tolerances and high-quality surface finishes are required.[3][1][9]

Professional CNC machining services in the UK and globally are structured to support:

- Single prototypes and functional samples.

- Small to medium batches for validation and pilot runs.

- High-volume production with scheduled call-offs or blanket orders.[5][4]

This flexibility allows UK companies to shorten development cycles while keeping a consistent manufacturing partner as volumes grow.

Material choice is a key factor in performance and cost, and UK buyers frequently work with:

- Aluminium alloys (such as 6082 and 7075) for lightweight structures and heat-sensitive parts.[1][3]

- Stainless steels (such as 304, 316, and 17-4PH) for corrosion-resistant and medical components.[4][1]

- Carbon and alloy steels for structural and wear-resistant parts in machinery and tooling.[2][7]

- Titanium and nickel-based superalloys for aerospace, medical, and energy applications requiring high strength-to-weight and temperature resistance.[9][1]

- Engineering plastics such as POM, PEEK, PA, and ABS for housings, insulators, and functional prototypes.[10][6]

A capable OEM supplier needs experience with machining behaviour, tool selection, and cutting parameters for each material, as well as heat treatment and finishing options such as anodising, plating, painting, and polishing.[3][1]

Many CNC machining projects for the UK are produced with general tolerances around ±0.05 mm, and selected critical features can be held to significantly tighter limits when required. Achieving this repeatably depends on machine capability, process control, and a stable measurement environment.[11][5]

Reliable machining partners serving the UK market usually provide:

- ISO 9001-certified quality management systems.[1][3]

- Dedicated inspection departments with CMMs, height gauges, and calibrated instruments.[9][1]

- First Article Inspection Reports (FAIR) and PPAP, where required for automotive or aerospace projects.[5][8]

- Material traceability with EN 3.1 certificates and RoHS/REACH compliance for relevant parts.[4][3]

These elements ensure that every batch can be traced, verified, and reproduced, which is crucial for long-term OEM projects and regulated industries.

Manufacturing lead time is a major consideration for CNC machining UK buyers. Typical expectations and reference ranges include:[12][7]

- Quotations issued within 24-72 hours for standard CNC enquiries.[13][4]

- Standard machining lead times of around 2-4 weeks, depending on complexity, materials, and capacity.[7][5]

- Expedited or rapid-turn services for urgent prototypes, sometimes within a few days where the geometry allows.[14][6]

When working with overseas OEMs, buyers must also consider transit time, customs clearance, and shipping consolidation, but modern logistics can still keep total time competitive for planned series production.[10][4]

Buyer Priority | What It Means in Practice | Why It Matters for CNC Machining UK |

Precision & tolerances | Consistent parts at the specified tolerance, with CMM reports on request. | Ensures easy assembly, compatibility, and reliable field performance. |

Lead time | Clear lead times and realistic schedules, with options for rapid prototypes. | Supports faster product development and reduces downtime risk. |

Material & process range | Metals, plastics, plus turning, milling, 5-axis, and finishing services. | Limits the need to manage multiple vendors and transfers. |

Certifications & documentation | ISO 9001, material certificates, FAIR, PPAP, and traceability where needed. | Helps meet aerospace, medical, and automotive compliance demands. |

Cost & scalability | Competitive pricing from prototypes to high-volume batches. | Balances budget with quality, enabling long-term partnerships. |

Overseas CNC machining specialists with strong export experience can complement UK capacity by delivering cost-effective precision parts while adopting UK-compatible quality standards and documentation. Established export-oriented factories regularly ship machined components to UK and EU customers, often with high on-time delivery rates backed by digital logistics tracking.[10][3][4]

Such partners typically:

- Provide CNC milling, CNC turning, 5-axis machining, plastics machining, silicone parts, and metal stamping within a single organisation.

- Offer DFM (Design for Manufacturability) reviews to reduce machining risk and cost.

- Support prototype runs as well as mass production, with consolidated shipments tailored to UK warehouses or distribution centres.[3][4]

The CNC machining sector is experiencing rapid change, driven by digital manufacturing and new product demands. Key 2025 trends include:

- Increased automation and AI integration in scheduling, toolpath optimisation, and in-process inspection to reduce lead times and increase throughput.[15][16]

- On-demand manufacturing models, where buyers upload CAD data, receive instant quotes, and choose between local or global production depending on cost and lead-time priorities.[13][4]

- Greater focus on complex, high-value parts for sectors like aerospace, EV, and medtech, supported by 5-axis machining and high-performance materials.[1][9]

Buyers who understand these trends can choose partners that are investing in the right technologies and systems for long-term cooperation.

For engineers and procurement teams planning CNC machining UK projects, the following practical steps help reduce risk and improve outcomes:

- Prepare 2D drawings and 3D models with all critical dimensions, tolerances, and GD&T.

- Specify material grade, heat treatment, surface finish, and required inspection level.[12][7]

- Look for proven experience in your sector (aerospace, medical, automotive, industrial machinery, etc.).[2][1]

- Confirm their capacity for your batch sizes and their ability to use the required materials.[4][3]

- Ask for pricing at multiple quantities to evaluate the cost curve.

- Invite DFM suggestions on design simplifications that can reduce machining time while keeping function intact.[7][12]

- Place a small order to verify quality, communication, packaging, and delivery performance.

- Compare measured data with drawings to validate capability and process stability.[11][5]

- Set up framework agreements or scheduled orders with agreed delivery windows and quality targets.

- Review performance regularly and discuss continuous improvement initiatives such as yield optimisation or cost reduction.[12][7]

Consider a UK industrial equipment brand launching a new range of machines that requires aluminium and stainless steel precision components. Domestic suppliers provide high quality but have limited capacity and longer lead times for the required batch sizes.[17][8][2][7]

By working with an export-experienced CNC machining OEM abroad, the brand can:

- Secure stable capacity for both ramp-up and volume production at competitive prices.[3][4]

- Combine CNC machining with plastics, silicone, and stamping for complete sub-assemblies rather than many single parts.

- Maintain the necessary documentation, inspection reports, and packaging standards for UK warehousing and assembly.[4][3]

This hybrid approach allows the UK company to keep design, testing, and final assembly close to home while using global manufacturing capacity to control cost.

Situation | UK-Based CNC Shop | Overseas OEM Partner |

Emergency repair or 24-72h turnaround | Well suited for urgent one-off parts and tooling fixes. | Less suitable due to international shipping times. |

Highly regulated aerospace/medical parts | Easier to audit, visit, and qualify locally. | Works well once processes and documentation are fully proven. |

High-volume, price-sensitive components | Domestic costs can be higher but offer simpler logistics. | Often more competitive on unit price for large batches. |

Multi-process assemblies | May require multiple local vendors for machining, molding, and stamping. | One-stop solution for CNC machining, plastics, silicone, and metal stamping. |

Time-zone and communication preferences | Same or similar time zone and easier on-site visits. | Digital collaboration with clear communication procedures and export support. |

As a professional OEM manufacturer in China, U-NEED focuses on:

- High-precision CNC machining for metal and plastic parts used by international OEMs and brand owners.

- Manufacturing of plastic products, silicone products, and metal stamping parts to complement machined components.

- Stable, long-term cooperation with overseas customers, including those serving the UK market, through structured quality control and export logistics.[17][9]

By combining multiple processes under one roof, U-NEED can supply individual CNC components or complete sub-assemblies, helping buyers reduce the number of suppliers they must manage and simplifying their supply chains.

If your company is planning or already running CNC machining UK projects and needs a reliable OEM partner, U-NEED is ready to support you with engineering experience, integrated processes, and export-ready quality systems. Whether you require prototypes, small pilot batches, or stable high-volume production, you can count on consistent precision, clear communication, and competitive pricing.

Send your 2D drawings and 3D models to U-NEED today to receive a fast, detailed quotation and DFM feedback tailored to your parts. Take the next step in securing a dependable CNC machining supply chain for the UK market by starting your project discussion with U-NEED now.

Aerospace, automotive, medical devices, energy, motorsport, and general industrial manufacturing rely heavily on CNC machining for critical precision components.

Many projects are manufactured at around ±0.05 mm, with tighter tolerances achievable on critical features when supported by proper inspection and process capability.

Yes. Many suppliers targeting the UK accept one‑off prototypes and small batches, then scale to higher volumes as the design stabilizes.

You should prepare 2D drawings, 3D models, material specifications, surface finish requirements, quantity, and any special inspection or certification needs such as material certs or FAIR.

Yes, especially for series production, as long as the OEM provides robust quality systems, inspection reports, reliable logistics, and clear communication aligned with UK standards.

[1](https://tirapid.com/cnc-machining-uk/)

[2](https://tarvinprecision.co.uk/insights/)

[3](https://roboconcnc.com/cnc-machining-uk-united-kingdom)

[4](https://www.hubs.com/cnc-machining/united-kingdom/)

[5](https://www.protolabs.com/en-gb/services/cnc-machining/)

[6](https://www.prototypeprojects.com/cnc-machining/)

[7](https://www.pentaprecision.co.uk/resources/cnc-machining-lead-times-explained-how-to-get-your-parts-faster)

[8](https://www.qimtek.co.uk/manufacturingservices/cnc-machining)

[9](https://tirapid.com/5-axis-large-cnc-machining-uk/)

[10](https://www.pcbway.com/rapid-prototyping/)

[11](https://smithstown.co.uk/milling/cnc-milling-service/)

[12](https://frigate.ai/cnc-machining/why-cnc-machining-lead-times-get-delayed-and-how-to-fix-it/)

[13](https://www.rapiddirect.com)

[14](https://www.parallelprecision.co.uk/blog/case-study-rapid-24-hour-turnaround-cnc-machining-for-a-technology-start-up)

[15](https://quickparts.com/top-cnc-machining-trends-to-watch-in-2025/)

[16](https://www.makerverse.com/resources/cnc-machining-guides/the-biggest-trends-in-cnc-machining-for-2025/)

[17](https://www.openpr.com/news/3964646/machining-market-2025-growth-applications-innovations)

[18](https://www.youtube.com/watch?v=fWEqRiP0MGo)

[19](https://tirapid.com)

[20](https://www.youtube.com/watch?v=aGnsv8ThFag)

[21](https://www.tradewheel.com/buyers/cnc-machined-parts/united-kingdom/)